Square storage box forming method

A storage box and square technology, applied in the field of sheet metal, welded sheet forming and deformation control, and overall assembly, can solve problems such as low production efficiency, poor assembly accuracy, and difficult control of welding deformation, so as to improve size and shape accuracy, The effect of less machine addition and overcoming secondary thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

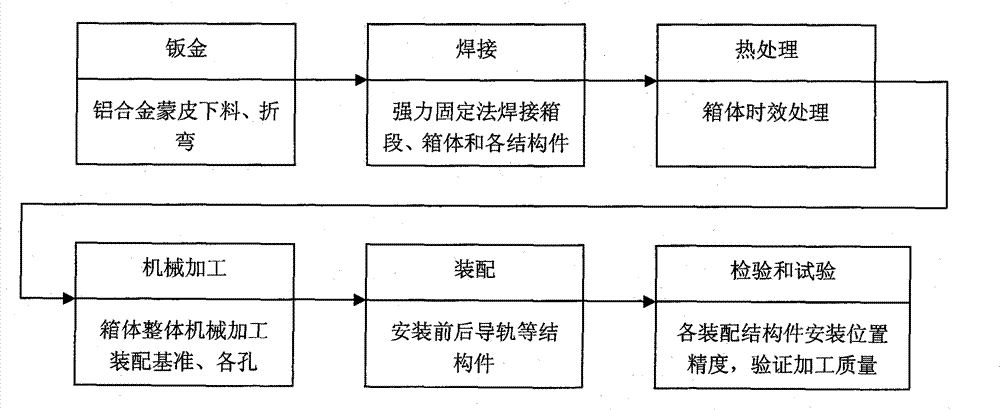

Method used

Image

Examples

example 1

[0084] This product has a total length of 7000mm, a height of 1111mm, and a width of 1068mm. The skin is made of 5A06-0 type II 5mm thick aluminum plate. It is a fully welded structure, and the total length of the weld is about 50m. It is required that the total length of the product be controlled within ±2mm, and the tolerance of the width and height of the box can be controlled within 0.5mm. The front and rear guide rails are installed inside the cabinet, and the height difference of the guide rails is guaranteed to be 163±0.1mm, and the symmetry is ±0.2mm.

[0085] Through the sheet metal forming process, first determine the bending coefficient, calculate the unfolded length according to the external dimensions, add 9.7mm to each bending, and control the length accuracy within ±0.5mm, smooth the burrs, and use the two ends of the following material as Bend the base edge, and bend it into a U shape at the same height.

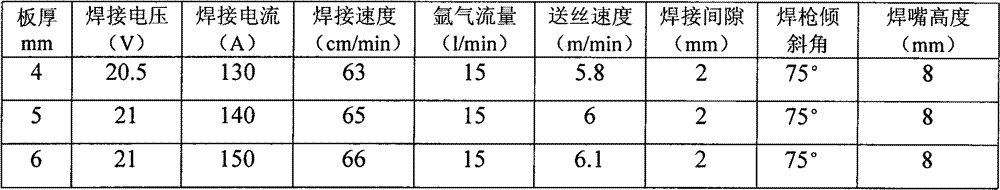

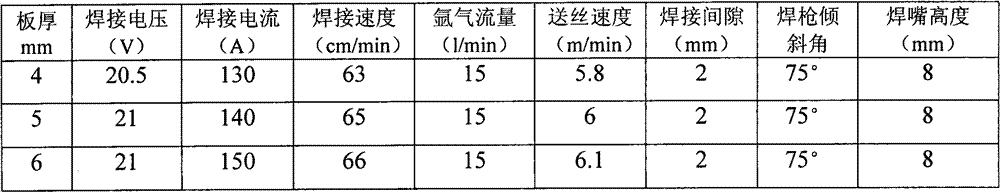

[0086] The 5mm thick Al-Mg series 5A06-H112 aluminum a...

example 2

[0098] The total length of this product is 8000mm, the height is 1351mm, and the width is 1200mm. The skin is made of 5A06-0 type II 6mm thick aluminum plate. It is a fully welded structure, and the total length of the weld is about 55m. It is required that the total length of the product be controlled within ±2mm, and the tolerance of the width and height of the box can be controlled within 0.5mm. The front and rear guide rails are installed inside the box, and the height difference of the guide rails is guaranteed to be 174±0.1mm, and the symmetry is ±0.2mm.

[0099] Through the sheet metal forming process, first determine the bending coefficient, calculate the unfolded length according to the external dimensions, add 11.8mm to each bending, and control the length accuracy within ±0.5mm, smooth the burrs, and use the two ends of the following material as Bend the base edge, and bend it into a U shape at the same height.

[0100] The 6mm thick Al-Mg series 5A06-H112 aluminum...

example 3

[0110] The total length of this product is 5500mm, the height is 952mm, and the width is 865mm. The skin is made of 5A06-0 type II 4mm thick aluminum plate. It is a fully welded structure, and the total length of the weld is about 48m. It is required that the total length of the product be controlled within ±2mm, and the tolerance of the width and height of the box can be controlled within 0.5mm. The front and rear guide rails are installed inside the box, and the height difference of the guide rails is guaranteed to be 98±0.1mm, and the symmetry is ±0.2mm.

[0111] Through the sheet metal forming process, first determine the bending coefficient, calculate the unfolded length according to the external dimensions, add 7.9mm to each bending, and control the length accuracy within ±0.5mm, smooth the burrs, and use the two ends of the following material as Bend the base edge, and bend it into a U shape at the same height.

[0112] The 4mm thick Al-Mg series 5A06-H112 aluminum all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com