Flexible wind wheel locking device for braking system of anti-typhoon wind generating set

A technology for wind turbines and braking systems, applied in wind engines, wind power generation, engines, etc., can solve problems such as reducing the design difficulty of wind turbines, reducing the load of the wind wheel and the whole machine, and the large load of the whole machine, etc., to achieve High reliability, reduce the load of the whole machine, and improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

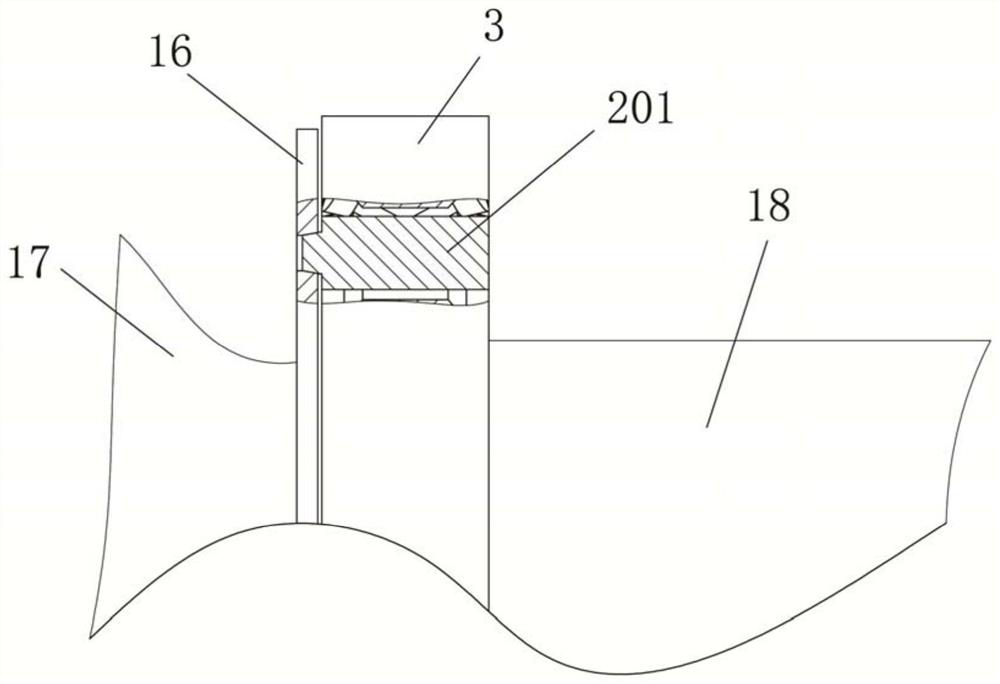

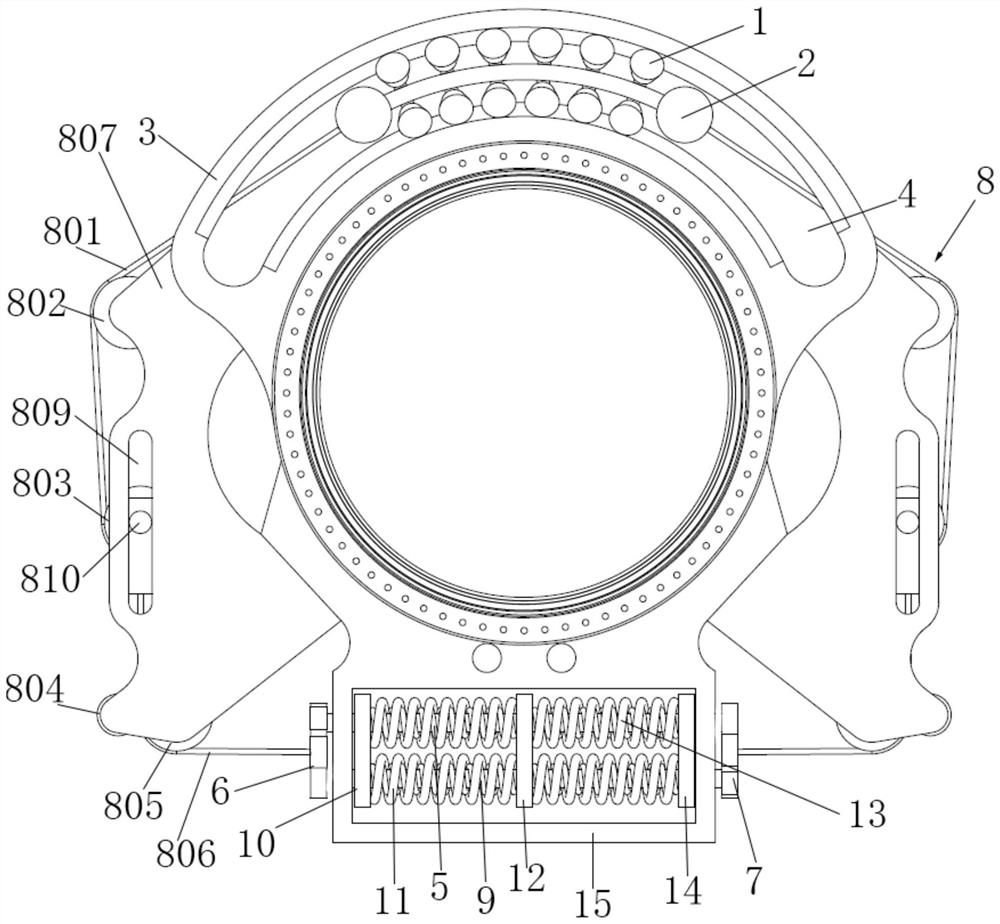

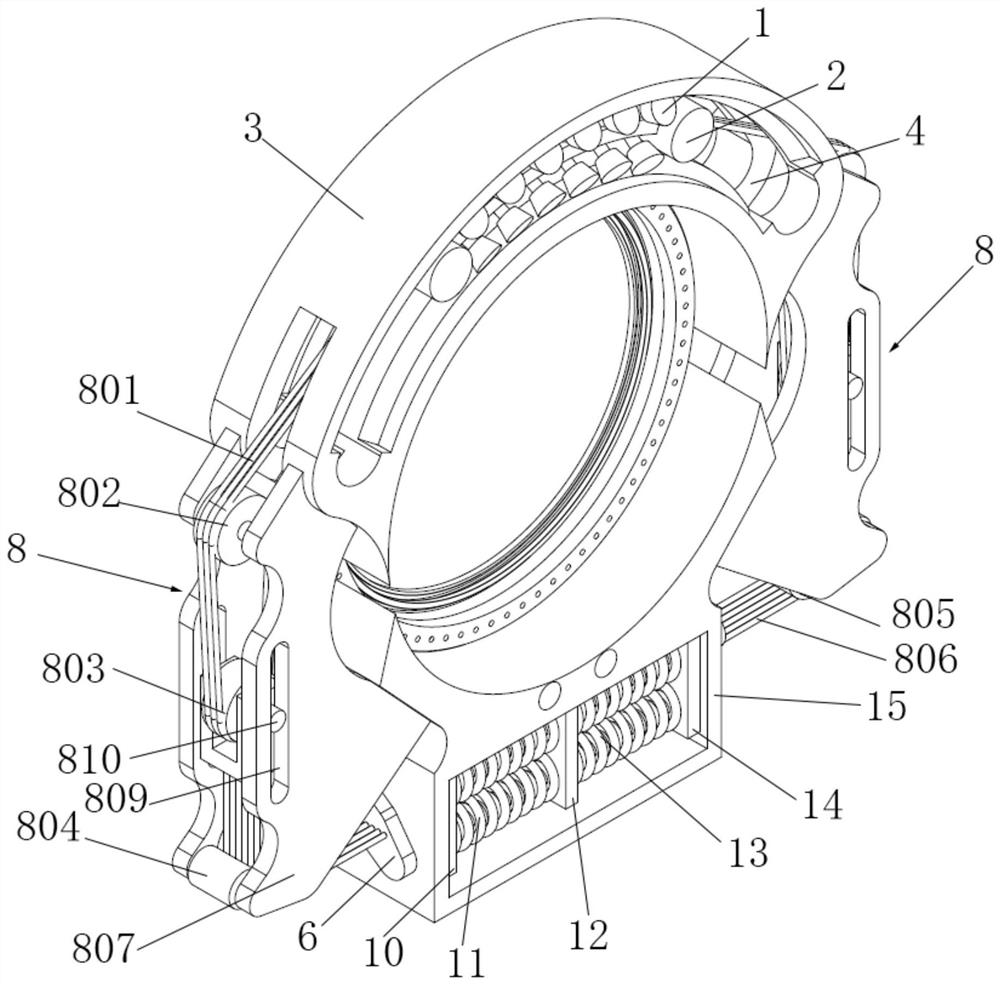

[0025] The flexible wind wheel locking device provided in this embodiment is mainly used for the braking system of typhoon-resistant wind power generating sets, such as figure 1 As shown, the braking system is mainly composed of the wind wheel locking disc 16, the front end flange 3 of the gearbox, and the wind wheel locking pin assembly 2. 17 is fixed by bolt connection, and the gearbox front end flange 3 is a part of the gearbox of the wind power generating set, which is respectively connected to the generator (not shown in the figure) of the wind power generating set and the nacelle shell 18 by bolt connection and fixing. The wind wheel lock pin assembly 2 includes a wind wheel lock pin 201 and a driving device (not shown in the figure) for driving the wind wheel lock pin 201 to extend or retract. When the wind wheel needs to be locked, the wind wheel is first locked The locking hole on the disk 16 is aligned with the wind wheel locking pin 201, and then the wind wheel lock...

Embodiment 2

[0036] see Figure 6 As shown, the difference from embodiment 1 is that this embodiment only adopts one wind wheel locking pin assembly 2, and the shell of the wind wheel locking pin assembly 2 is connected with one end of the swing trolley 1, and is solidly integrated as a whole. Similarly, the two Two rope receiving devices 8 are symmetrically distributed on the left and right sides of the front flange 3 of the gearbox, the first wire rope group 801 of one of the rope receiving devices 8 is connected to the outer shell of the wind wheel locking pin assembly 2, and the other rope receiving device 8 The first wire rope group 801 of the device 8 is connected with the other end of the swing trolley 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com