Capacitive pressure transducer with transition welding ring

A pressure sensor, welding ring technology, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve problems such as damage and leakage, and achieve the effects of buffering thermal stress and expansion stress, reducing manufacturing costs, and being safe and reliable in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

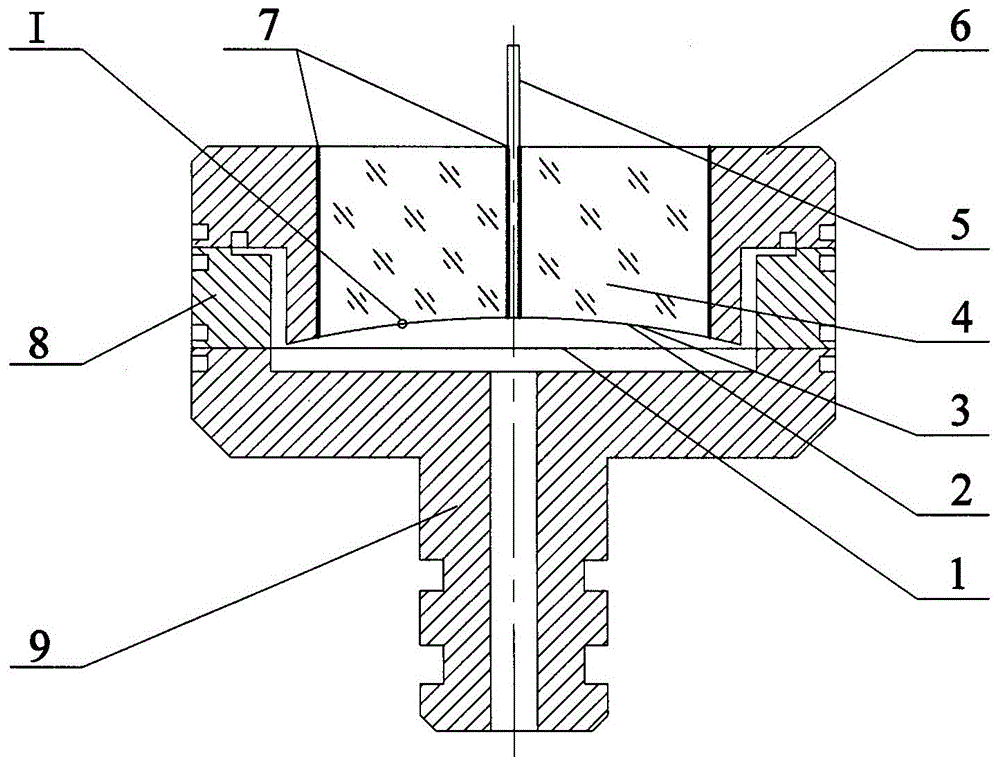

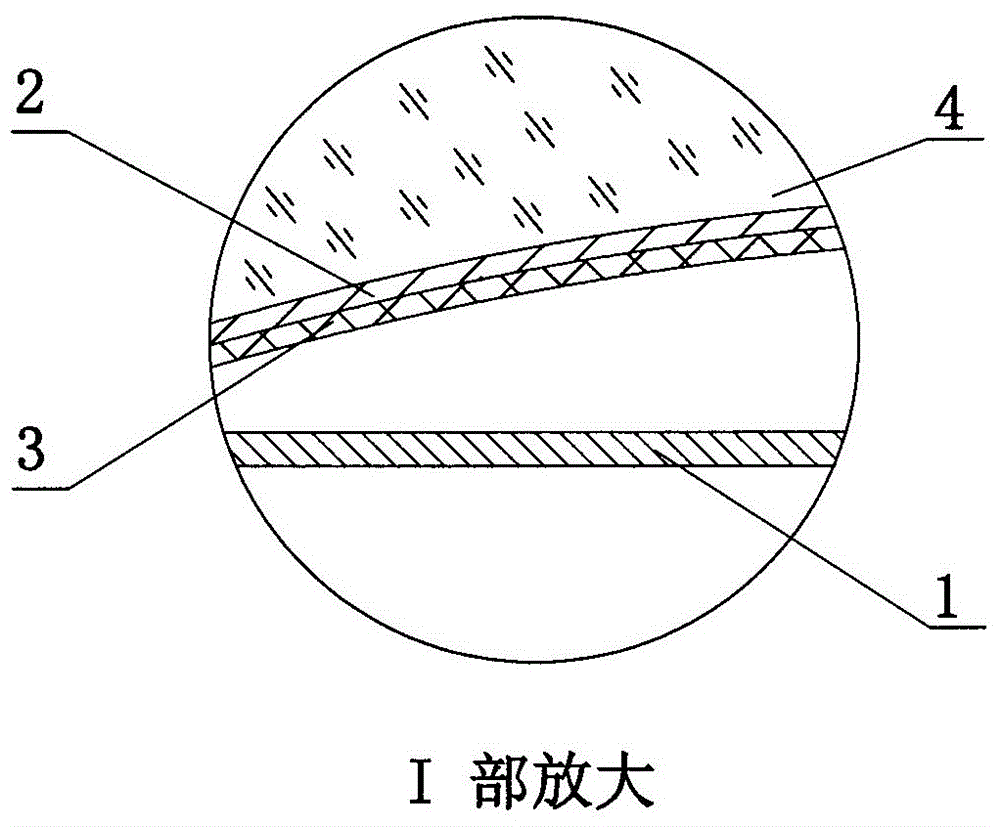

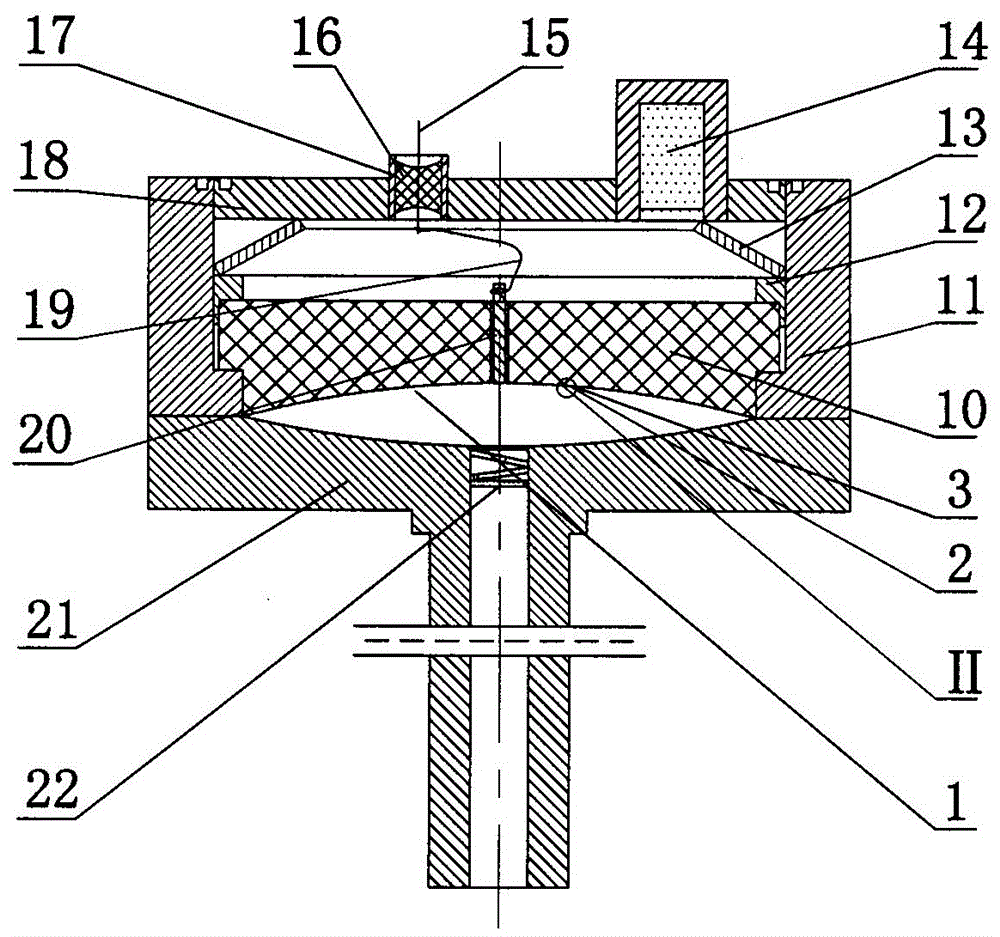

[0016] according to Figure 1~4 The specific structure of the present invention will be described in detail. The capacitive pressure sensor with a transition welding ring includes a matching housing 6 , a fixed electrode assembled with the matching housing 6 , a tubular lead-out electrode 5 , a moving electrode 1 , and a pressure port. Wherein the moving electrode 1 is made of a constant elastic corrosion-resistant nickel-based alloy film. The fixed electrode adopts a matching package structure, that is, the fixed electrode insulator 4 made of sapphire is highly matched with the material expansion coefficient of the matching shell 6 and the tubular lead-out electrode 5 . The conductive thin film layer 2 is connected with the tubular lead-out electrode 5, and the conductive thin film layer 2 is a metal film layer plated under high vacuum, covered with an insulating film layer 3, which is also plated under vacuum. The fixed electrode insulator 4 is made of sapphire, and is mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com