Fabrication method of carbon nanotube shading cover

A technology of carbon nanotubes and light shields, which is applied in the field of light shield preparation, which can solve the problems of large size and weight, difficult carbon nanotube growth process, insufficient ability to eliminate stray light, etc., achieve mechanical damage and dustproof protection, and save resources The effect of consumption and improvement of light absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

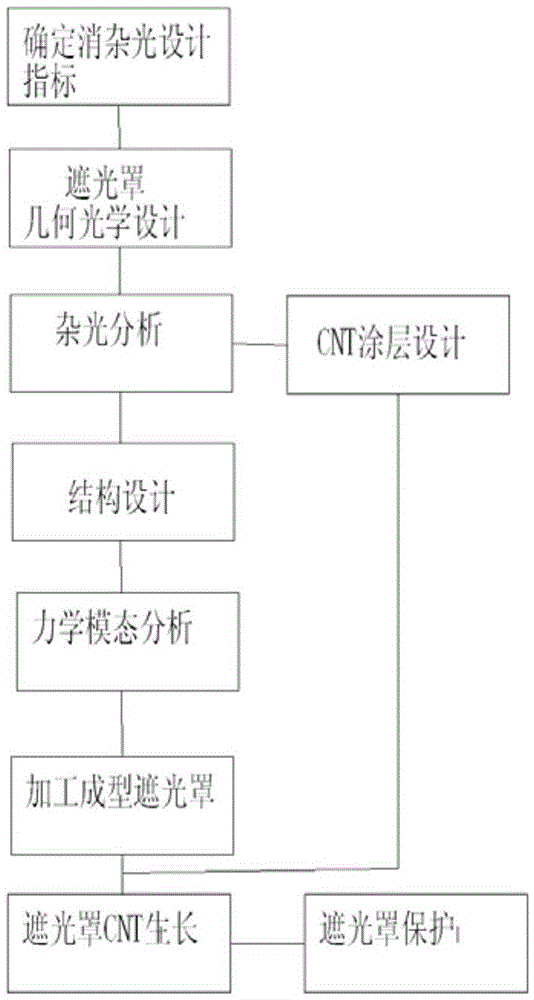

[0036] Such as figure 1 Shown, be the flow chart diagram of the inventive method, main steps are as follows:

[0037] (1) Determine the design index of stray light elimination.

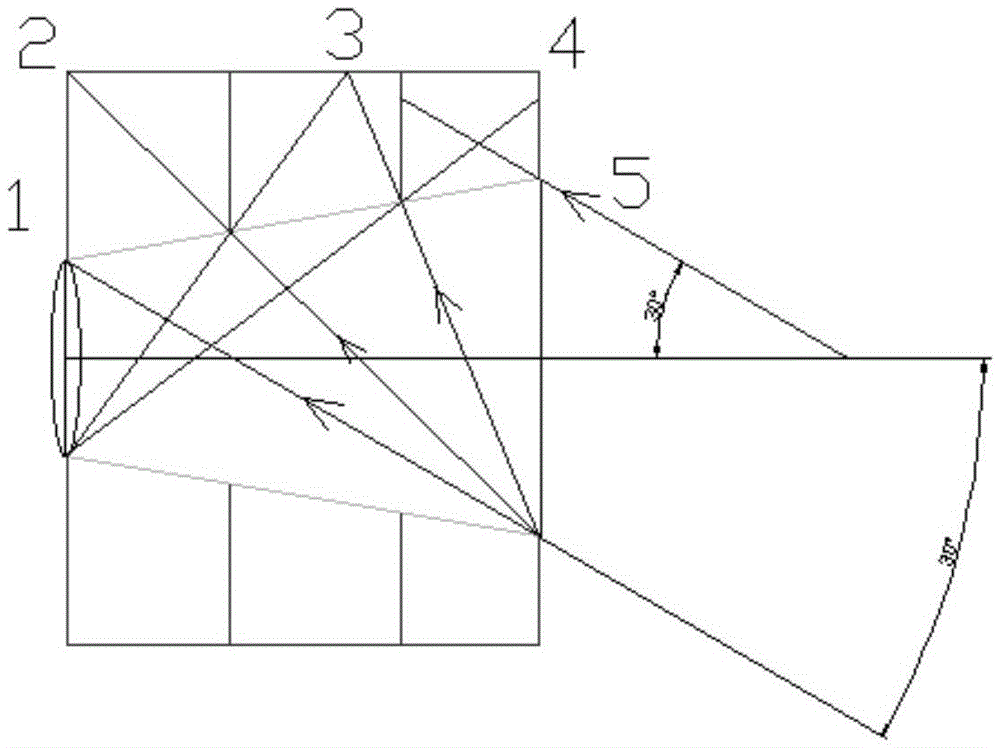

[0038] Generally, the stray light elimination object of the sunshade is the stray light directly irradiated by the sun, which first shines on the entrance of the sunshade, and after diffuse reflection one or more times, it exits from the exit and enters the lens. Therefore, the index of stray light elimination design is generally based on the ratio of the luminous flux of the outgoing light to the incident light under the stray light suppression angle (the minimum angle allowed between the incident sunlight direction and the optical axis), that is, the extinction ratio, This indicator is also the final evaluation indicator. The extinction ratio of the general system should not be greater than 10 -5 . Another evaluation method of extinction ratio index is to use point source transmittance, but the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com