Resistance spot welding electrode cap

A resistance spot welding and electrode cap technology, applied in resistance welding equipment, electrode features, pressure electrodes, etc., can solve the problems of unstable welding quality, low electrode life, large welding current, etc. life, the effect of increasing the nugget diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

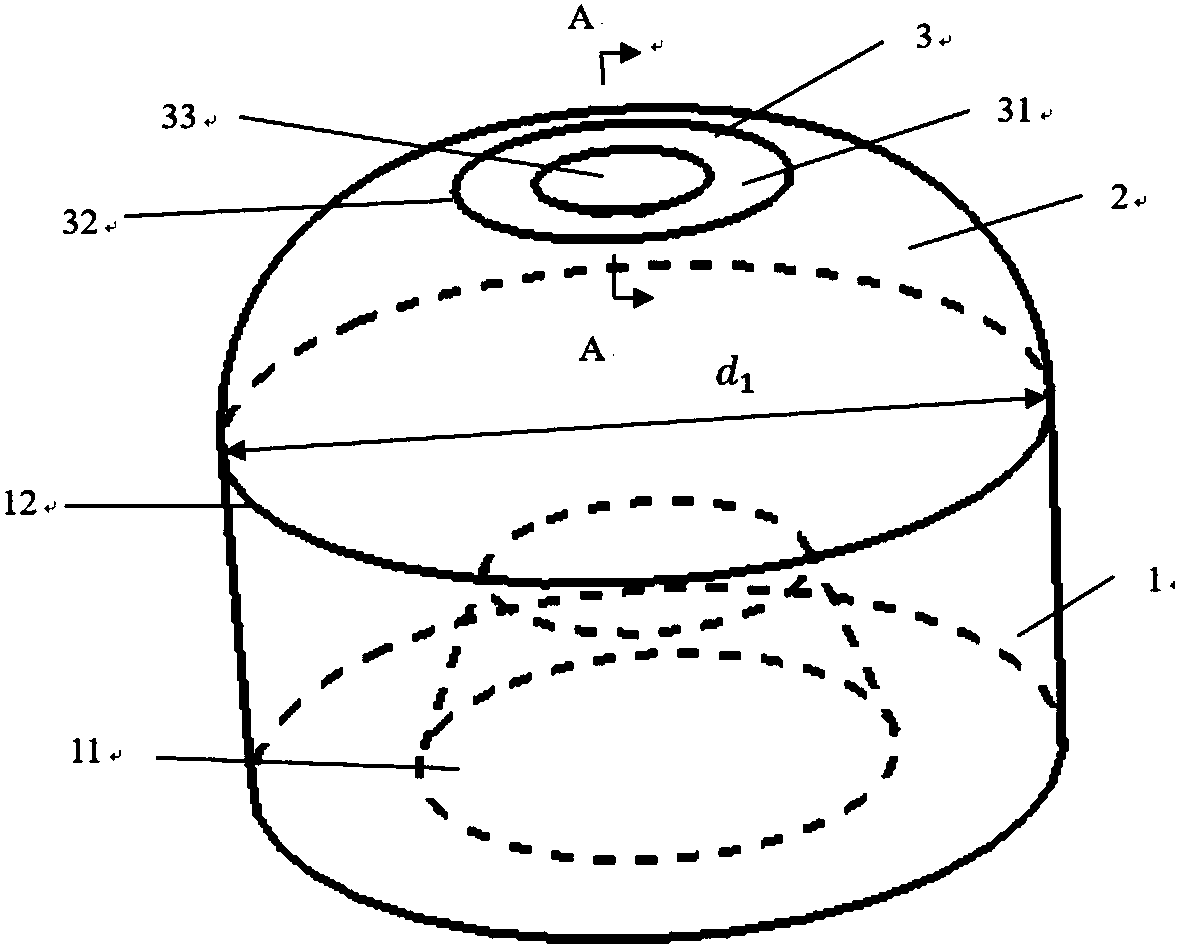

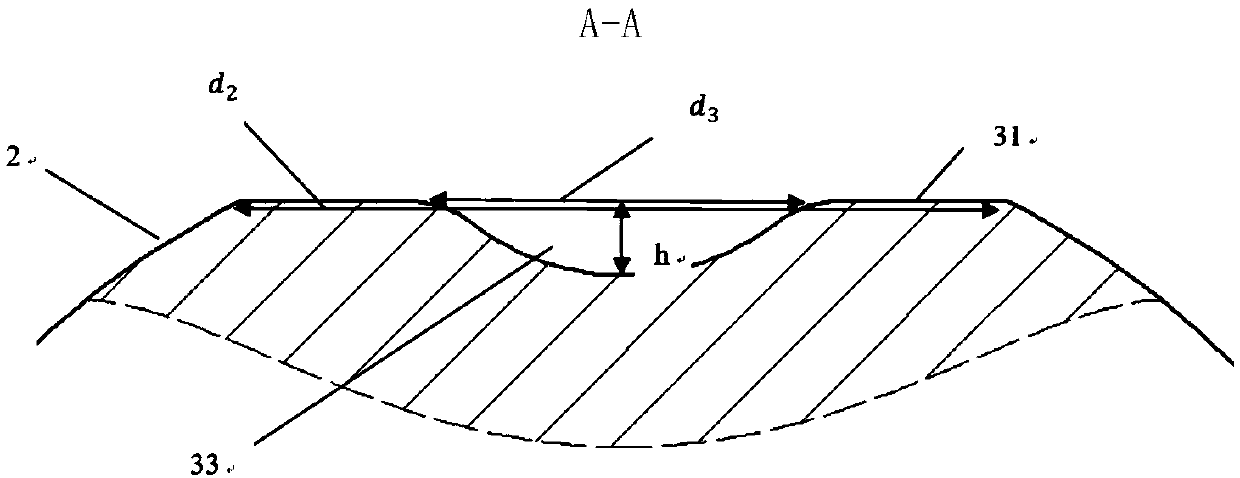

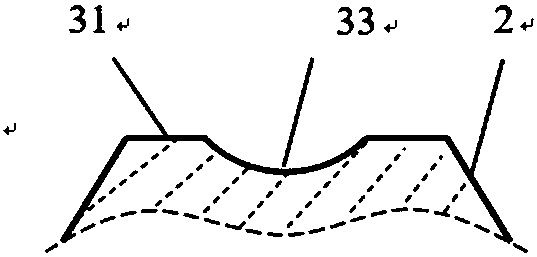

[0075] Such as Figure 1-2 As shown, the resistance spot welding electrode cap of this embodiment includes a substantially cylindrical electrode cap body 1 and a contact surface 3 between the electrode and the welding metal material. The body 1 has an electrode installation channel 11 at one end and a circumference 12 at the other end. The contact surface 3 includes a welding surface 31 , a circumference 32 and a groove 33 . The groove 33 is located in the central area of the contact surface 3 .

[0076] One end of the body 1 refers to the end connected to the resistance spot welding machine during resistance spot welding, and the other end refers to the end close to the contact surface of the welding workpiece.

[0077] In another preferred example, the shape of the electrode installation channel 11 is a truncated cone or a cylinder, and the shape of the electrode installation channel 11 may also be some other appropriate shapes.

[0078] The circle 32 is parallel to the...

Embodiment 2

[0088] The resistance spot welding electrode cap of the present embodiment is similar to Embodiment 1, and the difference is that there is a raised annular ridge 4 on the welding surface 31 or the groove 33 of the present embodiment, as Figure 15-16 As shown, the annular ridge 4 includes an inner annular ridge 41 , an outer annular ridge 42 and grooves 43 formed at intervals between different annular ridges. The annular ridge 4 can be understood as a cross-section 44 is a circular structure formed by rotating a plane with a certain structure around the central axis of the electrode cap, wherein the lower part of the cross-section 44 is in contact with the welding surface 31, and the entire cross-section 44 is in contact with the welding surface 31. The welding surfaces 31 are vertical. The central axis of the electrode cap is a straight line passing through the center of the circle 12 and perpendicular to the circle 12 . It should be noted that the number of the annular ridg...

Embodiment 3

[0093] This embodiment discloses the device and process of welding aluminum alloy workpieces using the electrode cap of the present invention, such as Figure 36 As shown, 5 is a welding torch that can be used for resistance spot welding to connect the welding position 8 of the first aluminum alloy workpiece 6 and the second aluminum alloy workpiece 7, and the welding torch 5 includes a first welding torch arm 51, a second welding torch arm 52, a first welding torch An electrode cap 53 and a second welding electrode cap 54 . The first and second aluminum alloy workpieces 6 and 7 are made of aluminum alloy such as aluminum-magnesium alloy, aluminum-silicon alloy, aluminum-magnesium-silicon alloy or aluminum-copper alloy, and the thickness of the aluminum alloy workpiece is 0.5-3mm. More preferably, the aluminum alloy workpiece can be 2.0mm thick 5182-O aluminum alloy. During welding, there can be two aluminum alloy workpieces (such as only 6 and 7) or a combination of more tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com