Patents

Literature

53results about How to "Reduce welding current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

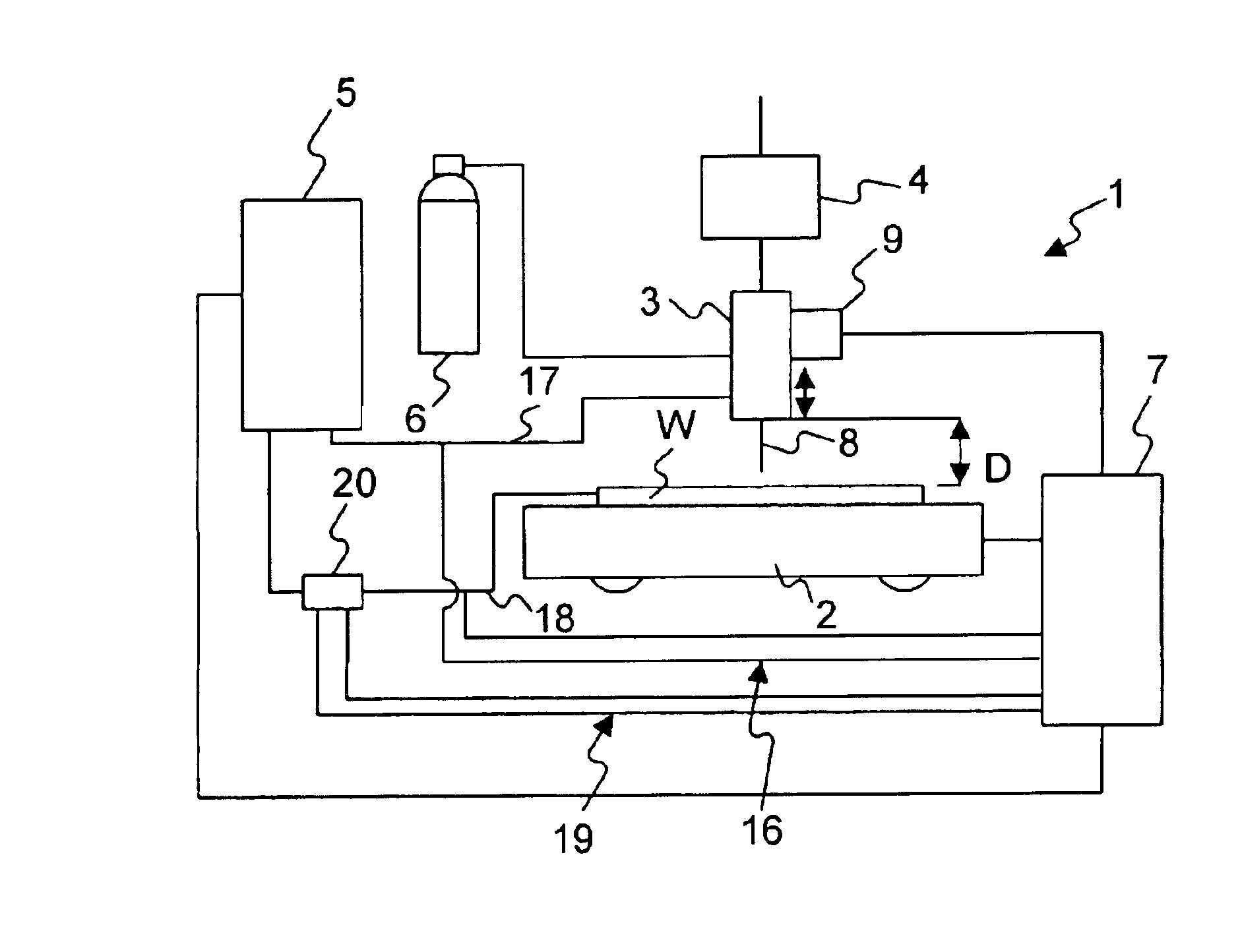

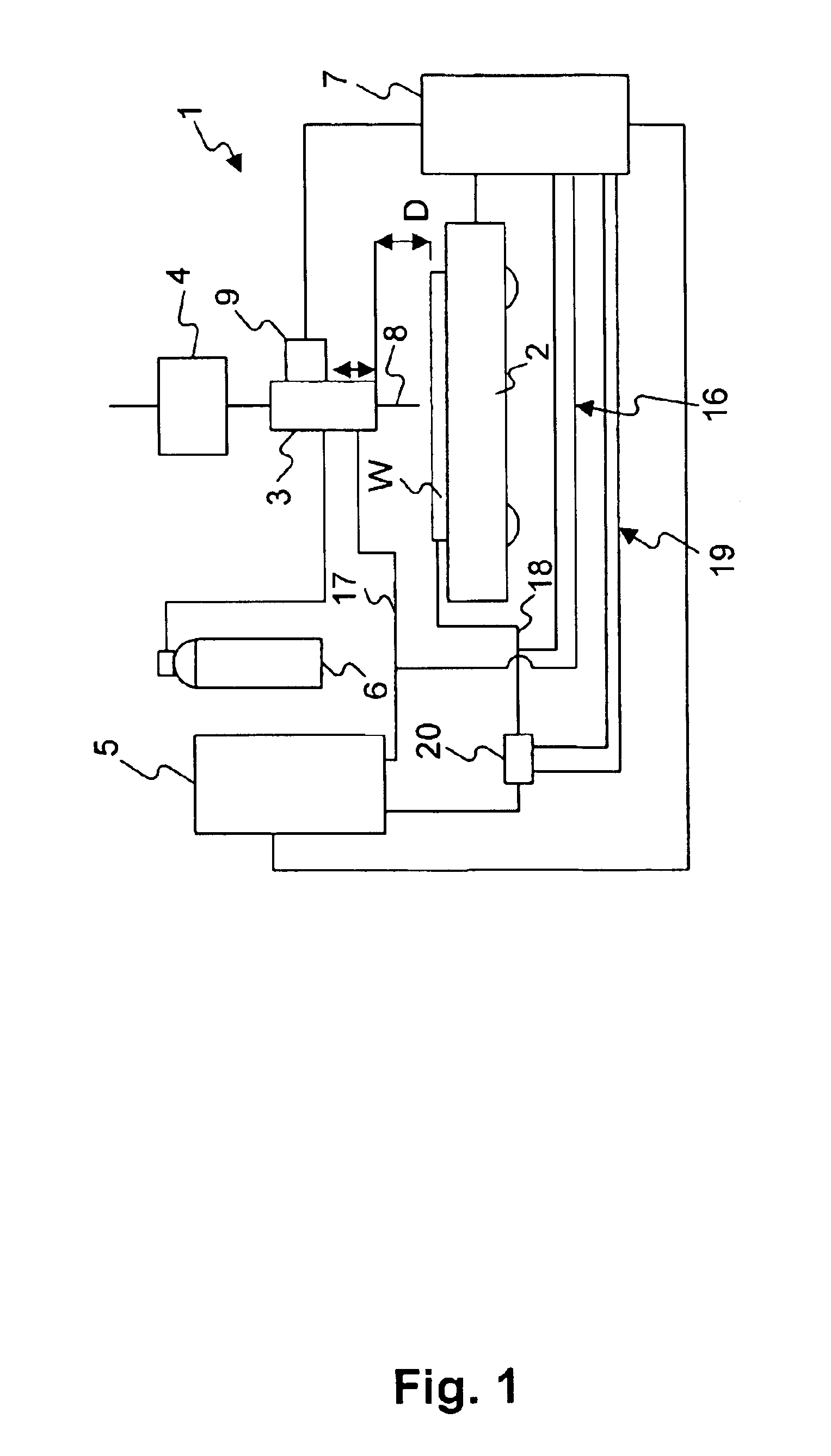

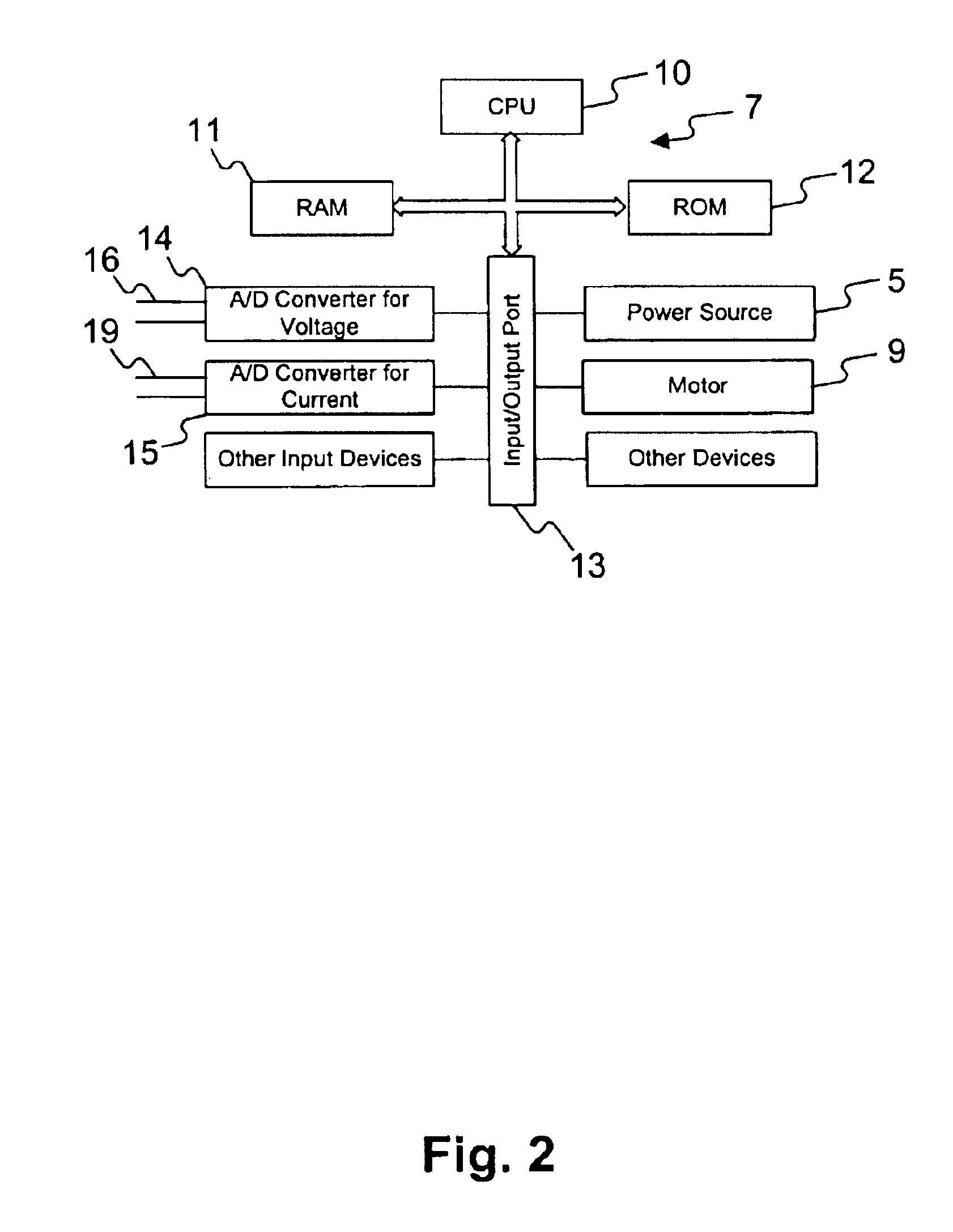

Arc welding method

The present invention relates to an arc welding method in which generation of spatters can be suppressed while the use quantity of gas to be supplied to a welding portion can be decreased. A welding wire 8 is brought into contact with a work W while applying a voltage between the welding wire 8 and the work W, so that the end of the welding wire 8 is caused to be fixingly welded to the work W. At this time, an electric resistance between the welding wire 8 and the work W is continuously obtained during the contact between the welding wire 8 and the work W, and thus, a minimum of the electric resistance is detected. When the current is temporarily reduced after the detection of the minimum of the electric resistance, the tip of the welding wire 8 hardly bursts, thus suppressing the expelling of molten particles, which may cause spatters, from the welding wire 8. The minimum value is also used for the torch-to-workpiece distance control.

Owner:TOSHISADA YASUMURA

Dedicated welding active agent for deep penetration TIG welding and using method

InactiveCN103990919ASimple welding processIncrease productivityArc welding apparatusWelding/cutting media/materialsActive agentMechanical property

The invention discloses a dedicated welding active agent for deep penetration TIG welding. The welding active agent is composed of, by mass, five percent to 15 percent of NaCl powder, 10 percent to 20 percent of CaO powder, 15 percent to 20 percent of MgF2 powder, 10 percent to 15 percent of Fe2O3 powder, seven percent to 10 percent of SiO2 powder, eight percent to 10 percent of TiO2 powder, 17 percent to 20 percent of Cr2O3 powder, four percent to five percent of La2O3 powder and four percent to five percent of Y2O3 powder. The using method of the active agent comprises the steps that calculation is carried out according to the mass percent, 92 percent to 95 percent of the powder of the dedicated welding active agent for deep penetration TIG welding is mixed with five percent to eight percent of acetone to form the pasty or grease-shaped welding active agent, the surface of a workpiece is evenly coated with the welding active agent through a brush, and welding is carried out after the acetone is fully volatilized. According to the welding active agent, complete penetration is achieved on AISI316 austenitic stainless steel and X70 pipeline steel with the thickness of 14 mm through deep penetration TIG welding, the welding process is simplified, a coarse structure is avoided, the mechanical property of a welding joint is improved, production efficiency is improved, and production cost is lowered.

Owner:ZHANGJIAGANG HUABAO MACHINERY MFG

Stainless heat-proof self-protecting flux-cored wire for magnesium smelting reduction tank

ActiveCN104259690AQuality improvementHigh welding currentWelding/cutting media/materialsSoldering mediaMisch metalVulcanization

A stainless heat-proof self-protecting flux-cored wire for a magnesium smelting reduction tank belongs to the technical field of materials processing engineering. A normal stainless steel band 304L or common carbon steel serves as a coating layer, and alloys in a powder core are rutile, sodium carbonate, feldspar, compound fluorides, chromium, nickel, manganese, molybdenum, chromium nitride, aluminium-magnesium alloy, misch metal and iron power. Compared with a conventional stainless steel welding rod, the stainless heat-proof self-protecting flux-cored wire has the advantages that higher welding current can be used; higher welding speed can be realized; the production efficiency is improved; and the labor intensity is lowered; c. Compared with a conventional stainless steel submerged-arc welding solid wire, the stainless heat-proof self-protecting flux-cored wire has the advantages that all-position welding can be realized; the heat input is small; the slag detachability is good; and the manufacturing technique is simpler. A welded joint formed by using the stainless heat-proof self-protecting flux-cored wire provided by the invention has favorable heat resistance, oxidation resistance, vulcanization and corrosion resistance and high-temperature creep resistance compared with welded joints formed by welding the stainless steel welding rod and the stainless steel solid wire.

Owner:BEIJING UNIV OF TECH

Activator for magnesium alloy welding

InactiveCN101244497AWell formed weldImprove joint qualityArc welding apparatusWelding/cutting media/materialsAlcoholActive agent

The invention relates to an active agent applying to magnesium alloy welding, belonging to the material engineering technical field, which is characterized in that: the active agent is composed of TiO2, Cr2O3, MgO, MnO2, and CaO and the weight proportion is TiO2: 40 to 70%, Cr2O3: 5 to 20%, MgO: 2 to 20%, MnO2: 5 to 20%, CaO: 5 to 20%. Firstly, the active agent is grinded to powder, then is dried and cooled; secondly, the active agent is mixed with acetone or alcohol and then is equally coated or sprayed on the surface of the welding bead; finally, after the acetone or the alcohol is volatilized, welding can be implemented. The active agent has the advantages that: the weld penetration can increase at least twice; the weld joint of magnesium alloy is well moulded; the joint is of high quality and the intensity can be above the 95% of the intensity of the parent metal; the deformation due to welding is reduced; the invention is of easy operation and high productivity.

Owner:DALIAN UNIV OF TECH

A resistance brazing method for galvanized steel sheets

InactiveCN102275046AFree from destructionExtended service lifeWelding apparatusMaterials scienceElectrical resistance and conductance

A resistance brazing method for galvanized steel sheets relates to the improvement of the resistance spot welding method for galvanized steel sheets. In the present invention, medium-temperature solder such as Zn-Al is placed on the two surfaces to be soldered. The solder can be sheet-like, foil-shaped, plated or sprayed on the surface to be soldered in advance, and the thickness of the solder is 0.05-0.5 mm. The electrode material can be an ordinary Cu-Cr-Zr electrode, and the electrode does not need special treatment. Set the resistance spot welding parameters, the welding current is 7000~14000A, the welding time is 10C~50C, the welding pressure is 0.7KN~5KN, start the resistance spot welding, and then let the weldment cool naturally. The invention can realize the connection without galvanized layer damage and copper pan under the premise that the galvanized steel sheet meets the strength, and improves the service life of the electrode.

Owner:CHONGQING UNIV OF TECH

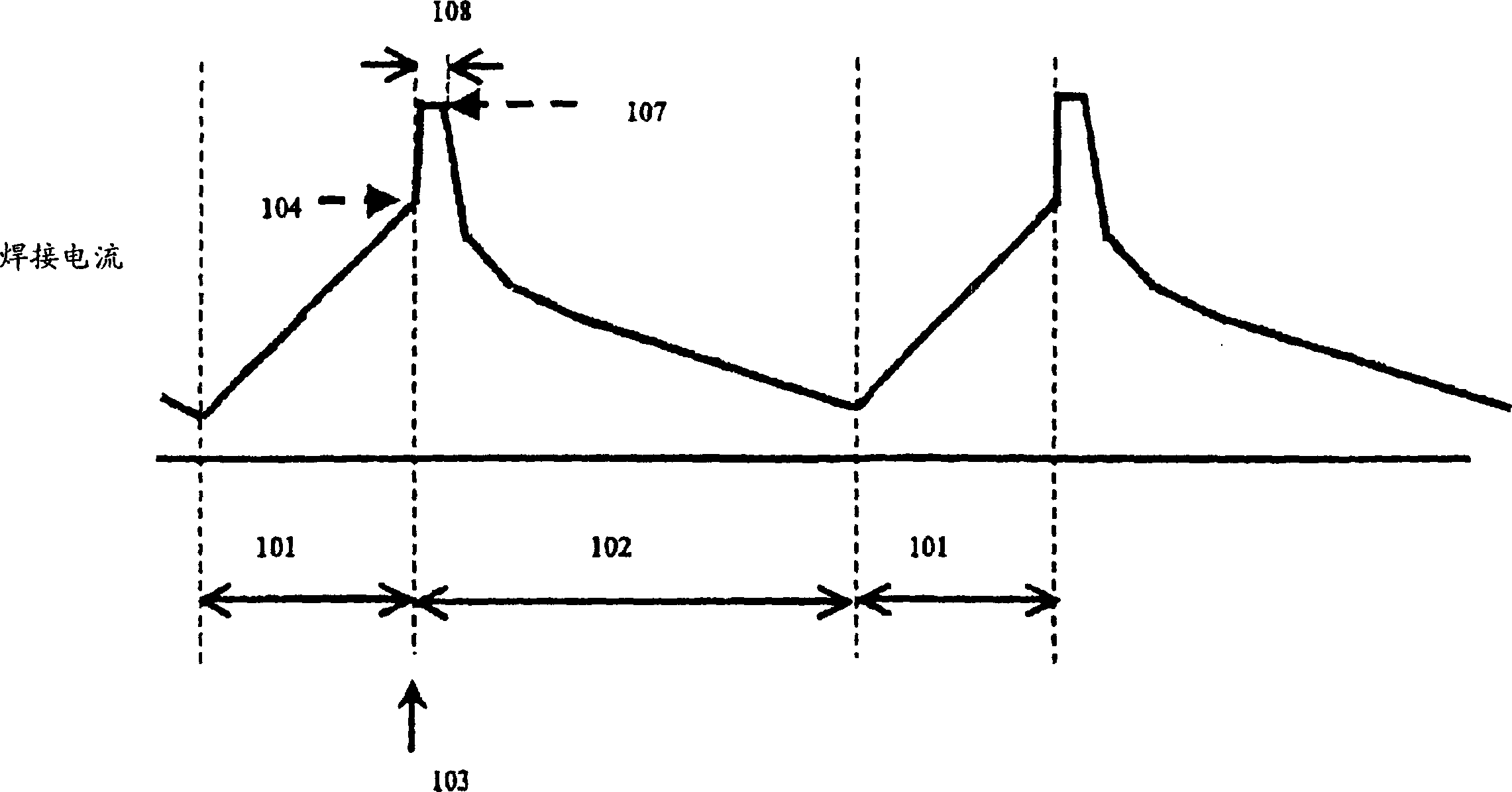

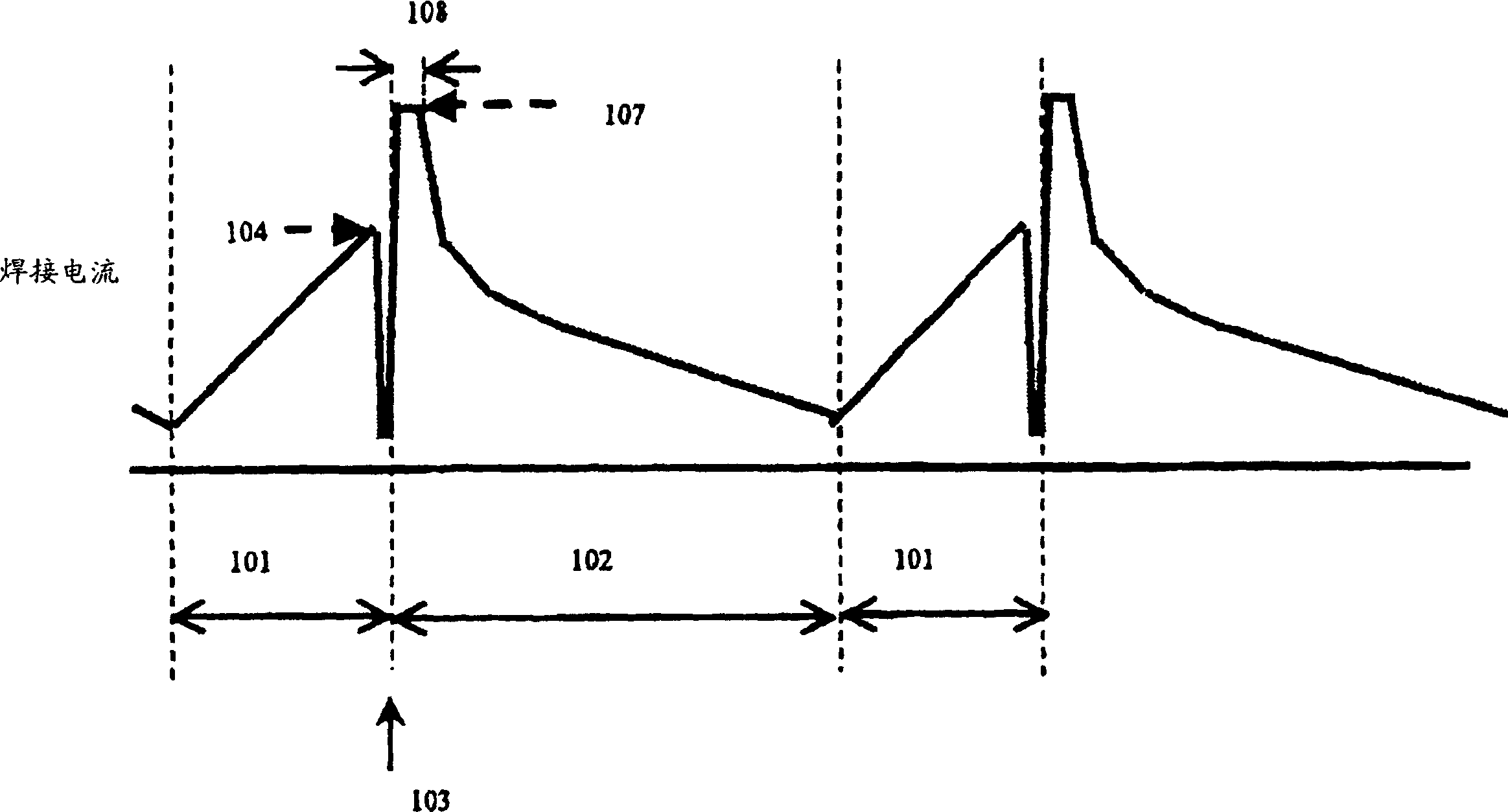

Arc welding control method and arc welding device

An arc welding control method performs welding of a work by alternately repeating a short-circuit period for short-circuiting a welding wire to a work and an arc period for regenerating an arc to perform arc discharge. The control is performed so that the welding output current immediately after regeneration of the arc is maintained higher than the welding output current immediately before the arc regeneration for a predetermined period of time.

Owner:PANASONIC CORP

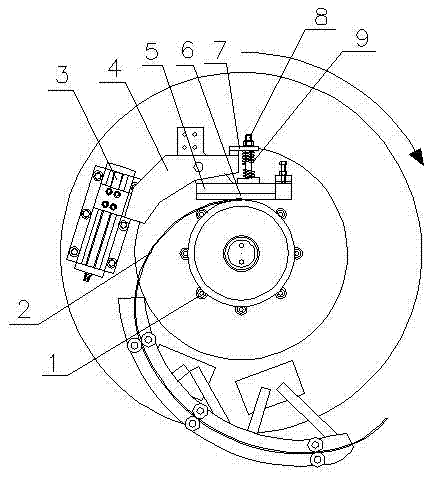

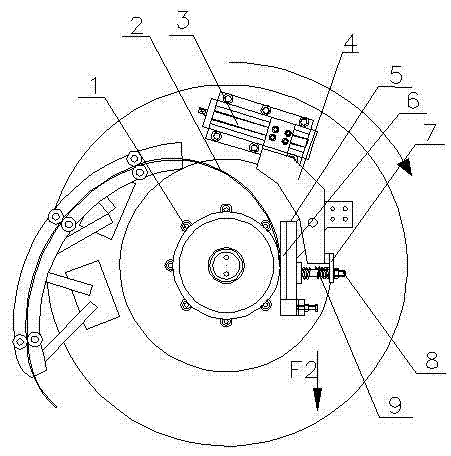

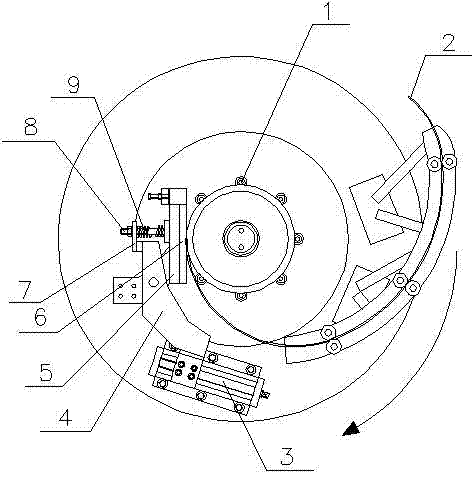

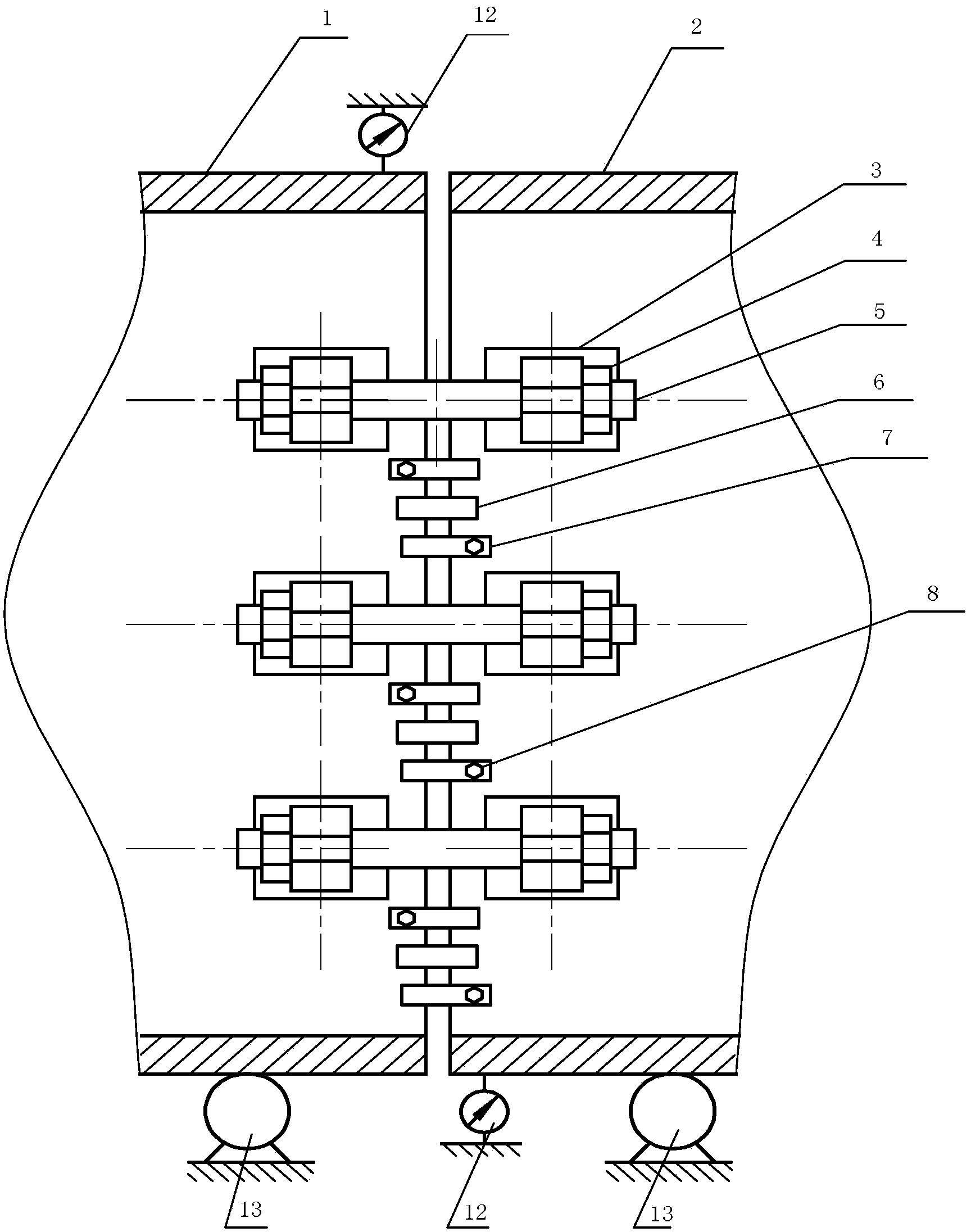

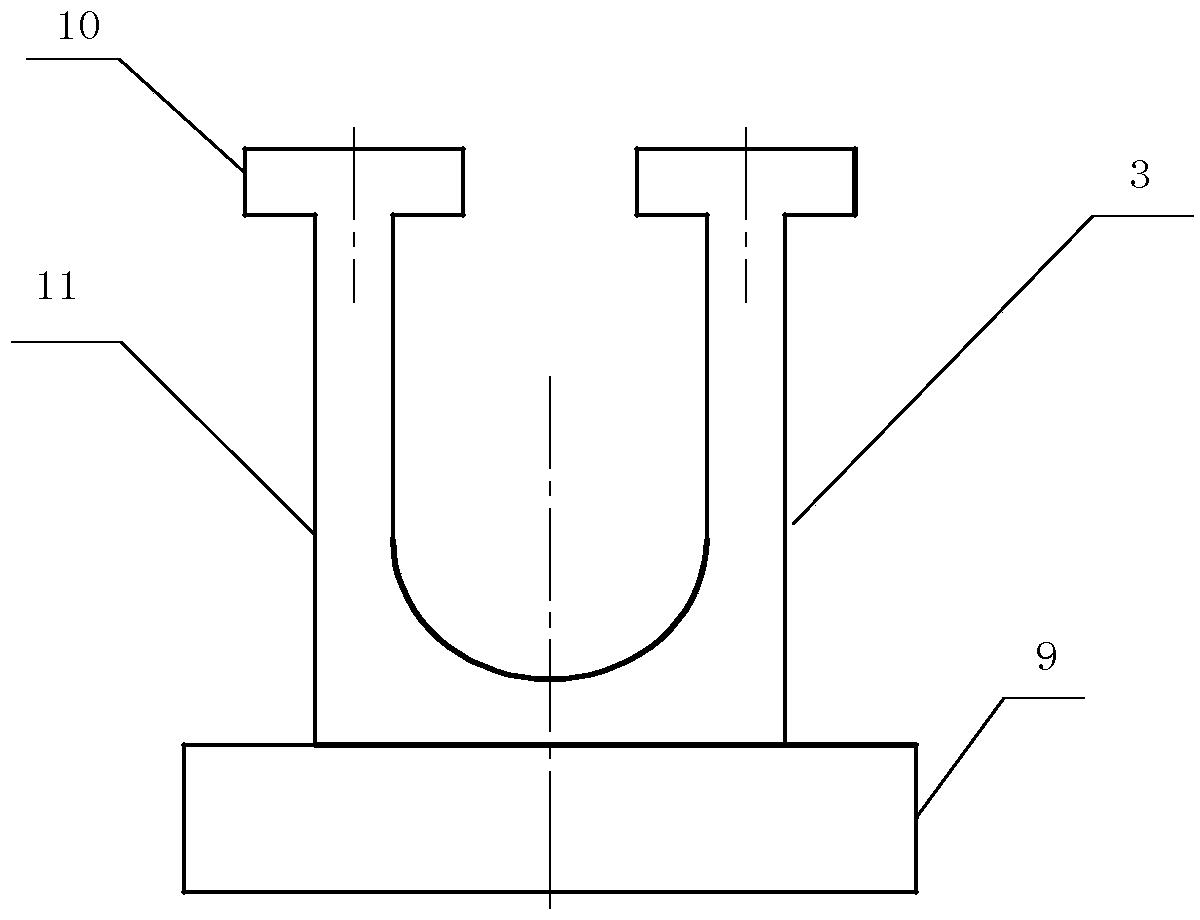

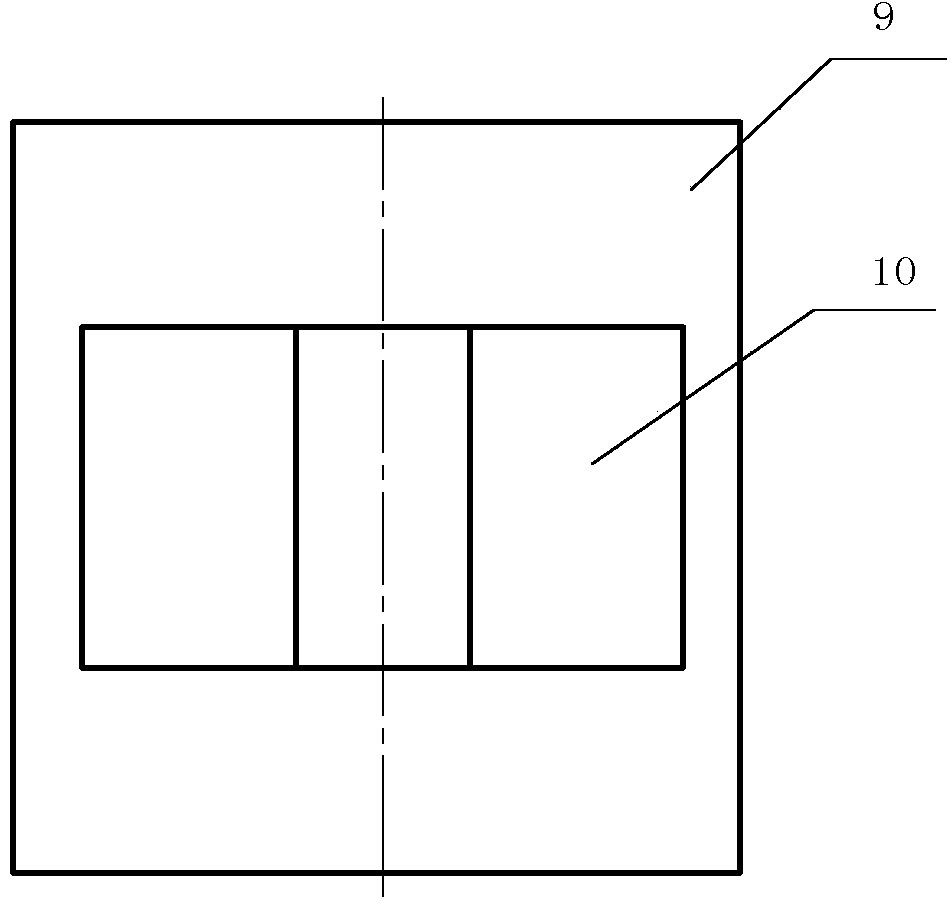

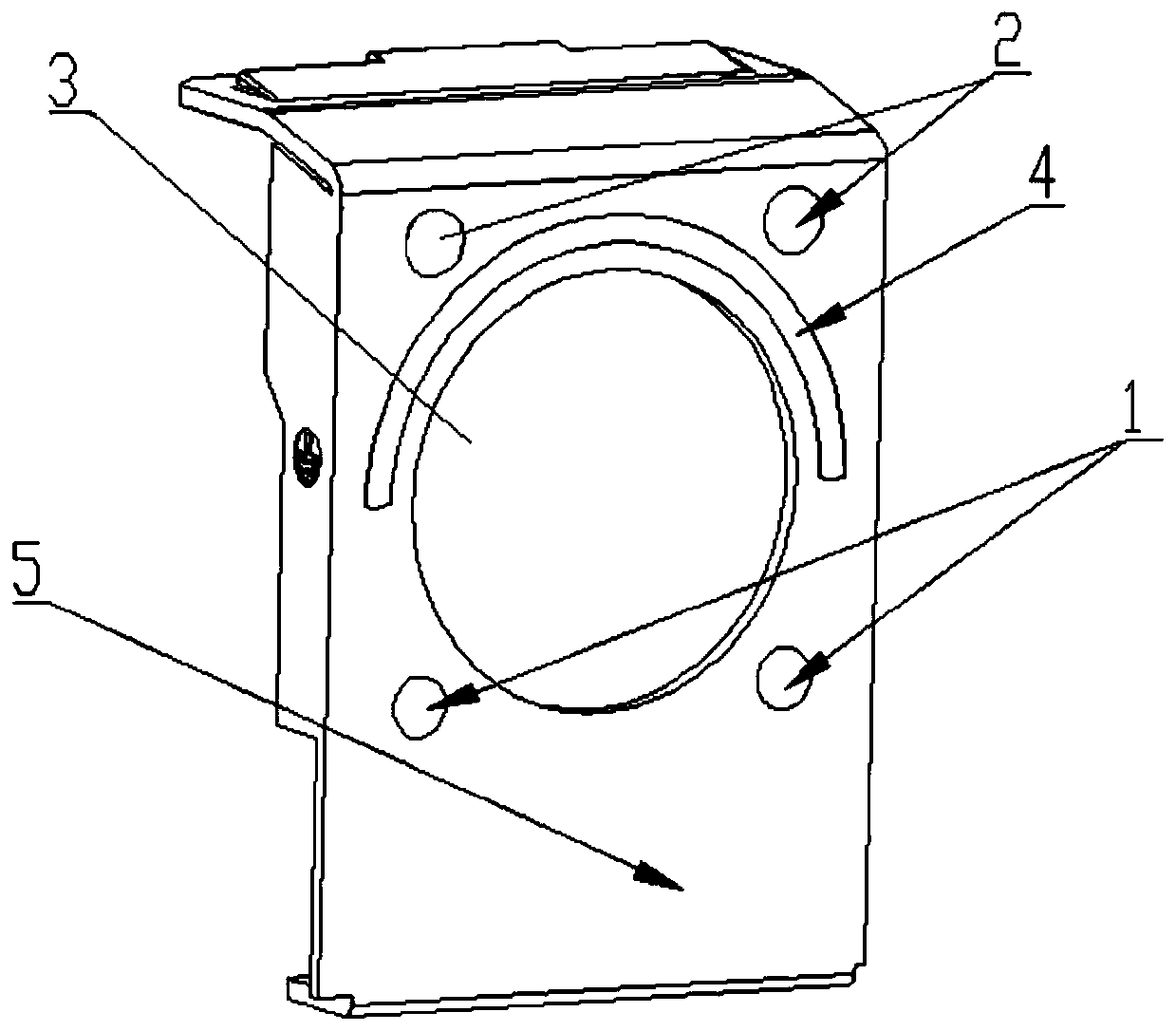

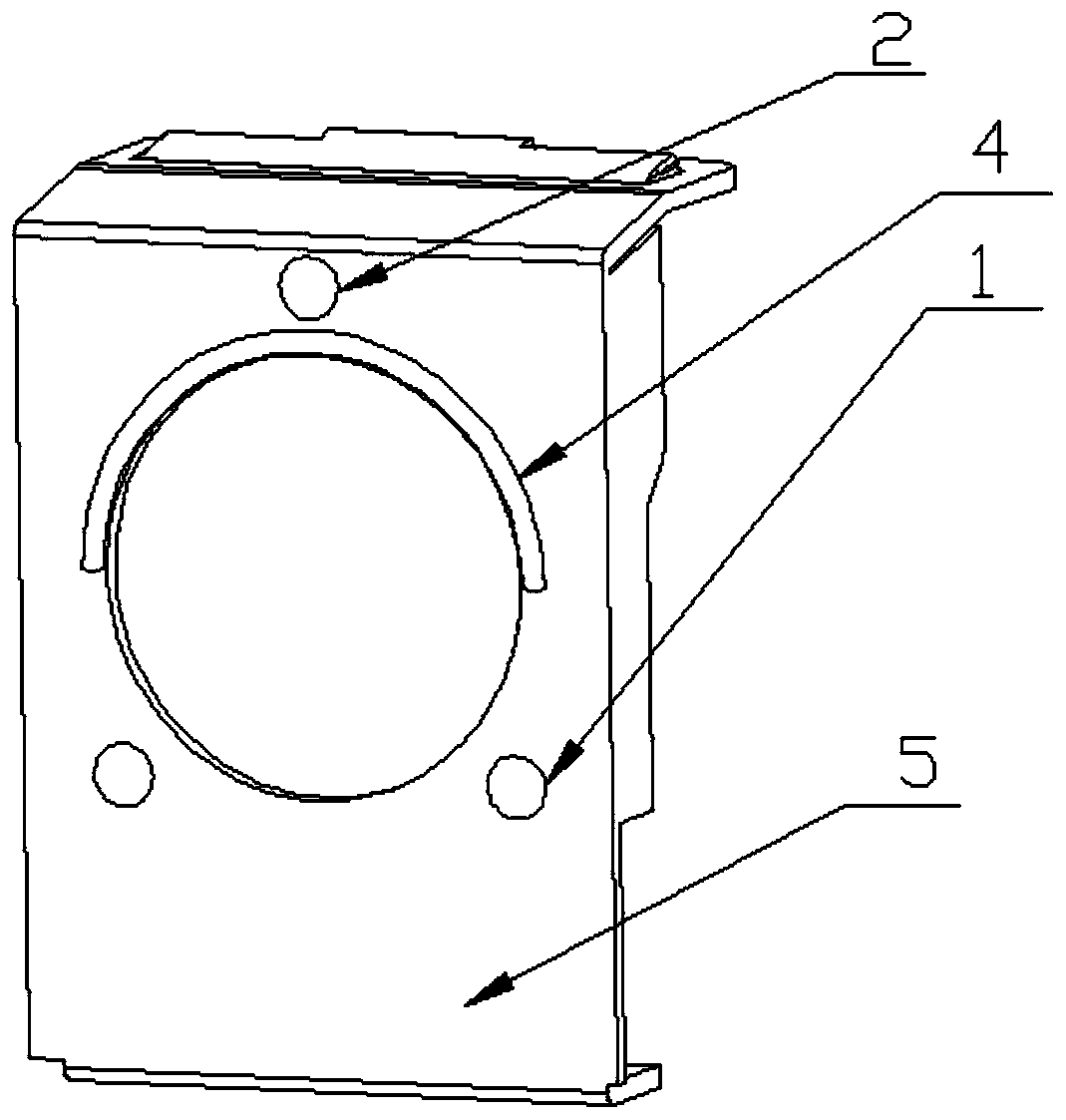

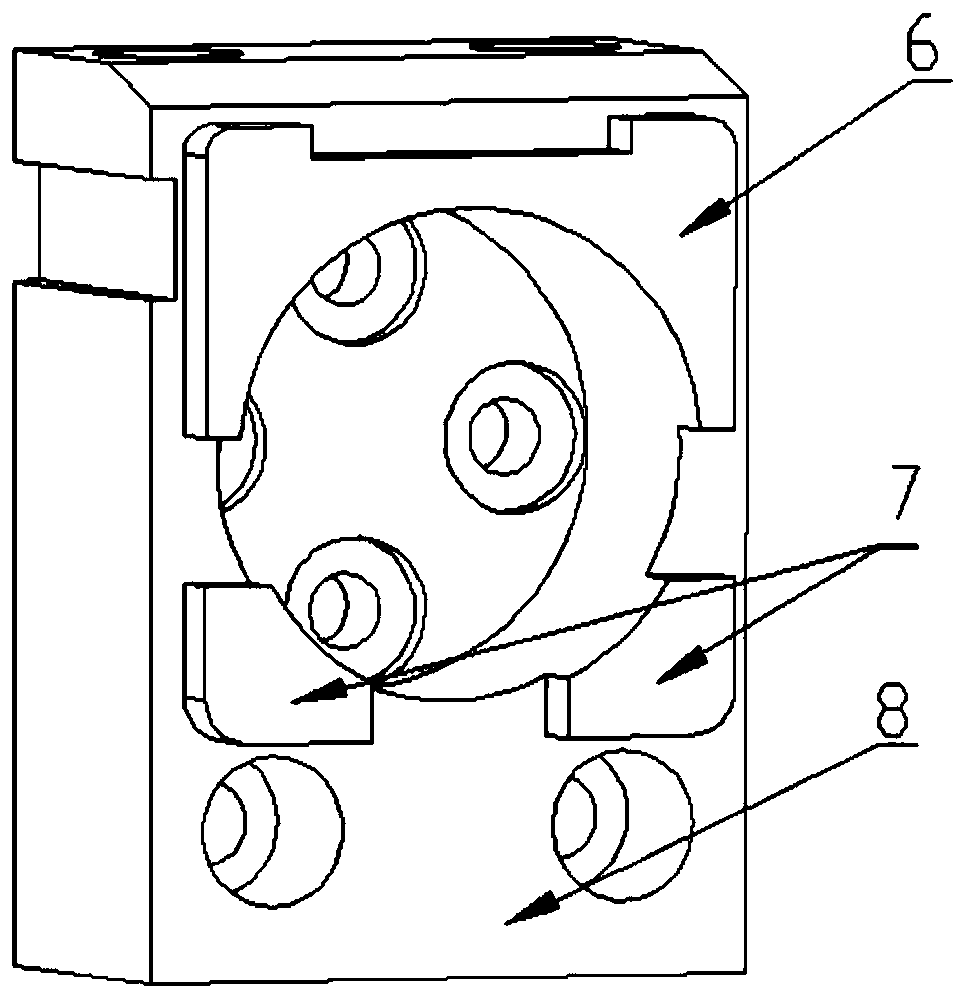

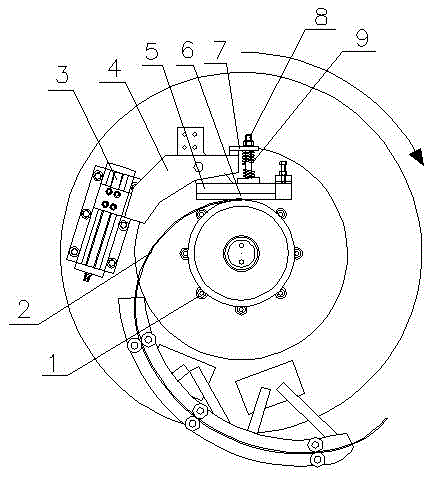

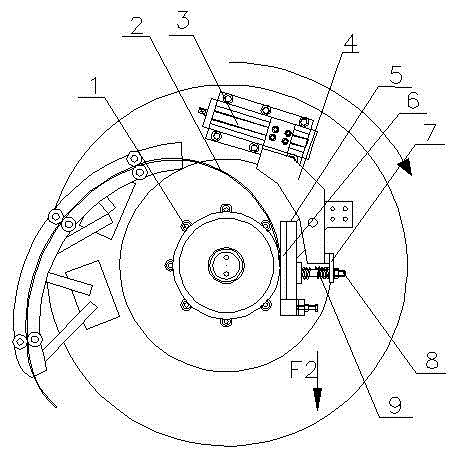

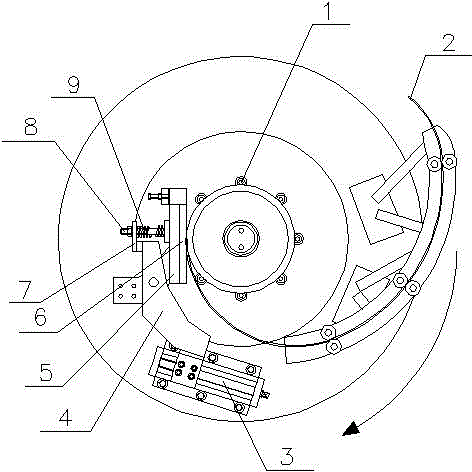

Rotating welding electrode structure of pipe pile seam welder

ActiveCN103286433AReduce welding currentRealize energy saving and consumption reductionResistance electrode holdersEngineeringPendulum

The invention relates to a pipe pile seam welder, in particular to a rotating welding electrode structure of the pipe pile seam welder. The rotating welding electrode structure comprises support plates, a conducting electrode plate, a welding electrode plate and a spring locating assembly. A pendulum shaft is assembled between the two corresponding support plates, the conducting electrode plate and the welding electrode plate which are assembled together through a locating sleeve are installed on a reinforcing plate, the reinforcing plate is fixedly connected to the pendulum shaft, one end of the reinforcing plate is hinged to a spring locating rod in the spring locating assembly, and a balance body is assembled at the other end of the reinforcing plate. The rotating welding electrode structure has the advantages that by additionally installing the balance body on a welding electrode, the gravity of the balance body and centrifugal force generated when the balance body works on the welding electrode are utilized to balance or offset the gravity or centrifugal force of the welding electrode through the pendulum shaft, so that the welding electrode can provide almost balanced welding pressure within a whole circumference range, complete conditions are provided for reducing welding pressure or welding current at the time, and accordingly energy conservation and consumption reduction are achieved indeed.

Owner:TANGSHAN TIANZE SPECIAL WELDING EQUIP

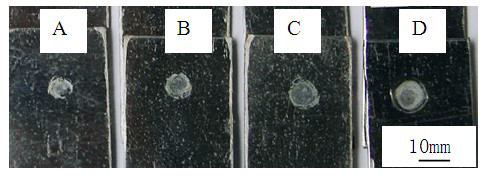

Point welding technique of magnesium alloy filled with reactive powder

InactiveCN103170694AIncrease contact resistanceGood welding performanceSoldering apparatusElectrical resistance and conductanceShielding gas

The invention relates to a point welding technique of magnesium alloy filled with reactive powder, and belongs to the welding field of magnesium and the magnesium alloy material. The point welding technique of the magnesium alloy filled with the reactive powder is characterized in that the reactive powder is used as a filled layer to improve the contact resistance of magnesium alloy material which is difficult to weld in an early welding period. Resistance heat serves as a welding heat source, under the actions of protection of protective gas and resistance heat of added thermal compensation blocks, partial melting of surfaces to be welded of material happens simultaneously. Under the action of appropriate electrode pressure impact, oxidation films are crushed, refining action of the reactive powder medium is promoted on the interface of the material to be welded, nuggets are formed on the interface, so that the effect that nugget grains are refined under a relatively small current is achieved. Welding is achieved under thermal compensation, flexibility is relatively strong, and the point welding technology of the magnesium alloy filled with the reactive powder is of relatively ideal project significance.

Owner:TAIYUAN UNIV OF TECH

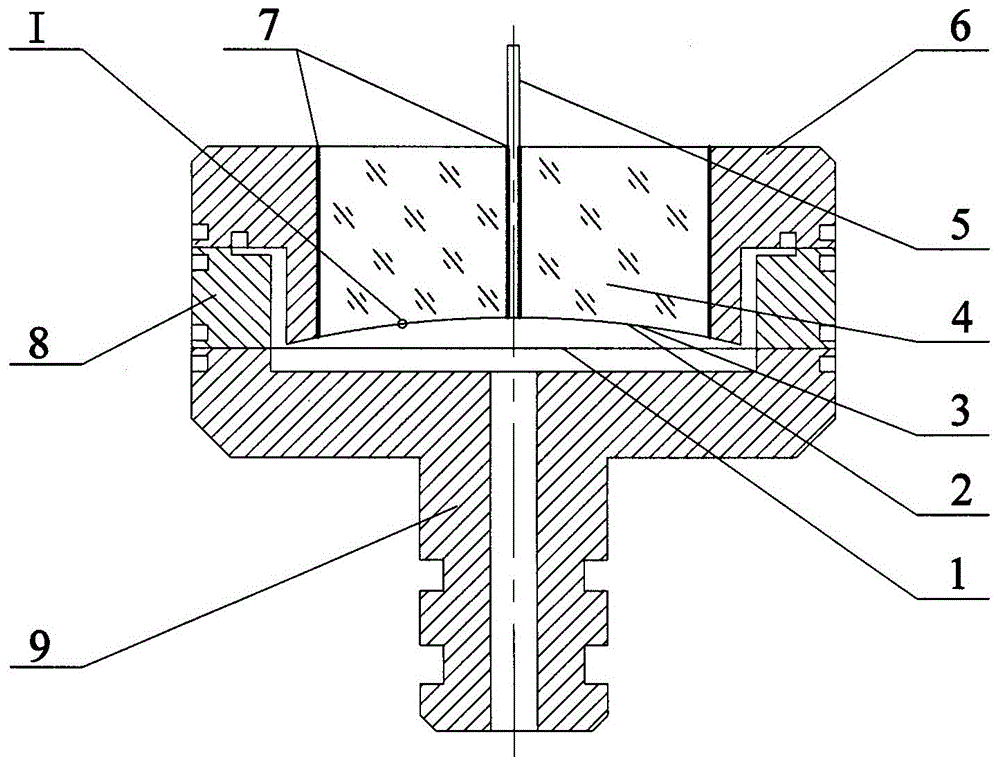

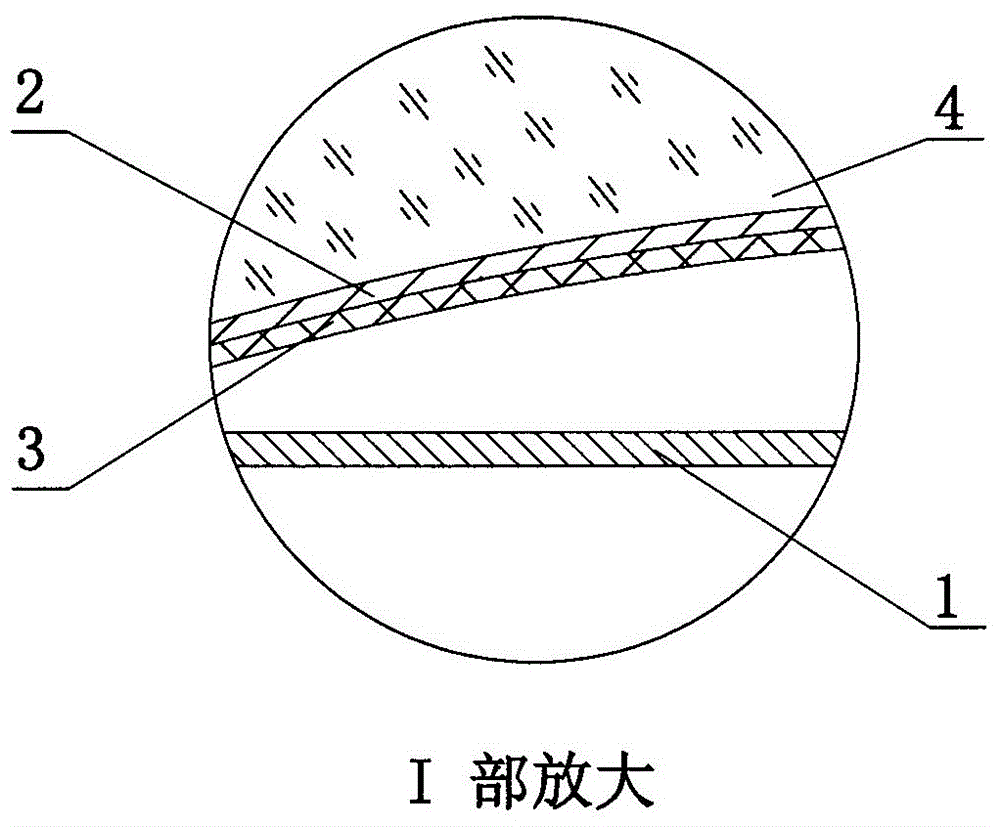

Capacitive pressure transducer with transition welding ring

InactiveCN106353014ABuffer expansion stressReduce unwanted changesForce measurementCapacitanceTransducer

The invention provides a capacitive pressure transducer with a transition welding ring, aiming at solving the problem of long-term slow leakage, accidental damage and the like since welding among unmatched materials of an existing capacitive pressure transducer easily causes thermal stress and swelling stress. The capacitive pressure transducer comprises a mated shell, a fixed electrode, a tubular extraction electrode, a moving electrode and a pressure drawing opening which are assembled with the mated shell. The capacitive pressure transducer is characterized in that a transition welding ring is arranged between the mated shell and a welding base with collars and pressure drawing openings; the moving electrode, the transition welding ring and the welding base with collars and pressure drawing openings are made of the same material which has an expansion coefficient larger than those of materials of the fixed electrode with a mated capsulated structure, and are welded together; and the fixed electrode and the moving electrode are welded together by utilizing the transition welding ring. The capacitive pressure transducer is reasonable in structure design, is safe and reliable, can be used for effectively buffering thermal stress and swelling stress generated by welding among unmatched materials and reducing undue changes of materials in the welding process, and has high yield rate, so that the manufacture cost can be reduced, and the measurement accuracy and stability can be improved.

Owner:SHENYANG SENSOR TECH INST

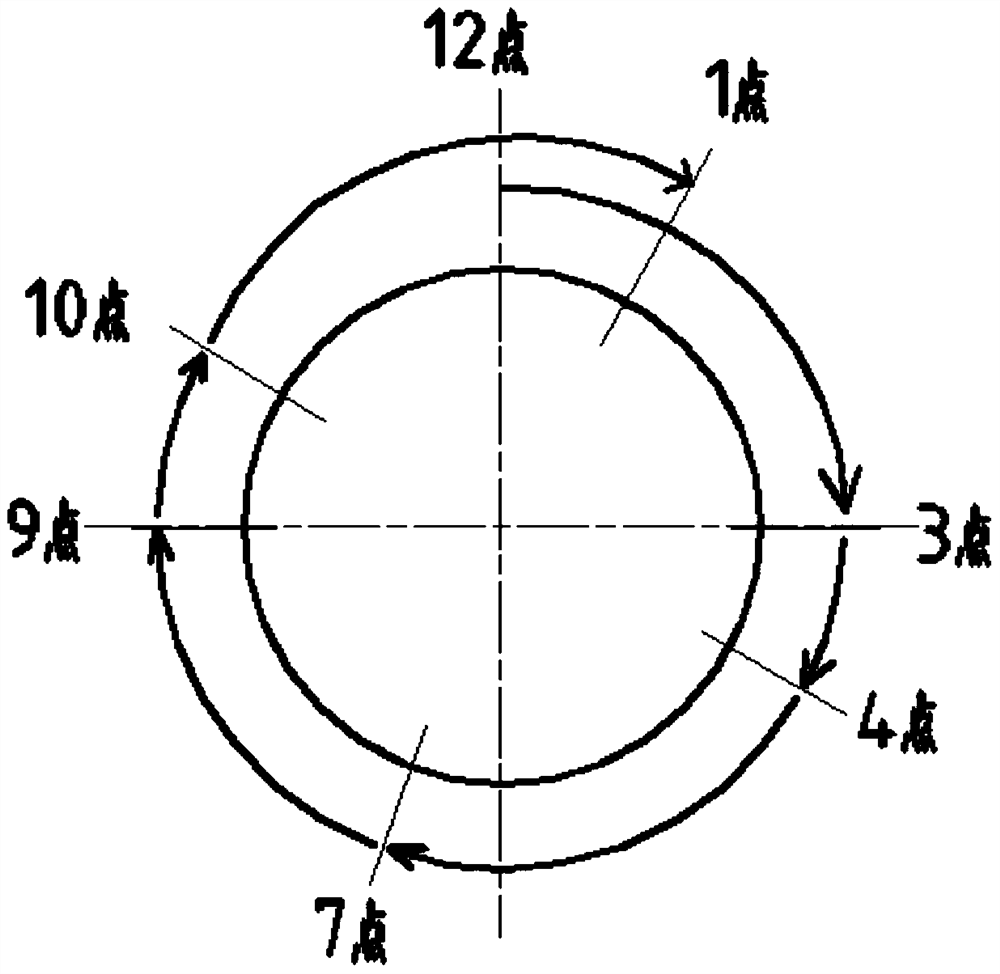

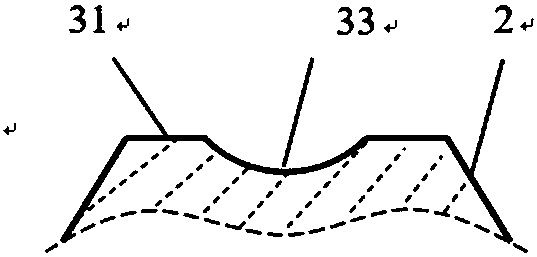

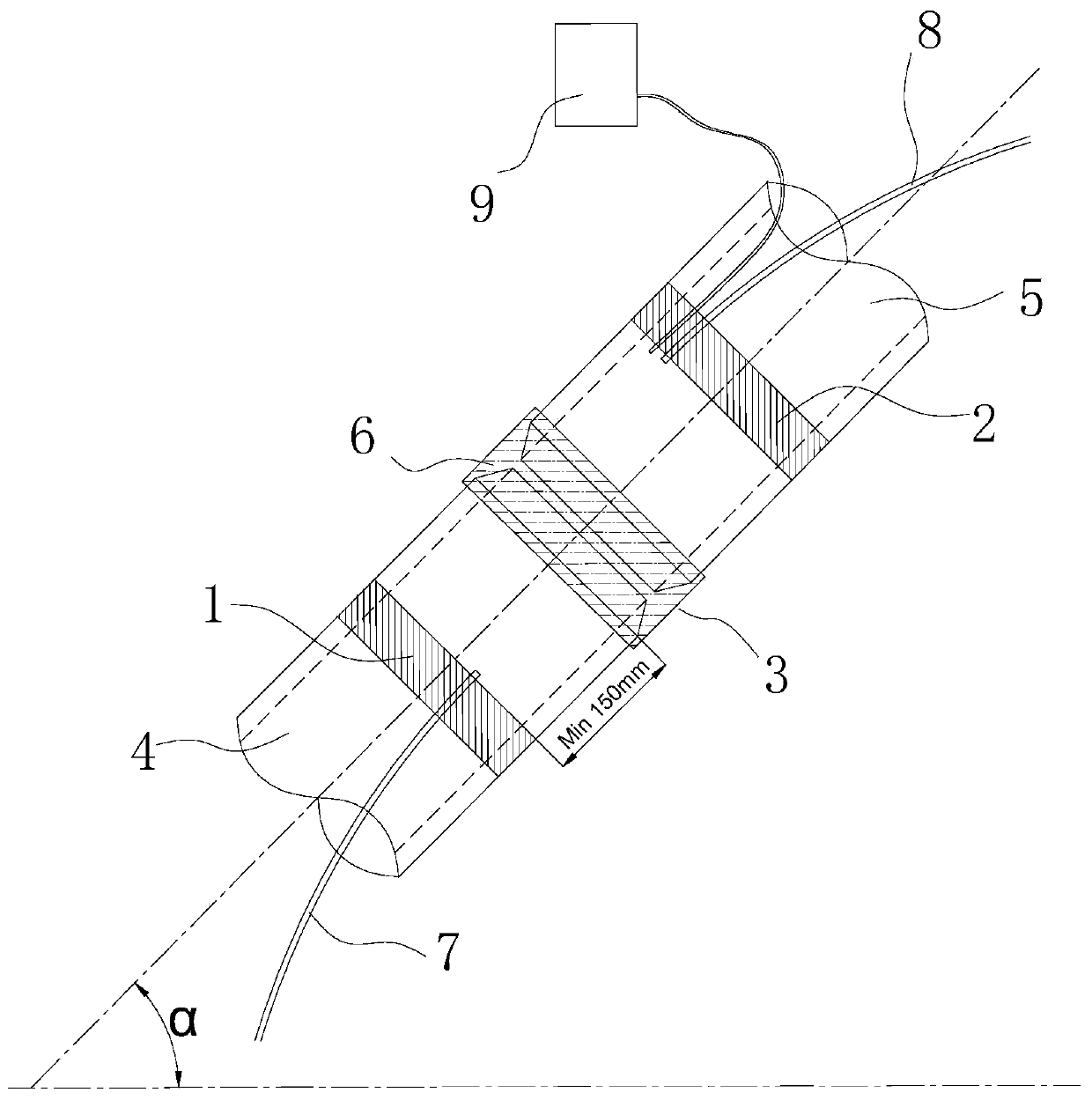

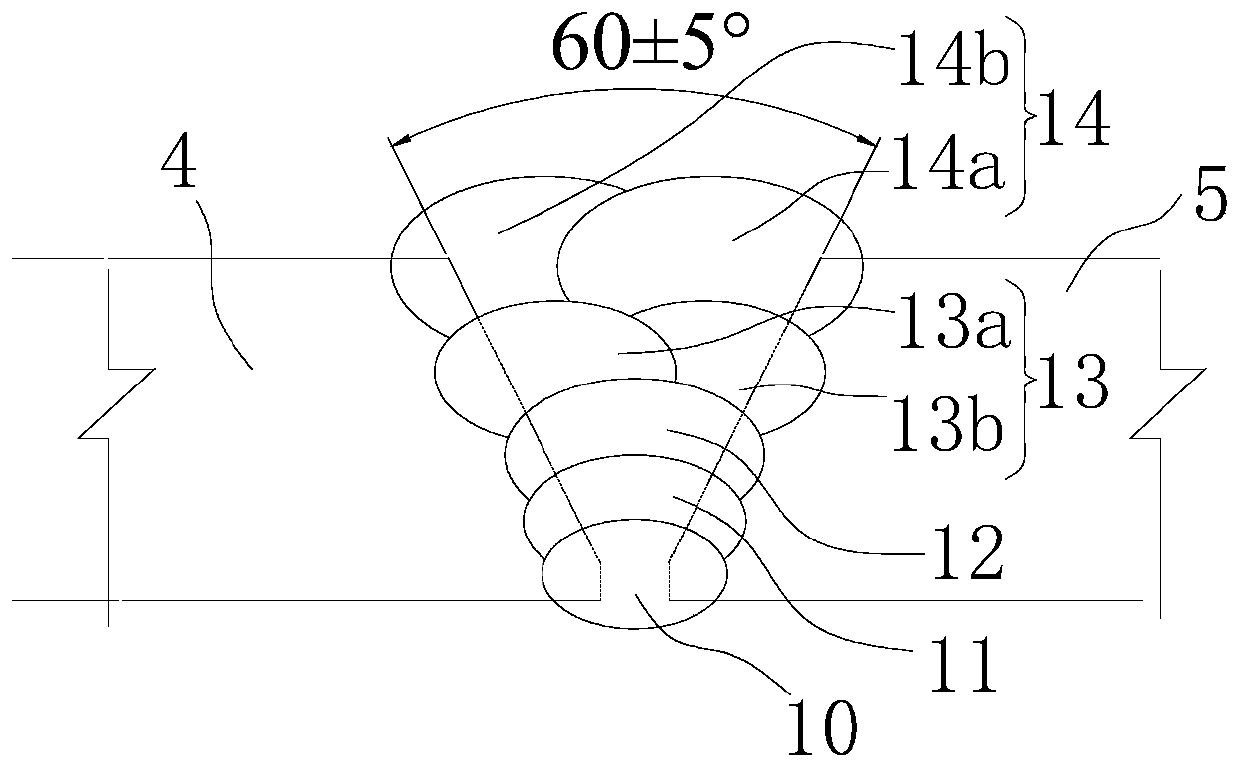

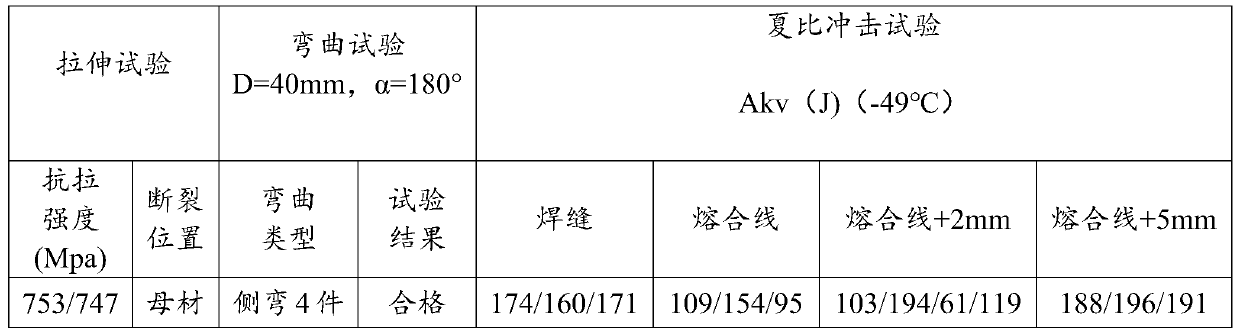

Rail TIG welding method for black-and-white pipes

The invention discloses a rail TIG welding method for black-and-white pipes, and belongs to the technical field of welding. When rail TIG welding is adopted for black-and-white pipe all-position welding, the difficulty lies in that smooth transition from welding materials in all directions (flat, downhill, uphill and the like) to a molten pool and stress balance in the molten pool crystallization process are guaranteed, otherwise, hot cracks are likely to appear on a base coat, inward concavities and the like are likely to appear on an overhead welding position, consequently, rail TIG welding cannot be successfully applied to butt joint of the black-and-white pipes, and wide application of rail TIG welding in boiler manufacturing is limited. According to the method, welding parameters are set in a partitioned manner, the welding rotating speed of the base coat is increased, the wire feeding amount and the welding current are reduced, and therefore the molten pool temperature at the overhead welding position at 4-7 o' clock is reduced, and generation of inward concavities of the base coat at the overhead welding position is effectively avoided; the welding rotating speed of a first filling layer at the overhead welding position is increased, the welding current is reduced, and the situation that when the first filling layer appears at the overhead welding position, inverse fusion is caused to the base coat, and consequently inward concavities are caused is effectively avoided; the welding parameters of the base coat are optimized, the arc extinguishing decay time and stroke are prolonged, the electric arc length is increased, and generation of arc extinguishing cracks of the base coat is effectively avoided; and the current and the wire feeding speed are changed in different areas, heat input of all the areas is accurately controlled, and generation of various poor fusion defects is effectively avoided.

Owner:WUHAN BOILER

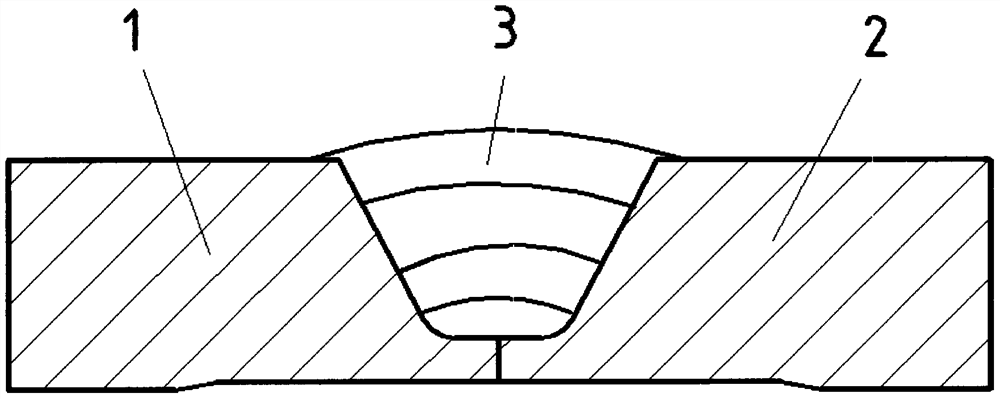

Resistance spot welding electrode cap

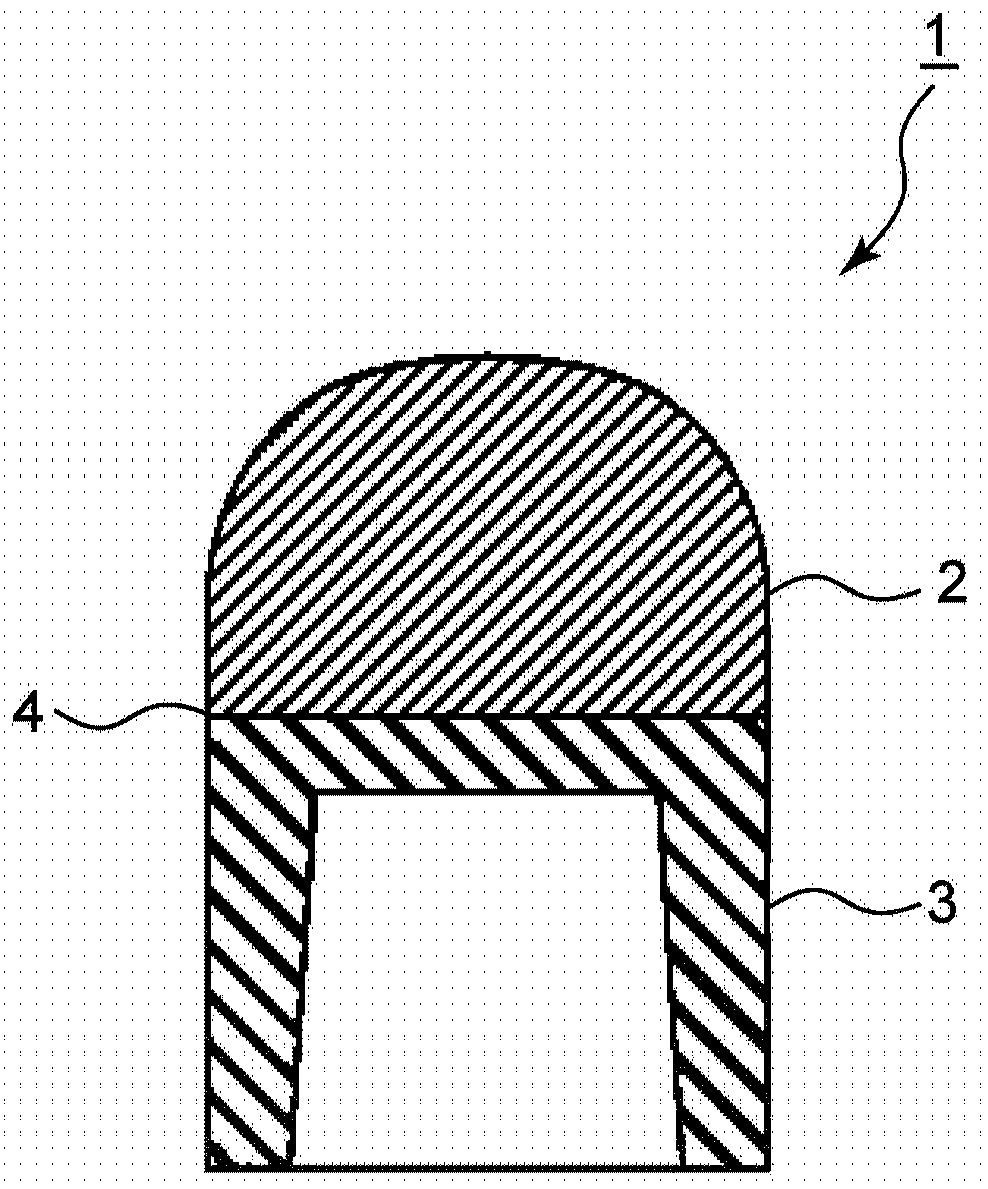

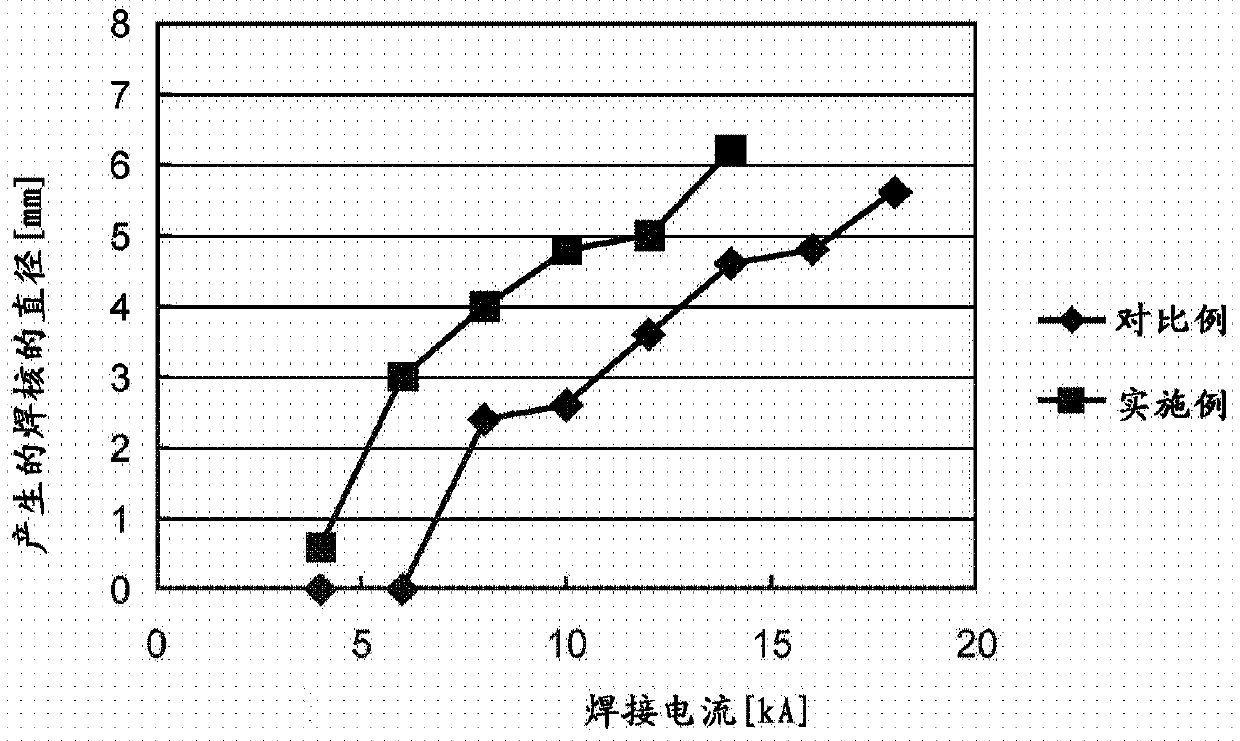

ActiveCN110369848AExtend your lifeAvoid it happening againPressure electrodesWelding/cutting media/materialsElectrical resistance and conductanceEngineering

The invention discloses a resistance spot welding electrode cap. A groove is formed in the center of a welding contact surface of the electrode cap; in the welding process, the contact area between the electrode cap and a to-be-welded metal workpiece is reduced due to the existence of the groove; in the initial stage, overall produced heat is concentrated to outer rings of welding spots, so that the heat dissipation speed is low, and formation of molten cores from outside to insideis facilitated; and due to the existence of the groove, the metal workpiece expands towards the sunk part of the center of an electrode, the molten cores of the welding spots areincreased, and splashing and deforming are reduced. Compared with a traditional electrode cap, the welding current needed for forming the welding spots inthe same size by the electrode capis lower, and the electric power cost is reduced; and when the same current is used, the strength and the stability of the obtained welding spots are higher, and the welding defects are fewer.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

TIP TIG welding process of duplex stainless steel

InactiveCN110497068AQuality improvementImprove efficiencyArc welding apparatusWelding/soldering/cutting articlesFriction weldingThermal deformation

The invention provides a TIP TIG welding process of the duplex stainless steel. The TIP TIG welding process comprises the following steps of 1, preparation of welding material and formulation of welding process, 2, welding groove machining, 3, pre-welding preparation. 4, welding of duplex stainless steel, and 5, weld joint detection. According to the TIP TIG welding process , by means of the semi-automatic TIP TIG welding process, the problems that the existing duplex stainless steel manual GTAW welding speed is low, the welding efficiency is low, and the submerged-arc welding SAW welding position is limited are solved, the welding quality can be guaranteed, the welding efficiency can be improved, and semi-automatic full-position welding in the duplex stainless steel high-quality, high-efficiency, full-working-condition and full-thickness range is realized; the welding quality is ensured, the welding current is reduced, the welding heat input is reduced, the heat affected zone is reduced, the welding thermal deformation is low, the surface forming of the weld joint is good, and the operation controllability is high; and the welding efficiency is improved, and the full-position welding of the duplex stainless steel can be realized in a workshop or a field construction site.

Owner:ZHONGHAI FULU HEAVY IND CO LTD

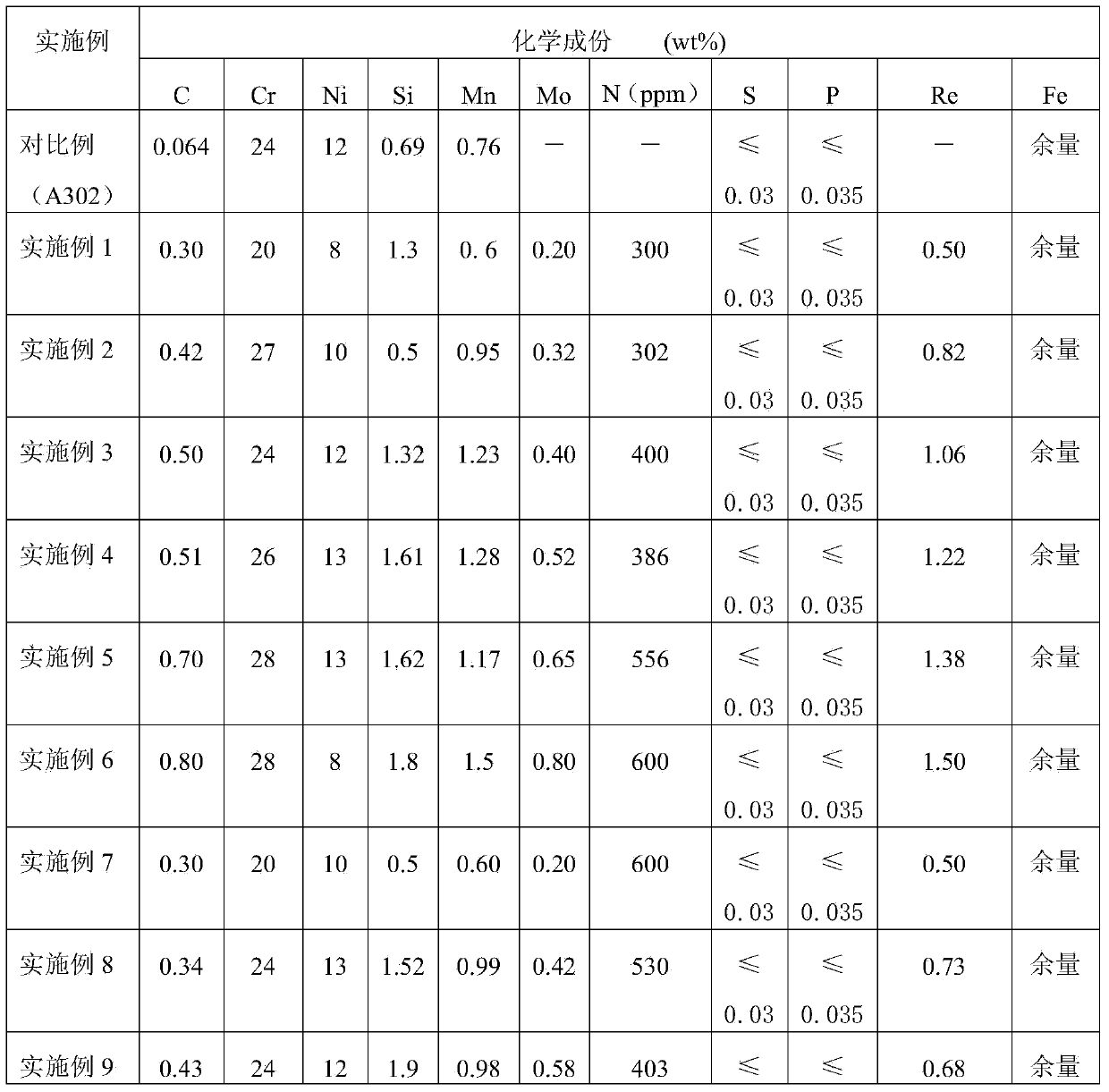

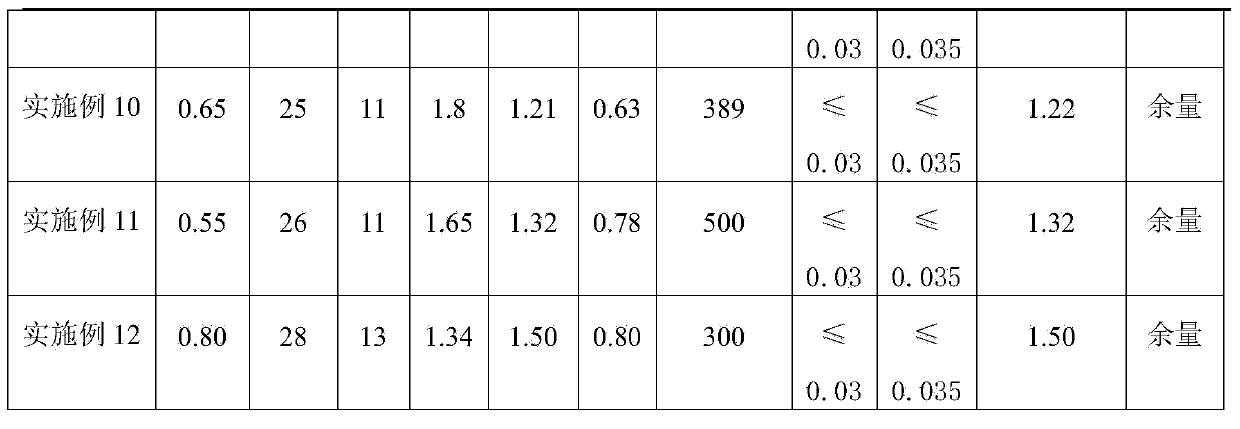

Metal core welding wire for submerged arc welding of A304 and A304L austenitic stainess steel

InactiveCN1887503ASuitable for high-speed automatic weldingImprove melting efficiencyArc welding apparatusWelding/cutting media/materialsSlagManganese

The metal core welding wire for submerged arc welding of A304 and A304L austenitic stainless steel belongs to the field of welding material widely used in petroleum, chemical, ship-building and other fields. The present invention features that the metal core welding wire is formed through adding metal mixture powder in 40-58 wt% into low carbon steel belt material or super low carbon steel belt material, and the metal mixture powder consists of Cr 37-57 wt%, Ni 17-28 wt%, Mn 3-9 wt%, reduced Fe 7.5-30 wt%, Bi2O3 0.5-1.5 wt%, and Al-Mg alloy 2-10 wt%. The corresponding welding specification includes welding current of 380-600 A, welding voltage of 30-40 V and welding speed of 450-800 mm / min. The metal core welding wire has simple production process and excellent post-welding slag removing performance, and is especially suitable for high speed automatic welding.

Owner:CHINA PETROLEUM & CHEM CORP +1

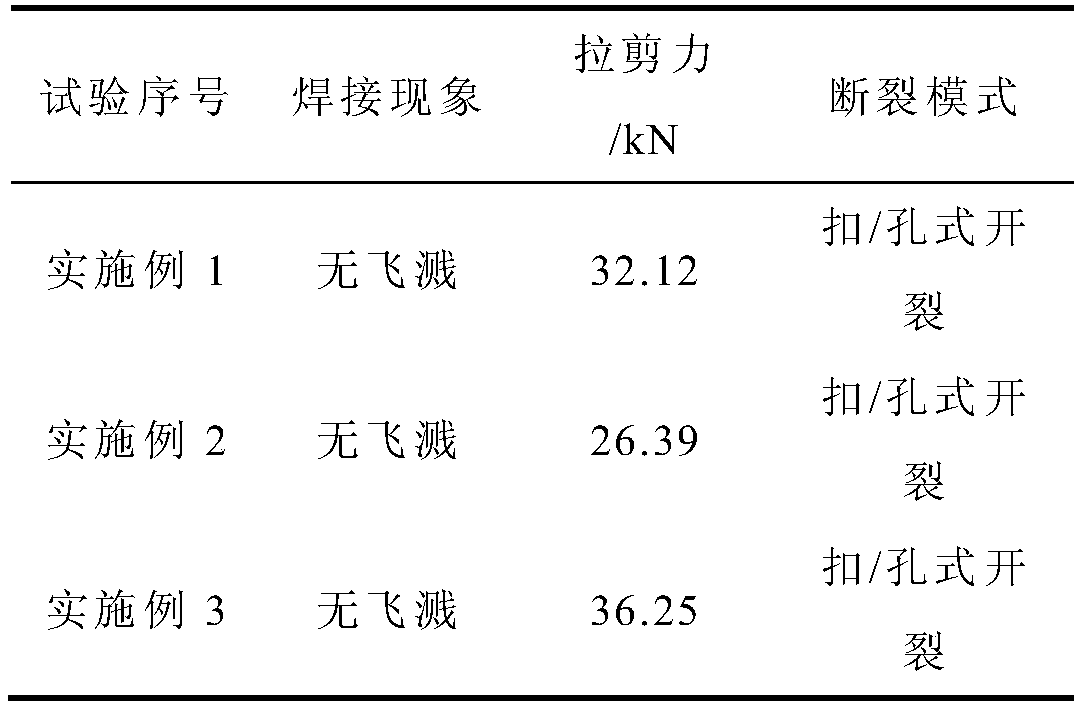

Splashing-free resistance spot-welding method of galvanized steel plates for car

InactiveCN110142492AAvoid destructionAvoid Weld SpatterResistance welding apparatusSpot weldingUltimate tensile strength

The invention discloses a splashing-free resistance spot-welding method of galvanized steel plates for a car. The method is characterized by comprising the following steps that 1, a Cu middle layer isarranged between to-be-welded portions of the two galvanized steel plates to be welded, and the thickness of the Cu middle layer is 0.02-0.20 mm; 2, spot welding pre-pressing is carried out on the two galvanized steel plates to be welded, and pre-pressing time is 1000-2000 ms; and 3, spot welding is carried out on the to-be-welded portions of the two galvanized steel plates to be welded. According to the method, generation of splashing in the welding process can be prevented, strength of welding spots is improved, and the problem of spot welding of the galvanized steel plates is solved.

Owner:武汉钢铁有限公司

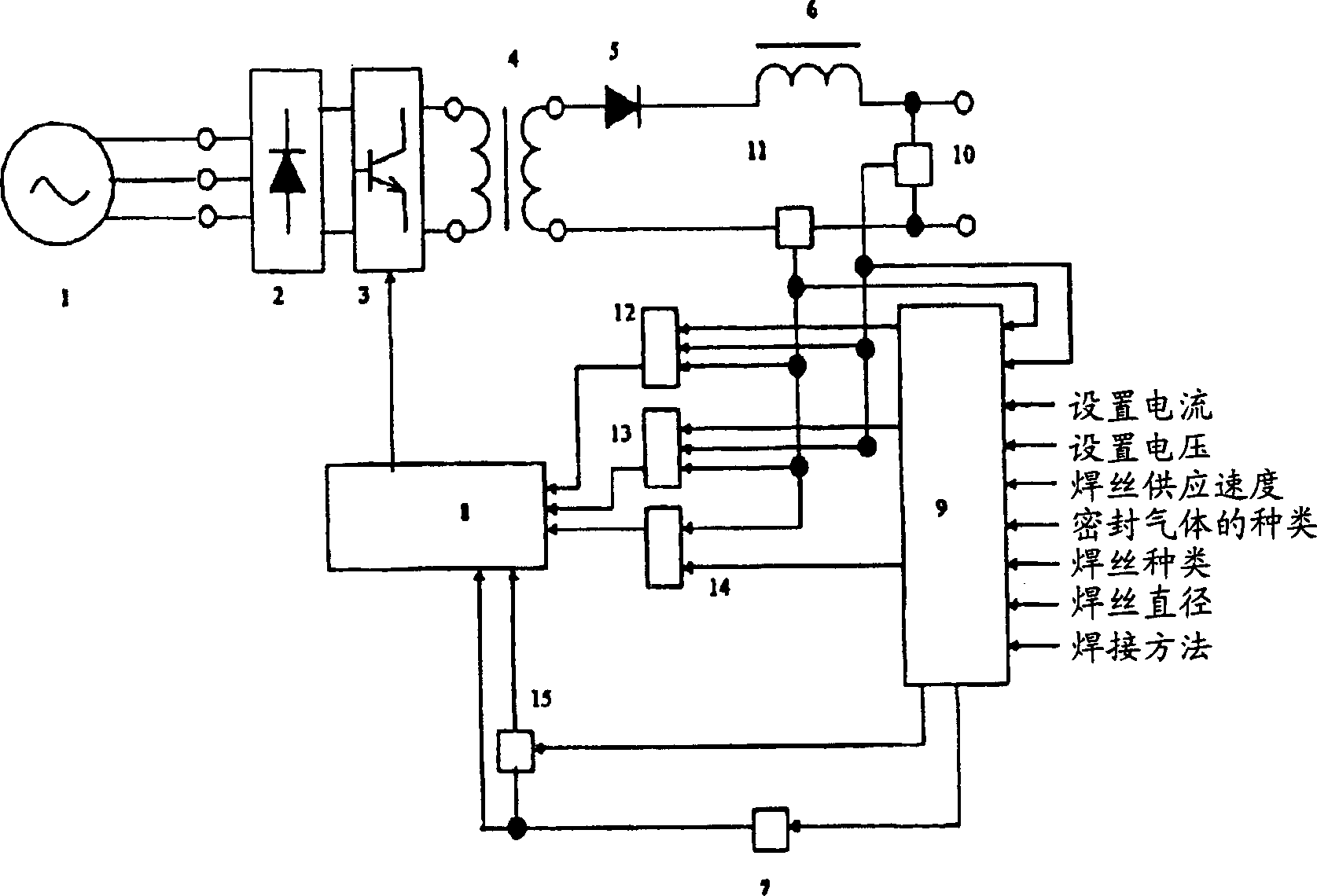

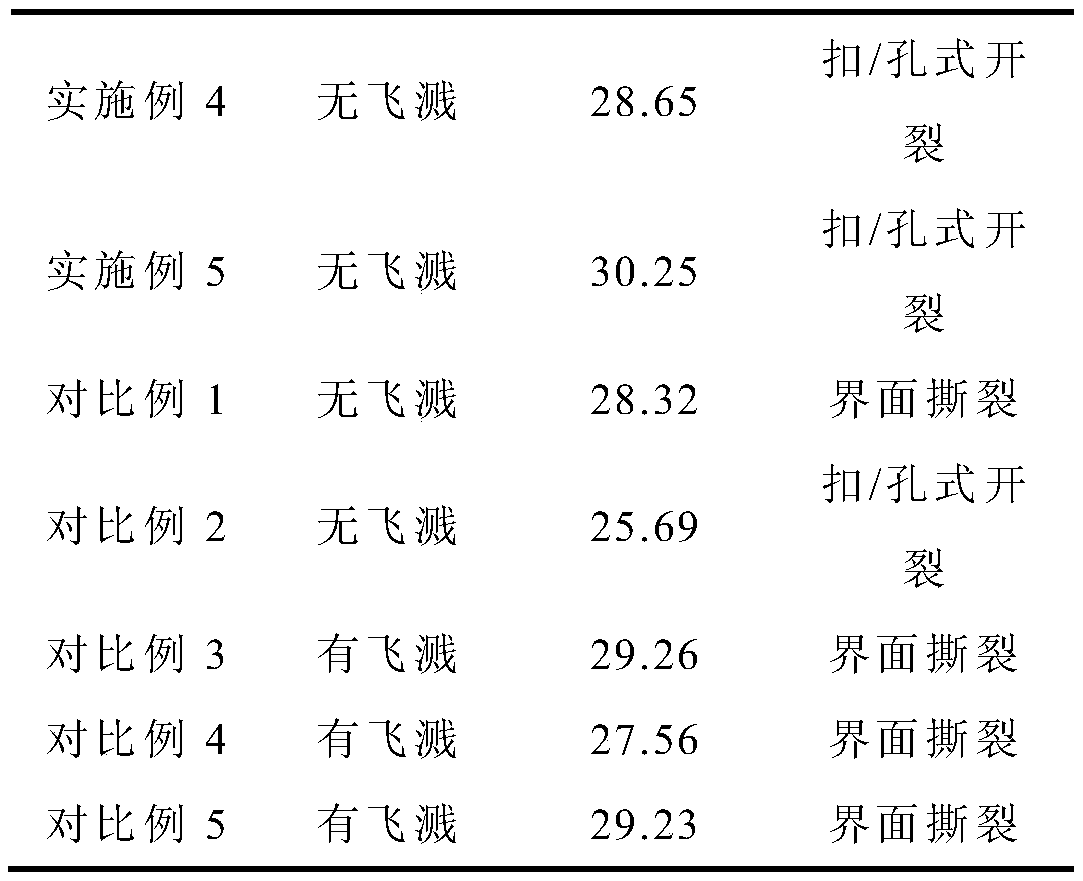

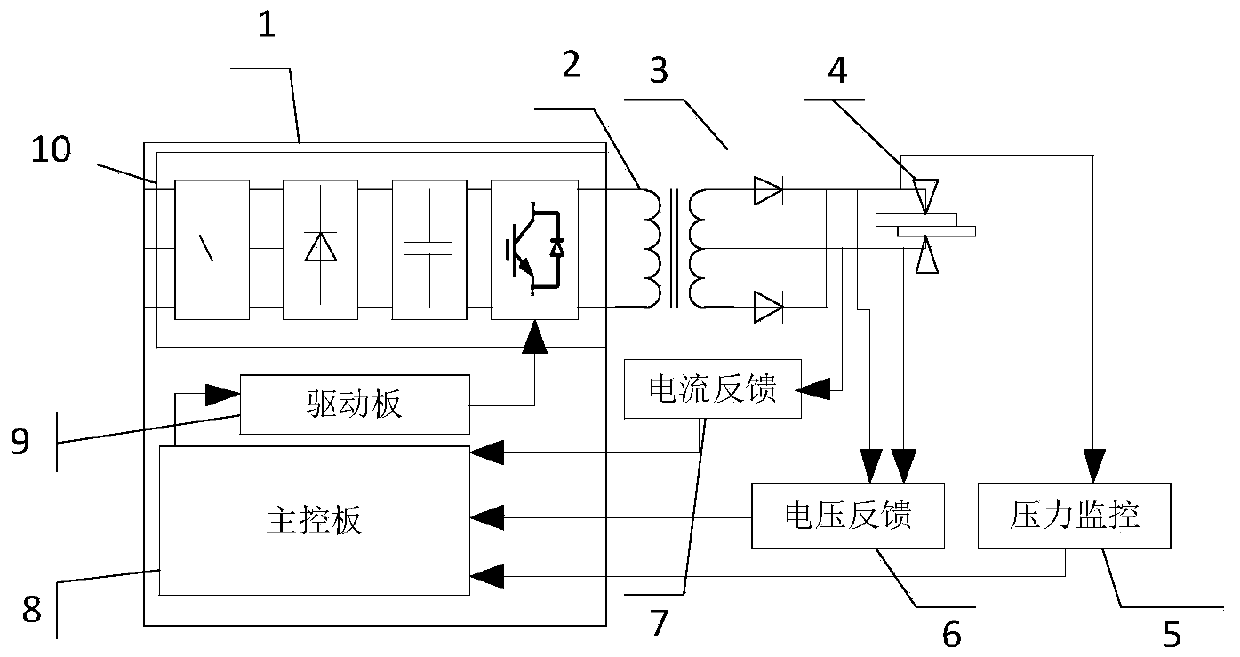

High-frequency inverting DC resistance welding power supply based aluminum spot welding system and method

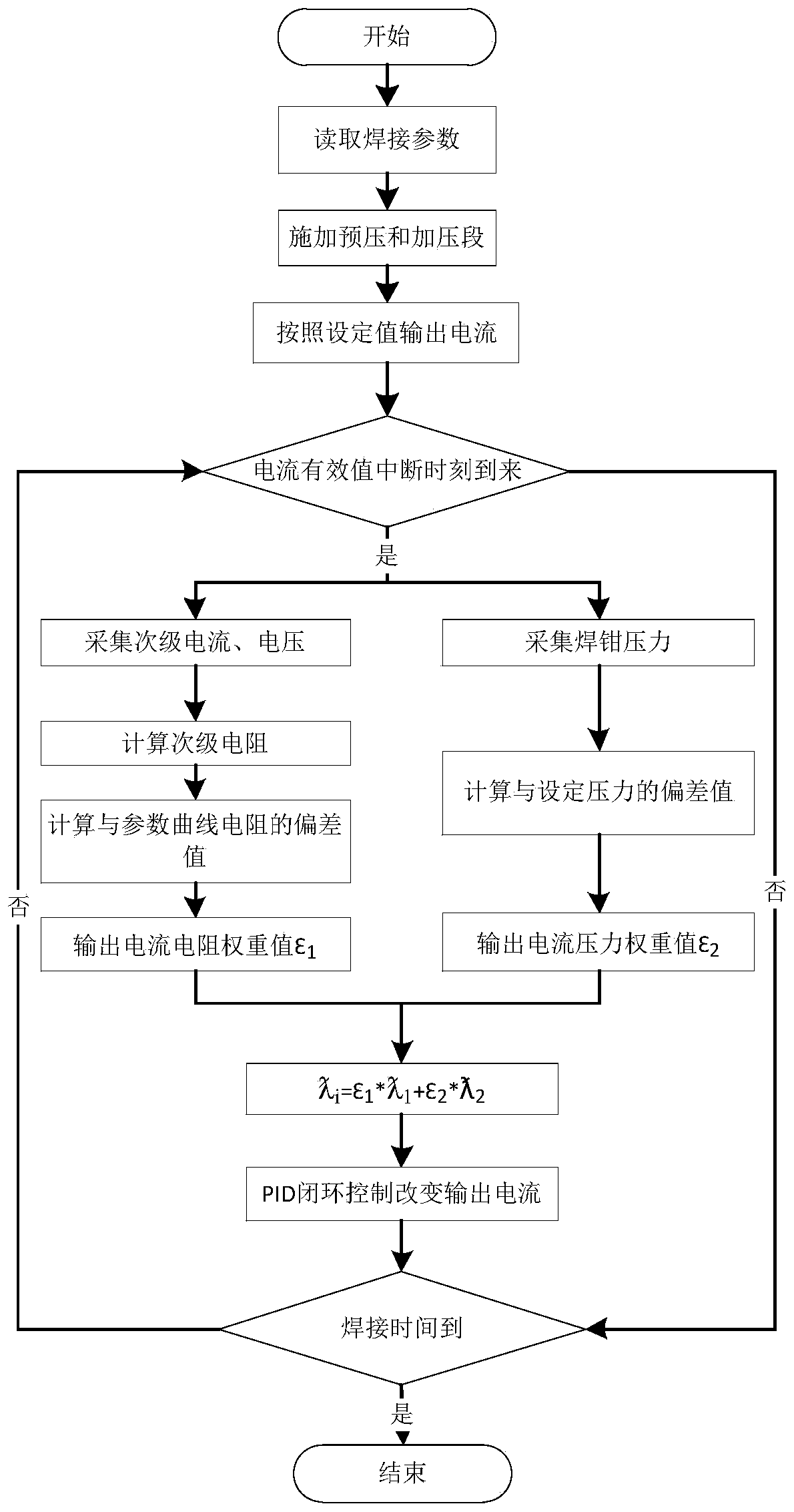

PendingCN110253129AFast adjustment frequencyEasy to adjustWelding monitoring devicesTransformerWelding power supply

The invention provides a high-frequency inverting DC resistance welding power supply based aluminum spot welding system and method. The system is characterized by comprising a resistance welding power supply, a high-frequency transformer, a high-frequency secondary rectifying unit, an electrode unit, a voltage monitoring unit, a voltage feedback unit and a current feedback unit, wherein the voltage monitoring unit is connected to a main control panel and is used for performing pressure detection feedback and controlling an electrode holder servo motor to pressurize a workpiece based on the set pressure; the main control panel is connected to the voltage monitoring unit, the voltage feedback unit and the current feedback unit so as to acquire welding pressure, secondary voltage and secondary current. According to the system, the inverting frequency is 10KHz; 20000 groups of data points can be acquired per second based on the output waveform of the acquired secondary current, so that the system acquiring rate is increased, and the welding process can be accurately controlled.

Owner:天津七所高科技有限公司

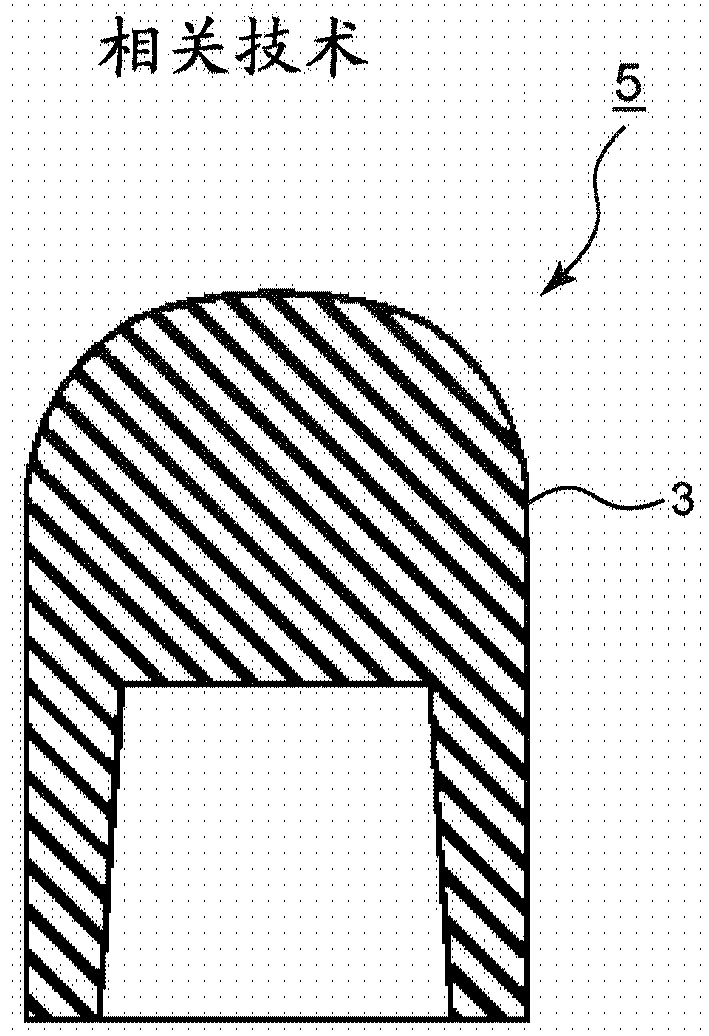

Spot welding electrode

InactiveCN105499778AReduce welding currentExtended service lifeElectrode featuresWelding/cutting media/materialsSpot weldingTungsten alloy

A spot welding electrode (1) is provided and includes a copper alloy (3), and a sintered tungsten alloy (2) disposed in a tip portion of the spot welding electrode (1), with the tip portion of the spot welding electrode (1) being brought into contact with an object to be welded. The sintered tungsten alloy (2) is connected only at a single flat surface to the copper alloy (3). A thermal conductivity of the spot welding electrode (1) is within a range from 60 W / mK to 120 W / mK. Uses of the spot welding electrode (1) for spot welding alloy materials are provided.

Owner:TOYOTA JIDOSHA KK

Anti-redness stainless steel electrode coating and electrode containing the coating

InactiveCN109483090AImprove breathabilityImproves anti-redness propertiesWelding/cutting media/materialsWelding/soldering/cutting articlesAdhesiveRutile

The invention provides an anti-redness stainless steel electrode coating and an electrode containing the coating, wherein the coating comprises dry powder and an adhesive; the dry powder comprises thefollowing components in percentage by mass: 35-40% of rutile, 8-16% of marble, 4-6% of fluorite, 1-3% of cryolite, 12-23% of feldspar, 3-5% of manganese metal, 10-20% of micro-carbon ferro chrome, 5-7% of mica and 1-3% of titanium dioxide. The adhesive is potassium sodium water glass, the modulus is 2.5-2.8, the addition amount is 18-22% of the total mass of the dry powder; the adhesive can increase the air permeability of the coating; caustic soda flakes with 0.15-0.25% mass of the potassium sodium water glass is added in the adhesive so as to increase the strength of the coating. The anti-redness stainless steel electrode comprises the coating and a stainless steel welding core, the heating value of the stainless steel electrode is reduced during welding, and the coating redness phenomenon is not generated at the end of welding of the electrode.

Owner:湖南湘工环保科技开发有限公司

Titanium alloy composite welding process based on small hole TIG and activated TIG, and active agent

ActiveCN111151846AReduce welding heat inputReduce welding distortionArc welding apparatusWelding/cutting media/materialsAluminum fluorideHeat-affected zone

The invention relates to a titanium alloy composite welding process based on small hole TIG and activated TIG, and an active agent. The active agent belongs to fluoride components and comprises analytically pure calcium fluoride, sodium fluoride, aluminum fluoride and silver fluoride. According to the titanium alloy composite welding process based on the small hole TIG and the activated TIG, the developed active agent is used for coating or being sprayed to welding surfaces before welding, the arc stiffness can be increased in the welding process, the arc penetration can be improved, and the effects that the melting width is reduced, the volume of a welding seam and a heat affected zone is reduced and the welding deformation effect is reduced are achieved, and meanwhile, welding air holescan be inhibited to a certain extent.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

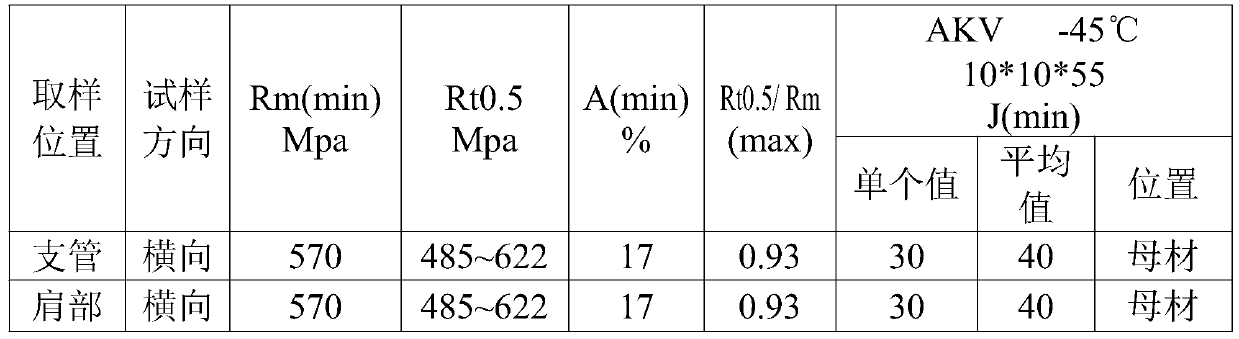

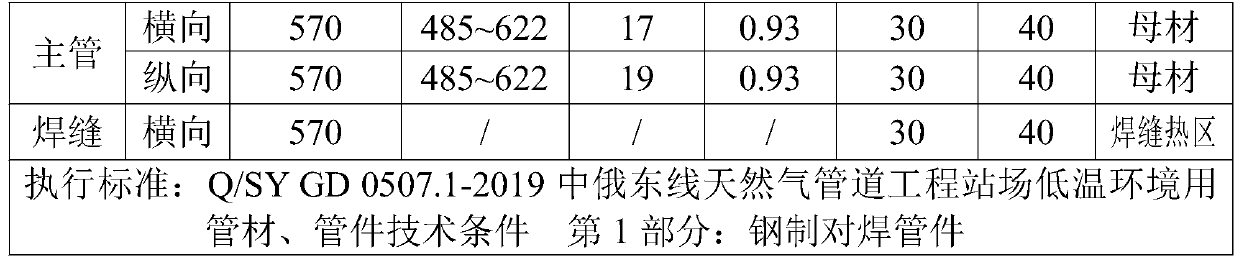

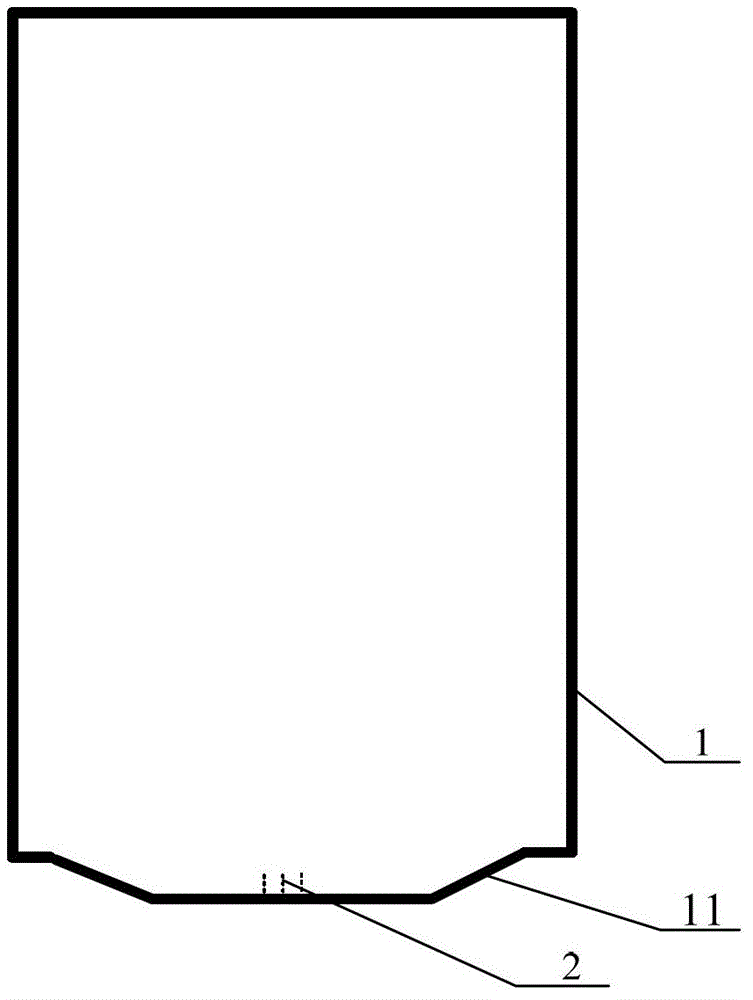

Process for preparing hot-pressing low-temperature three-way fittings by using X70 steel plates

PendingCN111112946AConsistent performanceReduce welding currentFurnace typesHeat treatment furnacesPipeMetal

The invention discloses a process for preparing hot-pressing low-temperature three-way fittings by using X70 steel plates. In the process, firstly, a suitable base material with high manufacturing performance is selected; and meanwhile, on the premise that the welding metal is sufficiently fused in the welding process, the welding current is further reduced, so that the welding speed is improved,the heat input amount is limited, and blank pipes with consistent performance is provided for finished products. According to the process, all the machining procedures for heat input to the products are strictly controlled, and the metal crystal structure reflects the main index of the performance of steel and the main index of the performance of the steel is effectively controlled, the rolling quantity of each time and the water quenching treatment after rolling are strictly controlled, the good metallographic organization of the products is ensured all the time, and the products meeting therequirements of the low-temperature environment standards is finally obtained.

Owner:河北恒通管件集团有限公司

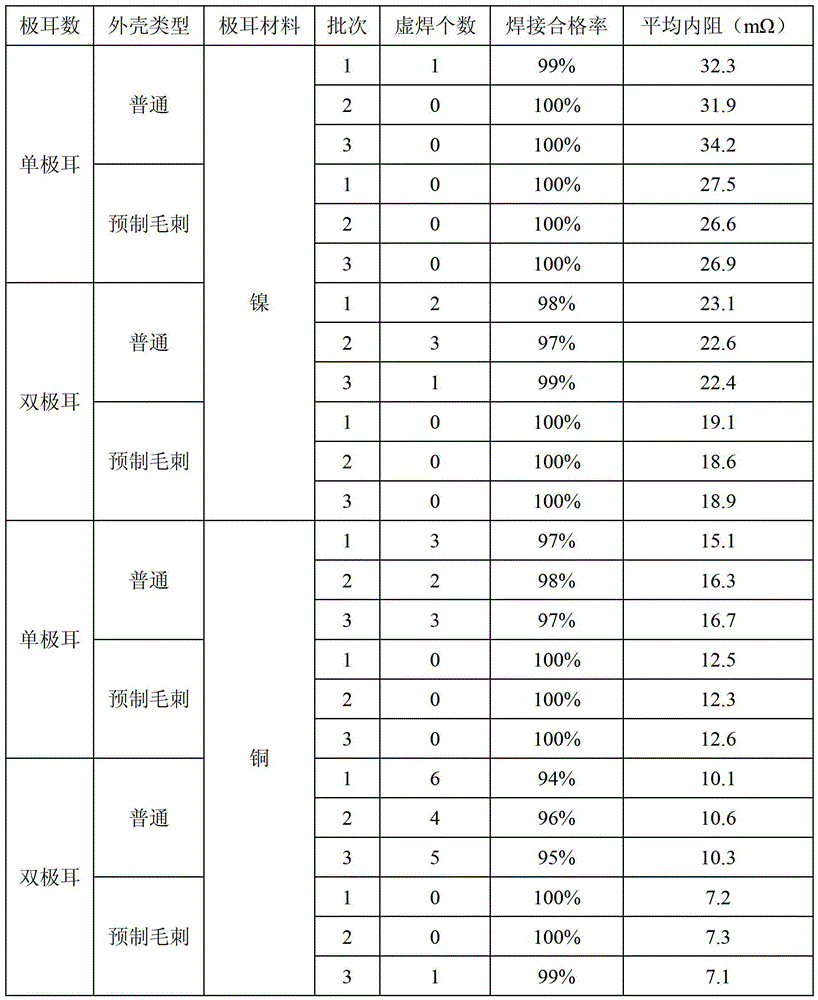

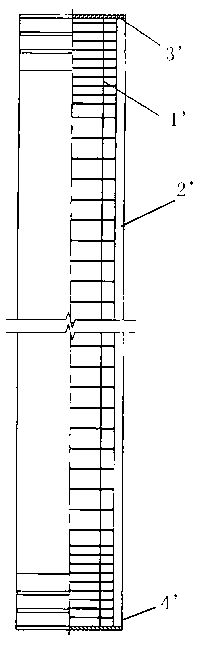

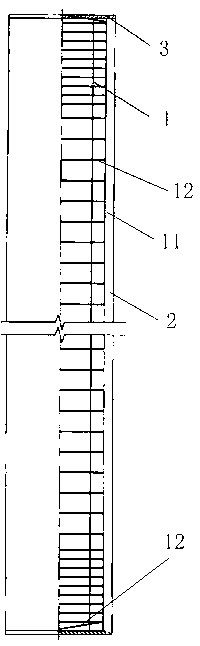

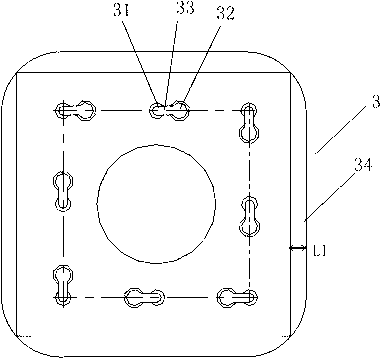

Lithium ion battery case with prefabricated burrs on bottom and lithium ion battery preparation method

InactiveCN103151473AEliminate virtual solderingAvoid Welding PhenomenonFinal product manufactureCell component detailsPunchingInternal resistance

The invention discloses a lithium ion battery case with prefabricated burrs on the bottom. The lithium ion battery case comprises a lithium ion battery case; and burrs are formed on one side of the bottom of the lithium ion battery case for being connected with tabs. By arranging the burrs on the bottom of the lithium ion battery case, cold solder occurring in the welding process of a multi-tab point bottom can be obviated effectively, and the welding strength between the lithium ion battery case and the multi-tab point bottom can be enhanced, thereby effectively reducing internal resistance and improving point bottom reliability of the lithium ion battery. The invention also discloses a lithium ion battery preparation method, which comprises the steps of prefabricating concave holes at the top end of a punch of a forming mold, molding by deep punching to obtain the lithium ion battery case with the prefabricated burrs, welding the lithium ion battery case with the tab point bottom, and carrying out subsequent treatment to obtain a lithium ion battery. The yield of the lithium ion battery can be improved greatly.

Owner:浙江铁鹰新能源科技有限公司

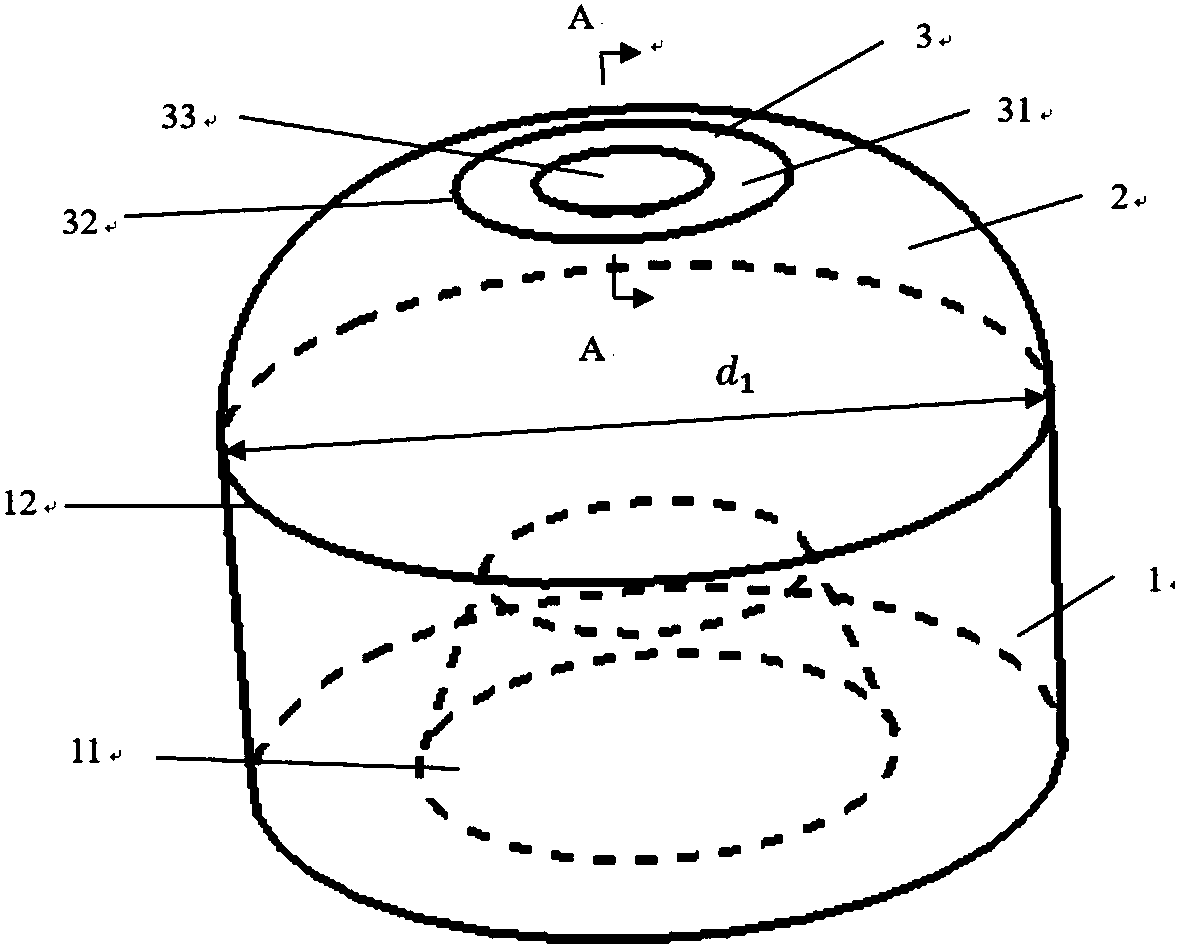

Concrete prefabricated product for underground construction and production method of product

The invention provides a concrete prefabricated product for underground space construction. The concrete prefabricated product comprises a reinforcement cage and concrete, wherein the reinforcement cage comprises longitudinal reinforcements subjected to longitudinal force and transverse reinforcements subjected to shear force, the transverse reinforcements are spirally fixed on the longitudinal reinforcements, the two ends of the reinforcement cage are respectively provided with a metal end plate, each metal end plate is provided with taper holes and screw holes, and an aqueduct is formed between each taper hole and the corresponding screw hole; and the longitudinal reinforcements are arranged in the taper holes and connected with the metal end plates, the two ends of a pile body of the concrete prefabricated product are not provided with hoops, and the metal end plates are directly connected with the two ends of the pile body. Because the two ends of the pile body of the concrete prefabricated product are not provided with the hoops, the production efficiency is high, the production cost is lowered, and environment pollution is alleviated.

Owner:汤始建华建材(淮安)有限公司

Lime kiln barrel assembling and welding method

ActiveCN103406708AEasy to operateHigh adjustment accuracyWelding/cutting auxillary devicesArc welding apparatusTheodoliteLime kiln

The invention discloses a lime kiln barrel assembling and welding method which comprises the following steps: firstly, measuring straightness of a first barrel, a second barrel to a nth barrel through a laser theodolite, and arranging dial indicators on the outer circumferences of the adjacent barrels respectively; secondly, welding a plurality of matched centering adjusting clamps on the inner circumference surfaces of the first barrel and the second barrel which are butted together so as to make the seam distances of the first barrel and the second barrel identical; thirdly, uniformly welding a plurality of tongue-shaped pressing plates on the inner circumference surfaces of the first barrel and the second barrel so as to correspondingly adjust the roundness of the first barrel and the second barrel; fourthly, welding welded blocks on the inner surfaces of the first barrel and the second barrel between two adjacent centering adjusting clamps; fifthly, welding in a CO2 protection semi-automatic welding mode, and welding the welding seams among the second barrel to the nth barrel in the same mode. By virtue of the effective welding method, welding operators are greatly reduced, the cost is saved, and the working efficiency is improved.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

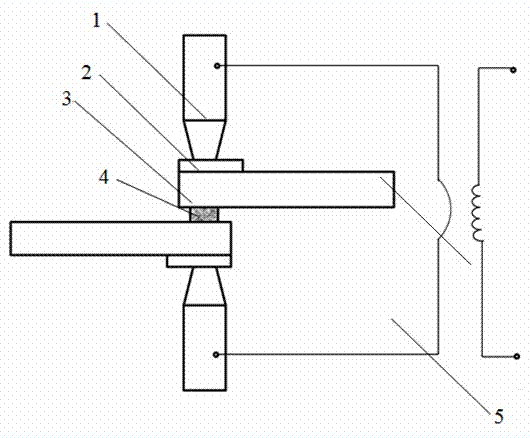

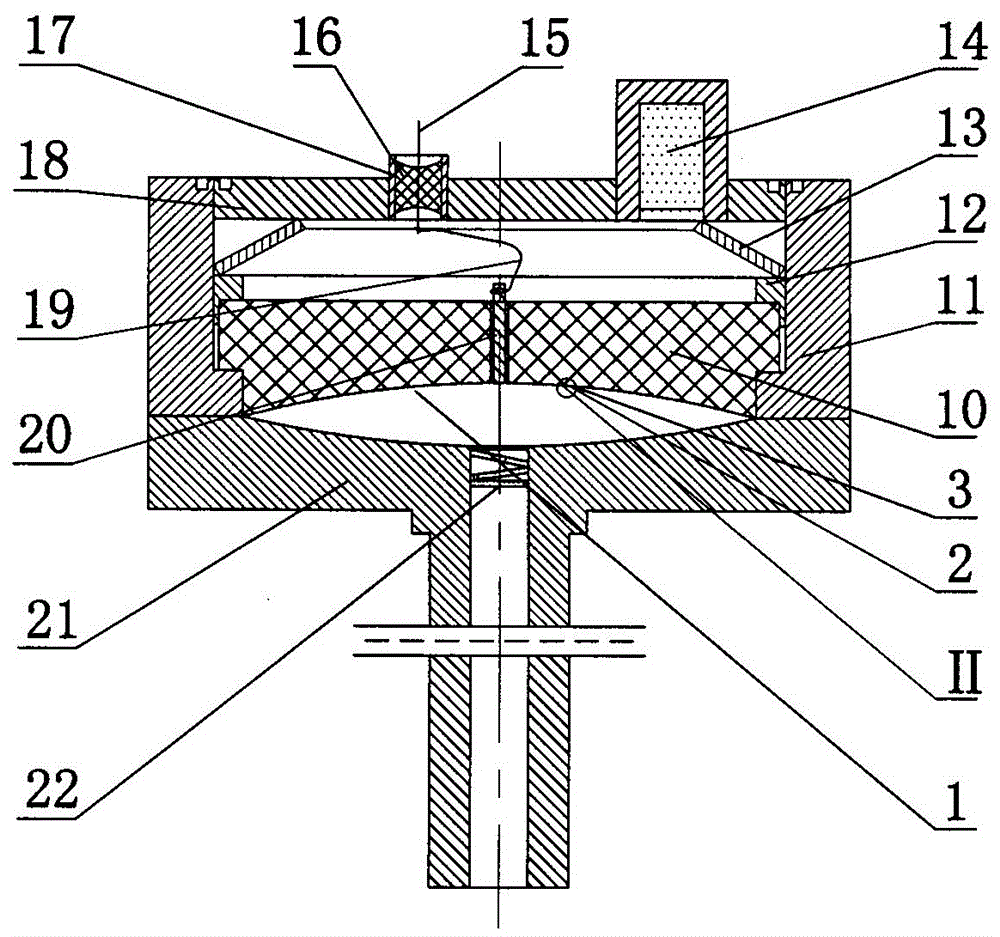

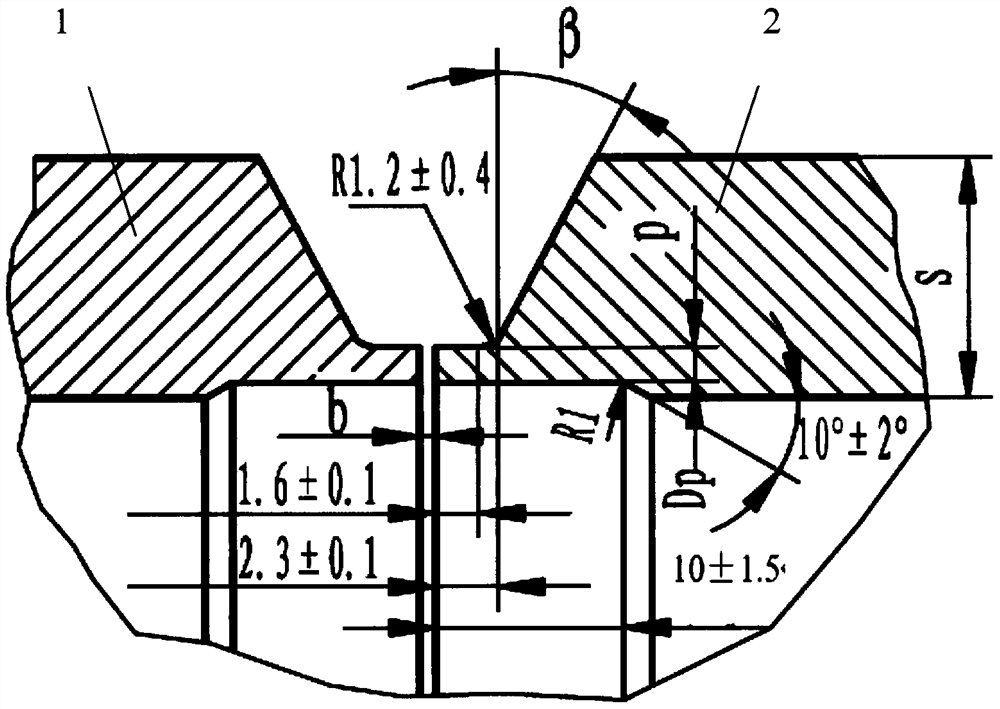

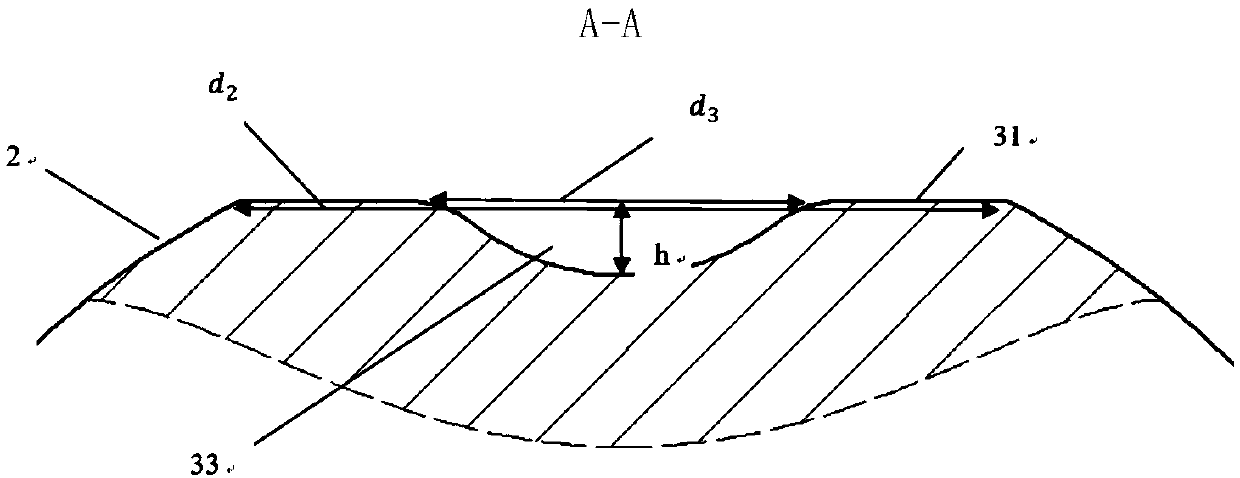

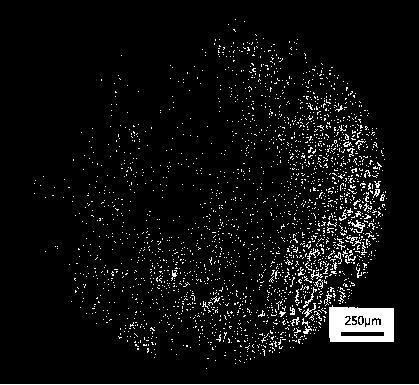

Aluminum Alloy Ultrasonic Resistance Composite Butt Brazing Method

InactiveCN105798411BReduce softeningImprove flatnessWelding/cutting media/materialsSoldering mediaPower flowFree cooling

The invention discloses an ultrasonic resistance composite butt brazing method for an aluminum alloy and an insulated sliding welding device. The ultrasonic resistance composite butt brazing method comprises the following steps of processing an aluminum alloy end surface, mounting parent metal on the insulated sliding welding device, and connecting an electrode and the pare metal by using bolts; placing flaky brazing filler metal in a to-be-welded groove, wherein the thickness of the flaky brazing filler metal is 0.1 to 1mm; setting resistance brazing parameters: setting welding current at a first stage to 2 to 2.5KA, welding time to 10 to 50CYC, welding current at a second stage to 3 to 9.5KA and welding time to 750 to 1500CYC, wherein ultrasonic waves are applied in the process, and the welding pressure is 150 to 240KN; and starting resistance brazing, and subsequently enabling weldments to be naturally cooled. The insulated sliding welding device is characterized in that a matrix (1) and a guide rail (2) are connected by bolts; a sliding part consists of the guide rail (2), an upper sliding block (3) and a lower sliding block (3'); the upper sliding block (3) and the lower sliding block (3') are arranged on the guide rail (2); right surfaces (M3) of the upper sliding block (3) and the lower sliding block (3') are smooth and are parallel to a right surface (M1) of the matrix (1); and an axial lead (OO') of an insulating cap (6) is perpendicular to a plane where a right surface (M4) of an insulating plate (4) is positioned.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Compressor protecting rack and welding method thereof

PendingCN110985343AImprove waterproof performanceReliable weldingPositive displacement pump componentsPositive-displacement liquid enginesStructural engineeringWeld strength

The invention discloses a compressor protecting rack and a welding method thereof. The protecting rack is connected with a housing of a compressor; through holes communicating with the housing are formed in the protecting rack; a waterproof reinforcement is connected to a part above the through holes in the protecting rack; the protecting rack is welded with the housing through an upper welding point arranged above the waterproof reinforcement and lower welding points arranged below the through holes; the welding method of the compressor protecting rack realizes reliable welding of the compressor protecting rack and the housing; a space separation method is adopted, the welding points of the protecting rack are distributed above the waterproof reinforcement and below the through holes, andthe reliable and stable welding of the protecting rack and the housing is realized; and the production efficiency is high, the cost is reduced, the welding strength is high, the protecting reinforcements have an effective waterproof effect, and the waterproof effect is good.

Owner:WUHU ABAUR MECHANICAL & ELECTRICAL

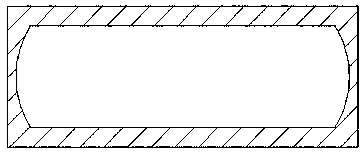

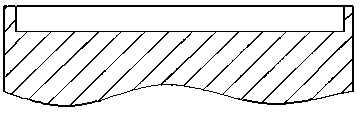

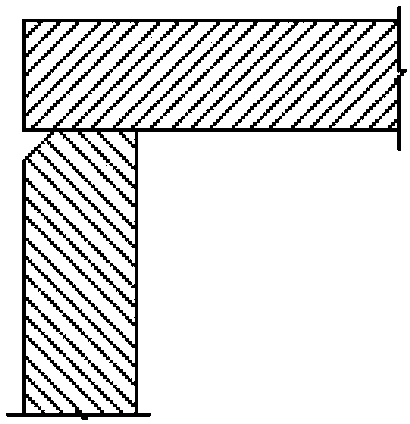

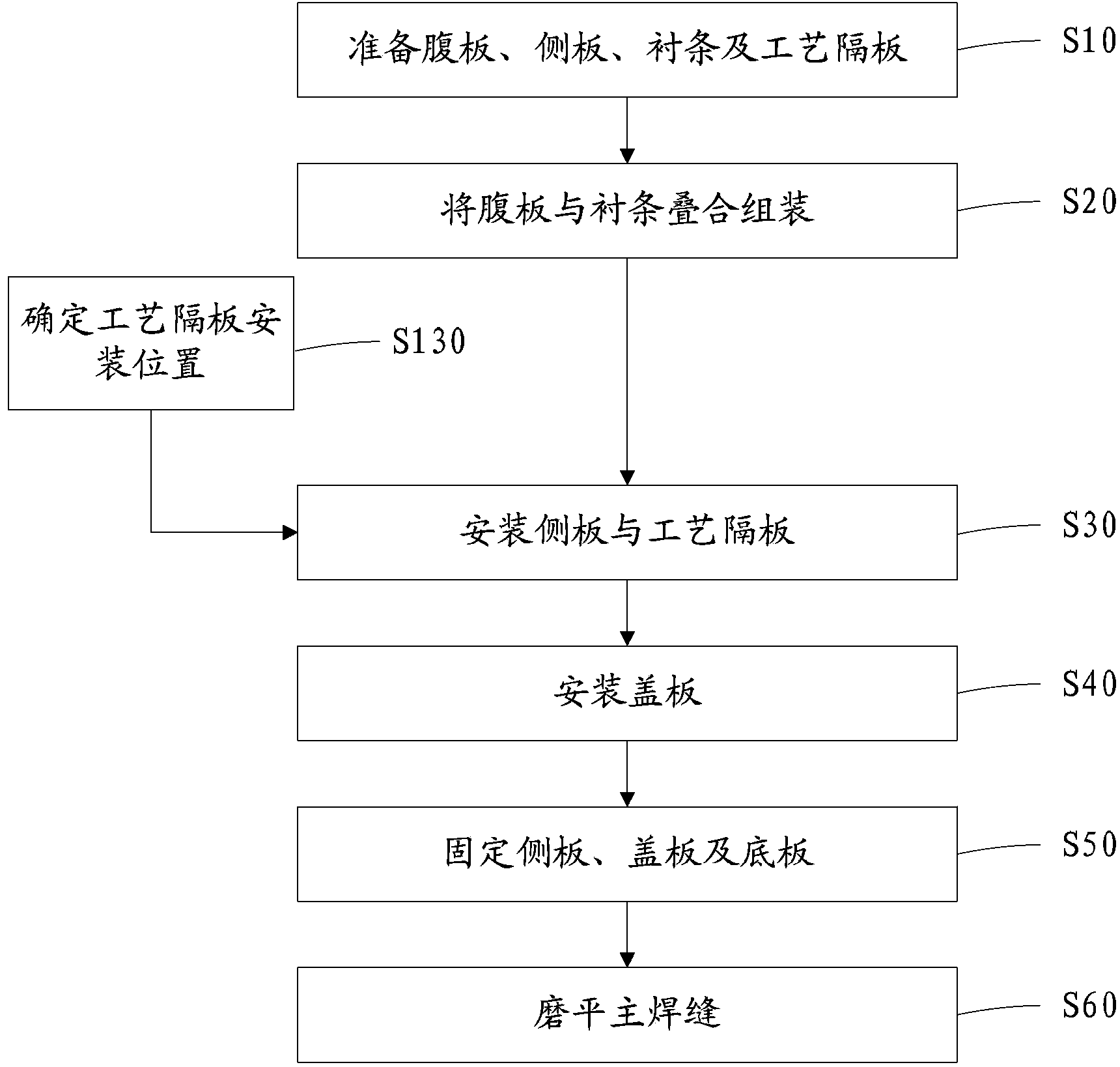

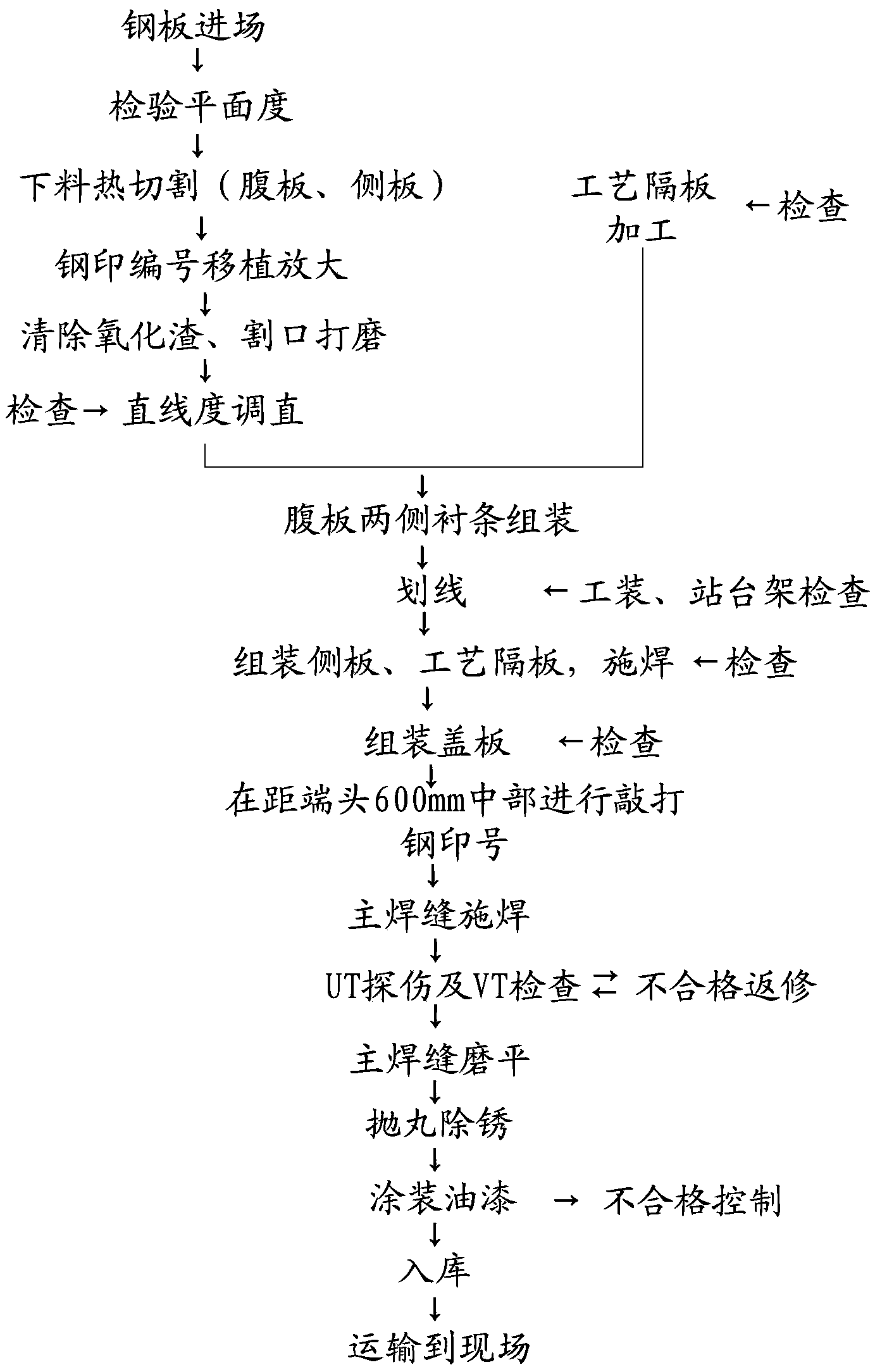

Process for manufacturing rectangular box pipe

ActiveCN102672359BHigh precisionGuaranteed accuracyWelding apparatusWhole bodyIndustrial engineering

The invention discloses a process for manufacturing a rectangular box pipe. The process comprises the following steps of: 10, preparing a web, side plates, liners and process separating plates; 20, assembling the web and the liners in a superposed mode; 30, arranging the side plates and the process separating plates; 40, arranging a cover plate; 50, fixing the side plates, the cover plate and a bottom plate; and 60, grinding a main weld joint. By the process for manufacturing the rectangular box pipe, the side plates and the web are welded by the liners, so that welding current is reduced, the welding sequence of the side plates, the web and the process separating plates is reasonable, the whole body is divided into a plurality of parts, the complicated process is changed into the simple process, the accuracy of a single body is improved, and the accuracy of the whole rectangular box pipe is ensured. In addition, a plurality of process separating plates are arranged in the rectangular box pipe along the length direction, so that strength is enhanced, the rectangular box pipe cannot be subjected to twist deformation, and the requirement on straightness is met.

Owner:FUJIAN RONGSHENG STEEL STRUCTURE IND

Active agent formula for 304 stainless steel A-TIG welding and use method

PendingCN113927200AReduce consumptionAvoid bulkyArc welding apparatusWelding/cutting media/materialsActive agentSS - Stainless steel

The invention discloses an active agent formula for 304 stainless steel A-TIG welding and a use method. The active agent formula is composed of the following components of, by mass percentage, SiO2 powder, Cr2O3 powder, Al2O3 powder, TiO2 powder, MnO2 powder, B2O3 powder and Fe2O3 powder. According to the formula, halide and other substances contained in an active agent in the prior art are abandoned, and harm to the human body is avoided; and the welding quality is good, the weld penetration is increased, the production cost is reduced, and the production efficiency can be greatly improved. The formula and the use method have the advantages that needed welding current can be effectively reduced by using the active agent for welding, energy consumption is reduced, meanwhile, heat input is reduced to a certain extent, and a thick structure is avoided; and the preparation method is simple, an active agent formula period is short, operation is easy, the production efficiency is improved, and the production cost is reduced.

Owner:CHINA NUCLEAR IND 23 CONSTR

Rotating welding electrode structure of pipe pile seam welder

ActiveCN103286433BReduce welding currentRealize energy saving and consumption reductionResistance electrode holdersEngineeringCentrifugal force

The invention relates to a pipe pile seam welder, in particular to a rotating welding electrode structure of the pipe pile seam welder. The rotating welding electrode structure comprises support plates, a conducting electrode plate, a welding electrode plate and a spring locating assembly. A pendulum shaft is assembled between the two corresponding support plates, the conducting electrode plate and the welding electrode plate which are assembled together through a locating sleeve are installed on a reinforcing plate, the reinforcing plate is fixedly connected to the pendulum shaft, one end of the reinforcing plate is hinged to a spring locating rod in the spring locating assembly, and a balance body is assembled at the other end of the reinforcing plate. The rotating welding electrode structure has the advantages that by additionally installing the balance body on a welding electrode, the gravity of the balance body and centrifugal force generated when the balance body works on the welding electrode are utilized to balance or offset the gravity or centrifugal force of the welding electrode through the pendulum shaft, so that the welding electrode can provide almost balanced welding pressure within a whole circumference range, complete conditions are provided for reducing welding pressure or welding current at the time, and accordingly energy conservation and consumption reduction are achieved indeed.

Owner:TANGSHAN TIANZE SPECIAL WELDING EQUIP

Activator for magnesium alloy welding

InactiveCN101244497BStrong penetrating powerImprove metallurgical qualityArc welding apparatusWelding/cutting media/materialsAlcoholActive agent

The invention relates to an active agent applying to magnesium alloy welding, belonging to the material engineering technical field, which is characterized in that: the active agent is composed of TiO2, Cr2O3, MgO, MnO2, and CaO and the weight proportion is TiO2: 40 to 70%, Cr2O3: 5 to 20%, MgO: 2 to 20%, MnO2: 5 to 20%, CaO: 5 to 20%. Firstly, the active agent is grinded to powder, then is driedand cooled; secondly, the active agent is mixed with acetone or alcohol and then is equally coated or sprayed on the surface of the welding bead; finally, after the acetone or the alcohol is volatilized, welding can be implemented. The active agent has the advantages that: the weld penetration can increase at least twice; the weld joint of magnesium alloy is well moulded; the joint is of high quality and the intensity can be above the 95% of the intensity of the parent metal; the deformation due to welding is reduced; the invention is of easy operation and high productivity.

Owner:DALIAN UNIV OF TECH

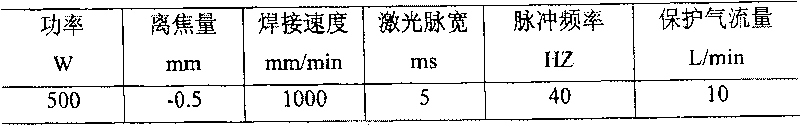

K-TIG-based thin-caliber pipeline double-sided double-arc welding system and method

InactiveCN109202225AEnhanced electromagnetic contraction effectIncreased Lorentz forceArc welding apparatusTubular articlesButt jointWelding power supply

The invention belongs to the technical field of welding and discloses a K-TIG-based thin-caliber pipeline double-sided double-arc welding system and method. A negative electrode of a welding machine power source is connected with a K-TIG welding gun, and a positive electrode of the welding machine power source is connected with a tungsten electrode ring; the tungsten electrode ring is disposed ina to-be-welded pipeline through an insulating rod; the tungsten electrode ring and the K-TIG welding gun are disposed on the two sides of a butt joint seam of the to-be-welded pipeline correspondingly; during welding, the tungsten electrode ring makes contact with the to-be-welded pipeline, the welding machine power source outputs welding current for arc striking; then the tungsten electrode ringis separated from the inner wall of the to-be-welded pipeline, and electric arcs are ignited; and the K-TIG welding gun is driven to perform circular motion along the butt joint seam of the to-be-welded pipeline, meanwhile the welding current is intensified, and welding is finished after circling by 360 degrees. According to the K-TIG-based thin-caliber pipeline double-sided double-arc welding system and method, an original K-TIG process and a double-sided double-arc perforating welding process are combined, the perforating current is reduced substantially, and the deformation degree of workpieces is lowered through a double-sided electric-arc welding process; and the advantages that the equipment operation cost is low, the process conditions are easy to achieve, and the welding preparation time is short are achieved.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com