Patents

Literature

87results about How to "Reduce radiant heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

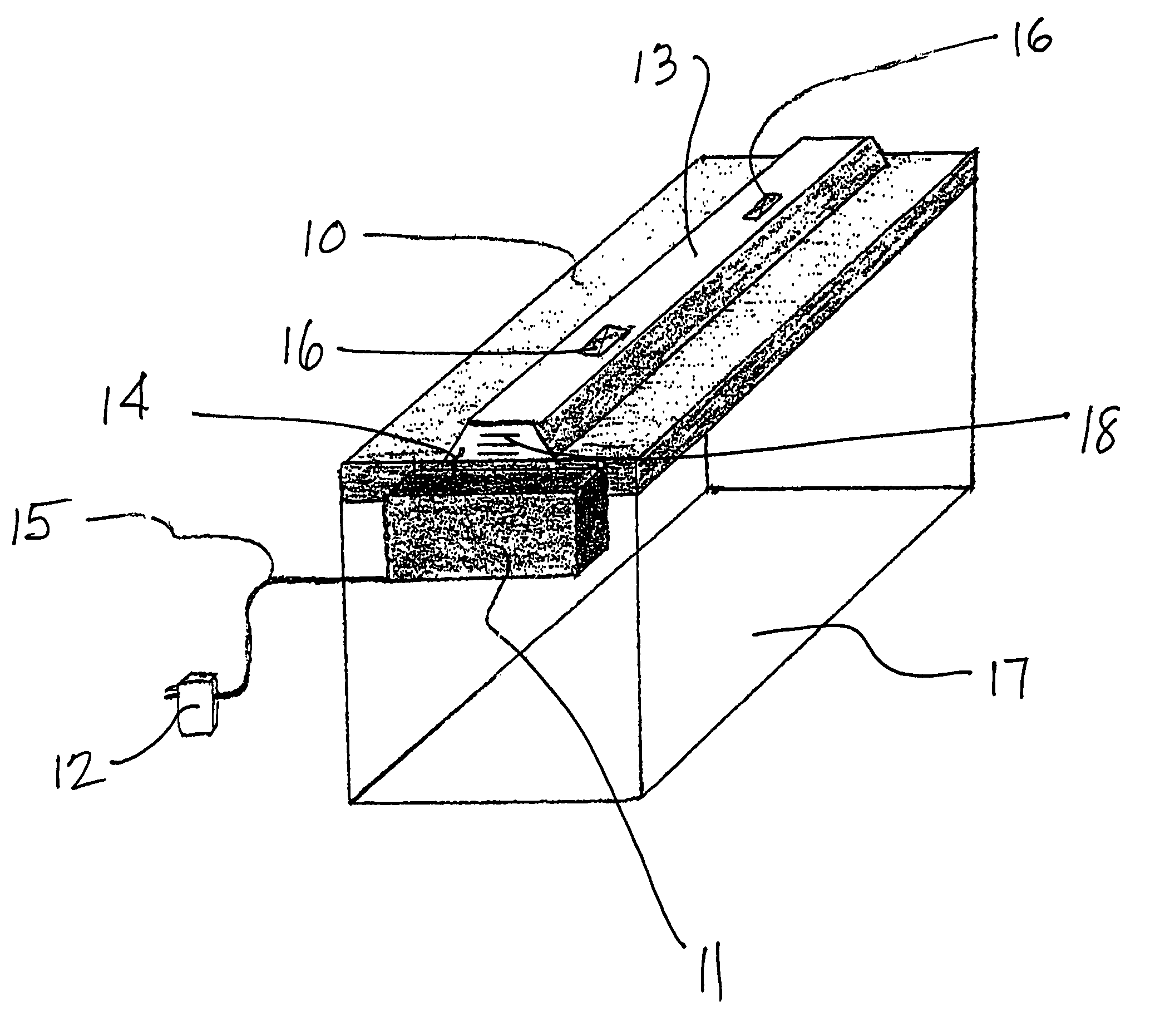

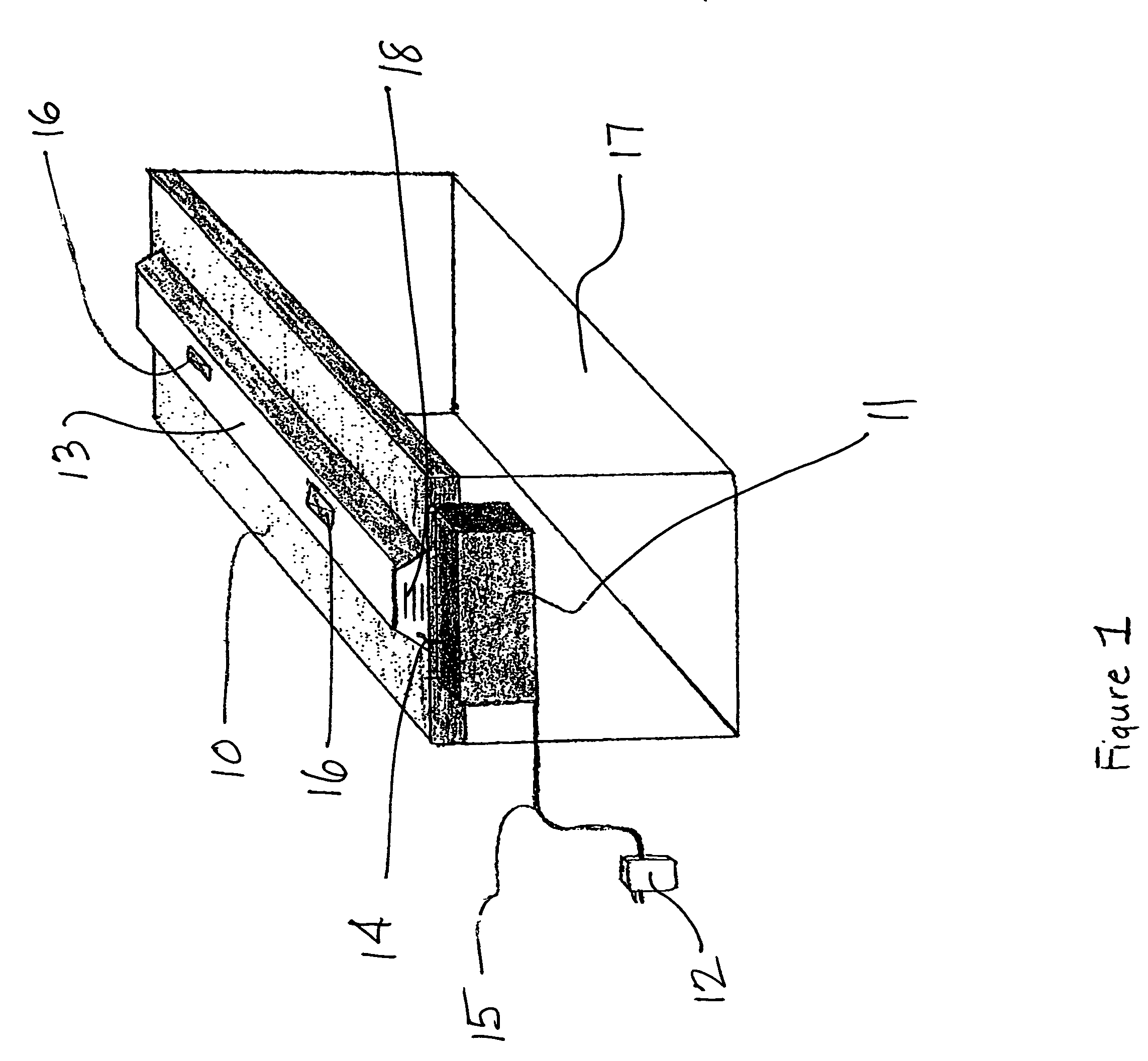

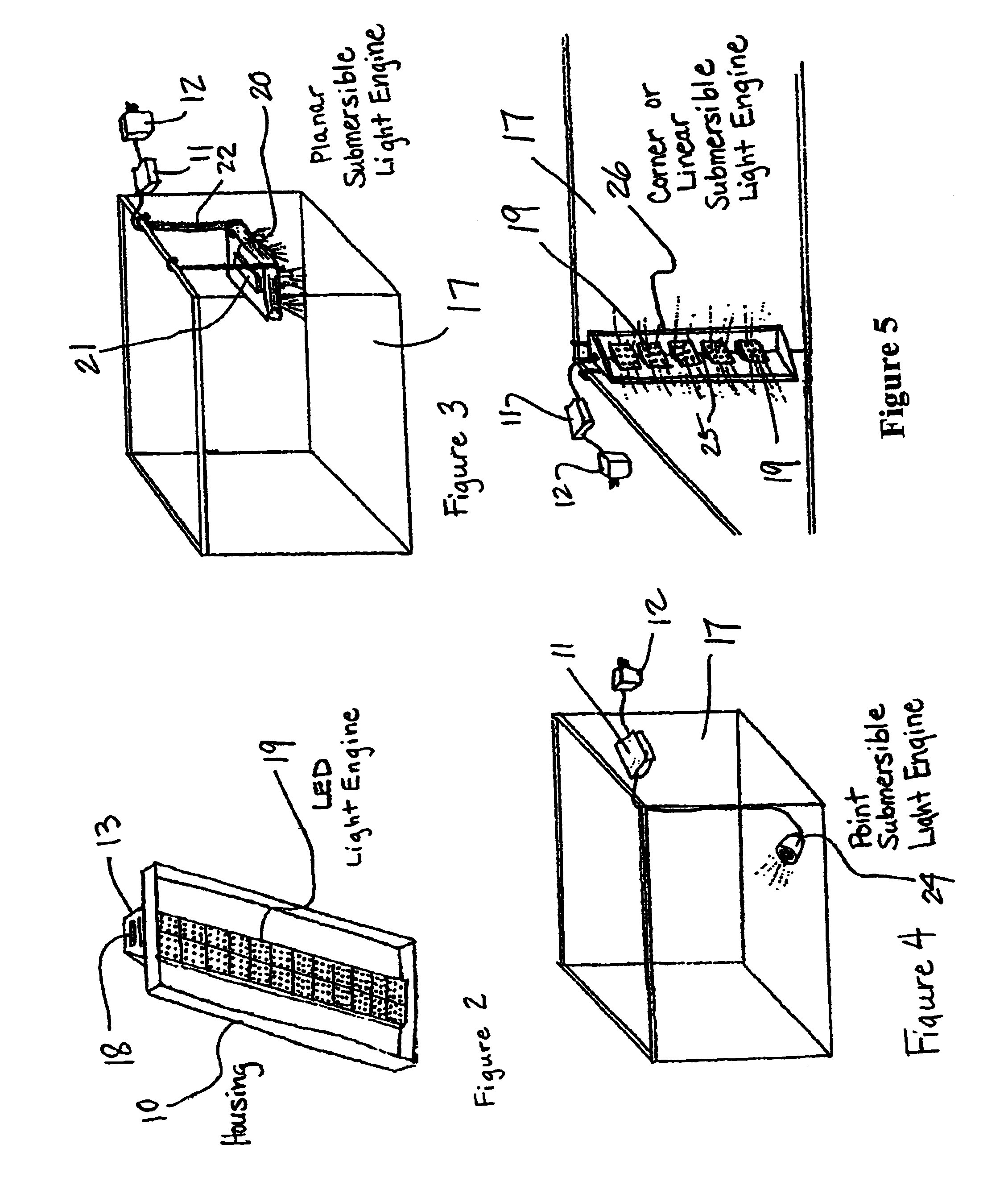

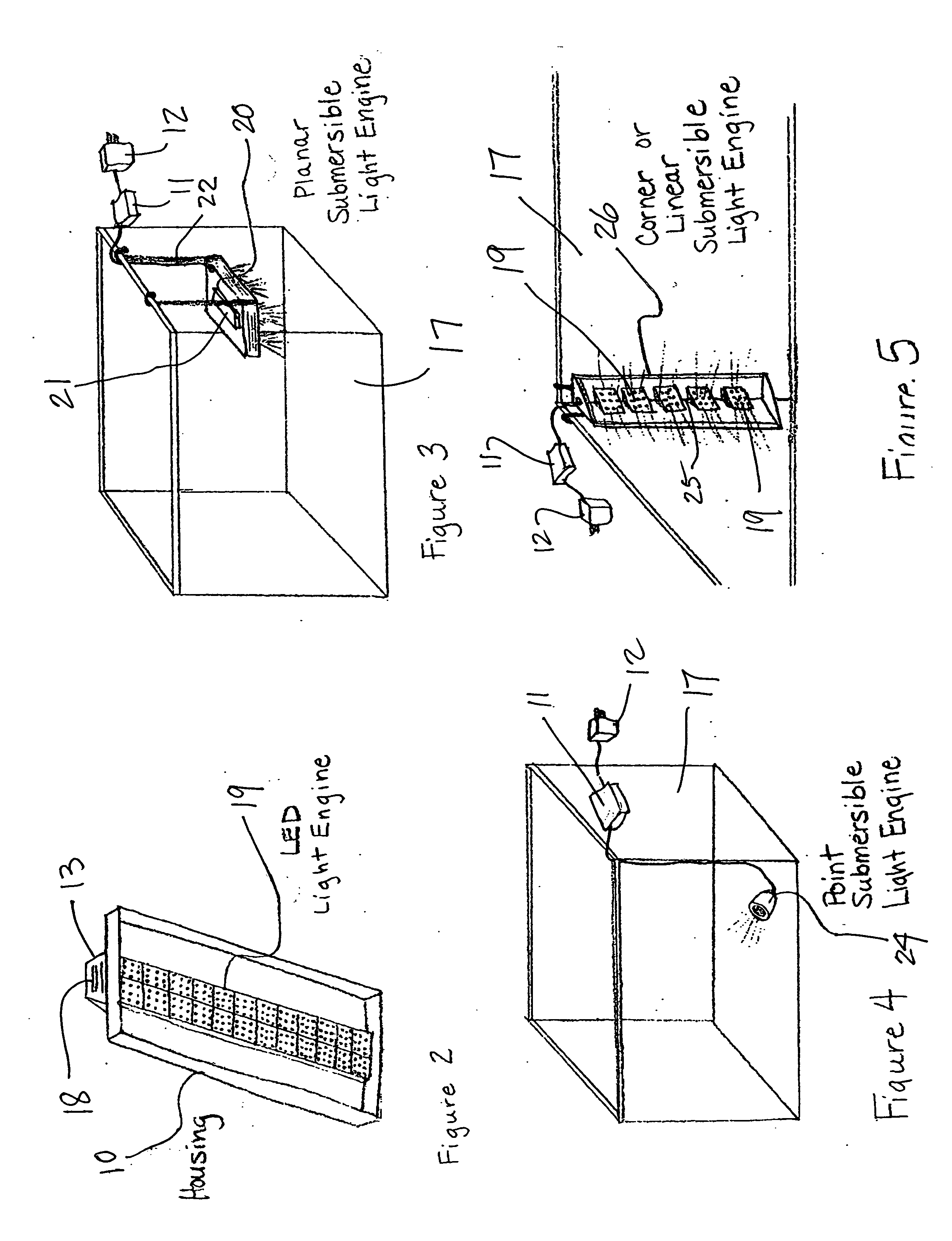

Marine LED lighting system and method

InactiveUS7220018B2High outputIncrease light intensityElectrical apparatusElectric circuit arrangementsMarine habitatsEngineering

A method and apparatus of lighting a marine habitat for growth utilizing an LED light system. The light system includes an LED light source, a power supply for such light source and a controller for controlling the activation status and the intensity of the LED light source.

Owner:ORBITAL TECH

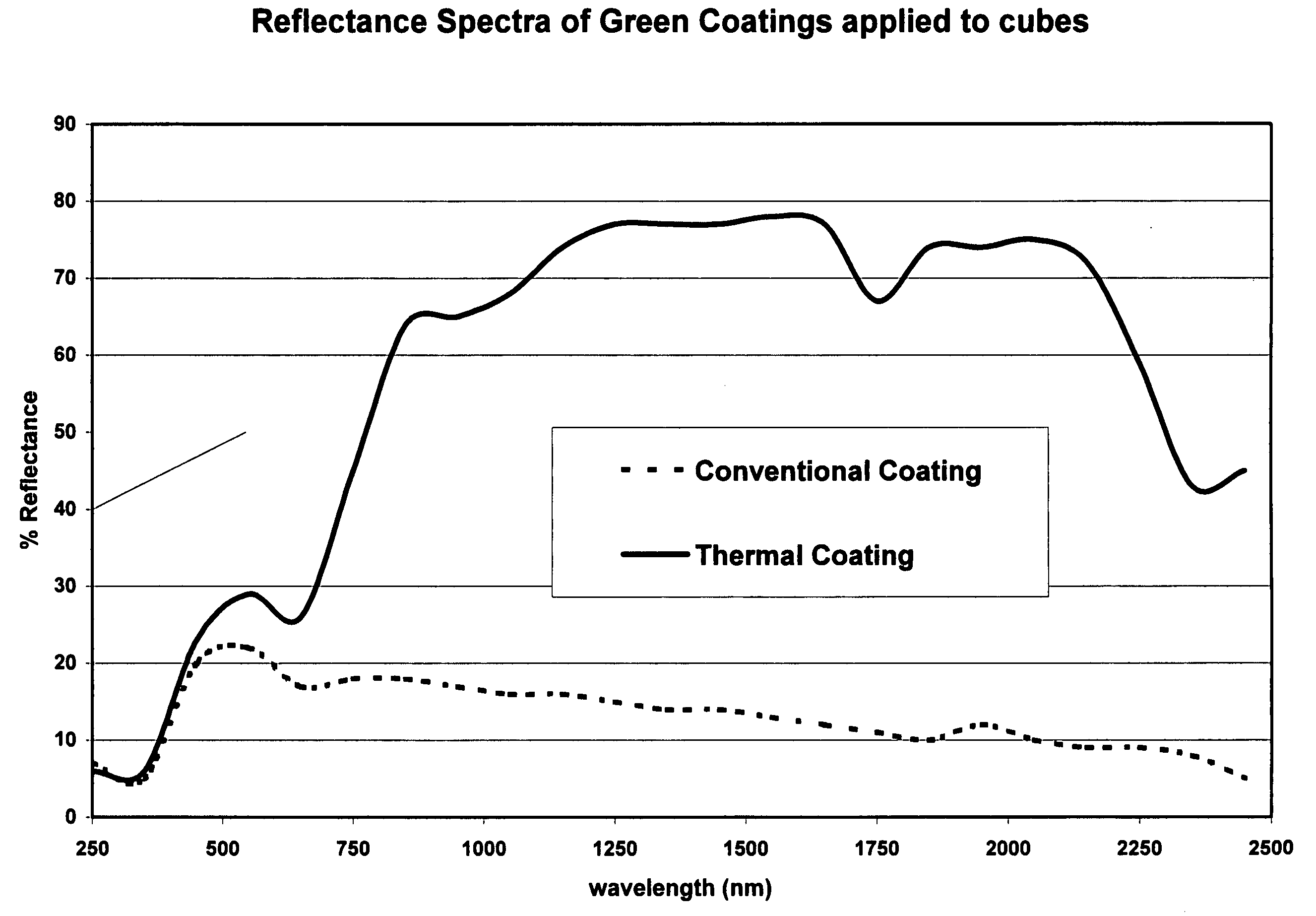

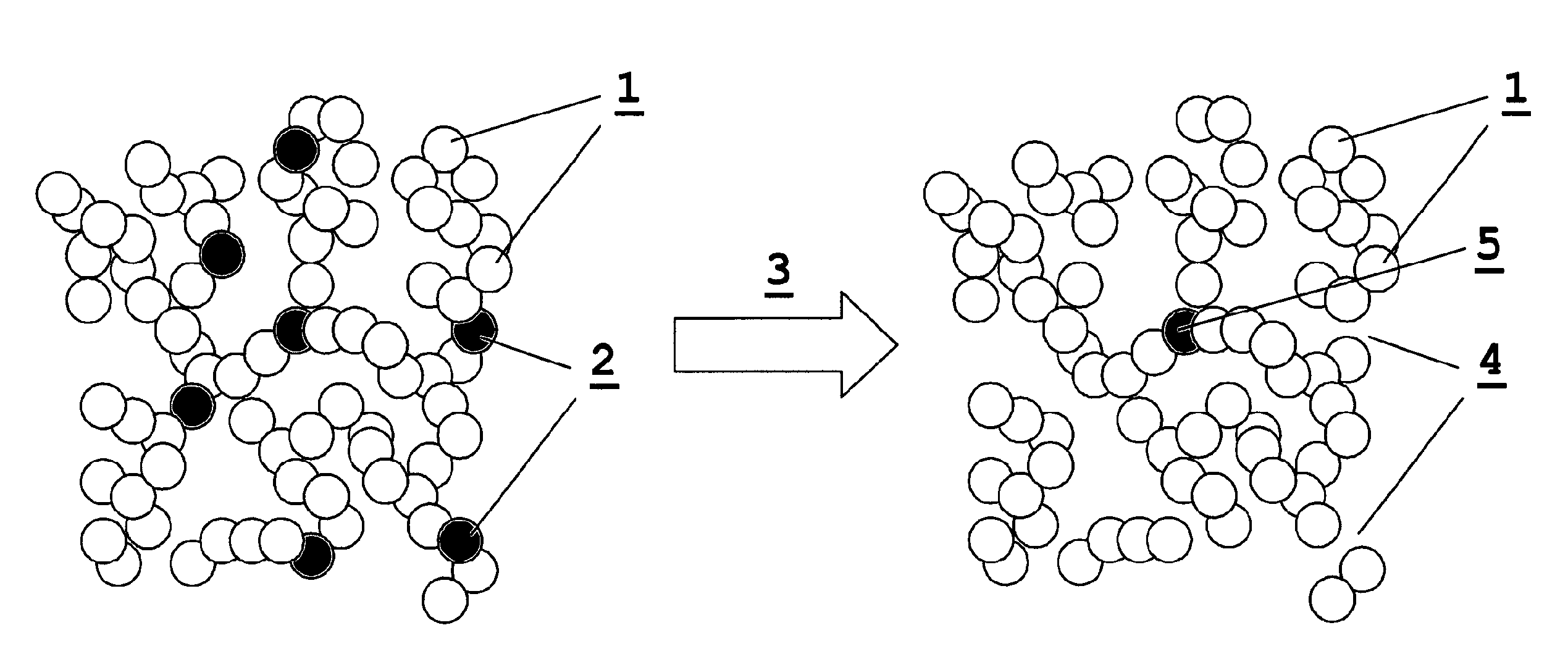

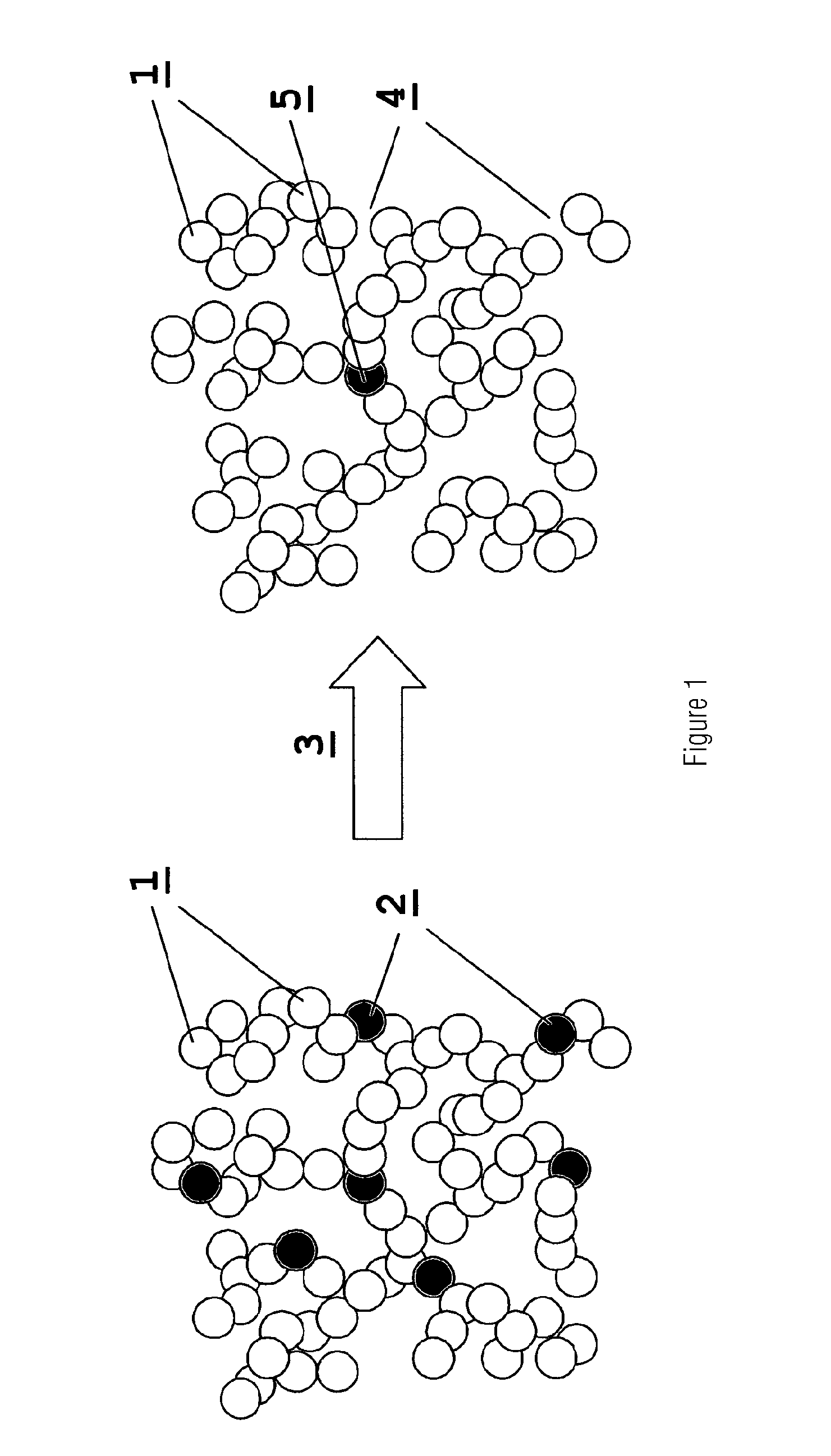

Composition of a thermaly insulating coating system

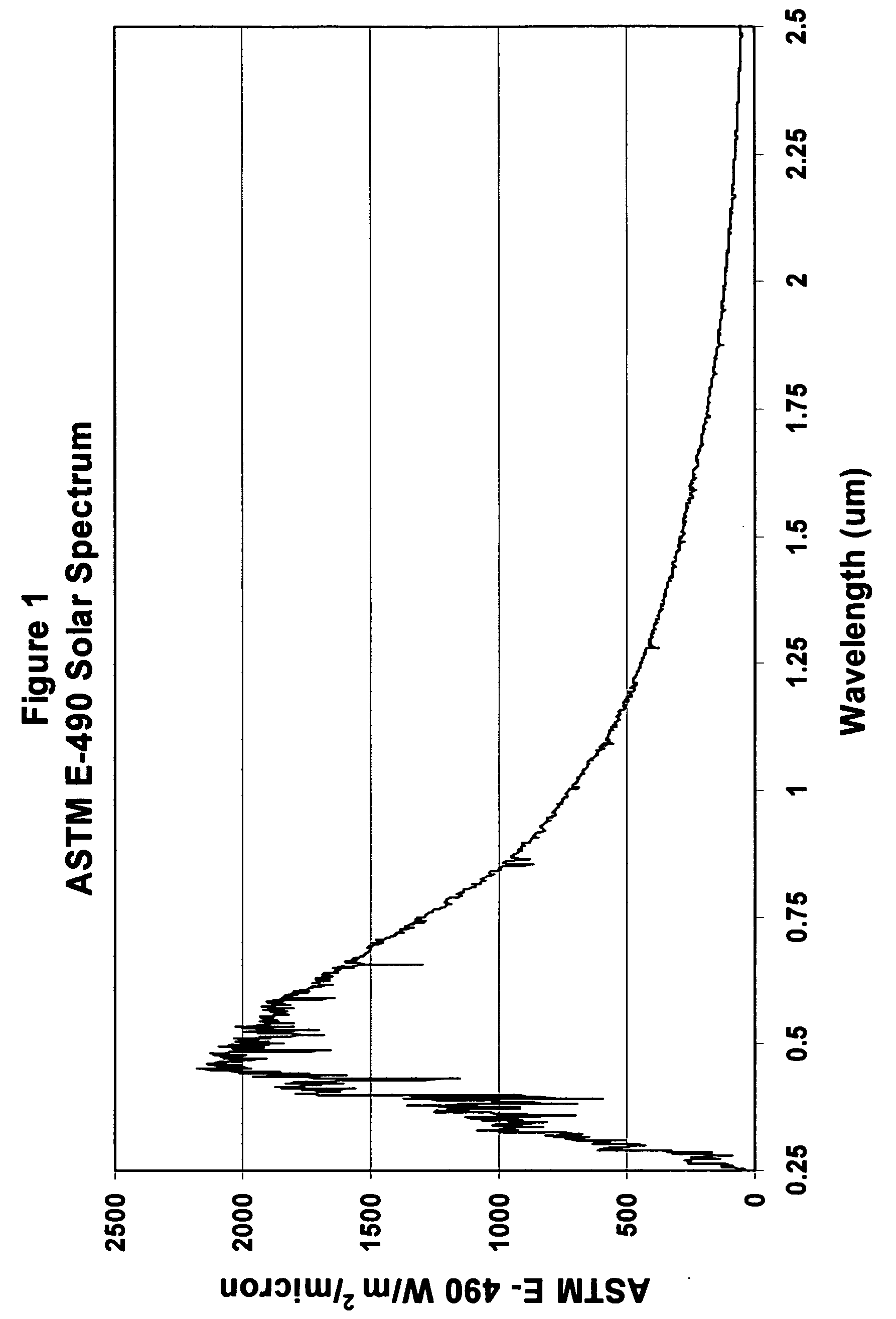

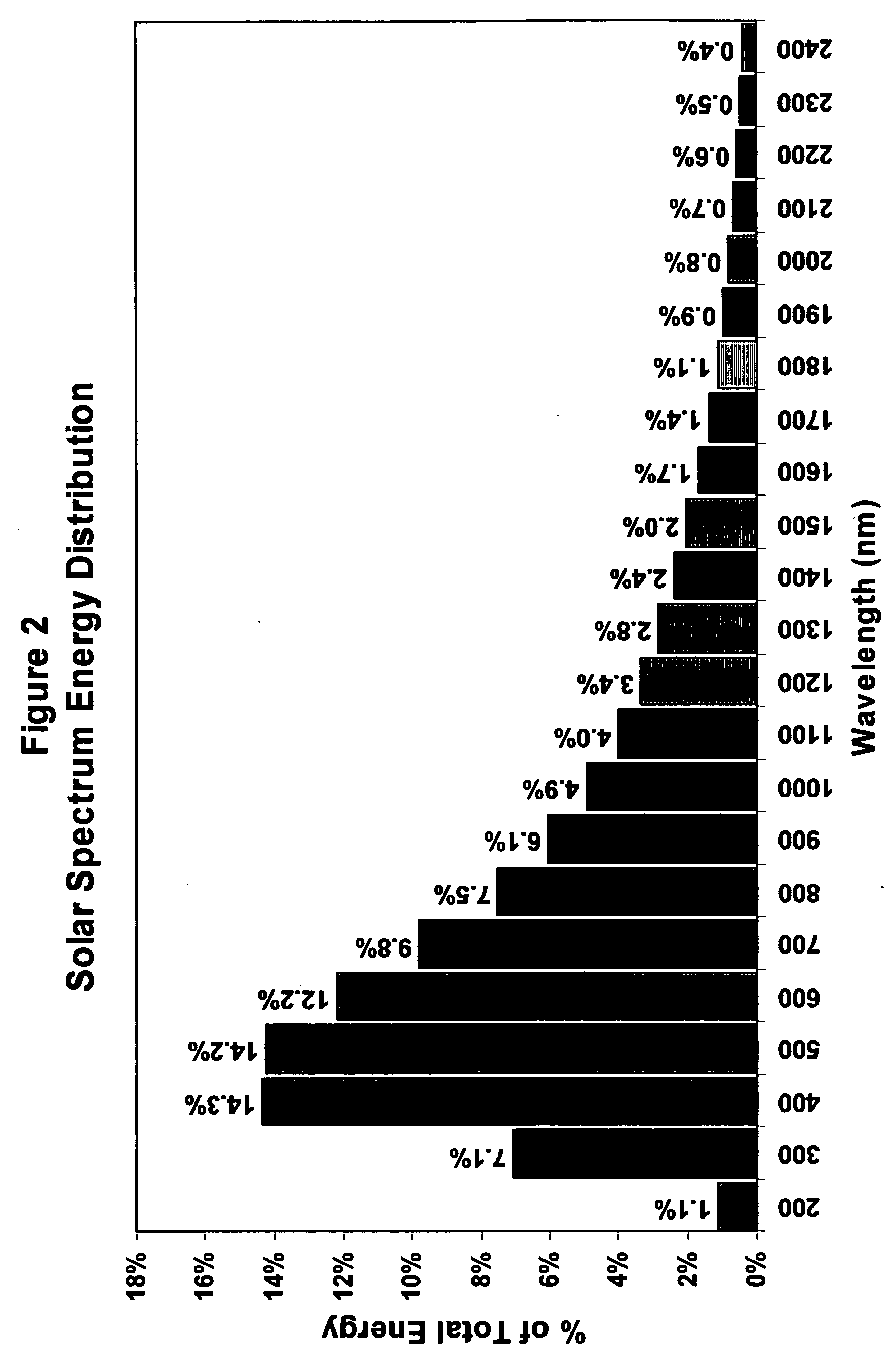

InactiveUS20050126441A1High infrared reflectivityLow thermal conductivityPigmenting treatmentCeramic layered productsCoating systemSolar spectra

A composition for a Coating System (paint) which forms an insulating material being designed to both reflect infrared radiation and have reduced thermal conductivity. The coating system may be either a single Thermal Coating or may be a Thermal Coating used in combination with a Thermal Primer. The Thermal Coating is formulated using conventional techniques and a resin used in paint manufacture, but utilizes primary pigments and extender mineral pigments which preferentially reflect in the infra red area of the solar spectrum. A method of characterizing particulate materials for their infra red reflectivity is described, which provides a means for preferential selection of particulate additives based on their relative visible light and infrared reflectivity. Additionally the incorporation of hollow micro-spheres is desired to reduce thermal conductivity. The Thermal Primer is designed to provide adhesion between the Thermal Coating and the substrate on which it is applied and uses conventional techniques to achieve those properties. However it has been found advantageous to incorporate hollow micro-spheres with low thermal conductivity, such as glass, ceramic or polymeric micro-spheres and / or an extender pigment with low thermal conductivity such as calcined clay to further reduce heat flow through the Coating System.

Owner:ANTHONY DAVID SKELHORN

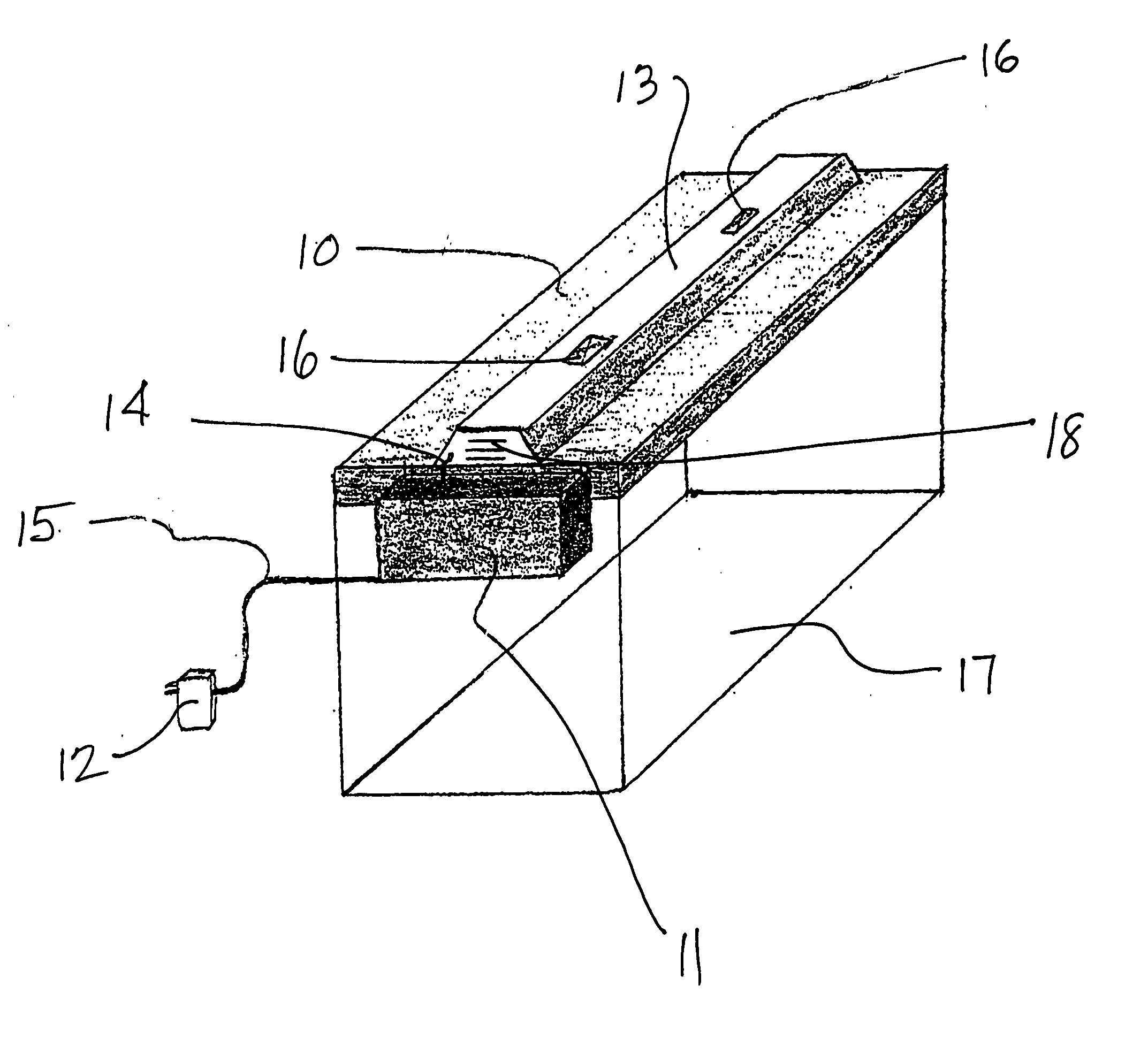

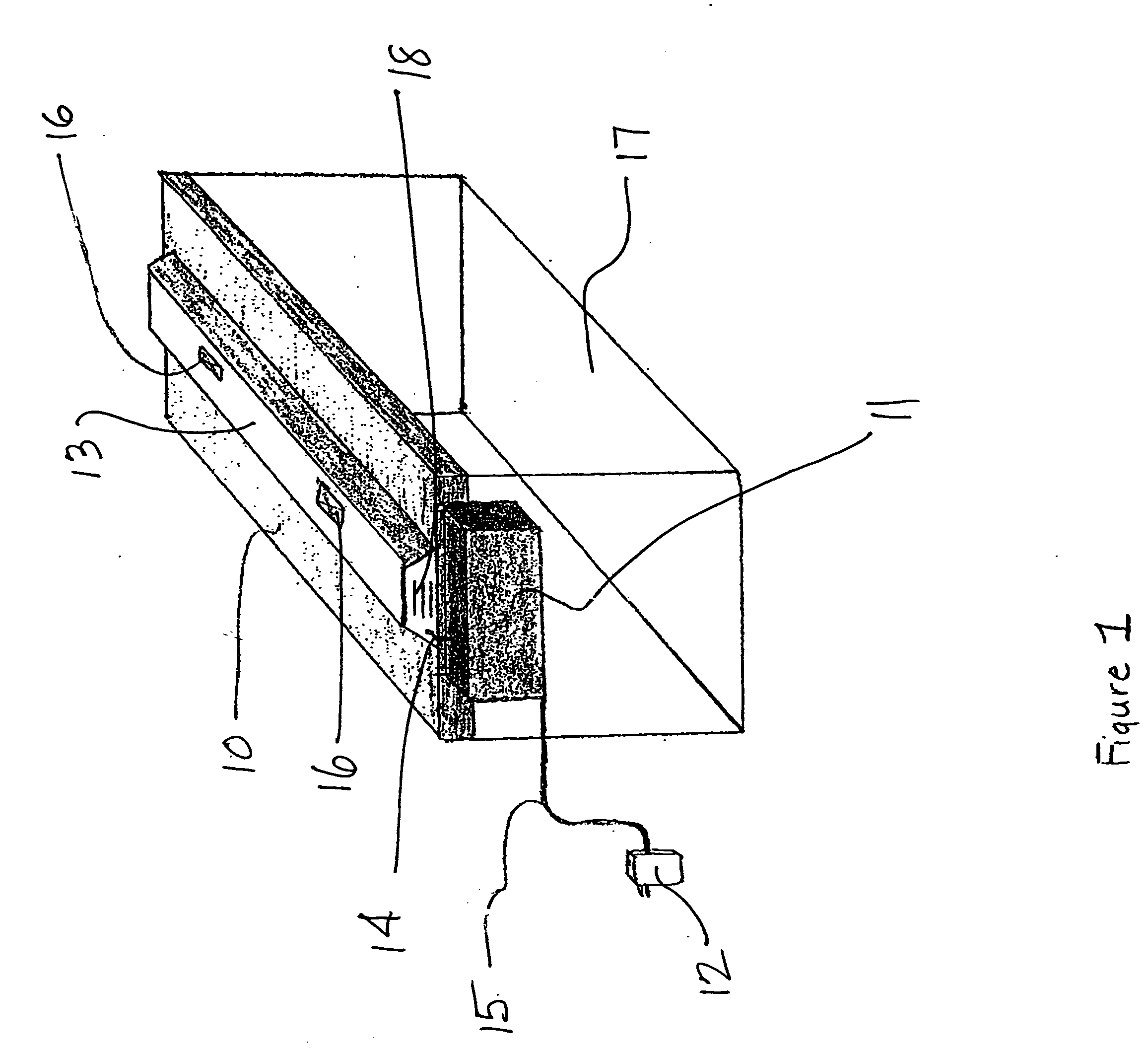

Marine LED lighting system and method

InactiveUS20050135104A1High outputIncrease light intensityElectrical apparatusElectric circuit arrangementsMarine habitatsEngineering

A method and apparatus of lighting a marine habitat for growth utilizing an LED light system. The light system includes an LED light source, a power supply for such light source and a controller for controlling the activation status and the intensity of the LED light source.

Owner:ORBITAL TECH

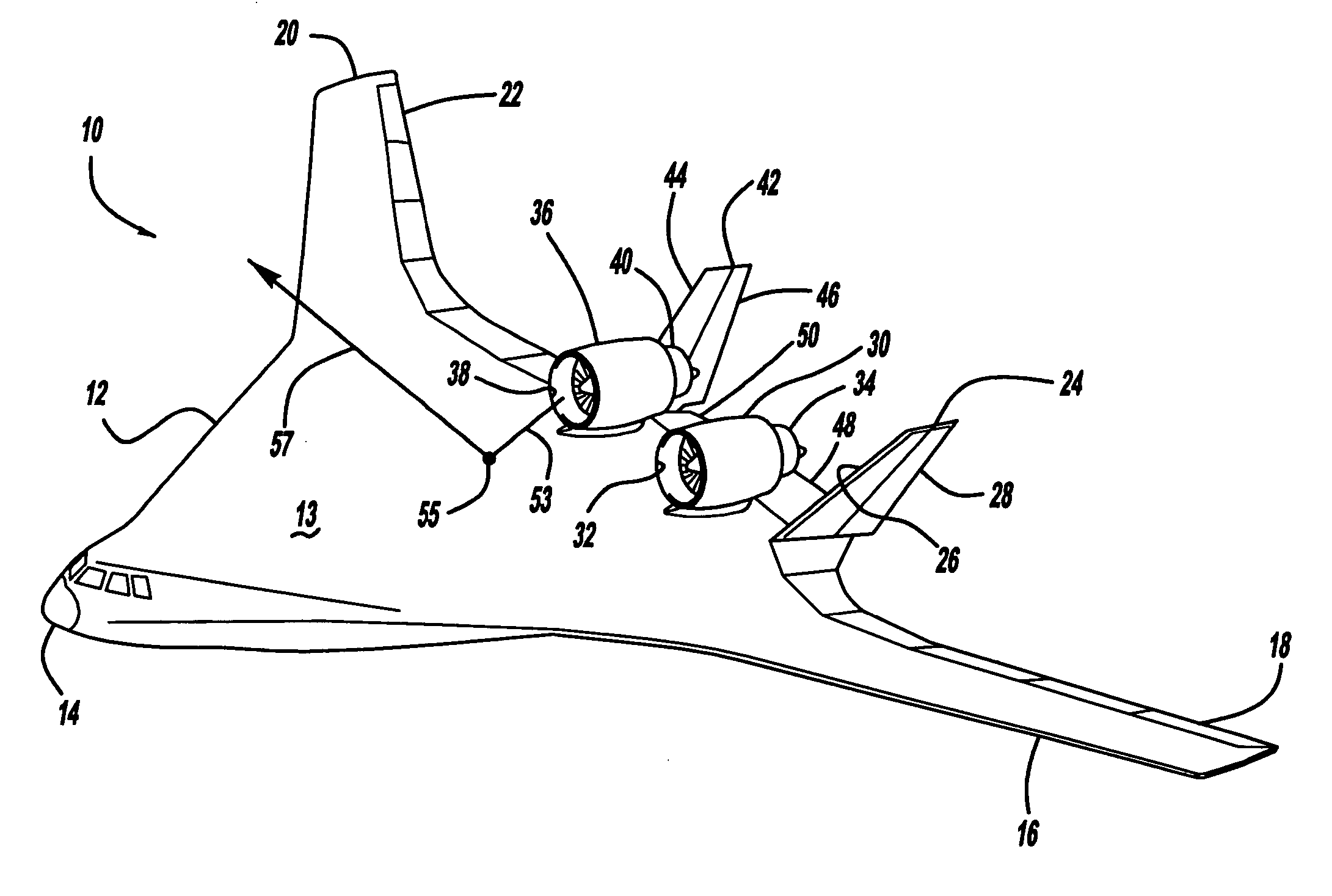

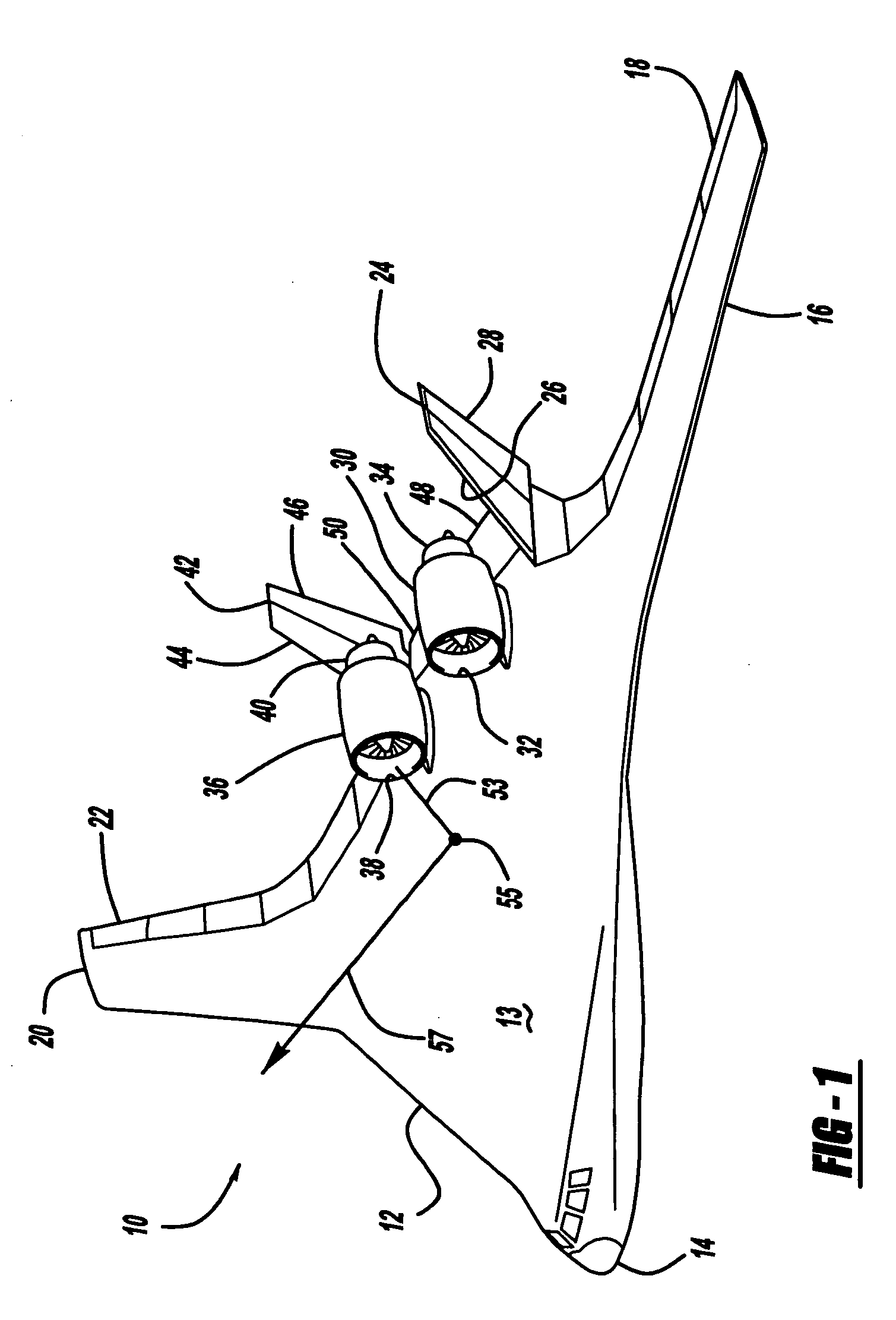

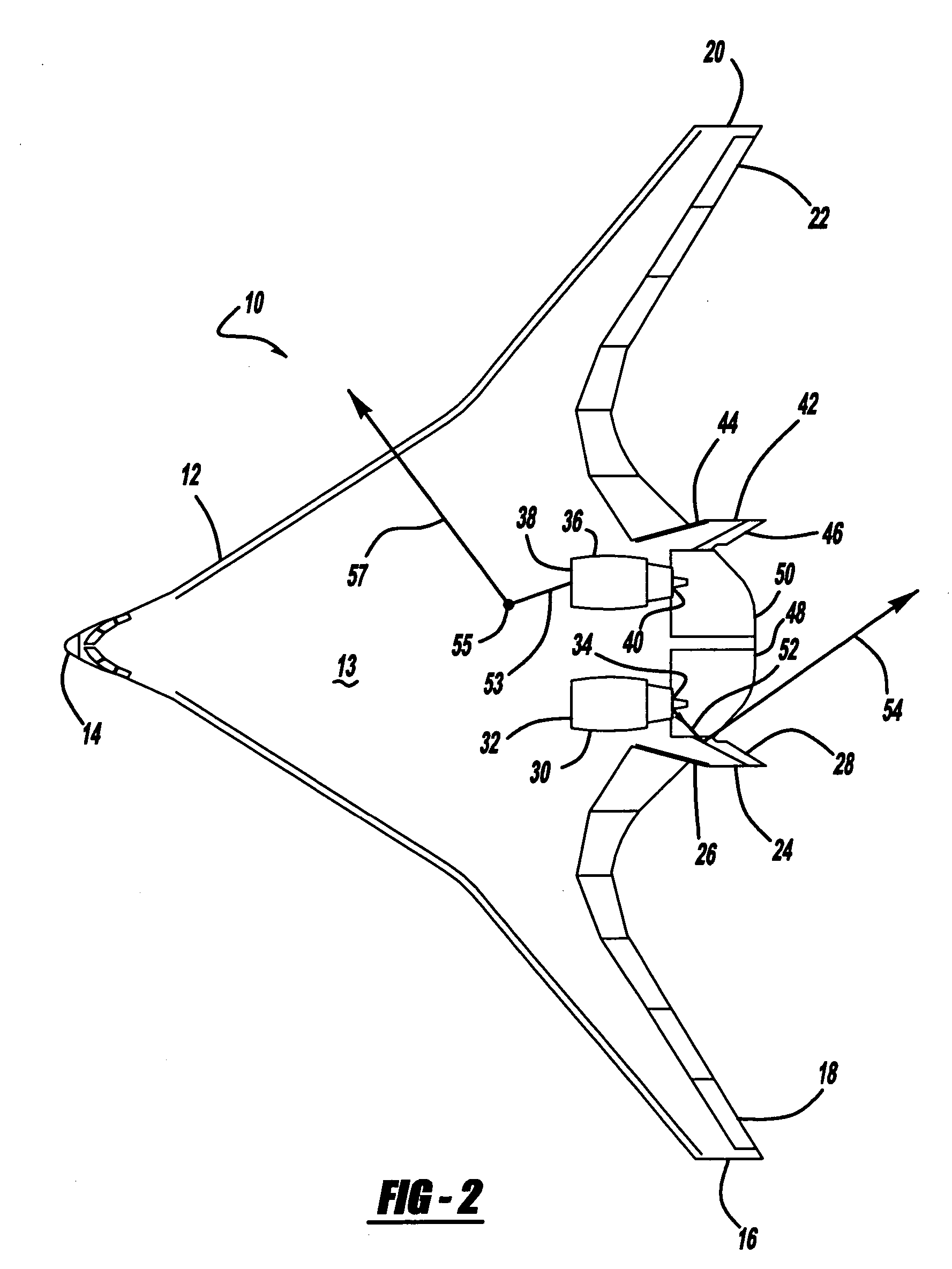

Quiet airplane configuration

InactiveUS20070023571A1Reduces acoustic signatureReduce radiant heatGas turbine type power plantsAll-wing aircraftNoise generationJet aeroplane

A blended wing aircraft reduces forward, aft, and sideline flyover noise and heat energy by reflecting it upward using the wing and vertical stabilizers positioned just outboard of the engines. The engines are located on top of the wing and forward of the trailing edge of the wing with the aft portion of the engines located over the wing. The nozzle exit perimeter is increased and shaped to increase shear and create vortices to move noise generation over the wing to cause the noise to be reflected upward off the wing and upward off of the canted vertical stabilizers. Engine thrust reversers cause the forwardly mounted engine's thrust to be directed toward the front of the aircraft in such a way as to create a download forward of the main landing gear to also secure the front landing gear.

Owner:THE BOEING CO

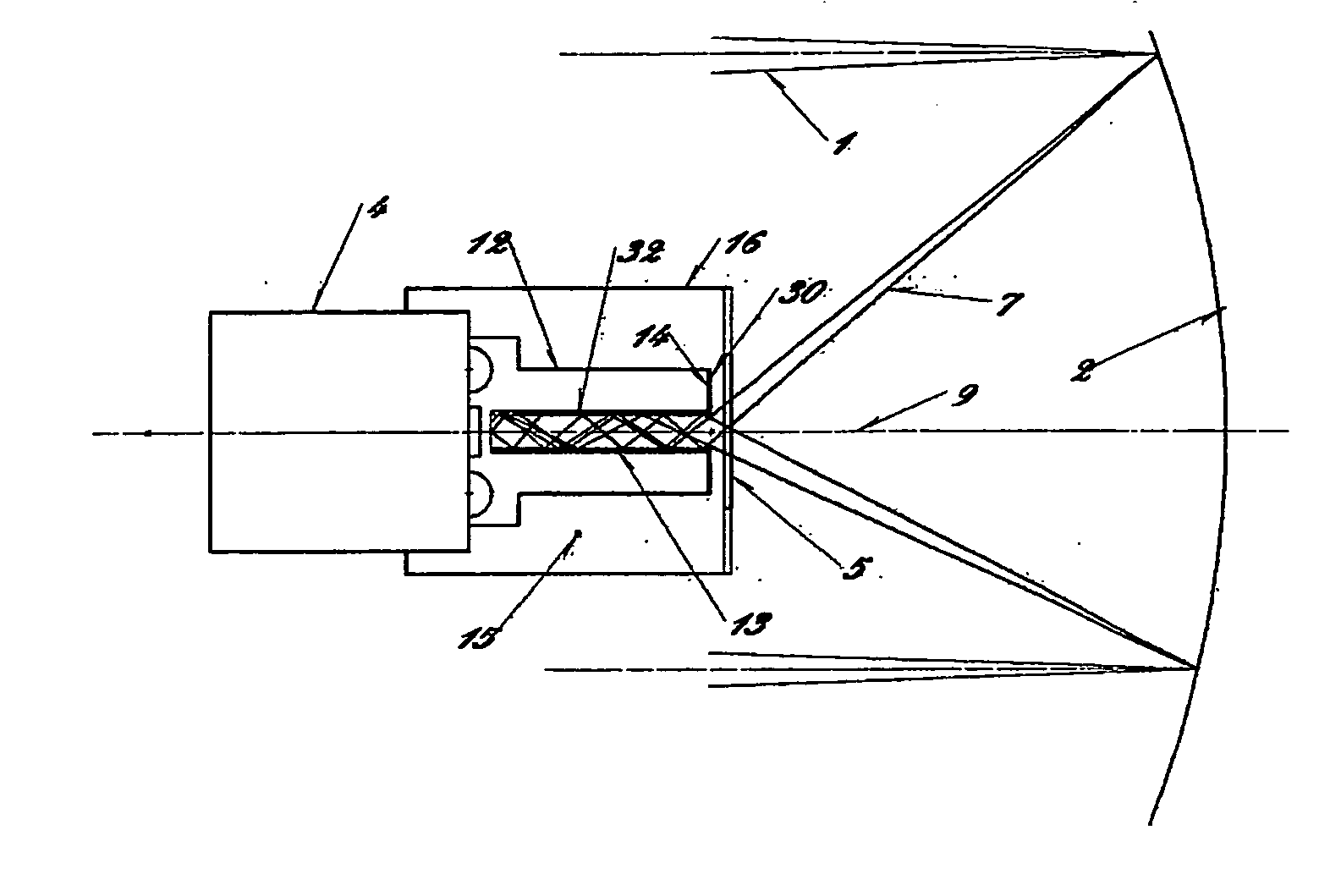

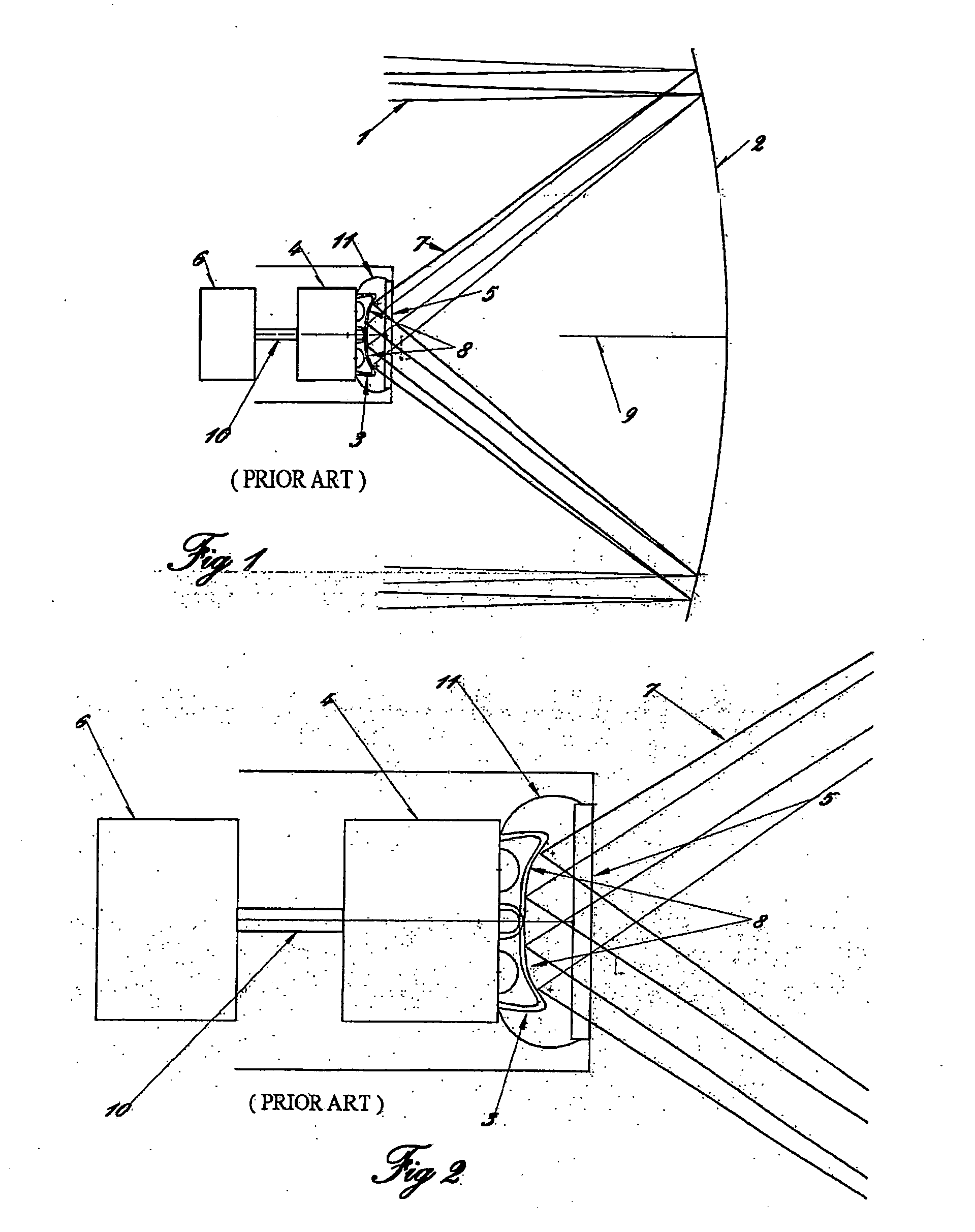

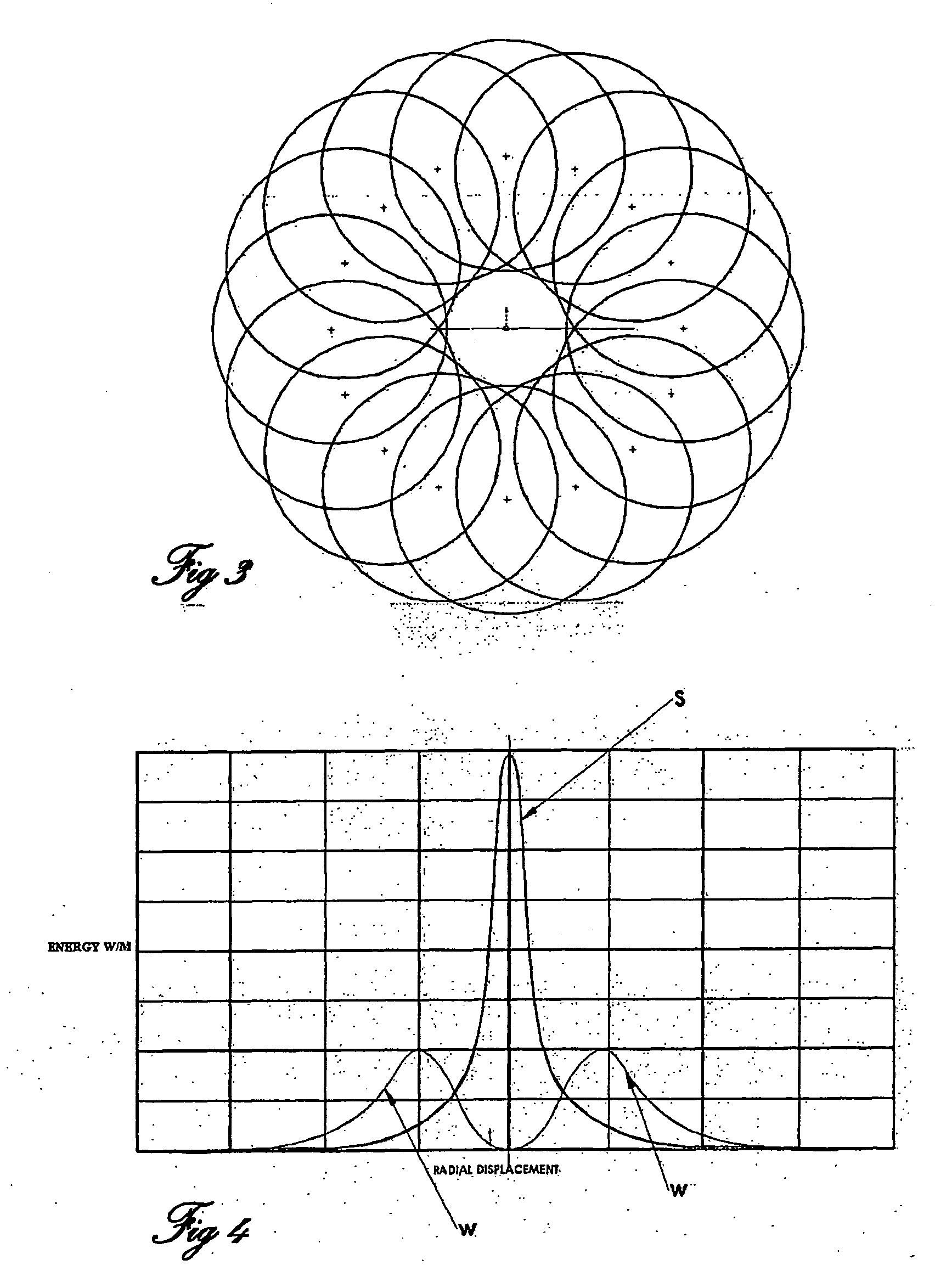

Solar Energy Collection Apparatus and Method

InactiveUS20080184990A1Reduce radiant heatSolar heating energyFrom solar energyReducing atmosphereCavity wall

An apparatus for collecting heat from a solar concentrator has an isothermal body defining an elongated cavity with a circular opening having a diameter equal to a diameter of a focus of the solar concentrator, the cavity having a reflective walls such that solar rays contacting the walls are substantially reflected. The circular opening is located at the focus of the solar concentrator and perpendicular to a principal axis of the solar concentrator, and the axis of the cavity is aligned with the principal axis of the solar concentrator. The heat generated in the isothermal body is absorbed by the heat sink. The length of the cavity is sufficient to absorb a desired proportion of the energy in the solar rays entering the cavity and is about 5 to 9 times the diameter of the opening of the cavity. Depending on material used, the isothermal body can be enclosed in a reducing atmosphere to maintain reflectivity of the cavity walls.

Owner:SHEC LABS

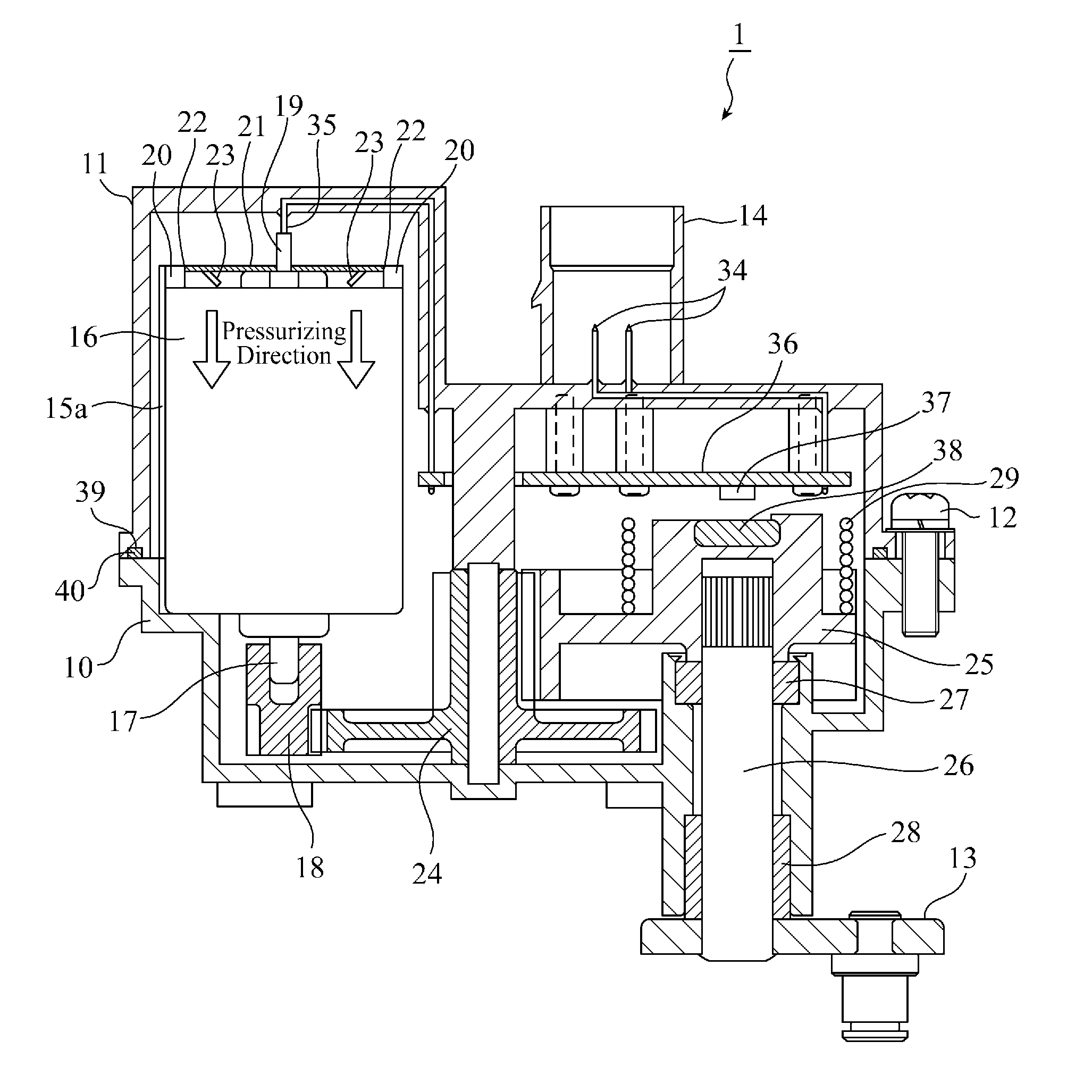

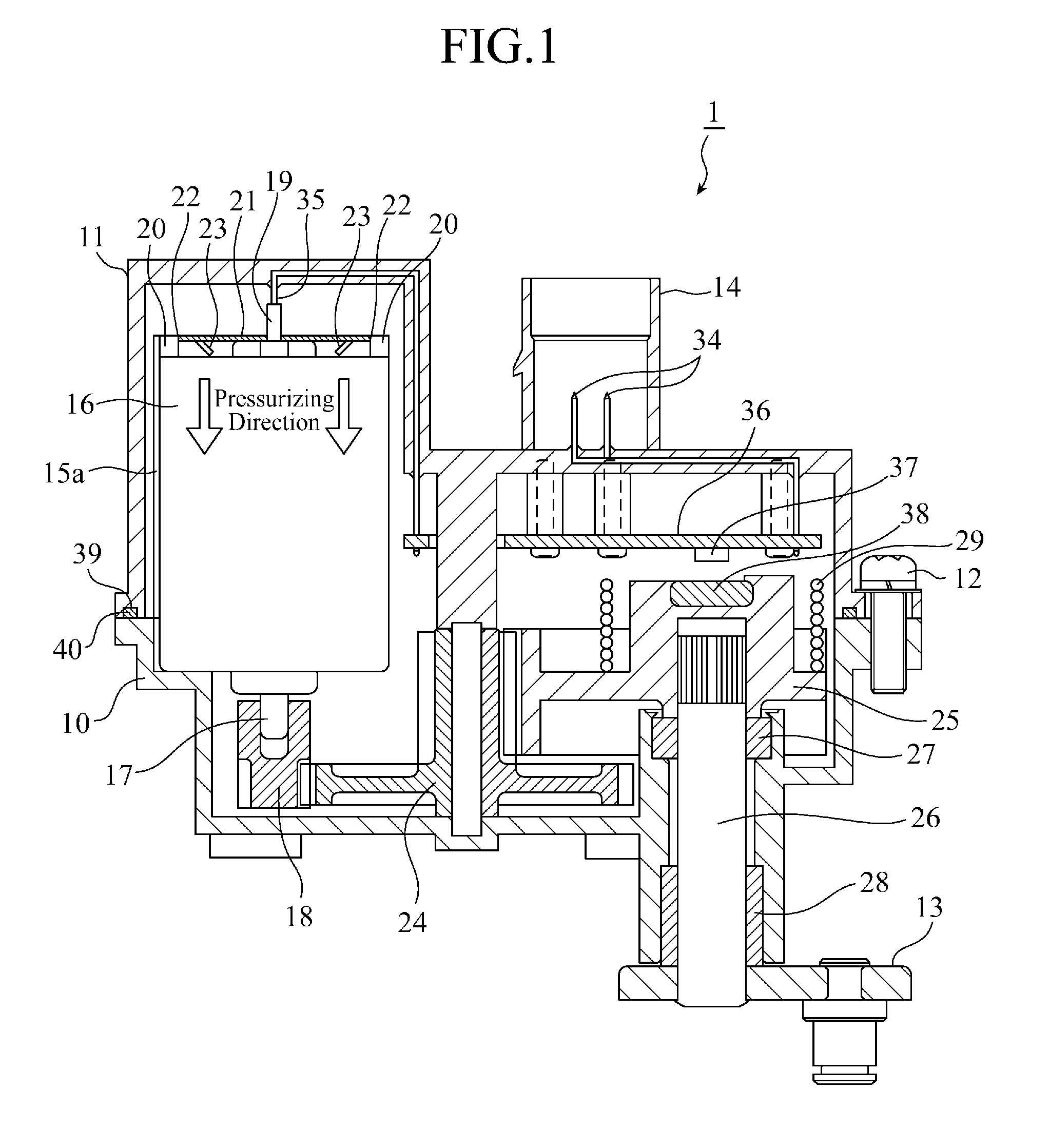

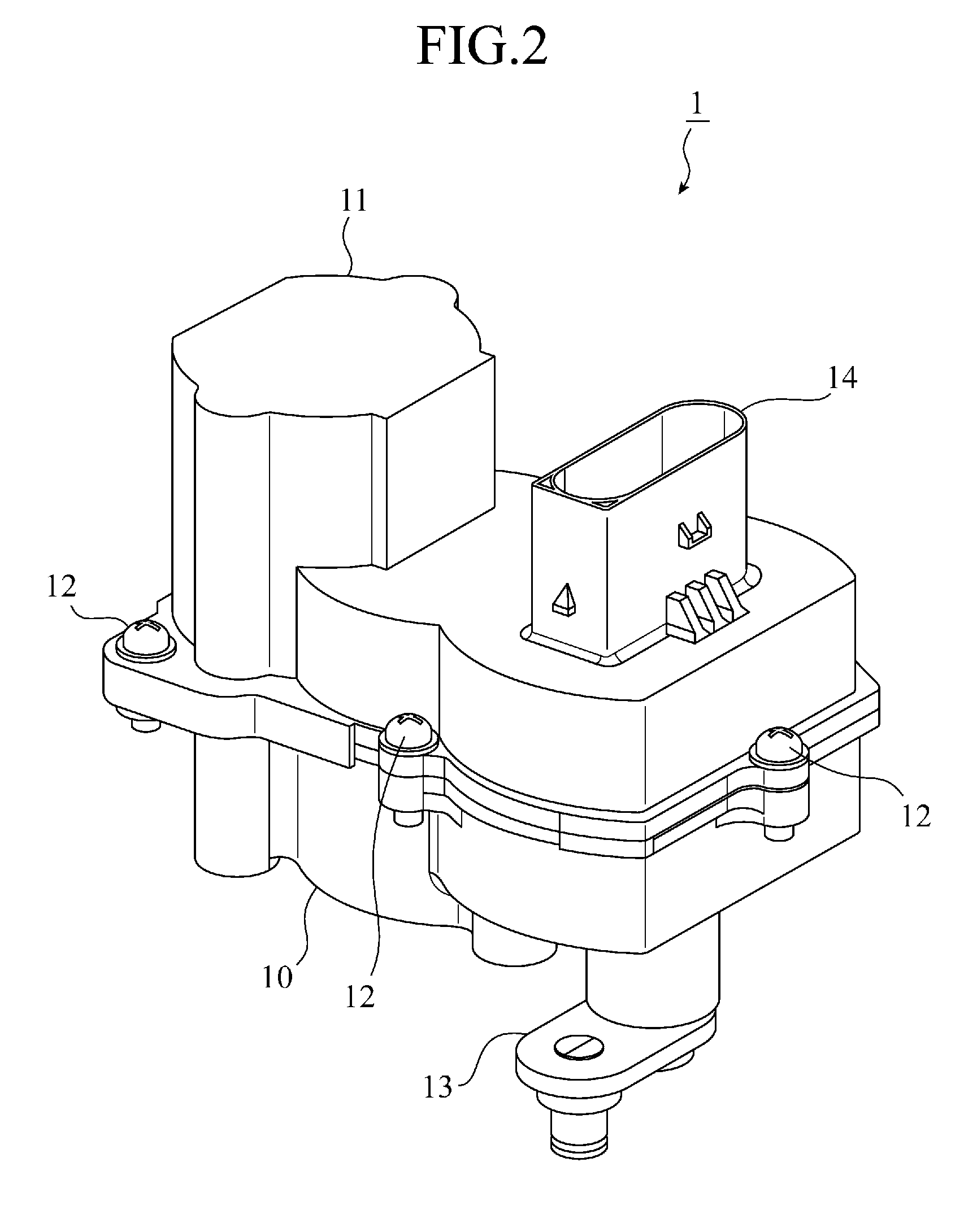

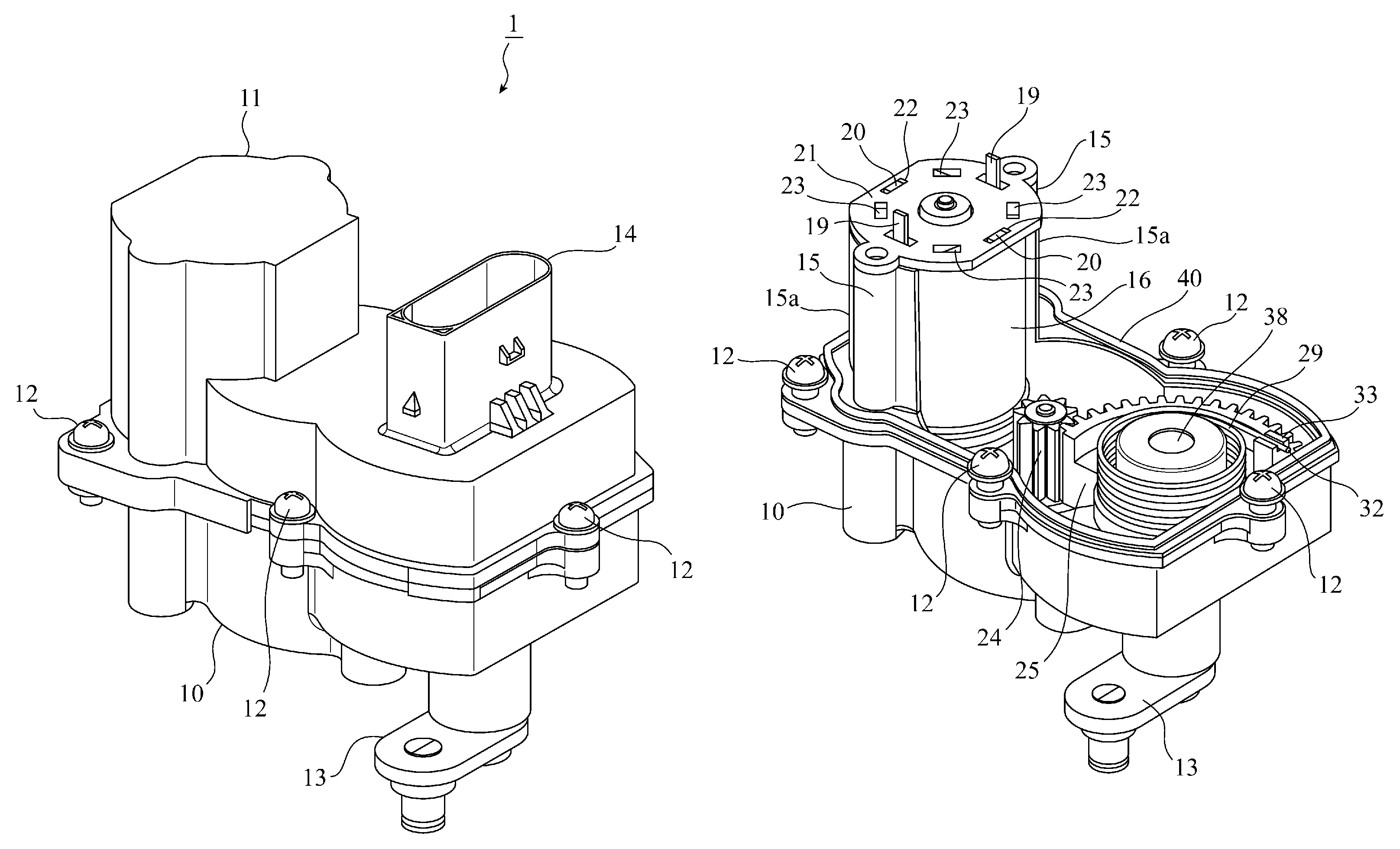

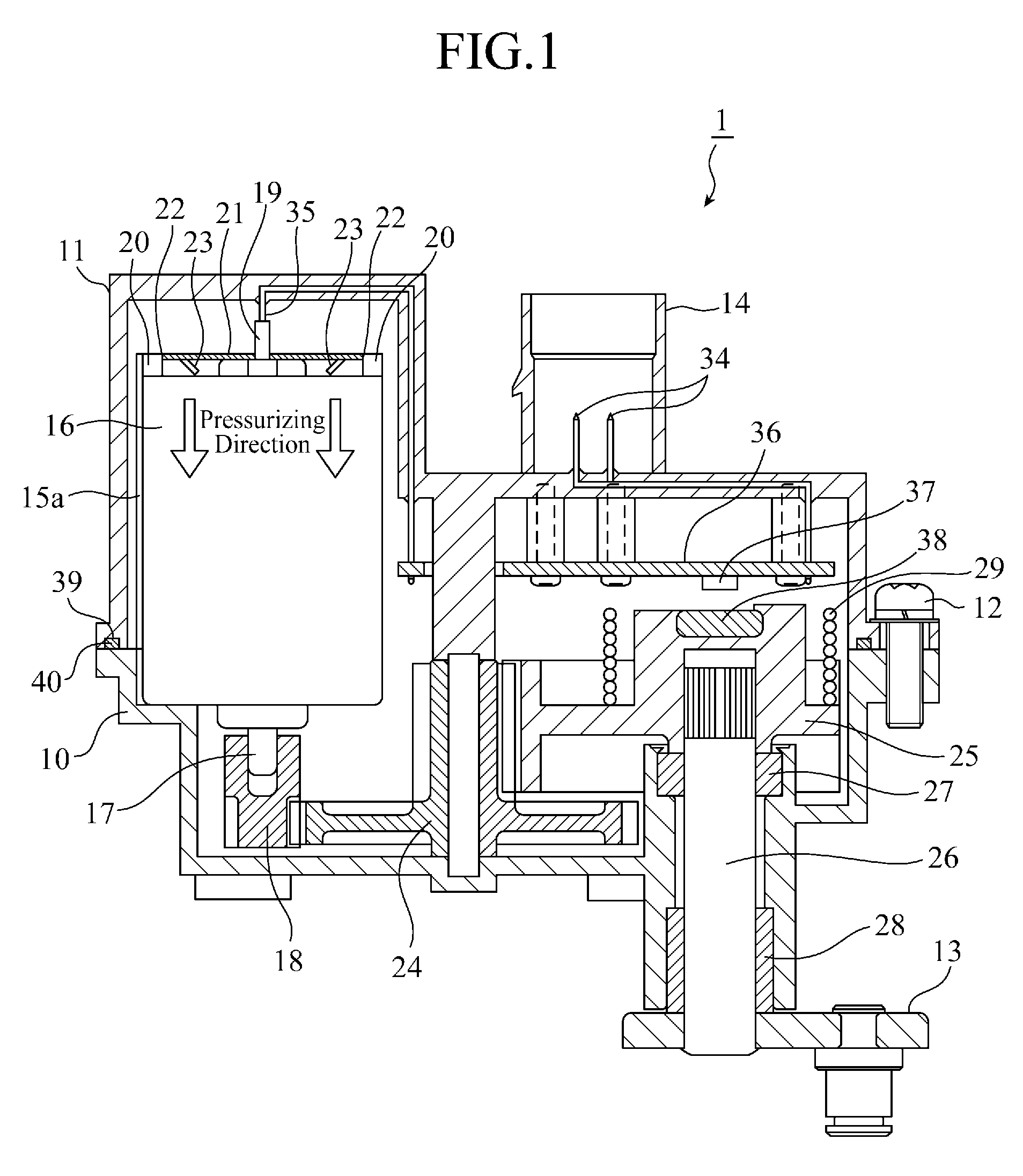

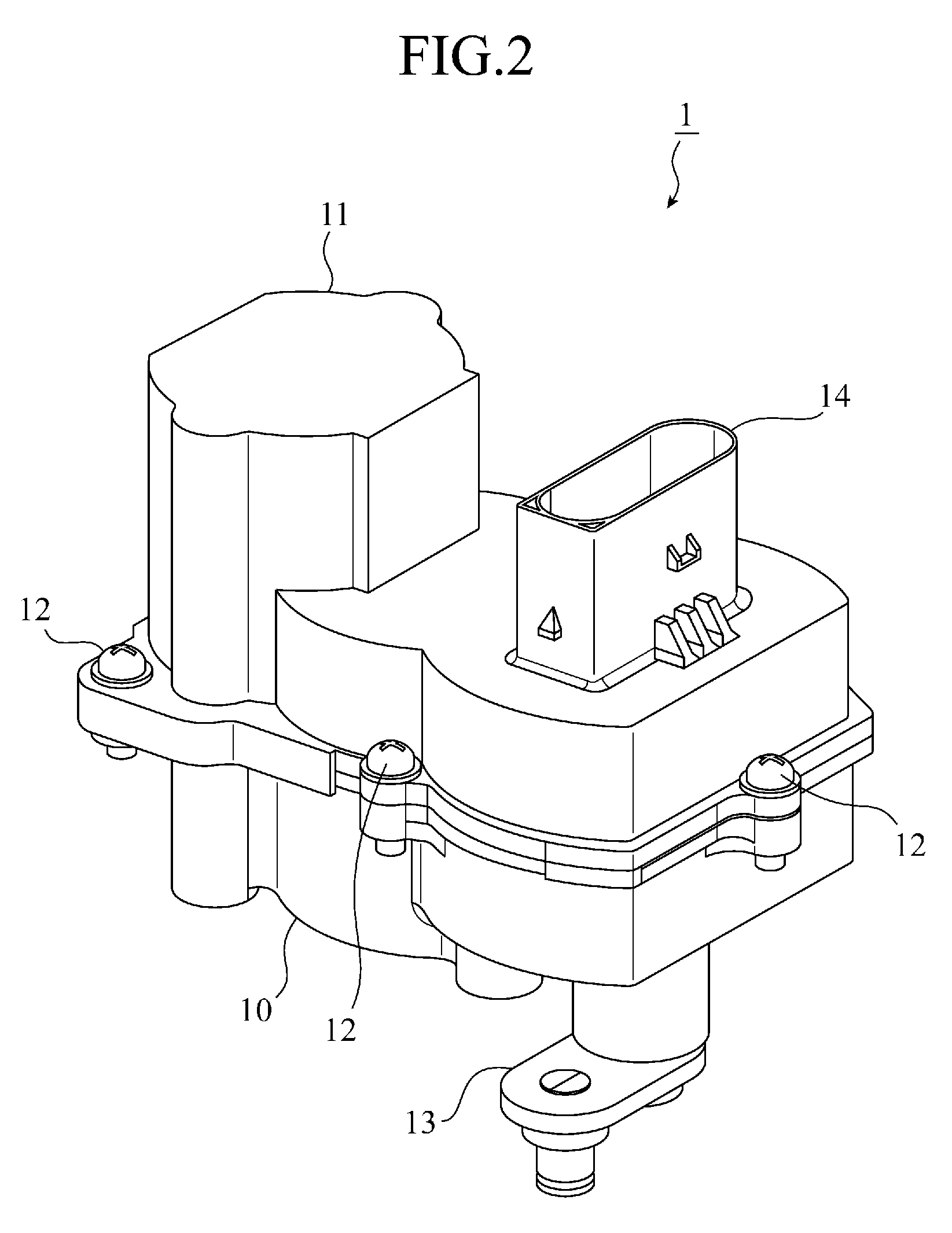

Electronically controlled actuator

ActiveUS20130049502A1Reduced life-timeReduce radiant heatInternal combustion piston enginesMechanical energy handlingActuatorTurbine

Owner:MITSUBISHI ELECTRIC CORP

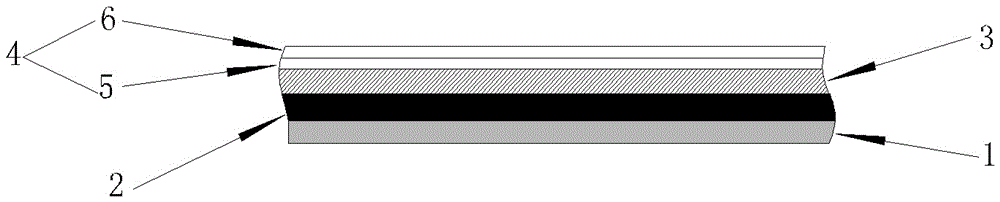

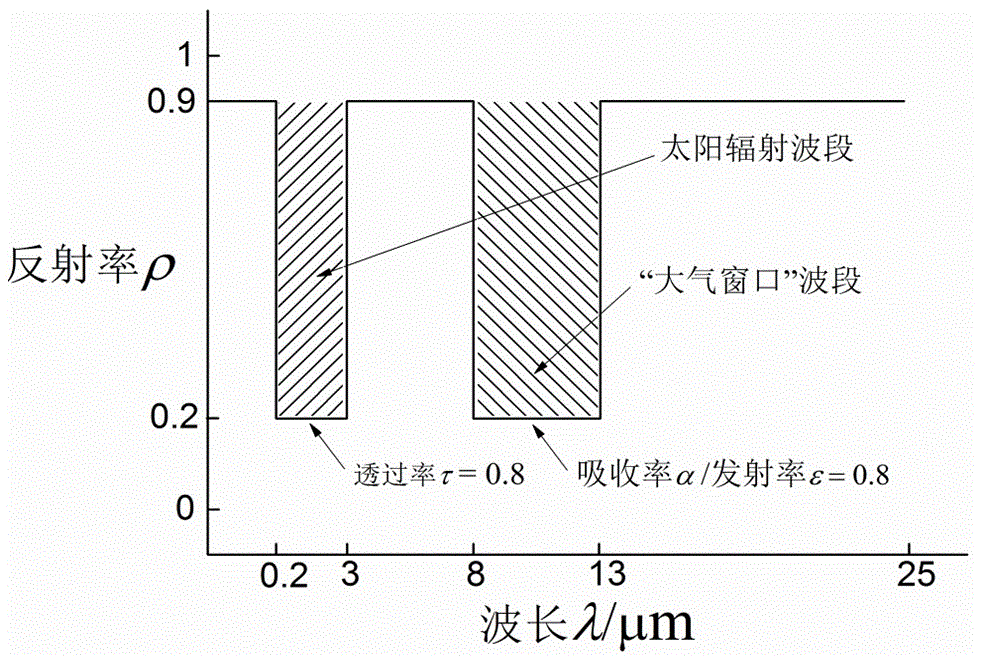

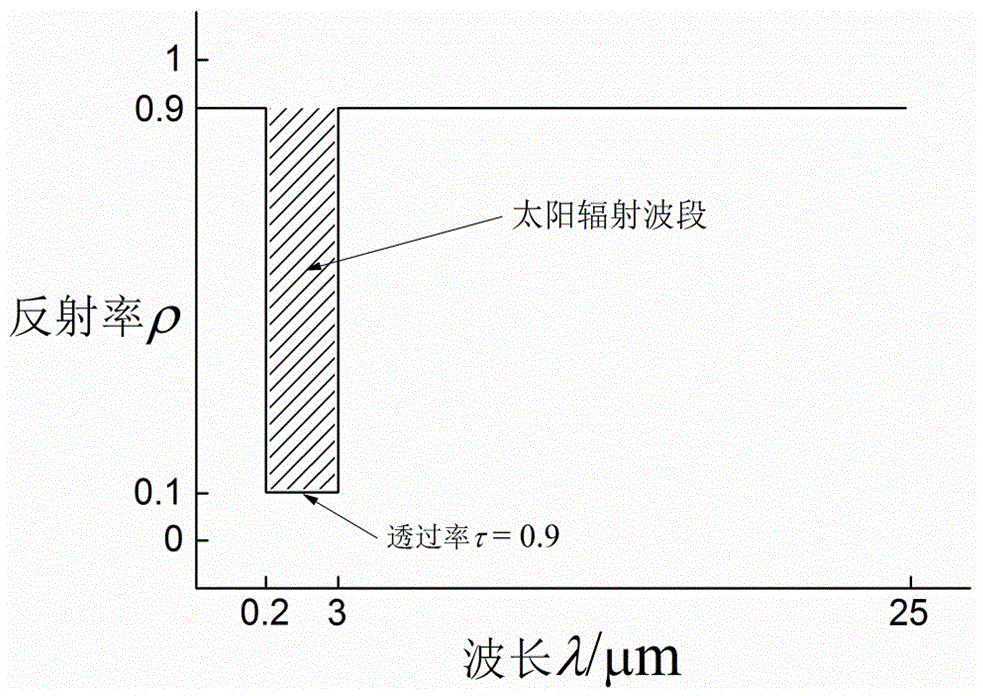

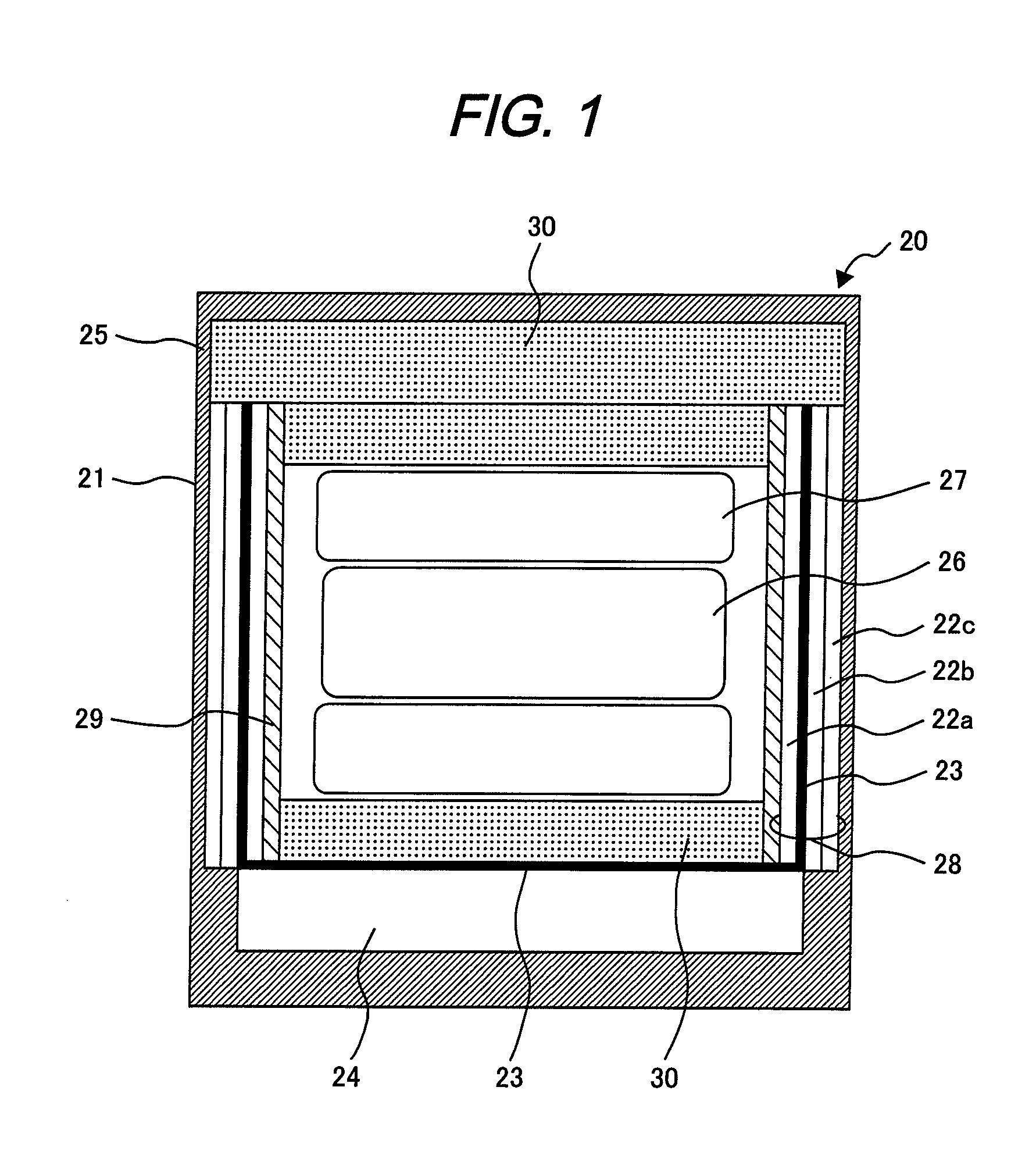

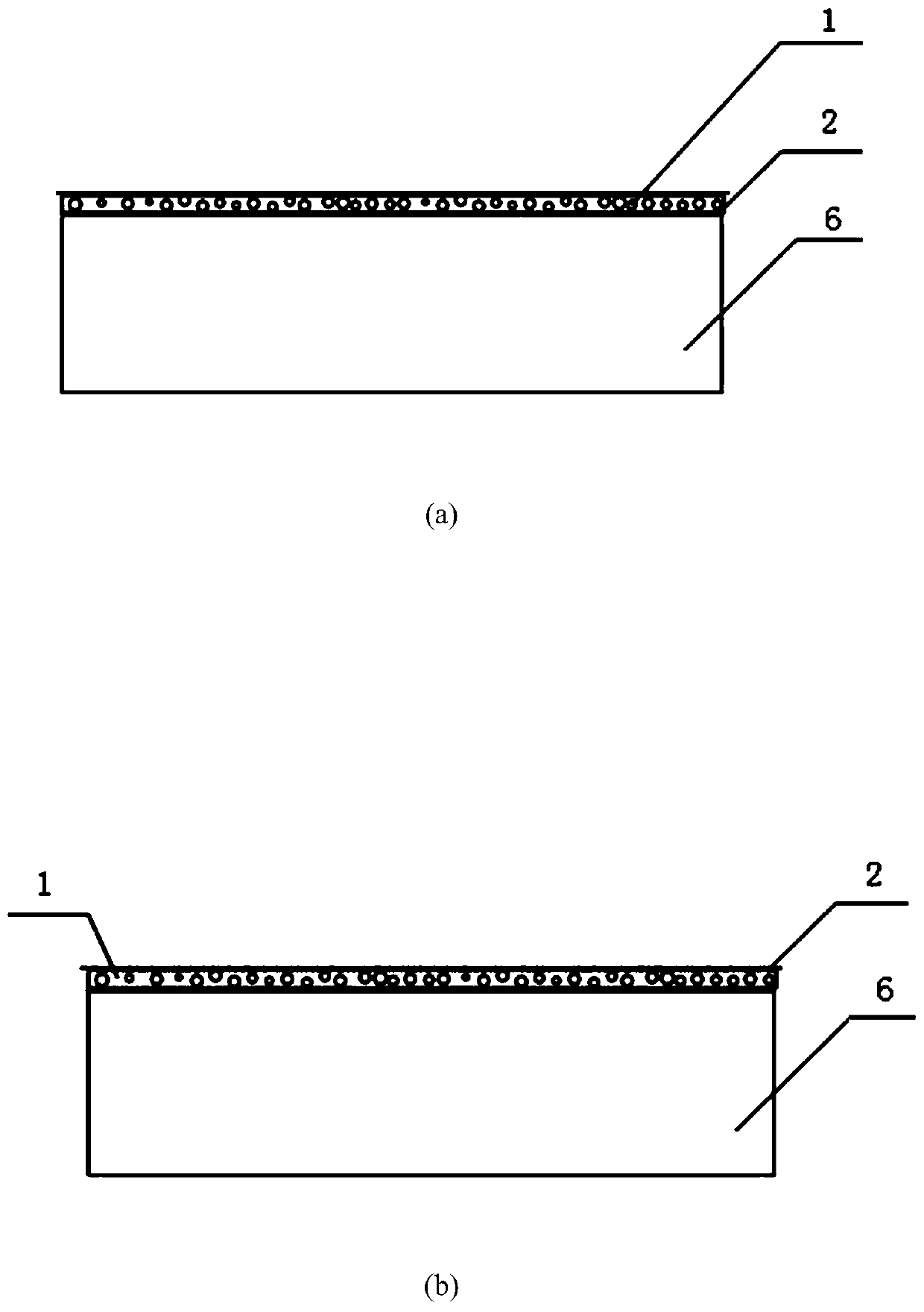

Multifunctional spectrum selective encapsulation material

ActiveCN105957912AImprove transmittanceHigh absorptivity/emissivityPhotovoltaic energy generationSemiconductor devicesPolyesterEmissivity

The invention relates to a multifunctional spectrum selective encapsulation material. The material comprises a substrate, and a black polyvinyl fluoride-polyester-polyvinyl fluoride (TPT) material layer, a photovoltaic cell and a spectrum selective composite material layer are sequentially arranged on one side of the substrate; and the spectrum selective composite material layer is compounded by a selective reflective film and a selective emission film. The transmittance of the spectrum selective composite material layer at the solar radiation band of 0.2-3mu m is more than 0.8, the emissivity at the ''atmospheric window'' band of 8-13mu m is more than 0.8, and the reflectivity at the band of more than 13mu m is more than 0.9. By adopting the material, electric energy and heat can be obtained by day via solar photovoltaic heating, and cold can also be obtained at night via radiation refrigeration, so that the limitations of traditional solar PV / T systems and radiation refrigeration devices are effectively solved.

Owner:UNIV OF SCI & TECH OF CHINA

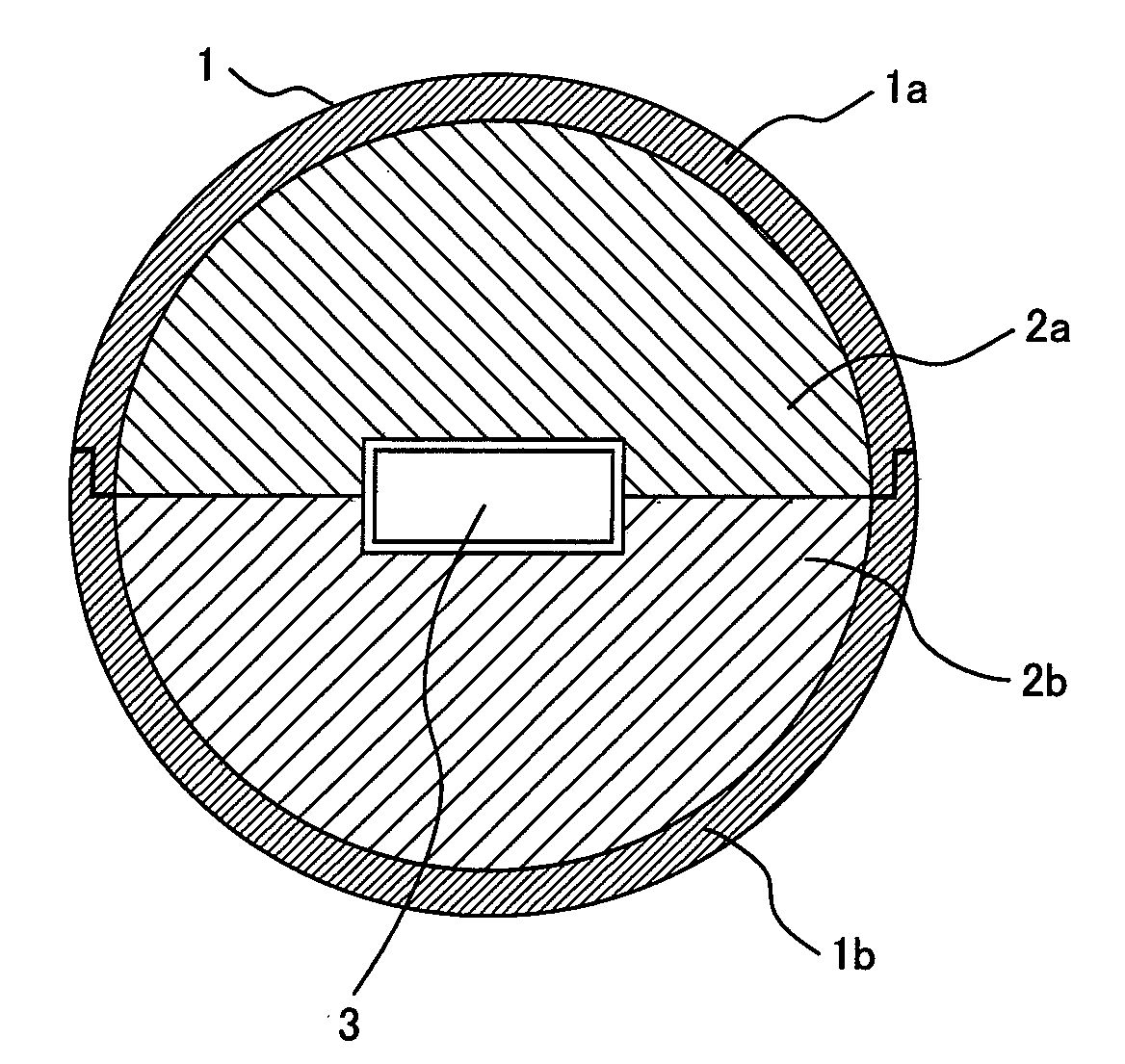

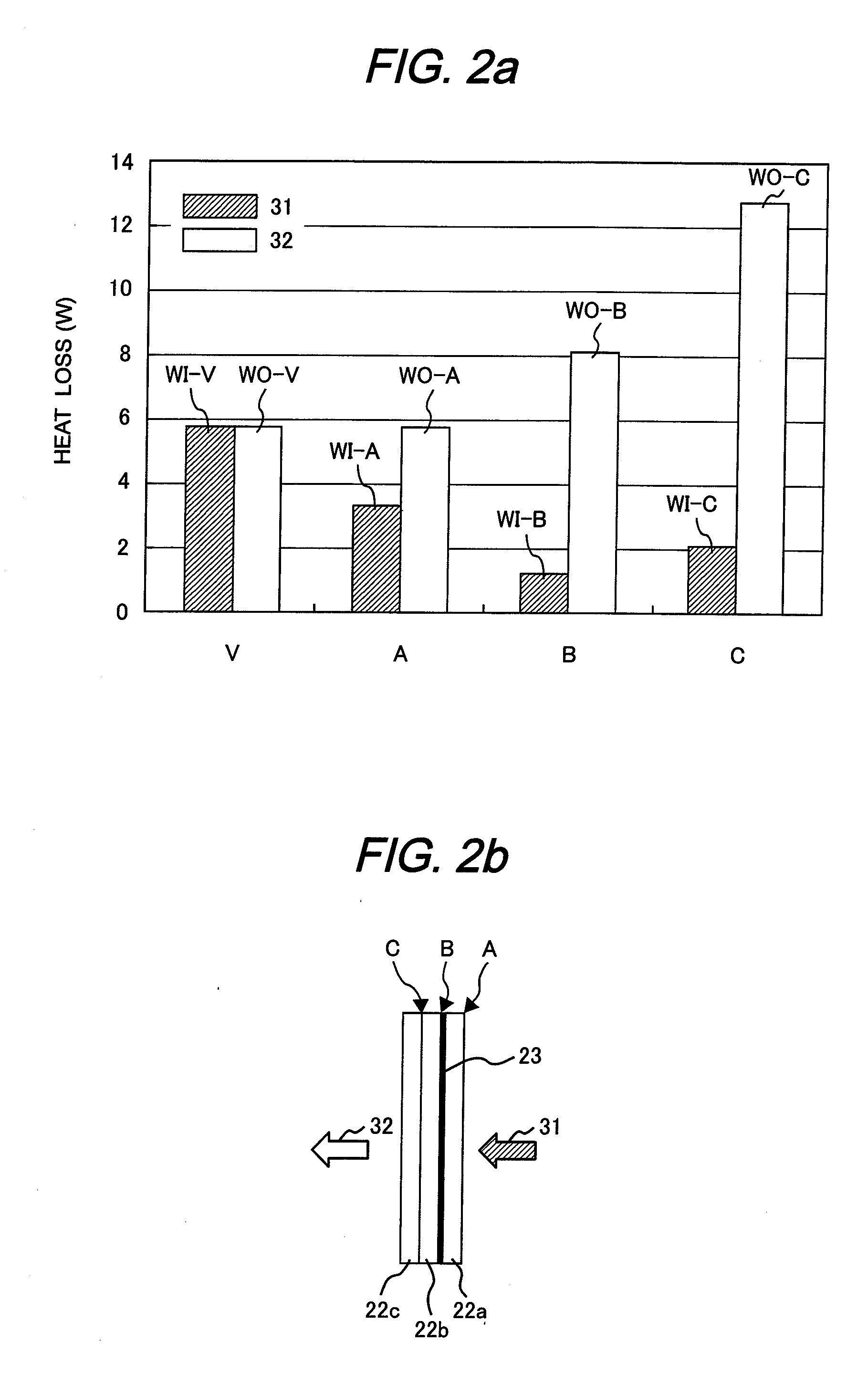

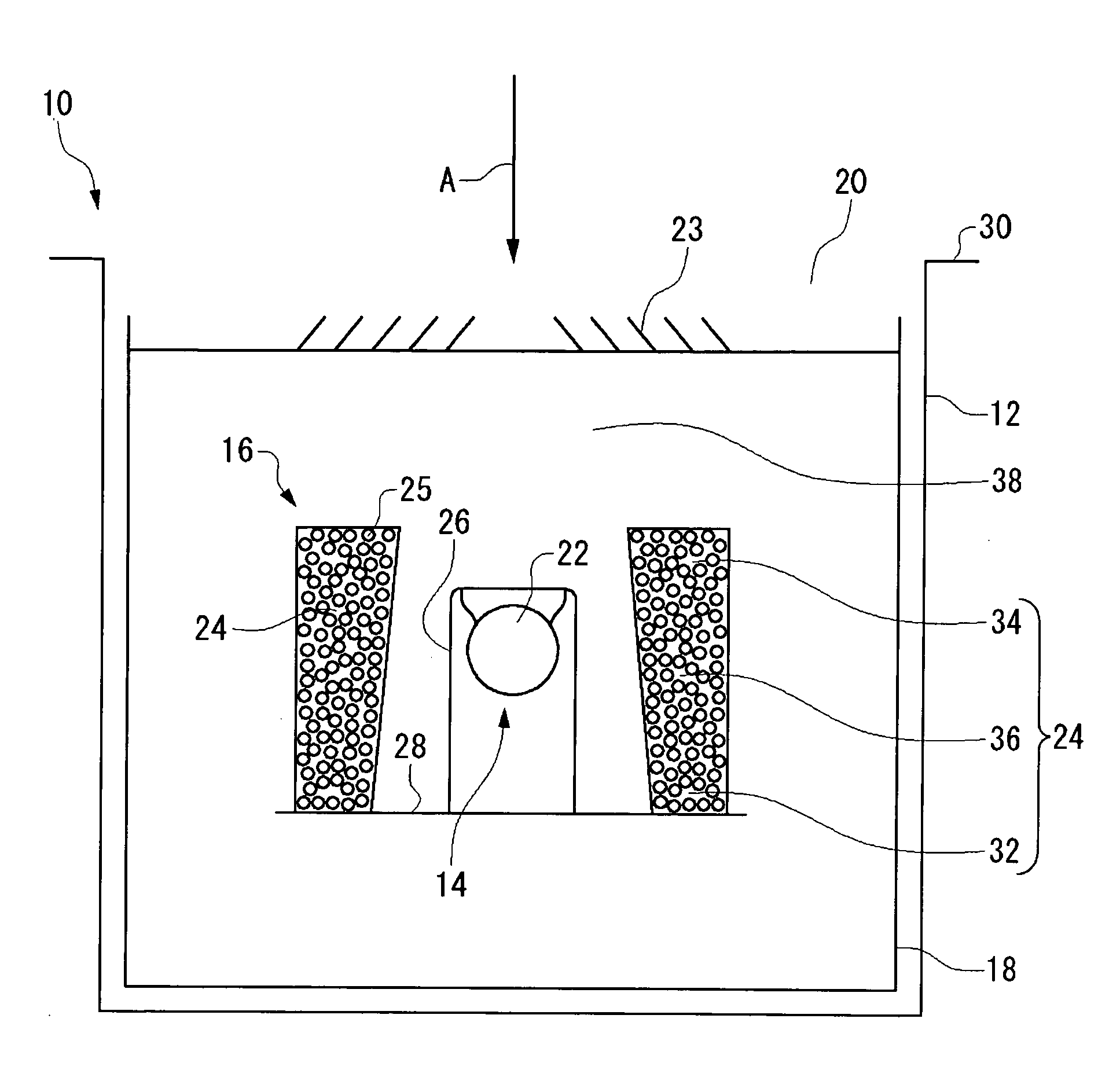

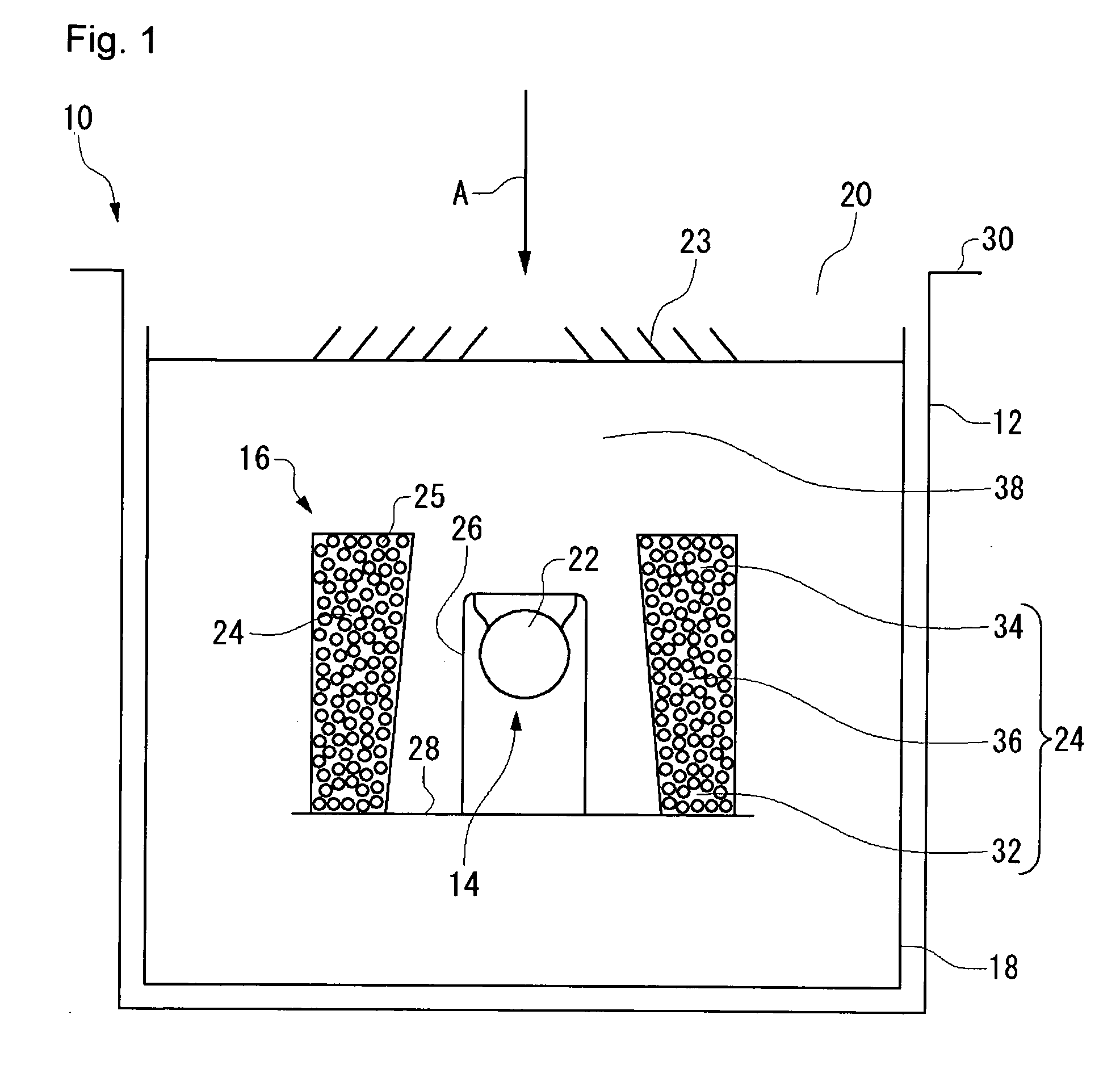

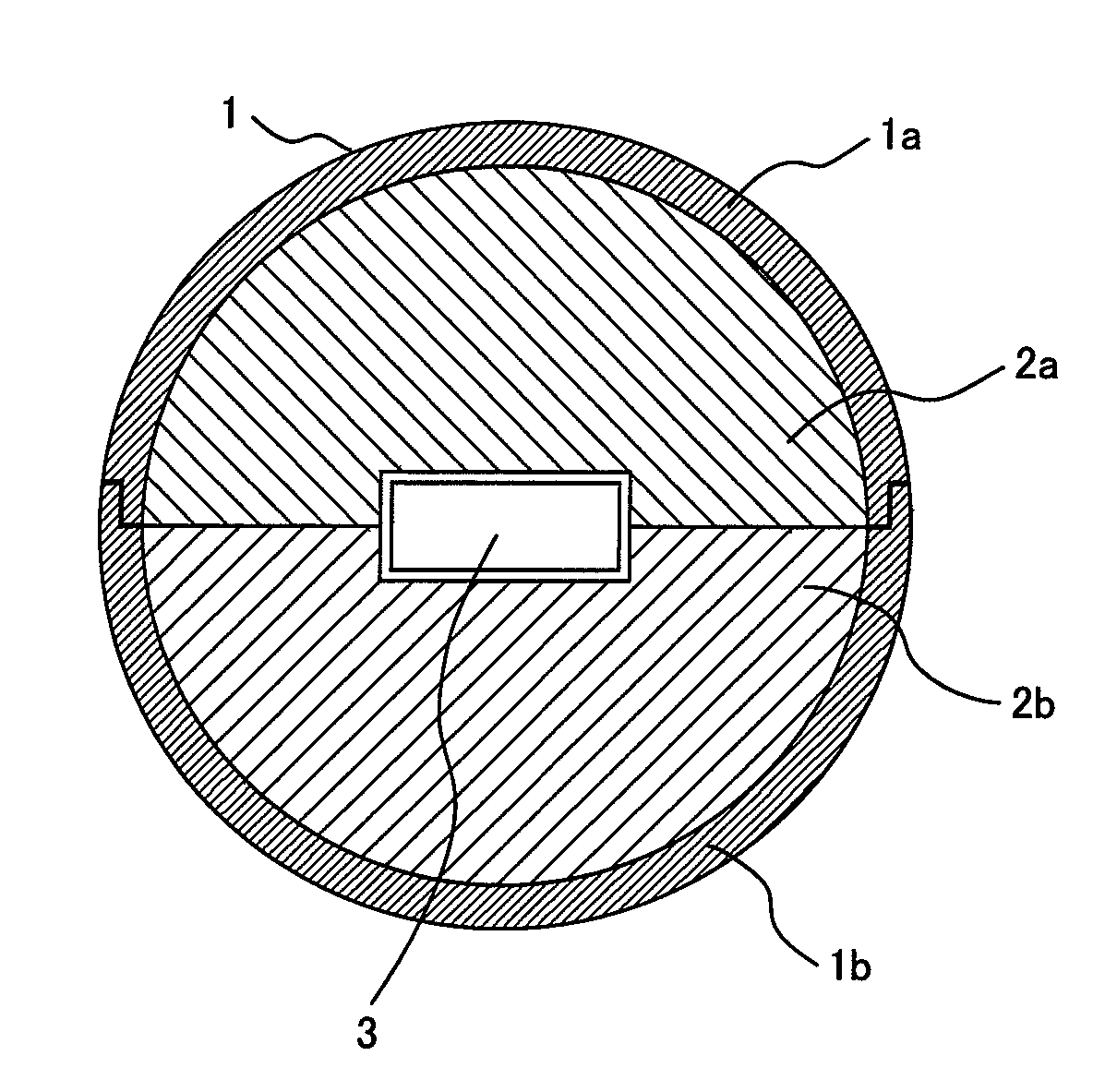

Transport container, transporting method for the same, and constant temperature transport container

InactiveUS20070245763A1Reduce heat radiation areaExtended retention timeDomestic cooling apparatusLighting and heating apparatusEngineeringSpherical form

Owner:HITACHI LTD

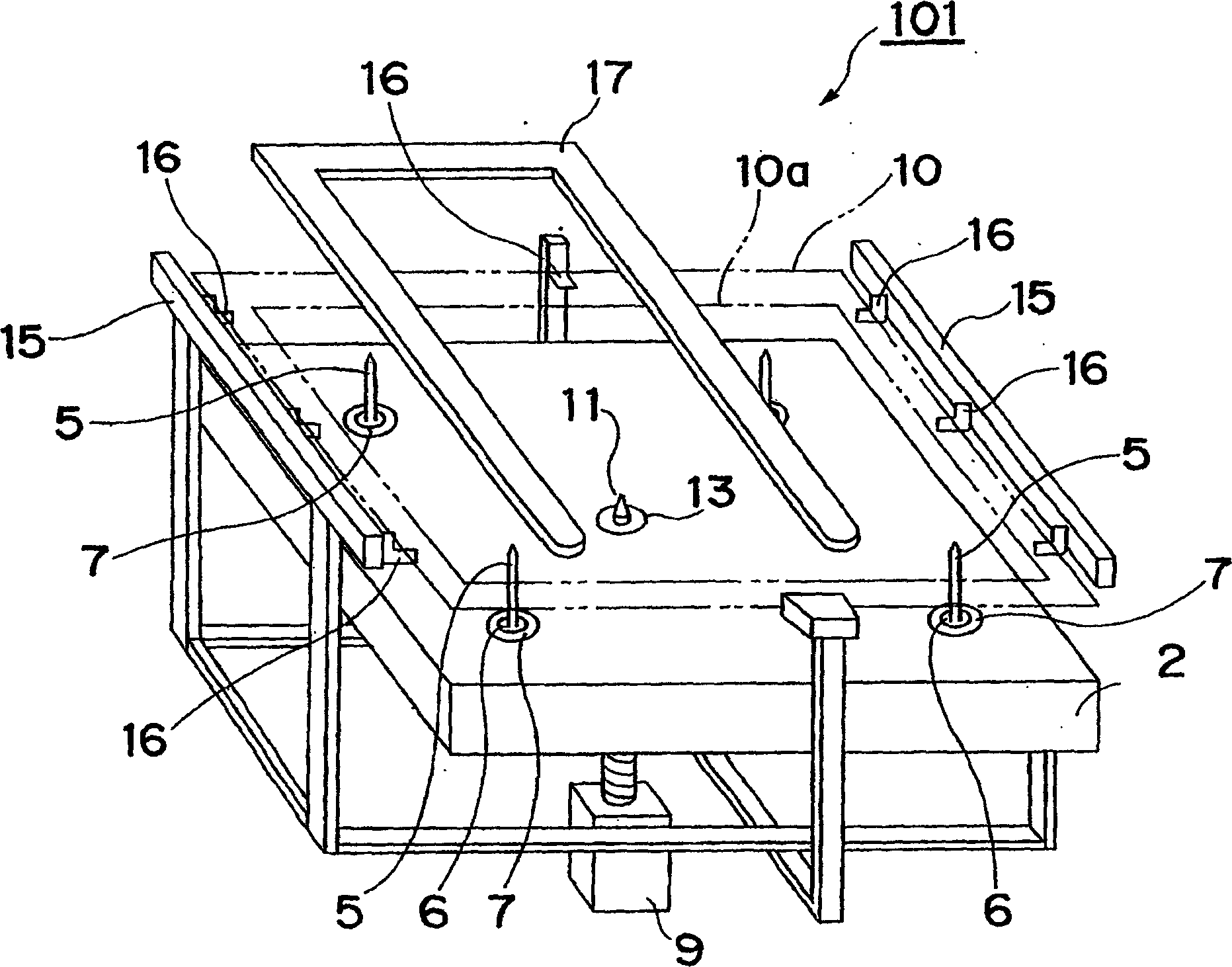

Cryopump and evacuation method

ActiveUS20090165469A1Improve pump performanceEliminate the effects ofSolidificationLiquefactionPump chamberEngineering

A cryopump includes: a cryopump chamber having an inlet port through which a gas to be pumped is introduced; a refrigerator provided with a second cooling stage provided in the cryopump chamber; an intermediate member thermally coupled to the second cooling stage; and a cryopanel having a connecting part connected to the intermediate member at a position farther from the inlet port in the direction in which the gas is introduced than the second cooling stage, and extending from the connecting part toward the inlet port. For example, a cryopump having a suspended panel structure is provided.

Owner:SUMITOMO HEAVY IND LTD

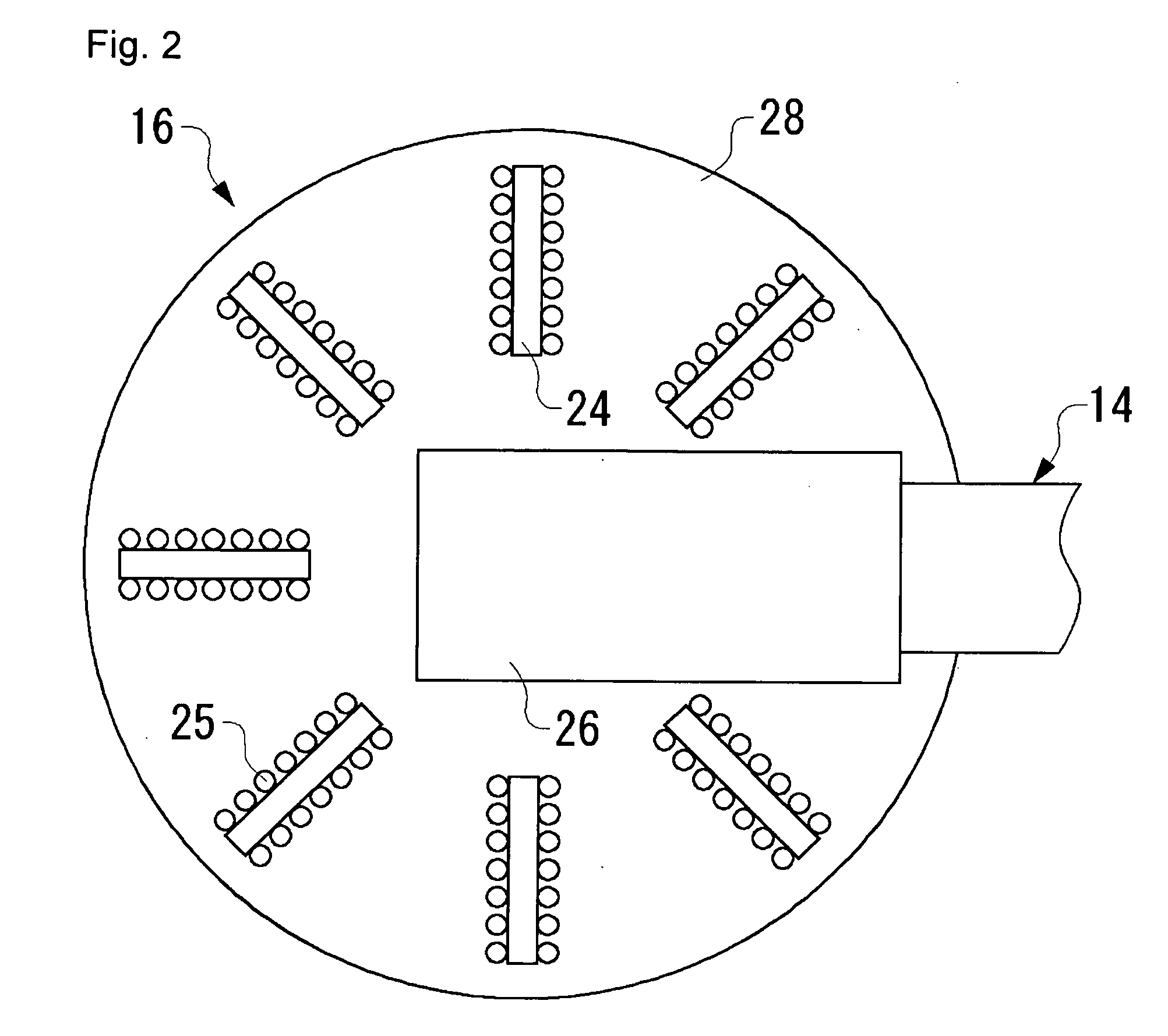

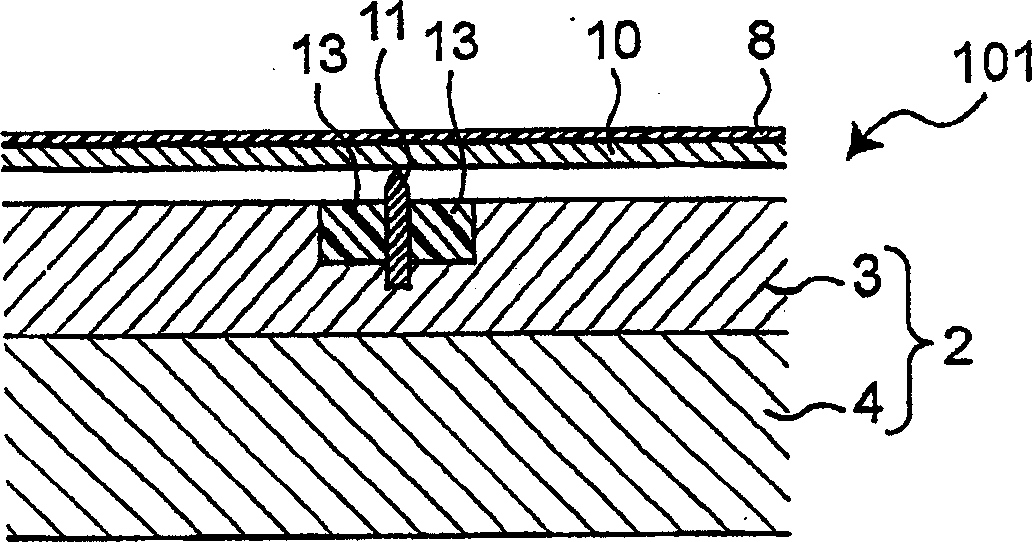

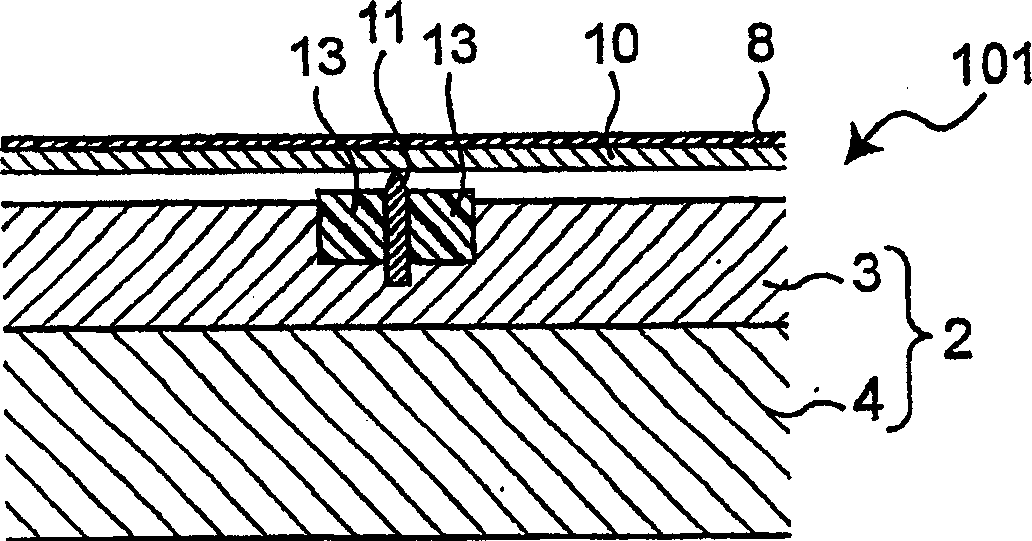

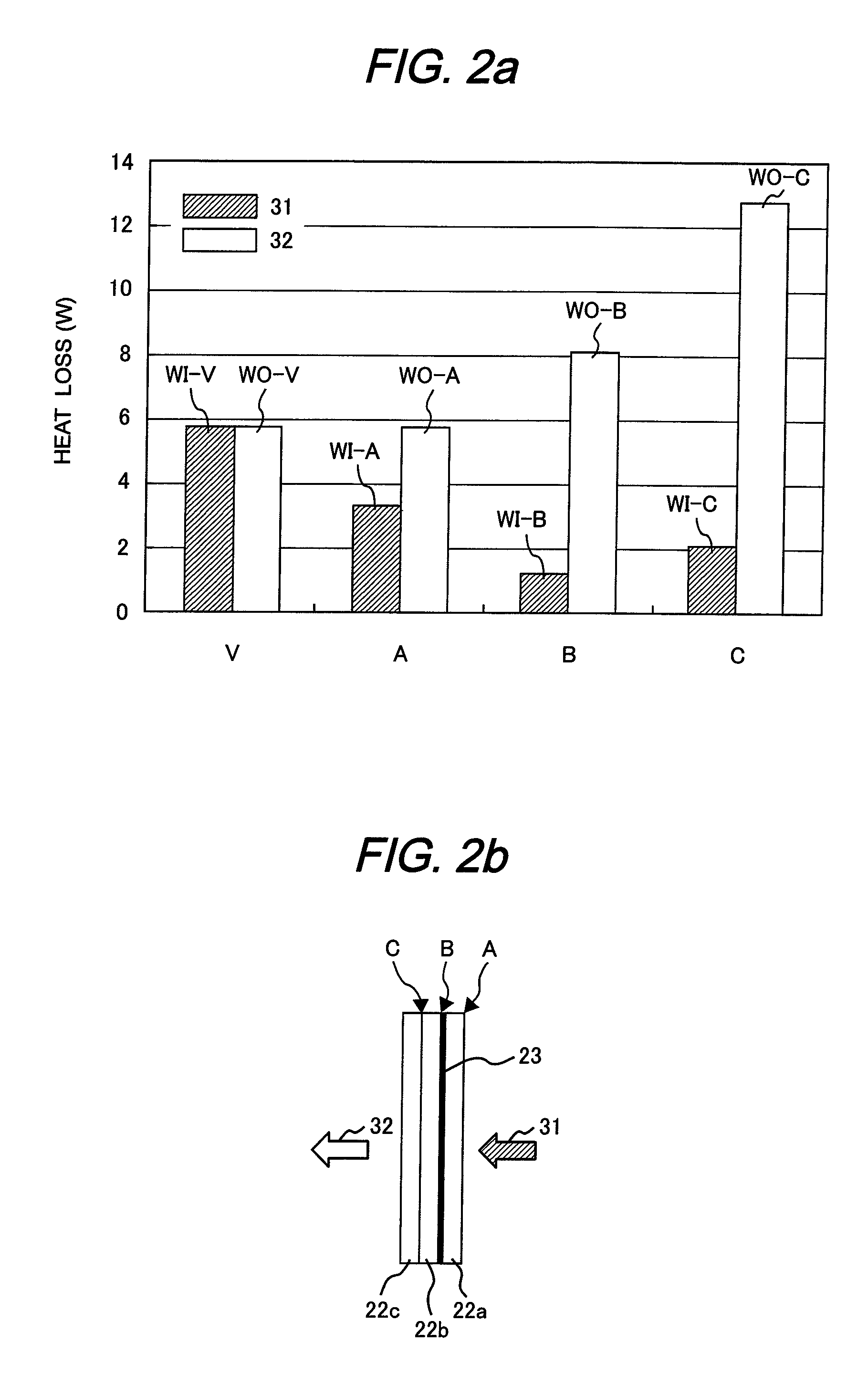

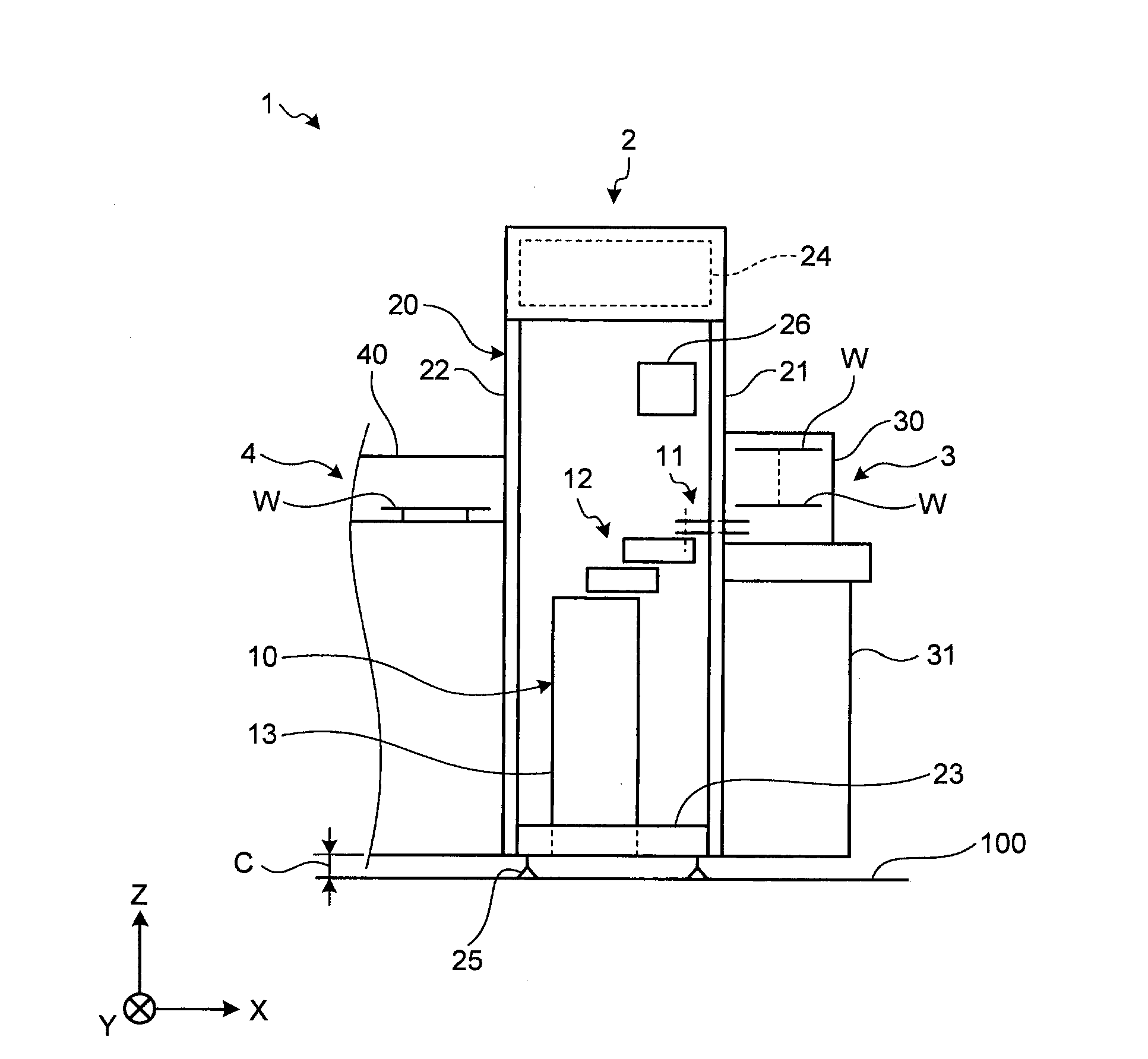

Heating apparatus

InactiveCN1745332AHeating evenlyAchieve homogenizationSemiconductor/solid-state device manufacturingHot plates heating arrangementsRadiant heatRadiant heating

A heating apparatus (101), comprising a hot plate (2) heating a heated substrate (10) by radiation, lift pins (5) liftably disposed in through-holes (6) formed in the hot plate and lifting the heated substrate, and a proximity pin (11) fixed to the hot plate and holding the heated substrate so as to be separated from the hot plate while the heated substrate is heated. Heat reducing parts (13, 7) reducing radiant heat are installed in the hot plate around the proximity pin or around the through-holes.

Owner:NISSHA PRINTING COMPANY

Transport container, transporting method for the same, and constant temperature transport container

InactiveUS7954661B2Improve accuracyReduce radiant heatDomestic cooling apparatusLighting and heating apparatusShipping container

Owner:HITACHI LTD

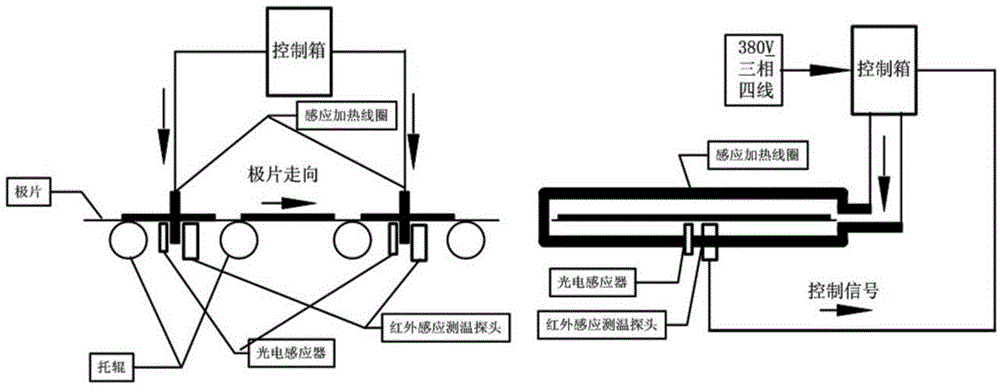

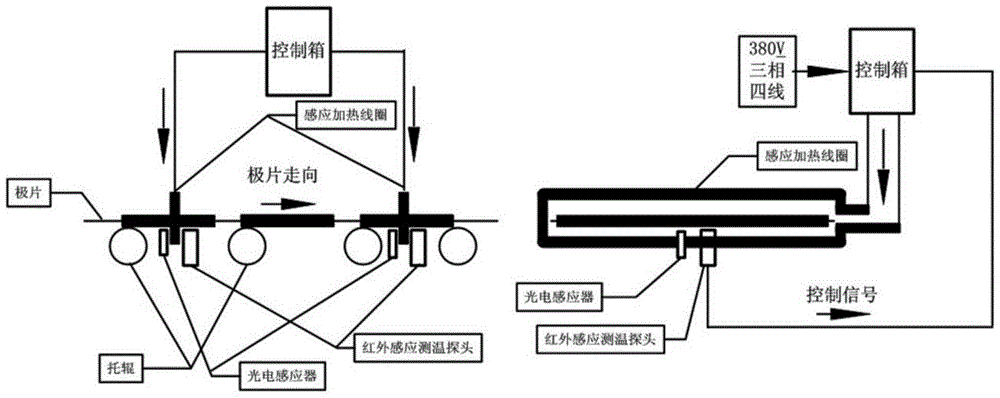

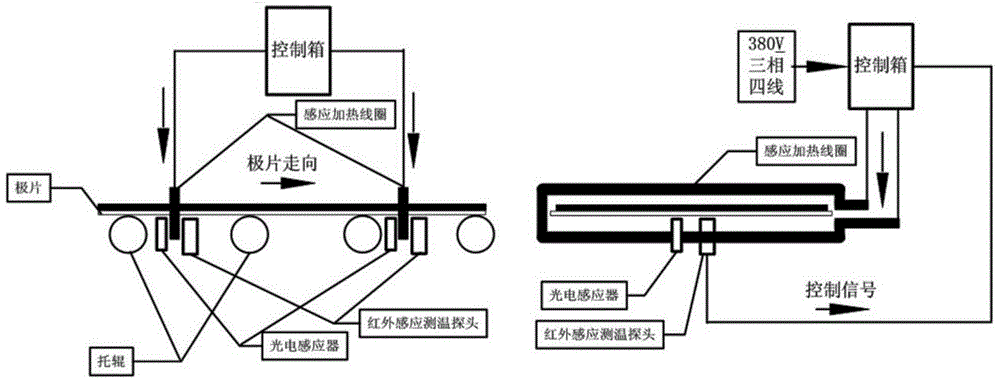

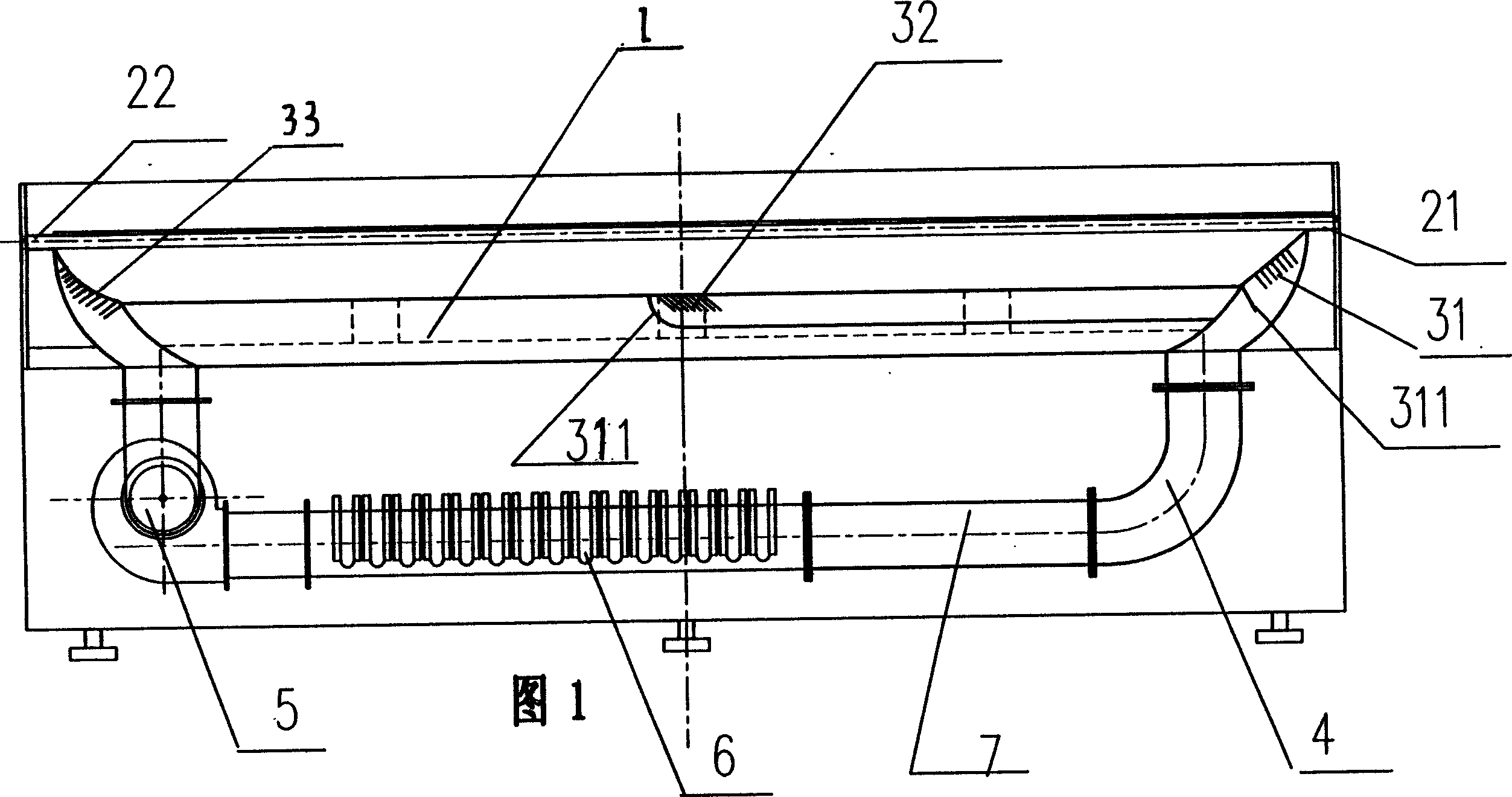

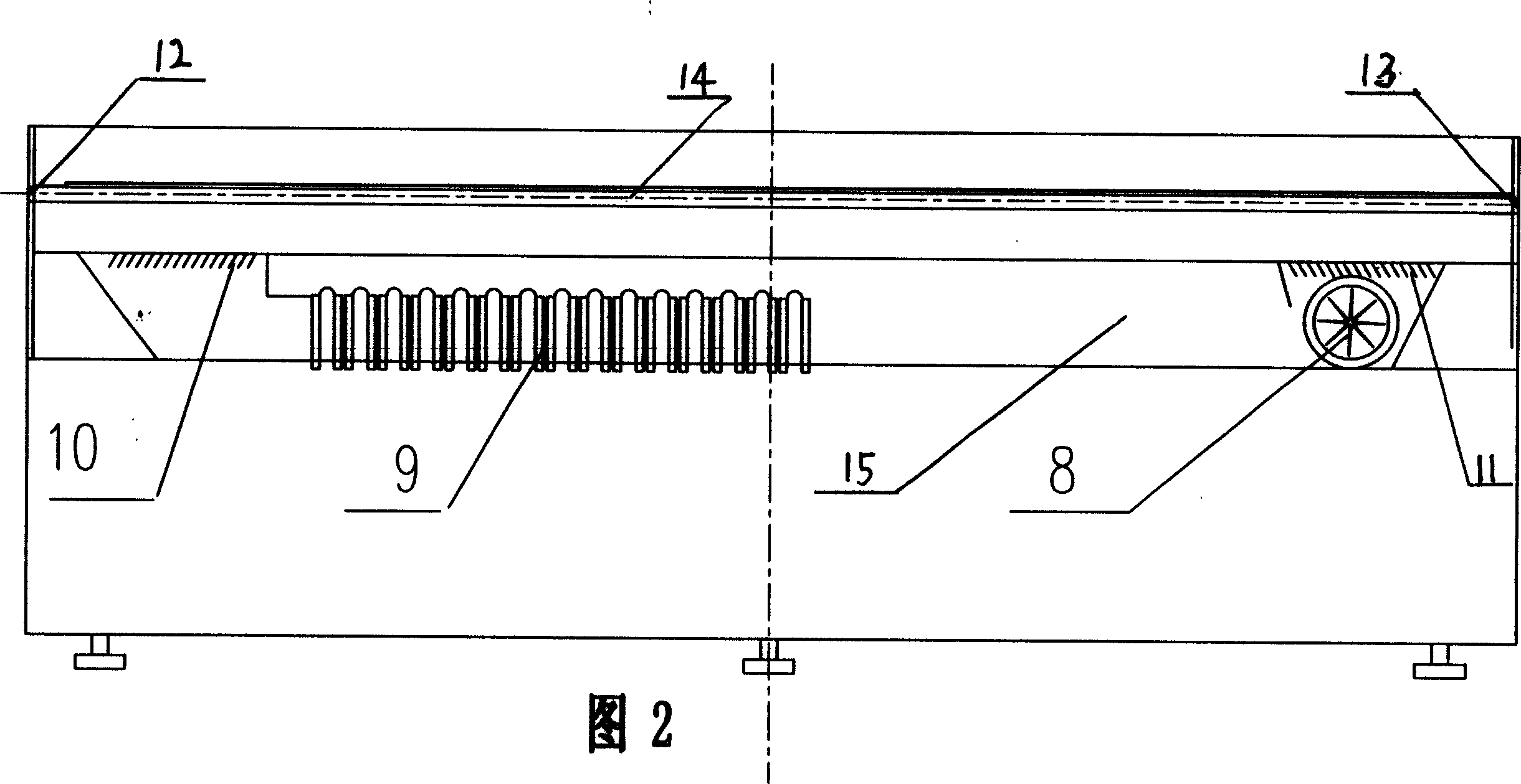

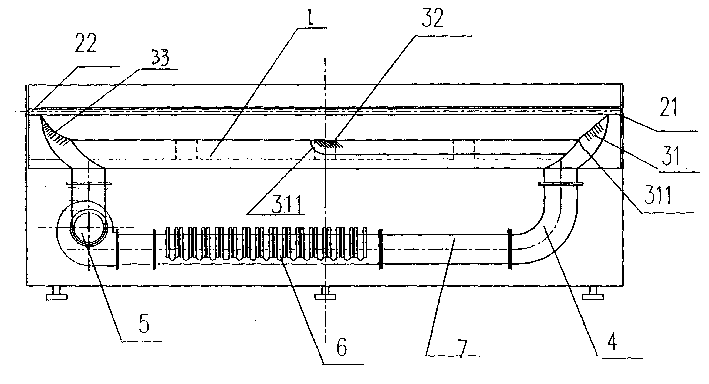

Drying method and drying device for pole pieces in pole piece plating process of lithium battery

InactiveCN105149186AReduce energy consumptionReduce radiant heatPretreated surfacesCoatingsSelf inductionSolvent

The invention relates to a new pole piece heating drying manner in a pole piece plating process of a lithium battery in a lithium ion power battery production process. According to the driving method and the driving device, electrode slurry plating on the pole pieces is finished through an induction heating coil on which intermediate-frequency AC power or high-frequency AC power is applied. The heating drying manner belongs to self-induction heating of a metal material. Heating of circulation air or heating to an overhigh temperature is not required, and therefore the drying device does not radiate a large amount of heat to an external environment, thereby realizing high heat efficiency. Furthermore energy consumption in a heating process and a cooling process for a large amount of circulation air is greatly reduced. Additionally, energy consumption in eliminating a solvent which is carried in the circulation air is reduced. The heating manner makes an overall thermal efficiency higher than 90%. Because a metal foil self-induction heating is adopted, the slurry which is plated on a substrate is dried from inside to outside, and micro channels which improve battery performance can be formed in the coated material.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

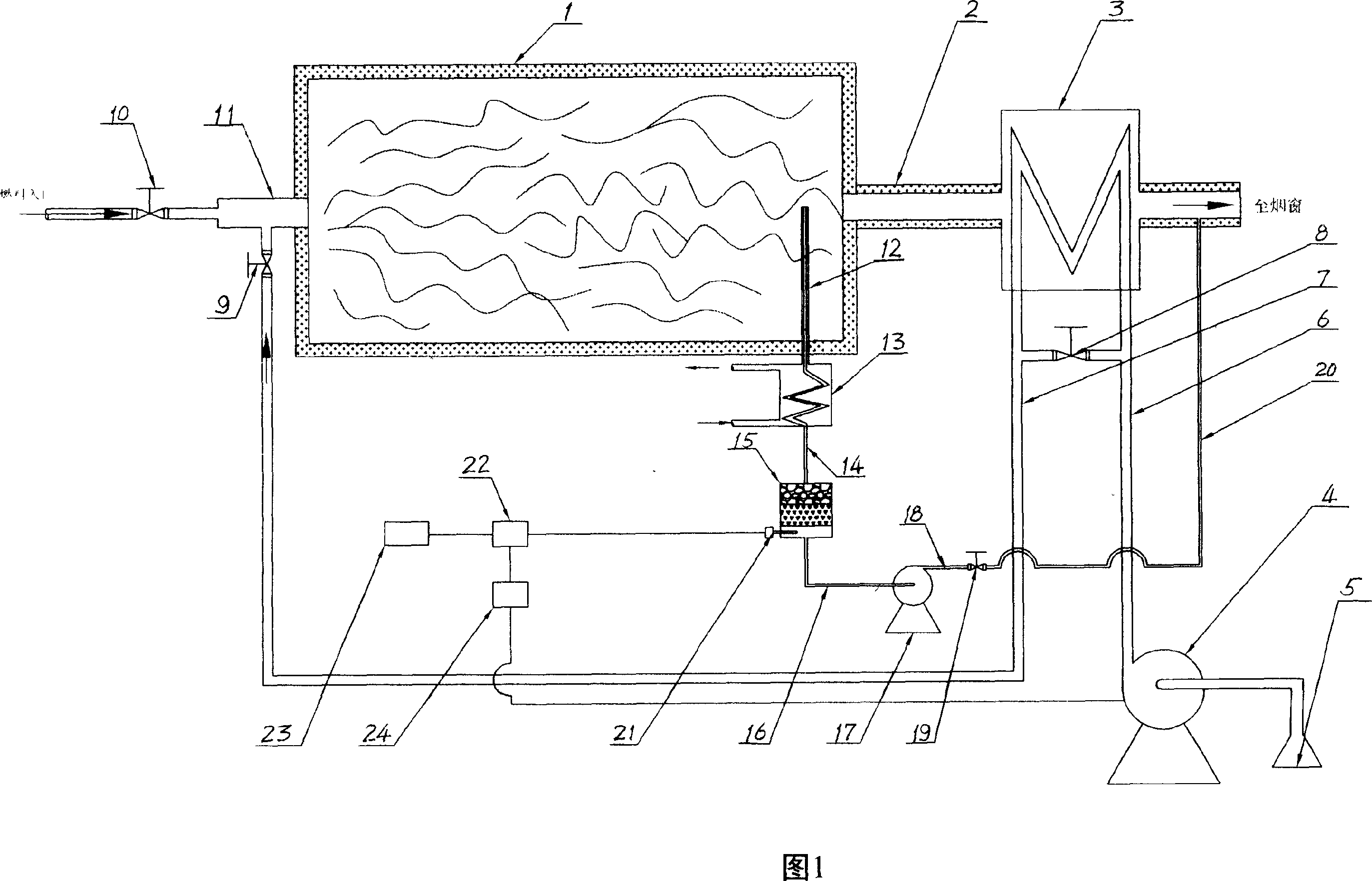

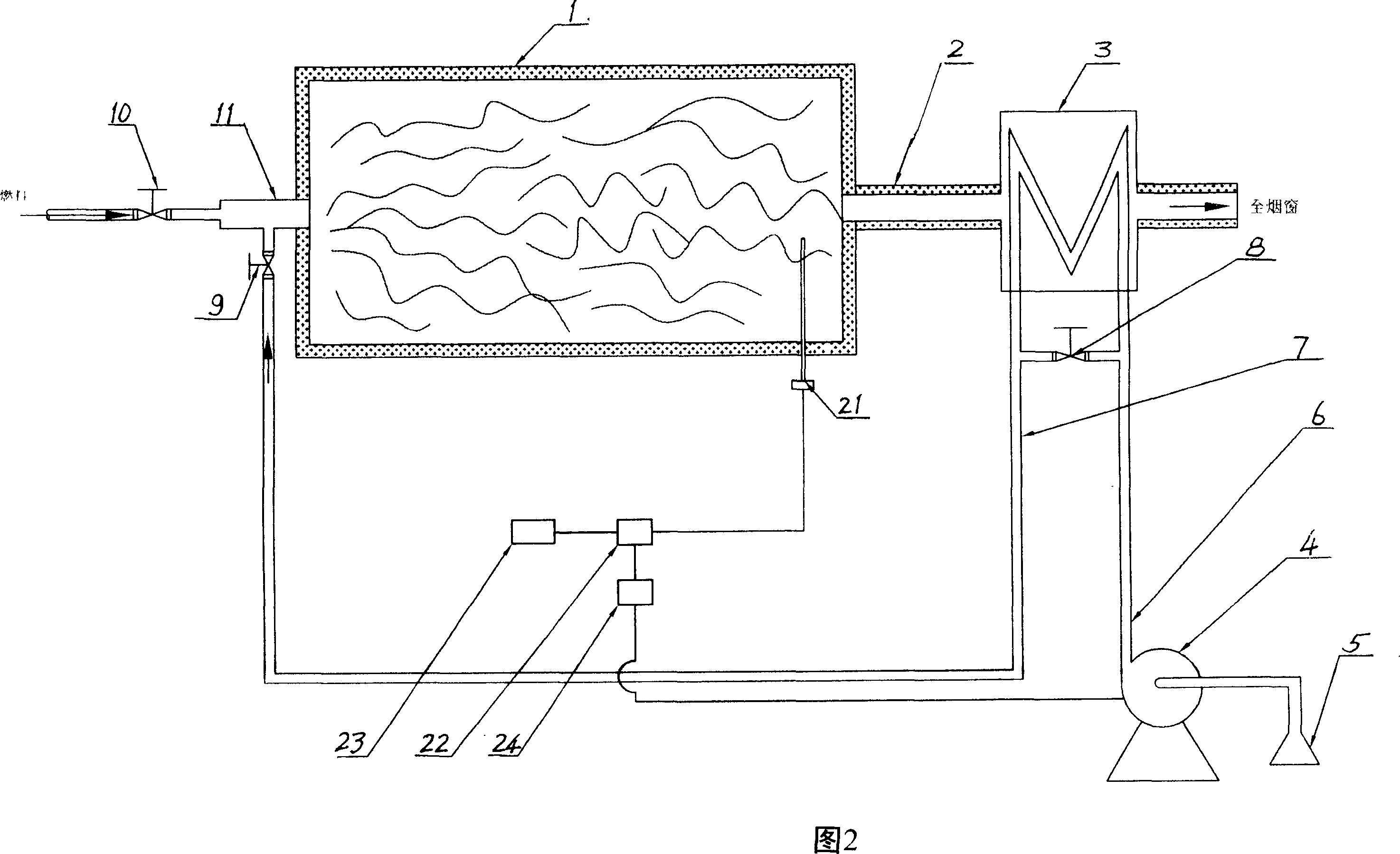

Combustion quality analysis and control system for industrial kiln

InactiveCN101055090AEnsure complete combustionReduce oxidation burnCombustion regulationAir blastCarbon monoxide

The invention discloses a burning quality analysis and control system used for industrial stoves such as heating furnace, hot blast stove, boiler. Sampling pipe disposed at tail of the stove or in flue transfers sampled flue gas to purifying sampling chamber after the flue gas has been cooled, and oxygen sensor detects oxygen content value of the flue gas. As the oxygen content value of the flue gas in stove exceeds the predetermined value, i.e. excessive air distribution, the oxygen transmits the signal to a controller for comparing, operating or processing, and then transmits the processed signal to speed governor to reduce the rotation speed of blower group, i.e. air reduction, until air amount is appropriate; contrarily, if the oxygen content value of the flue gas in stove, detected by the oxygen sensor, is lower than the predetermined value, i.e. lacking air distribution, the speed governor will increase the rotation speed of the blower group, i.e. air increase, until air amount is appropriate, thereby, keeping the air consumption system of the stove in region of 1.0 to 1.1. The analysis and control system can not only improve burning quality of the industrial stove thereby providing economic benefit for user, but can also greatly reduce the emission of nitrogen oxides or carbon monoxide, therefore, has great popularization value.

Owner:夏学苏

Water-borne architectural color coating with light reflection function and preparation method of coating

ActiveCN104861805AImprove reflectivityReduce radiant heatReflecting/signal paintsMicrosphereAir conditioning

The invention relates to a water-borne architectural color coating with a light reflection function. The water-borne architectural color coating is characterized by comprising the following components: elastic acrylic latex, rutile titanium dioxide, crystal form infrared reflection titanium dioxide, white carbon black, a hollow microsphere emulsion, mica powder, kaolin, talc, calcium carbonate, a dispersing agent, a wetting agent, an antifoaming agent, an anticorrosive agent, a mould inhibitor, a pH regulator, a coalescing agent, an antifreezing agent, a thickener, a leveling agent, an organic pigment and an inorganic pigment, wherein the hollow microsphere emulsion adopts a modified acrylate organic polymer as the sphere wall and is hollow inside. The water-borne architectural color coating with the light reflection function is used for coating an external wall of a building, can effectively reduce the surface temperature of the building so as to save air conditioning energy consumption, and can be used in areas with hot summer; a product can meet the requirement of customers for different colors, the energy-saving effect is obvious, energy saving and attractiveness are realized, and the water-borne architectural color coating has outstanding essence characteristics and significant progress compared with the coating only adopting white color or other light colors in the prior art.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

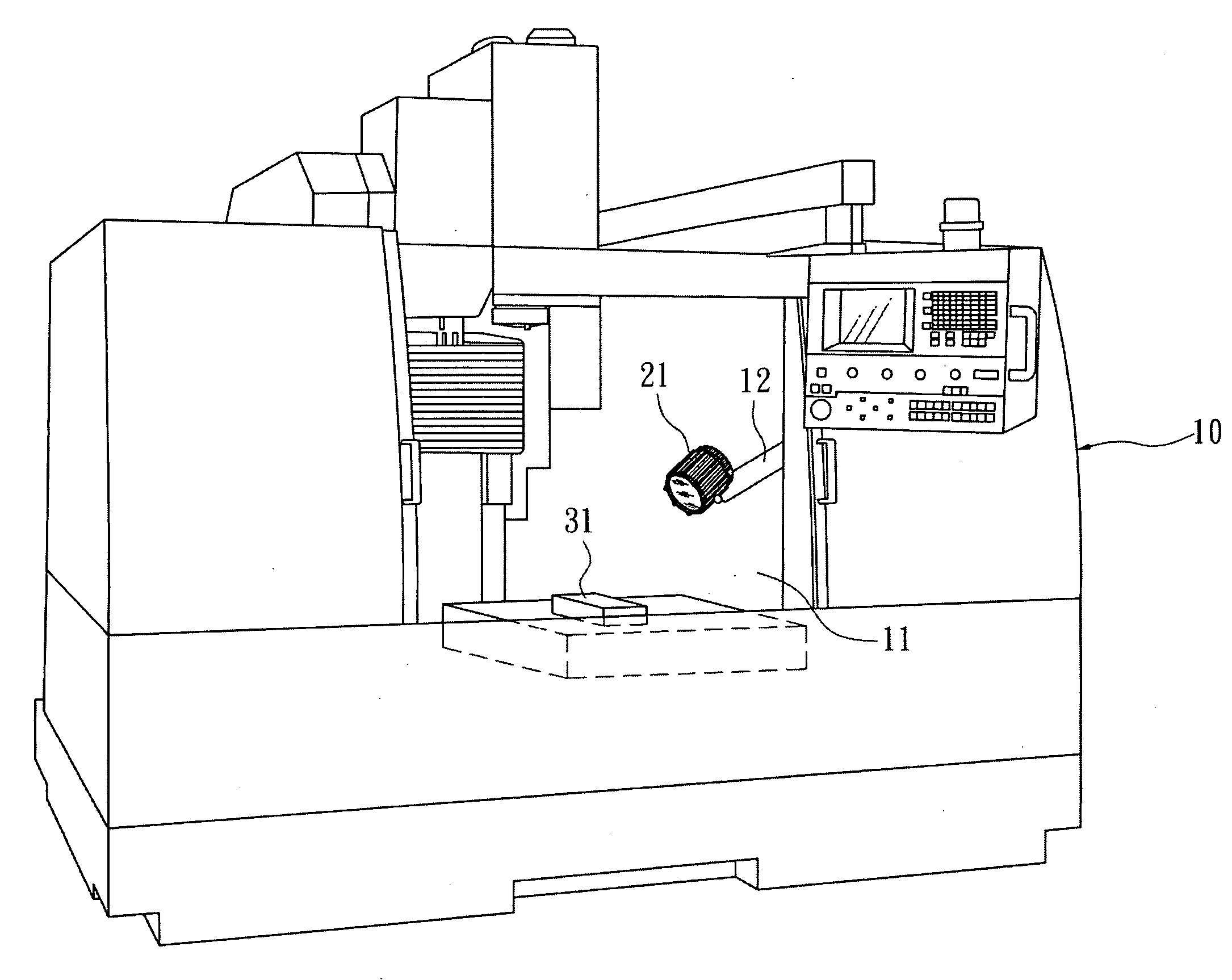

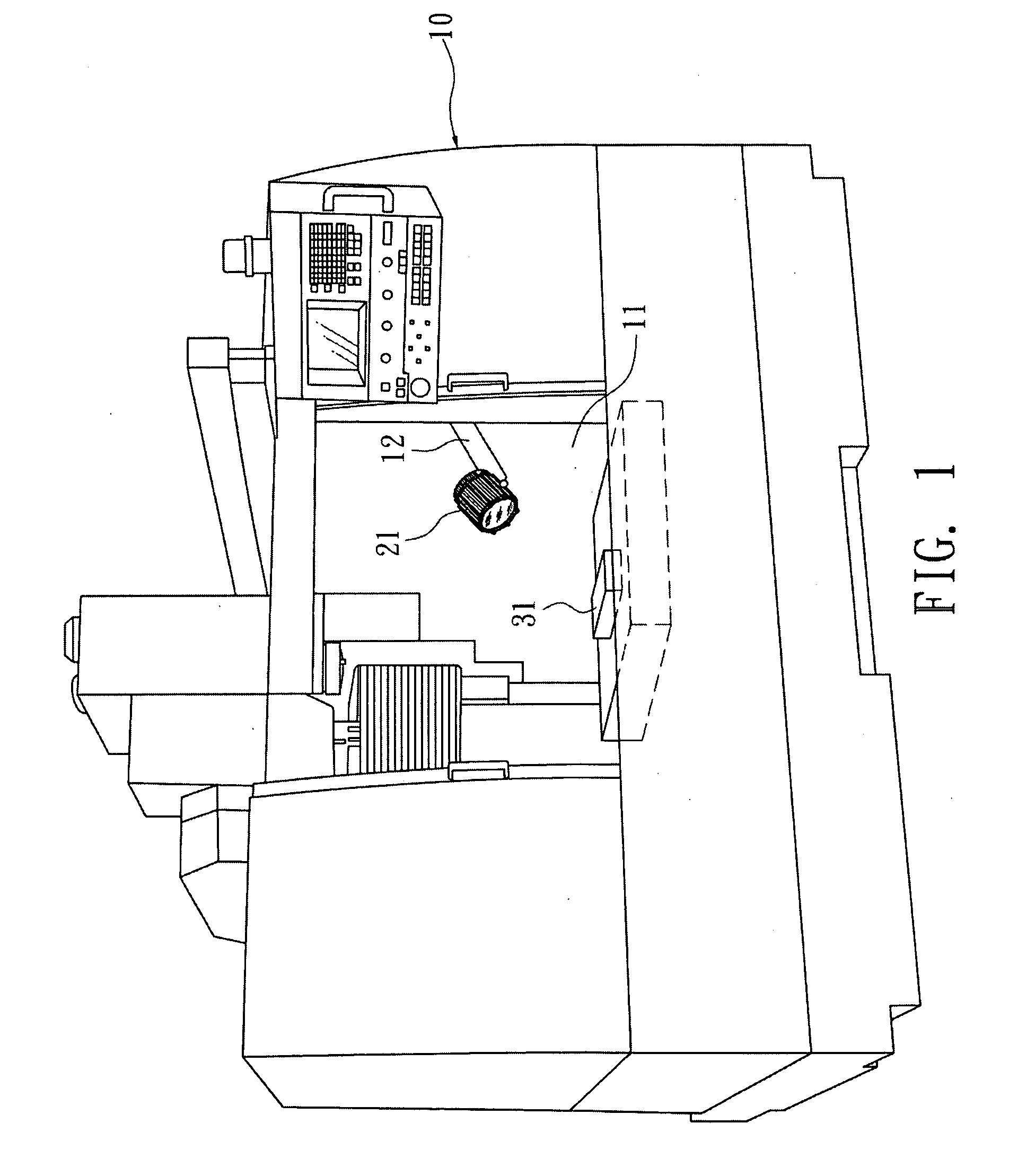

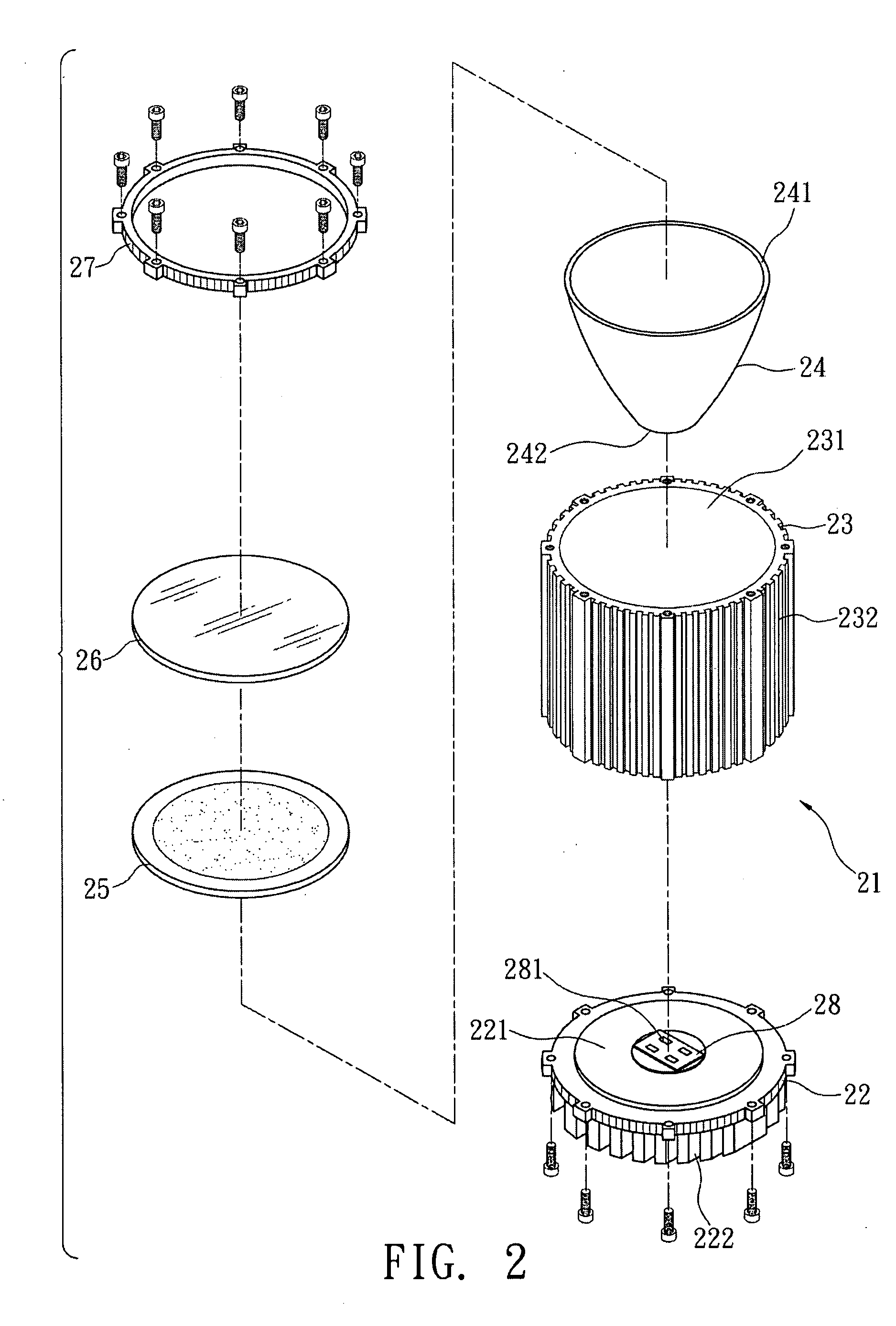

Illuminating Device For Tools

InactiveUS20100085730A1Reduce radiant heatAvoid radiating heatLighting applicationsMechanical apparatusEngineeringSingle lead

An illuminating device for machining tools is disclosed. A machining tool is installed with an illuminating device that uses a single LED prepared using the multi chip single module technique to provide high-power light. This elongates the lifetime of the illuminating device and has the advantages of power-saving and low temperature. The light thus produced does not have UV and IR components. In addition to no radiation injury to human bodies, the invention also avoids overlapped shadows in the case of multiple LED sources. Such a design of the cold and single light source can effectively bad influences on the precision of objects 31 being processed.

Owner:AVEX SG TECH +2

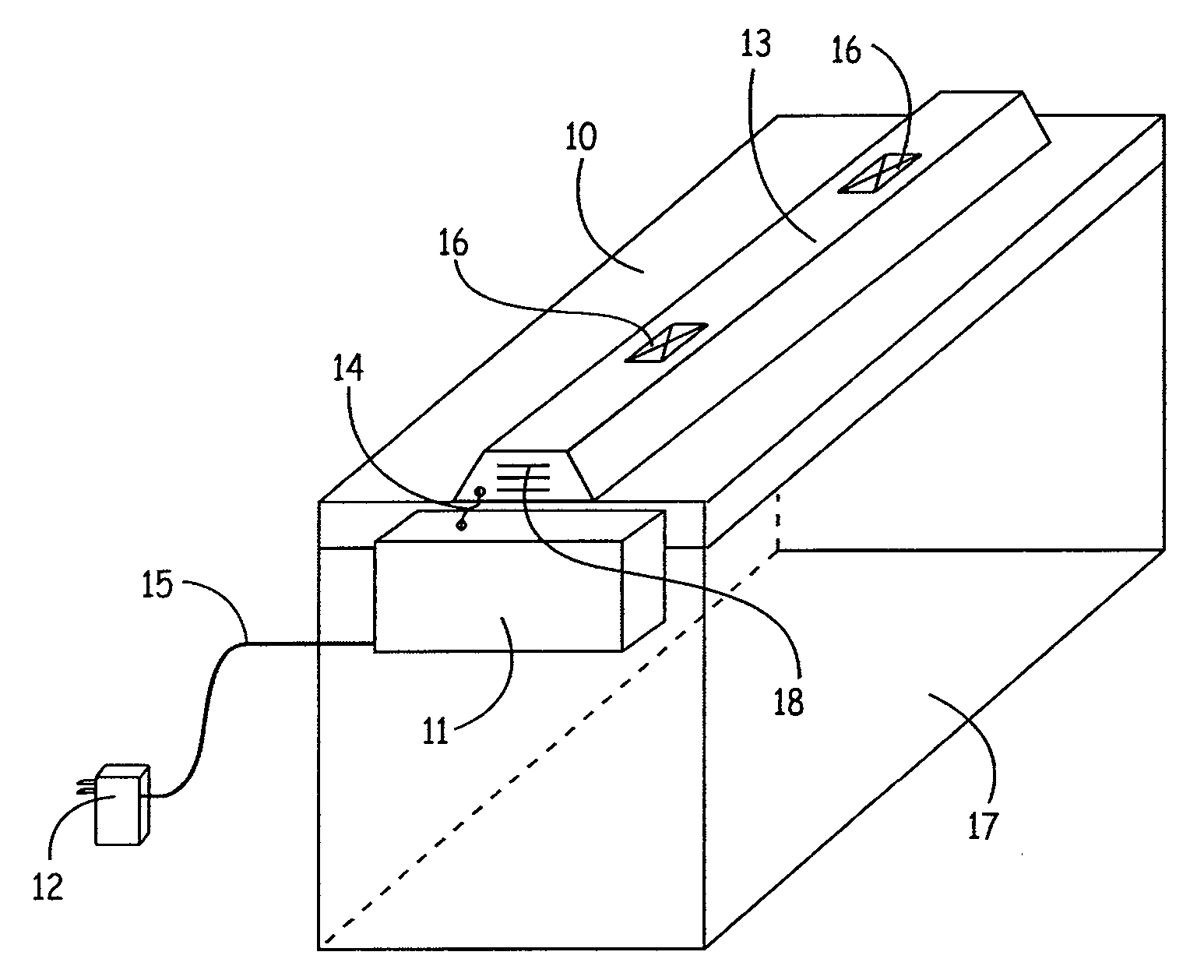

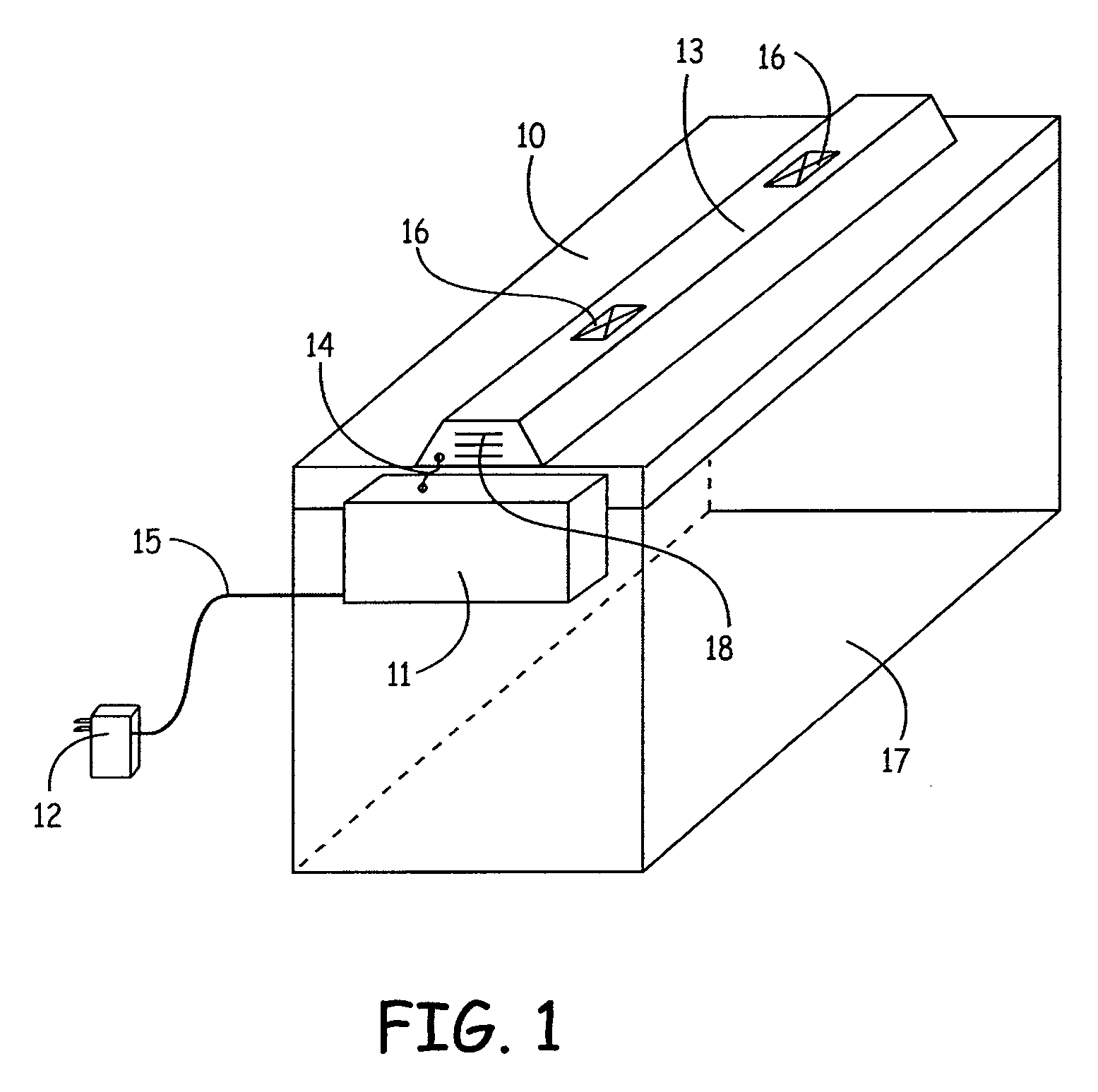

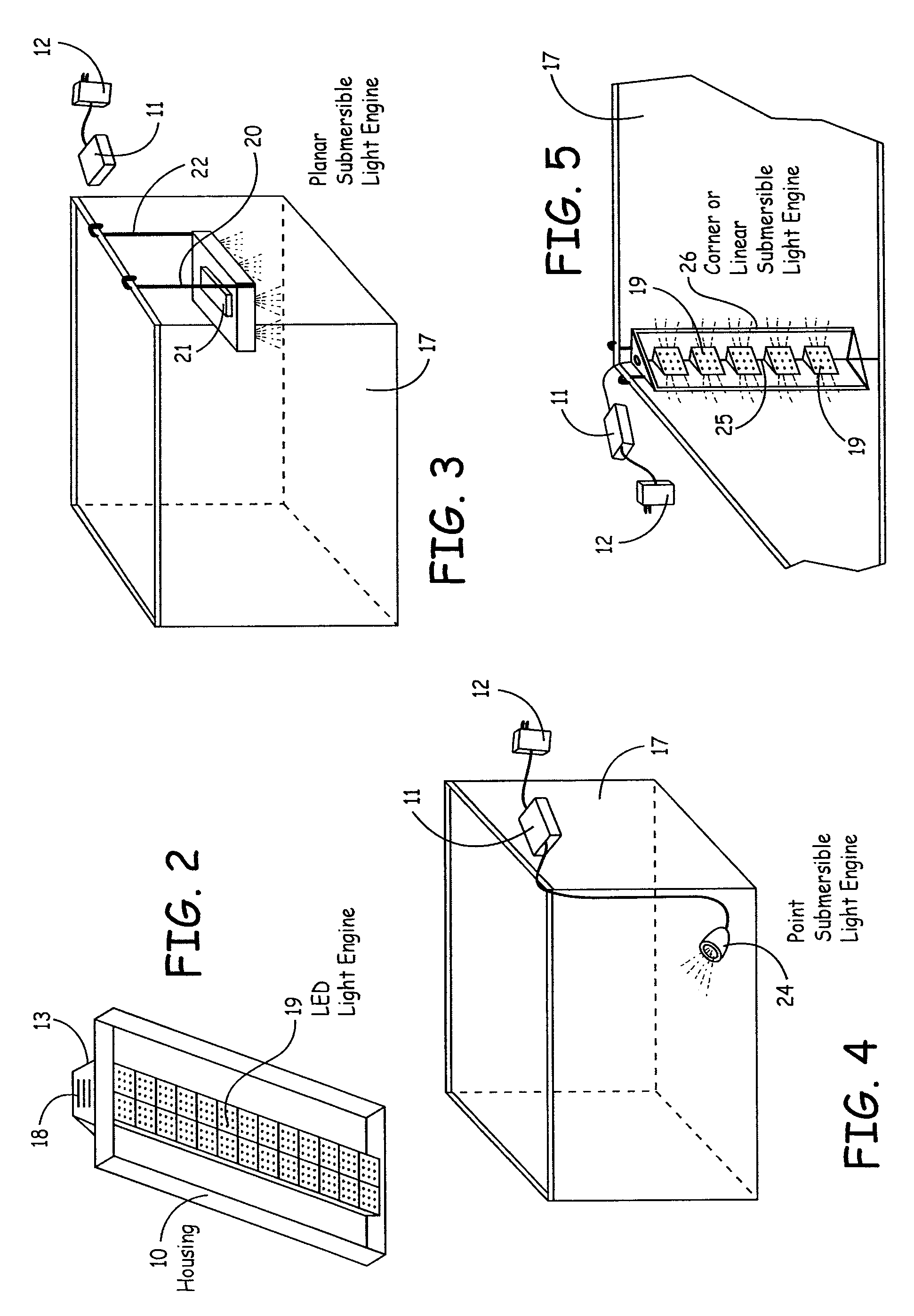

Marine LED Lighting System and Method

InactiveUS20070268693A1High outputIncrease light intensityElectrical apparatusLighting elementsMarine habitatsEngineering

A method and apparatus of lighting a marine habitat for growth utilizing an LED light system. The light system includes an LED light source, a power supply for such light source and a controller for controlling the activation status and the intensity of the LED light source.

Owner:SIERRA NEVADA CO LLC

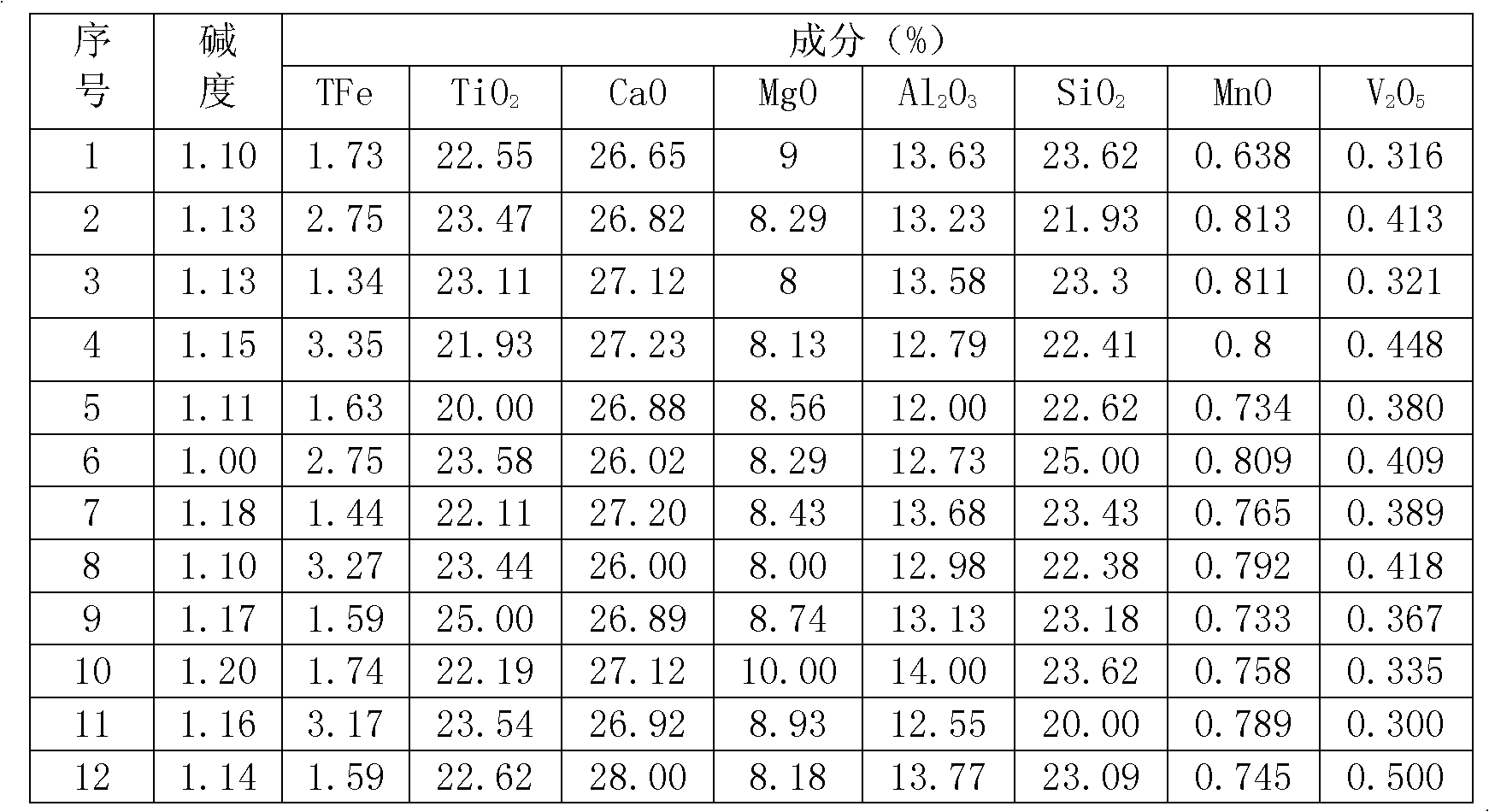

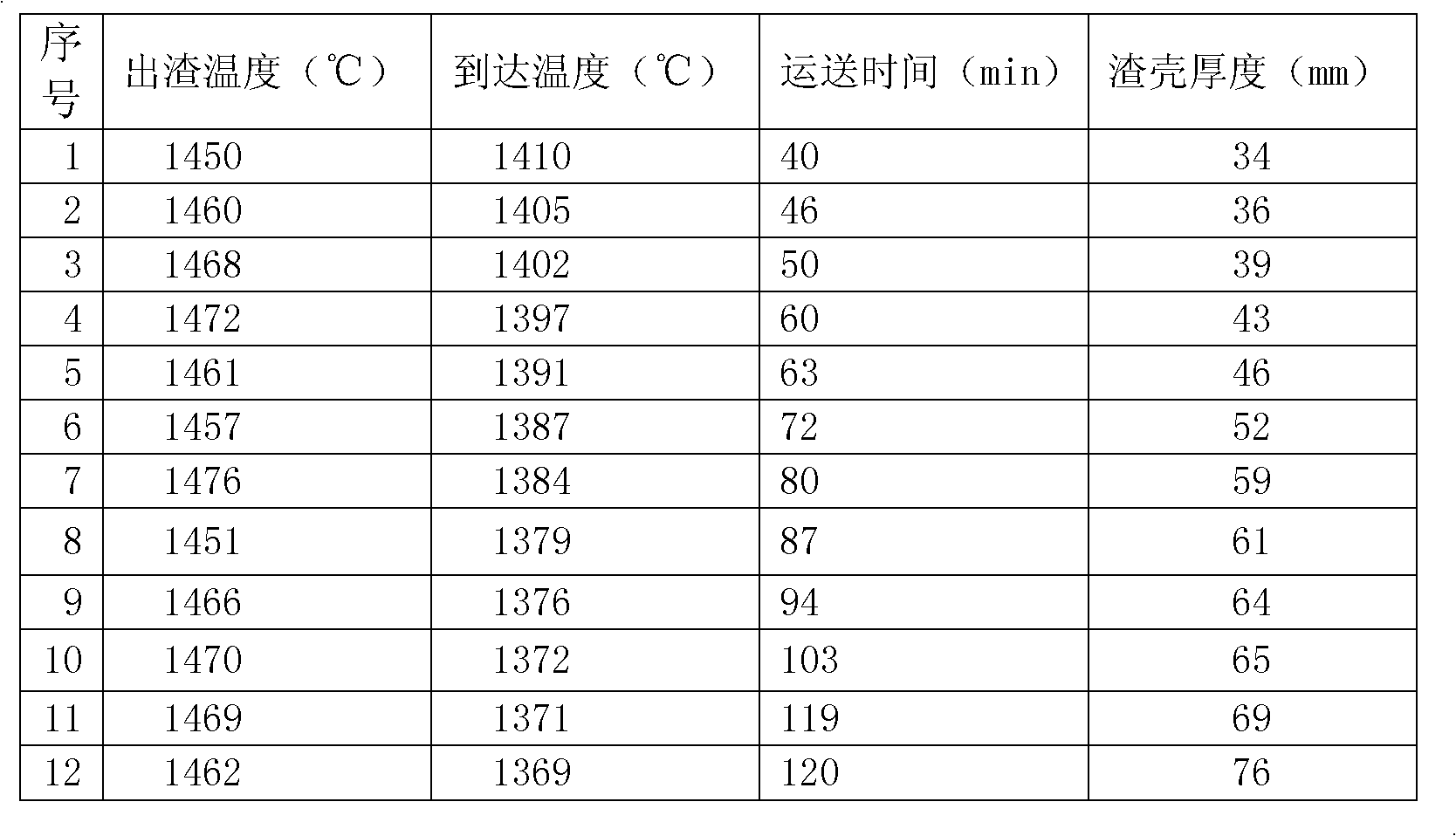

Electric furnace charging process for high-titanium blast furnace slag carbonization

The invention relates to the field of comprehensive utilization of high-titanium blast furnace slag, and provides an electric furnace charging process for high-titanium blast furnace slag carbonization. The process comprises the following steps of: 1) controlling the blast furnace tapping temperature at over 1,450 DEG C; 2) introducing liquid blast furnace slag into a slag pot car through a slag runner; 3) solidifying the blast furnace slag to form slag crust, and performing sealed heat insulation on the liquid blast furnace slag in the slag pot car; 4) conveying the slag to an electric furnace through the slag pot car for less than or equal to 2 hours; and 5) breaking the slag crust, and guiding the liquid blast furnace slag into the electric furnace through a guide plate and a guide trough. By charging the liquid slag into the furnace, the heat in the blast furnace slag is furthest kept so as to reduce the energy consumption of a blast furnace slag high-temperature carbonization process, reduce the time required for blast furnace slag high-temperature carbonization and smelting and avoid the water resource waste of the conventional water quenching slag; and meanwhile, the process has little modification on the conventional equipment, is easy to implement, and has low implementation cost. The process is suitable for charging of the high-titanium blast furnace slag carbonization.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

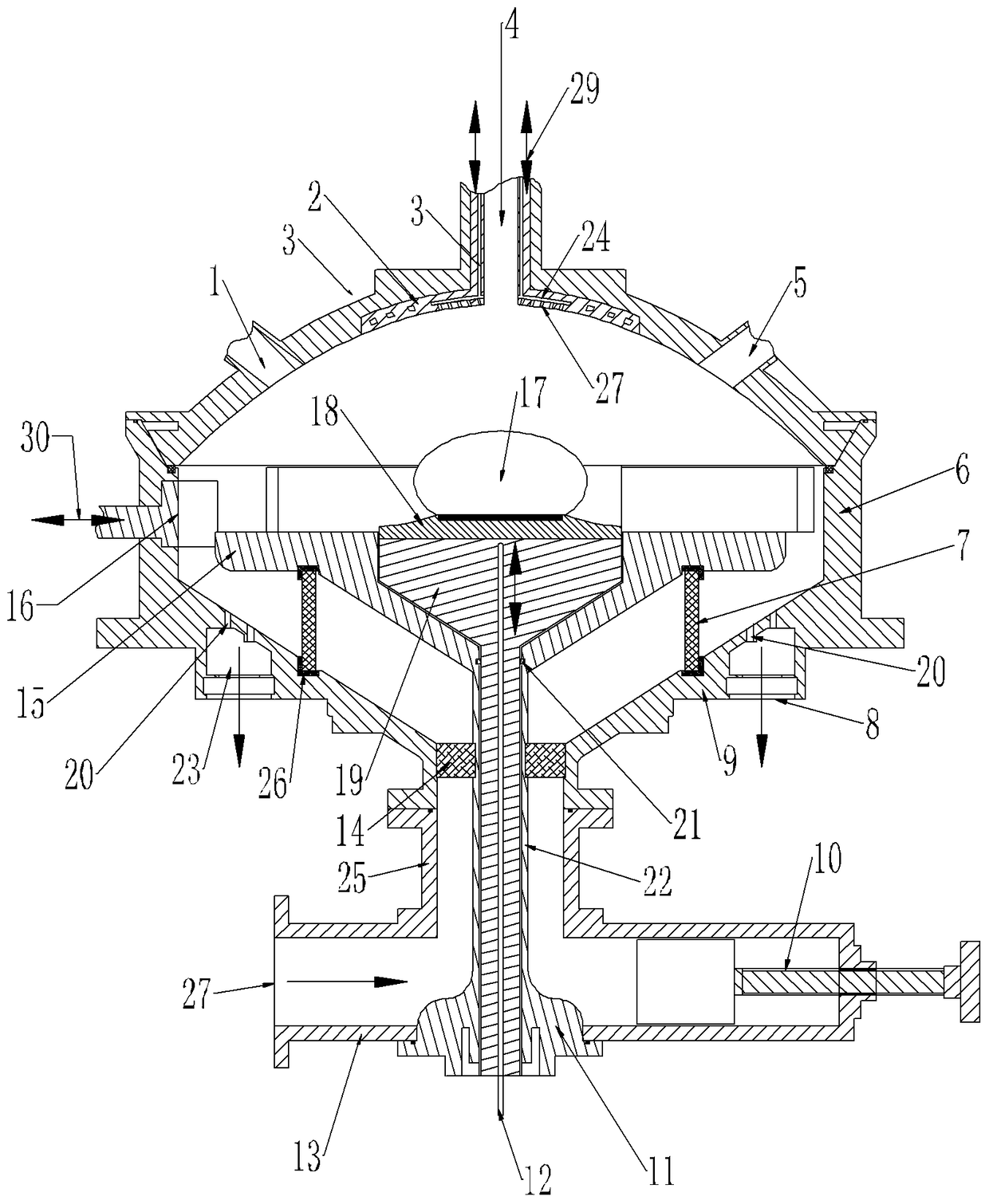

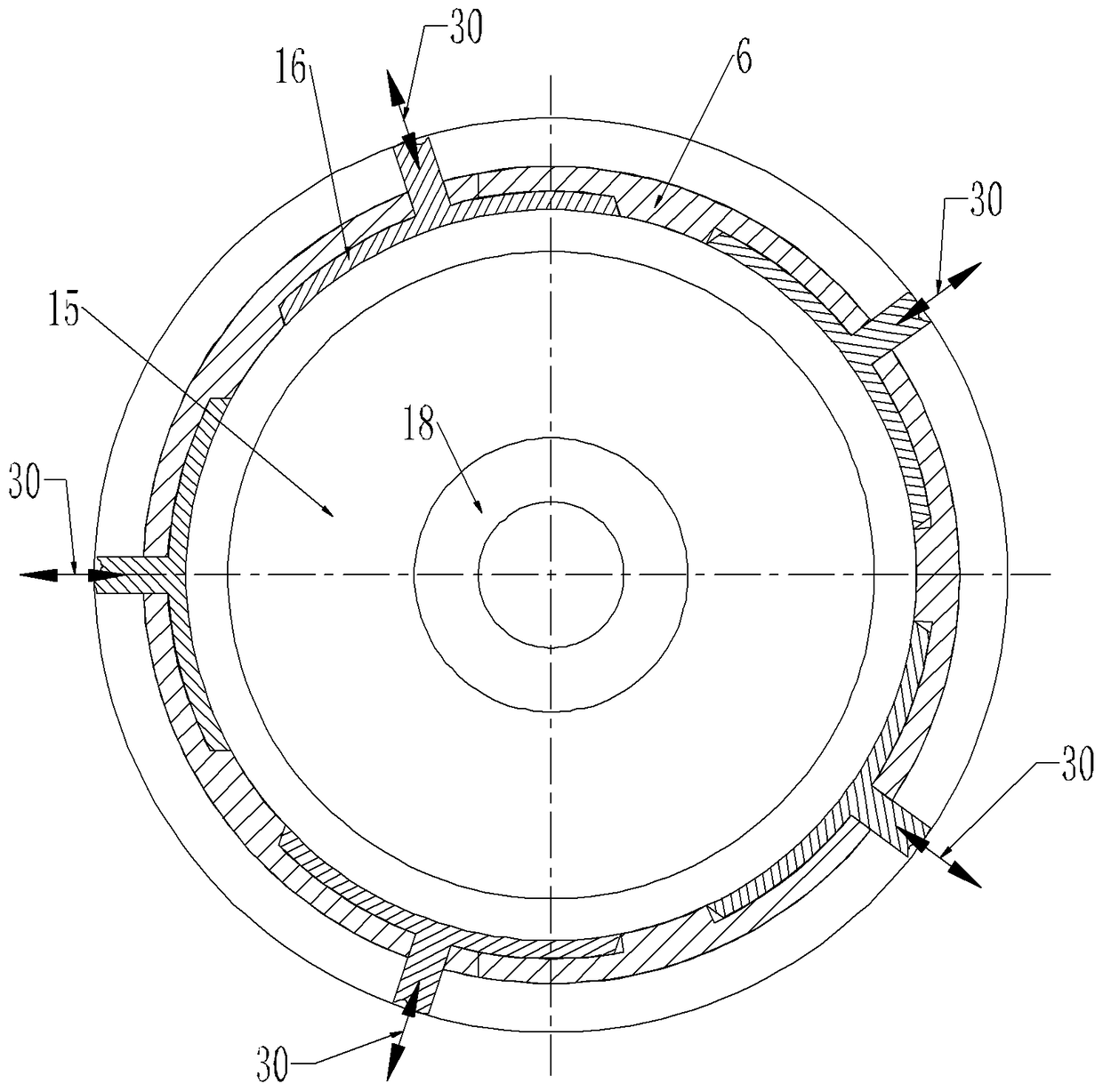

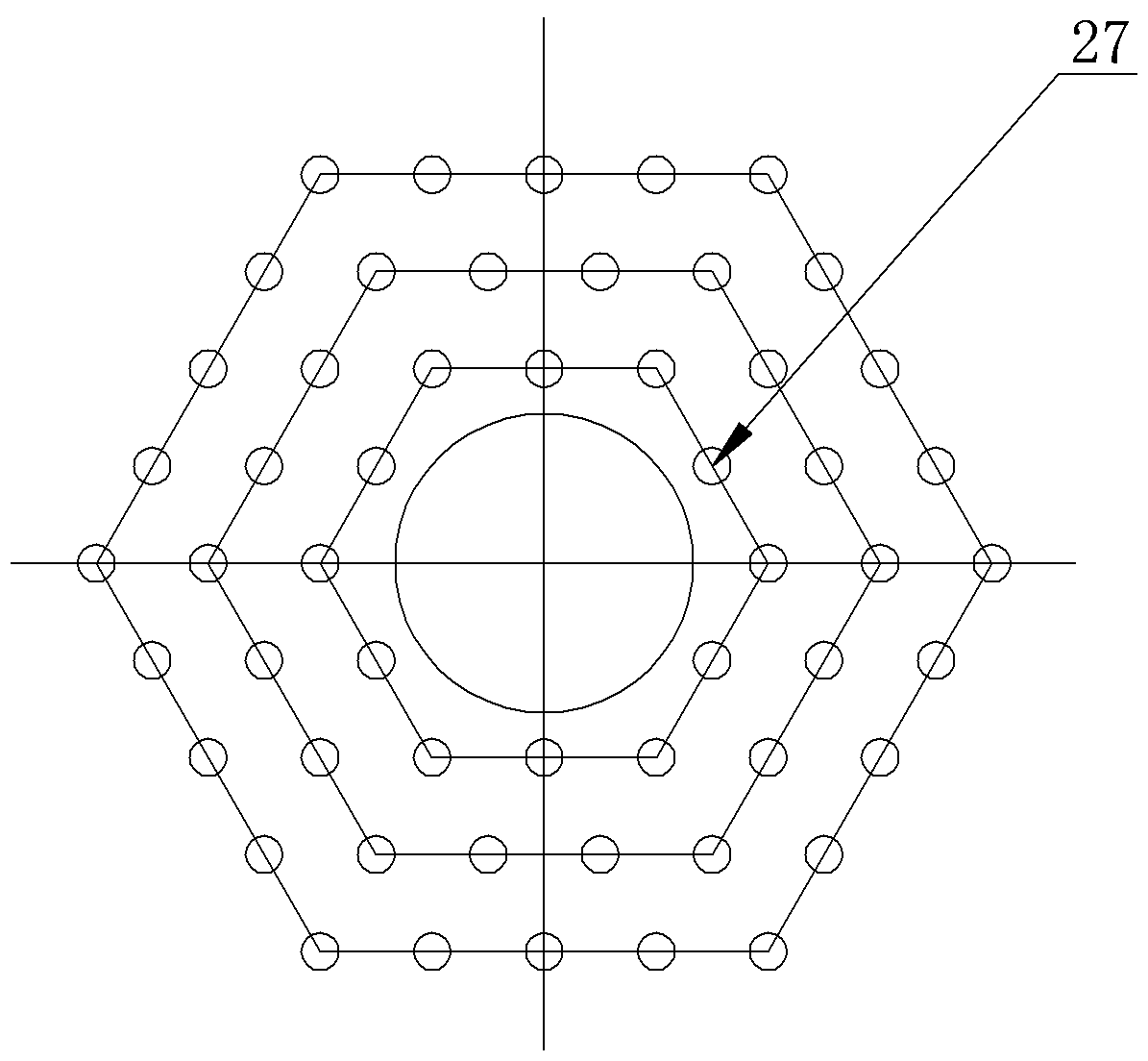

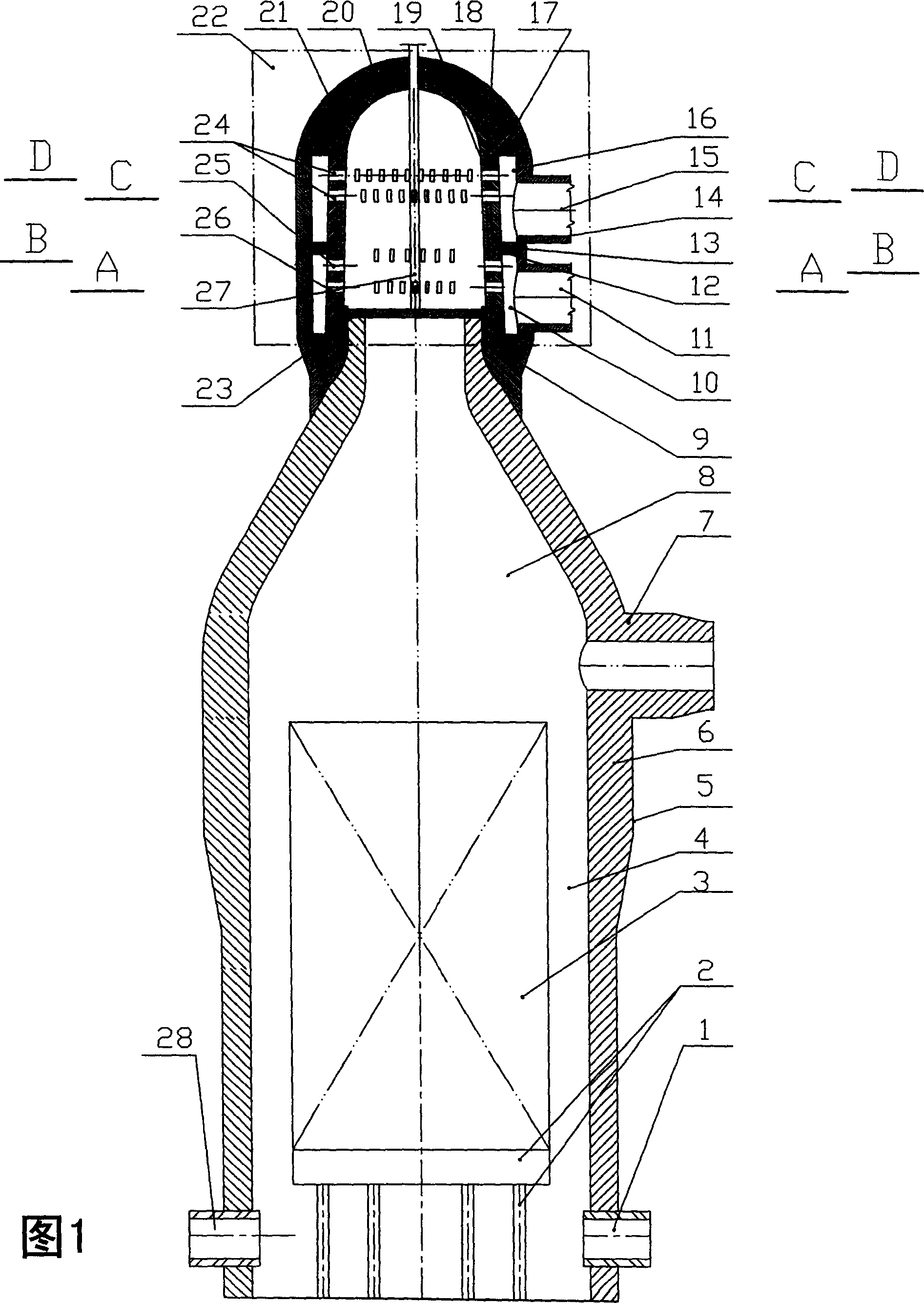

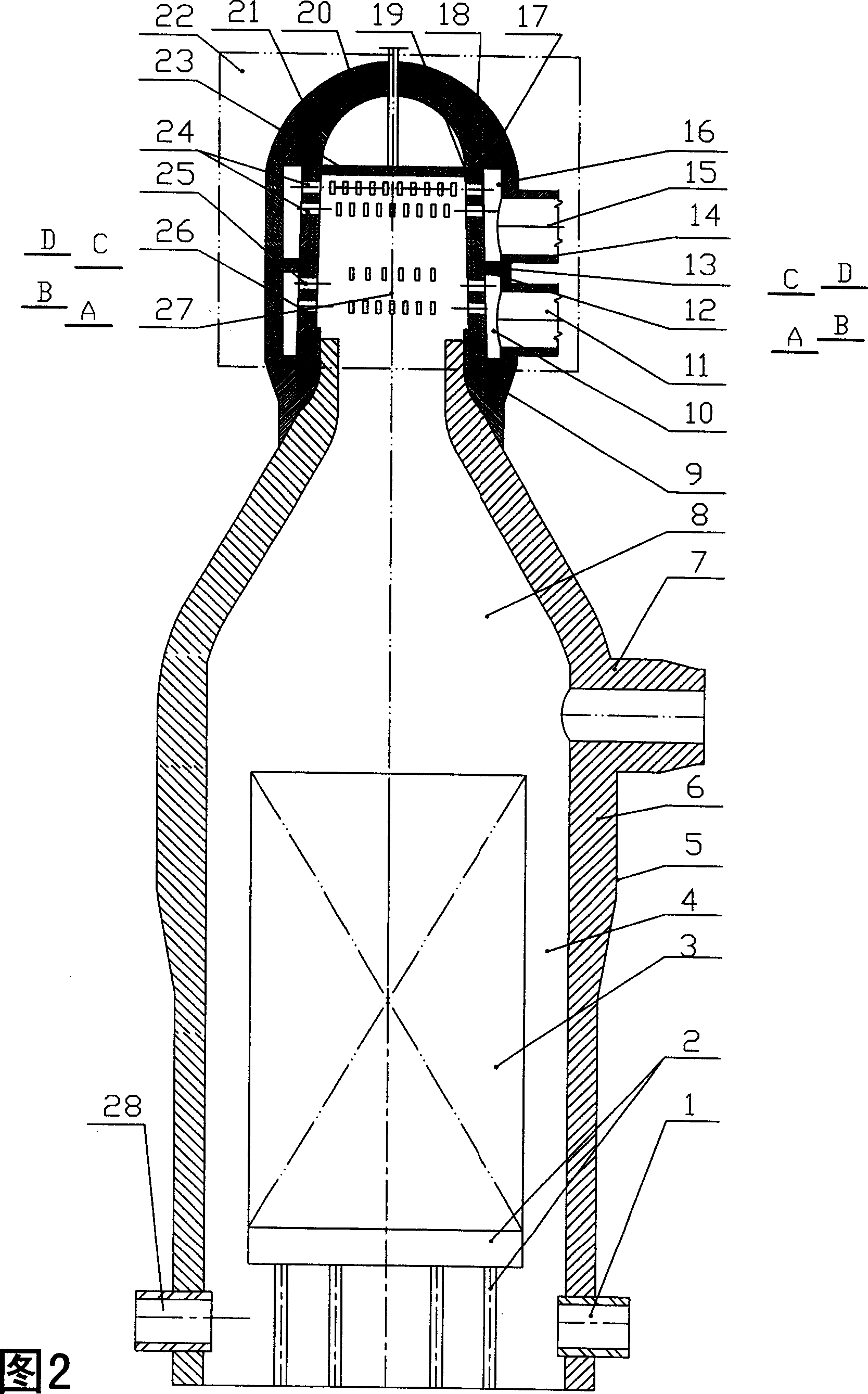

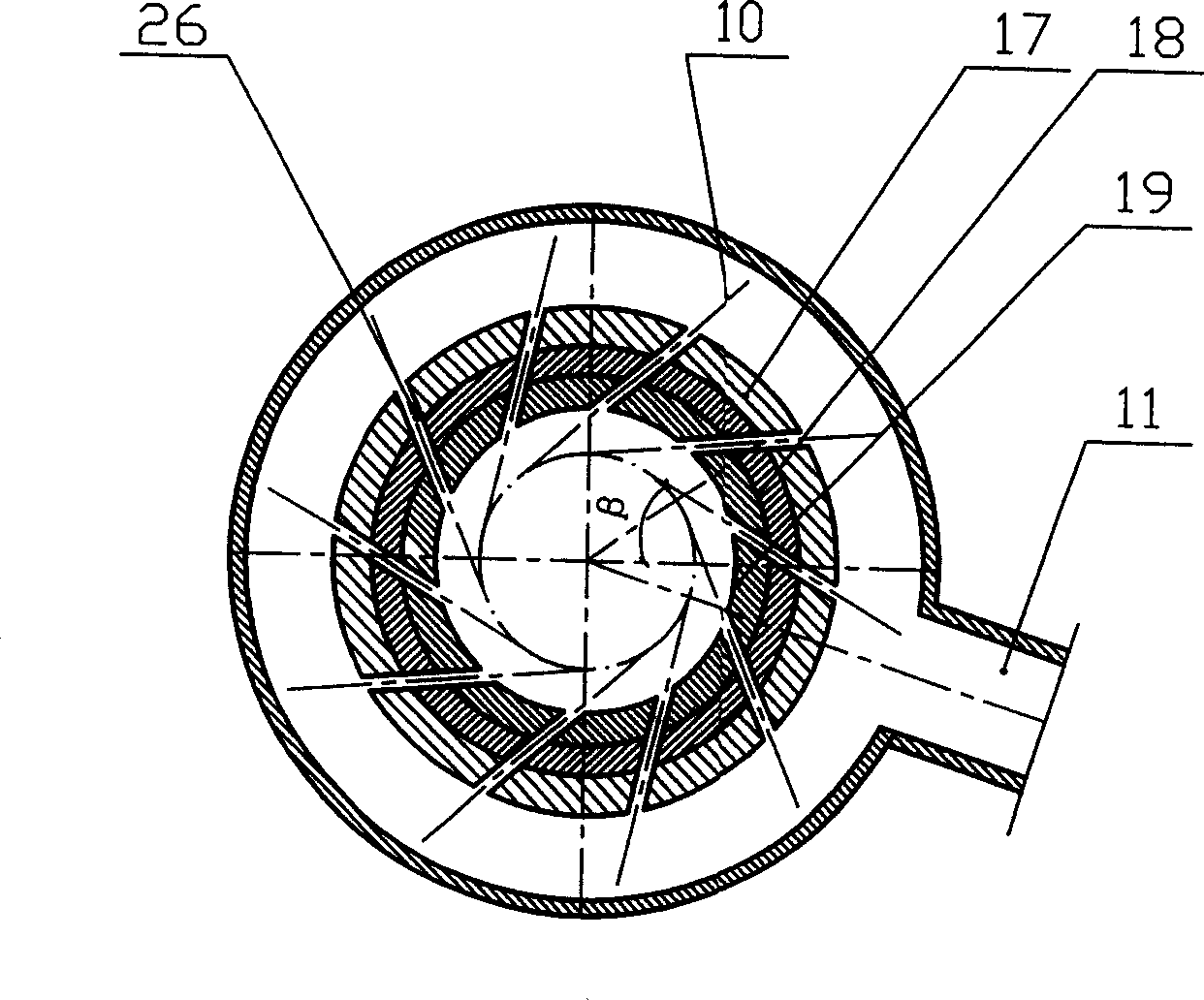

Tunable rounding cavity type high-power microwave plasma chemical vapor deposition device

ActiveCN108624870AEnhanced couplingImprove feedFinal product manufactureChemical vapor deposition coatingDistributed structureMicrowave resonance

The invention discloses a tunable rounding cavity type high-power microwave plasma chemical vapor deposition device which is composed of a microwave resonance cavity main body, a mode converter and amicrowave electric field adjusting system. According to the chemical vapor deposition device, by means of the rounding cavity type cavity, a sample table, the mode converter and an adjusting structurethereof, the problems of low microwave input power, the poor focusing ability, shortage of perfect adjusting measures and the too close distance between a unifying part and plasma existing in variousexisting devices can be effectively solved, gas is input from the top and output from the bottom, the multi-hole array distributing structure of a flow uniformizing ring and a buffering bin is adopted, uniformity of gas flow and distribution in a resonance cavity and on the surface of a base piece can be effectively is improved, and deposition efficiency and uniformity of a deposition diamond film are further improved. The device can achieve efficient deposition of large-area and high-quality diamond film under high power.

Owner:CHENGDU NEWMAN HERUI MICROWAVE TECH CO LTD

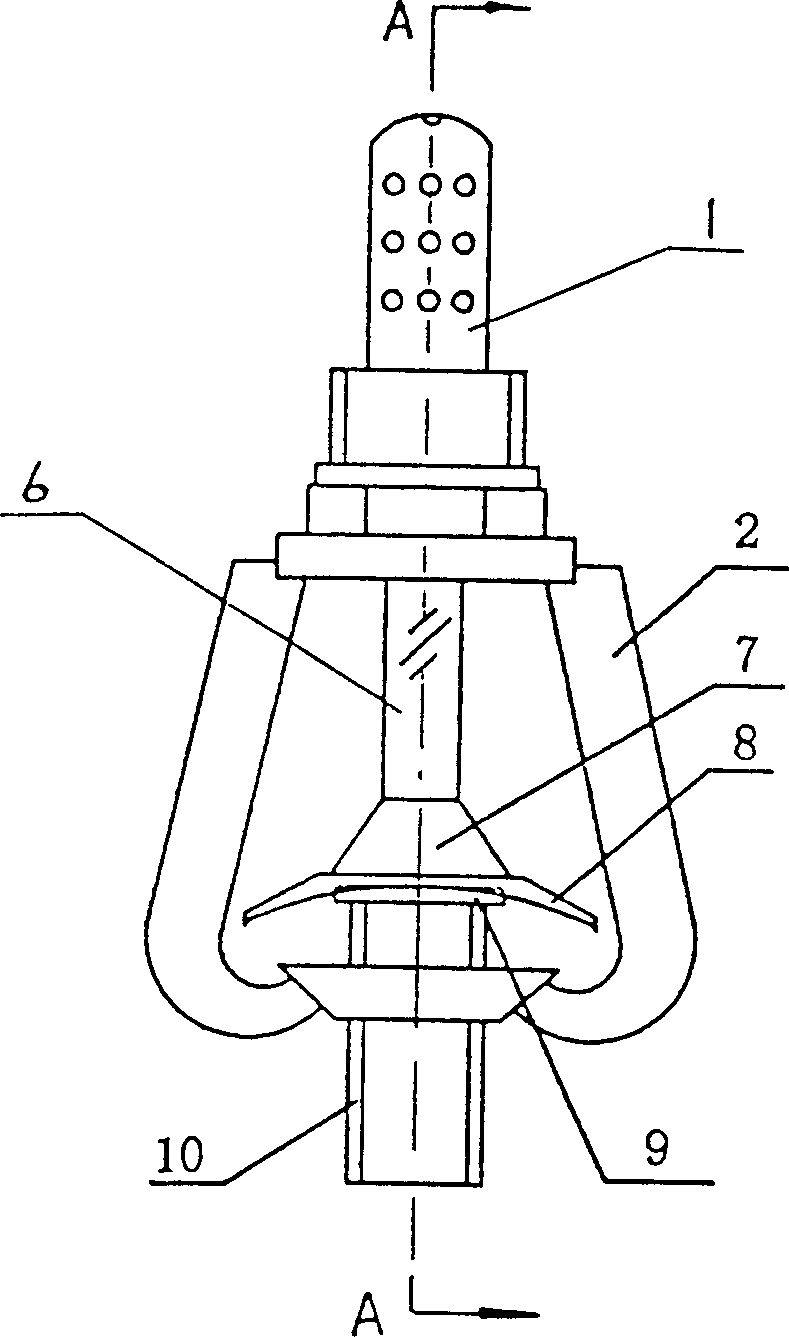

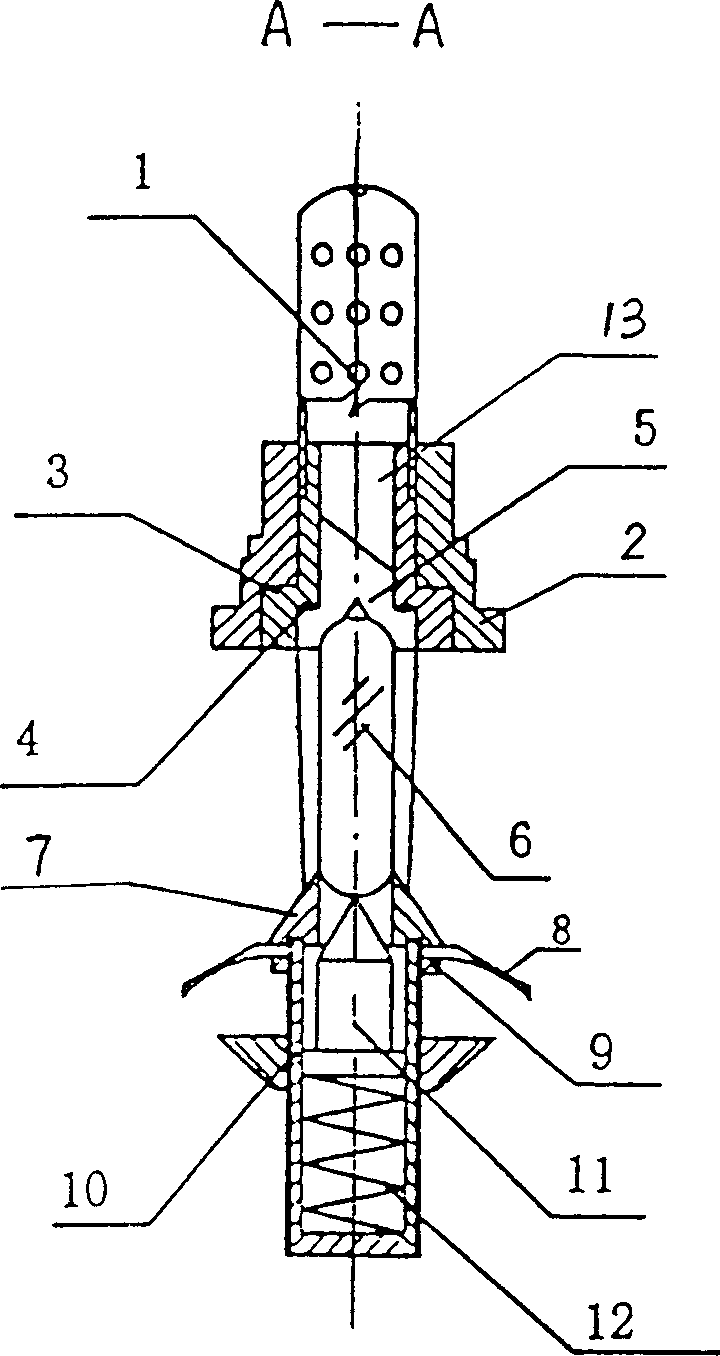

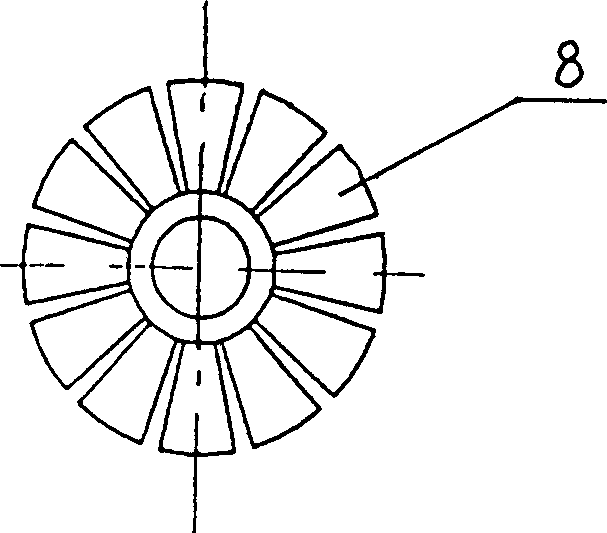

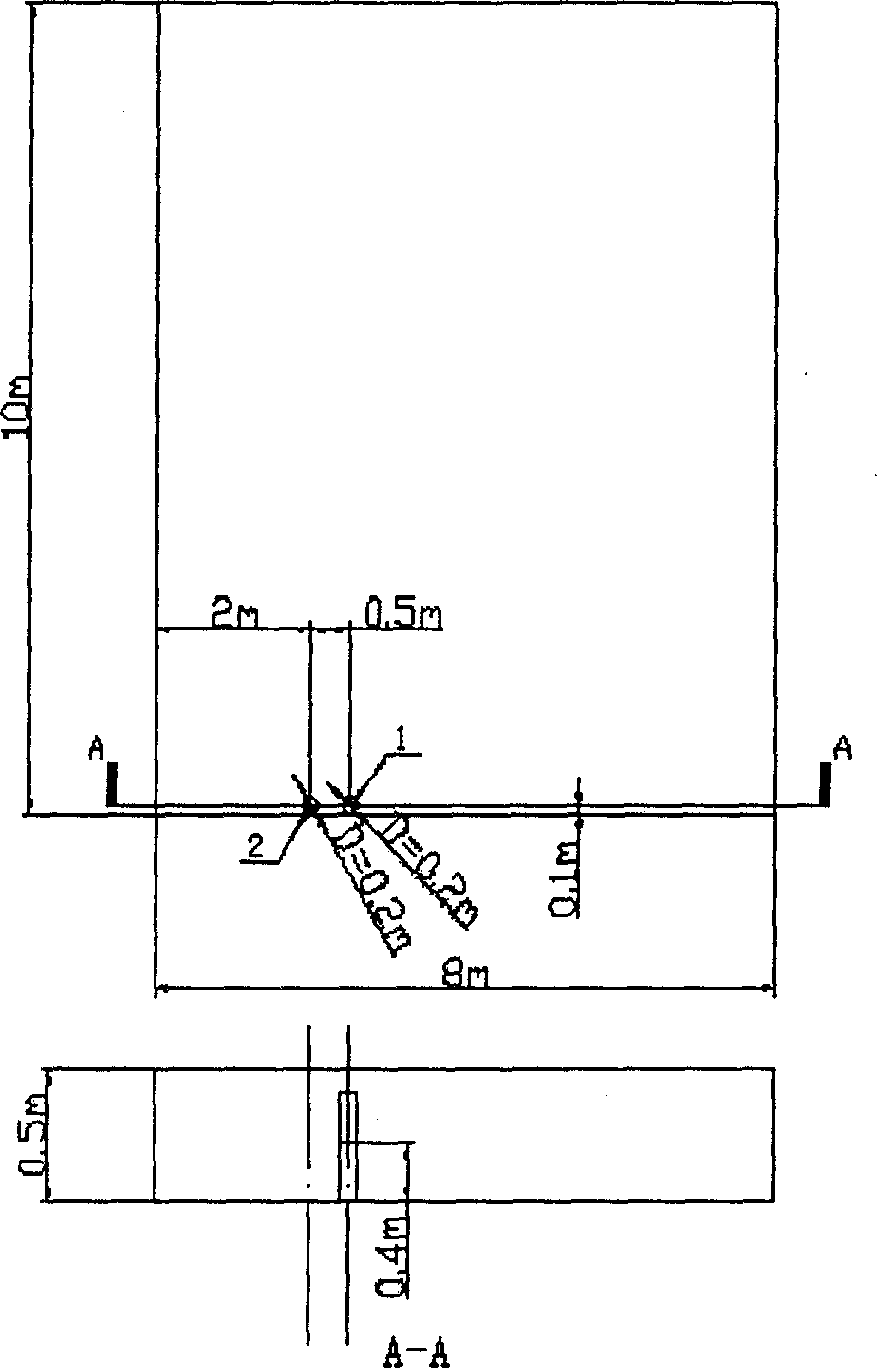

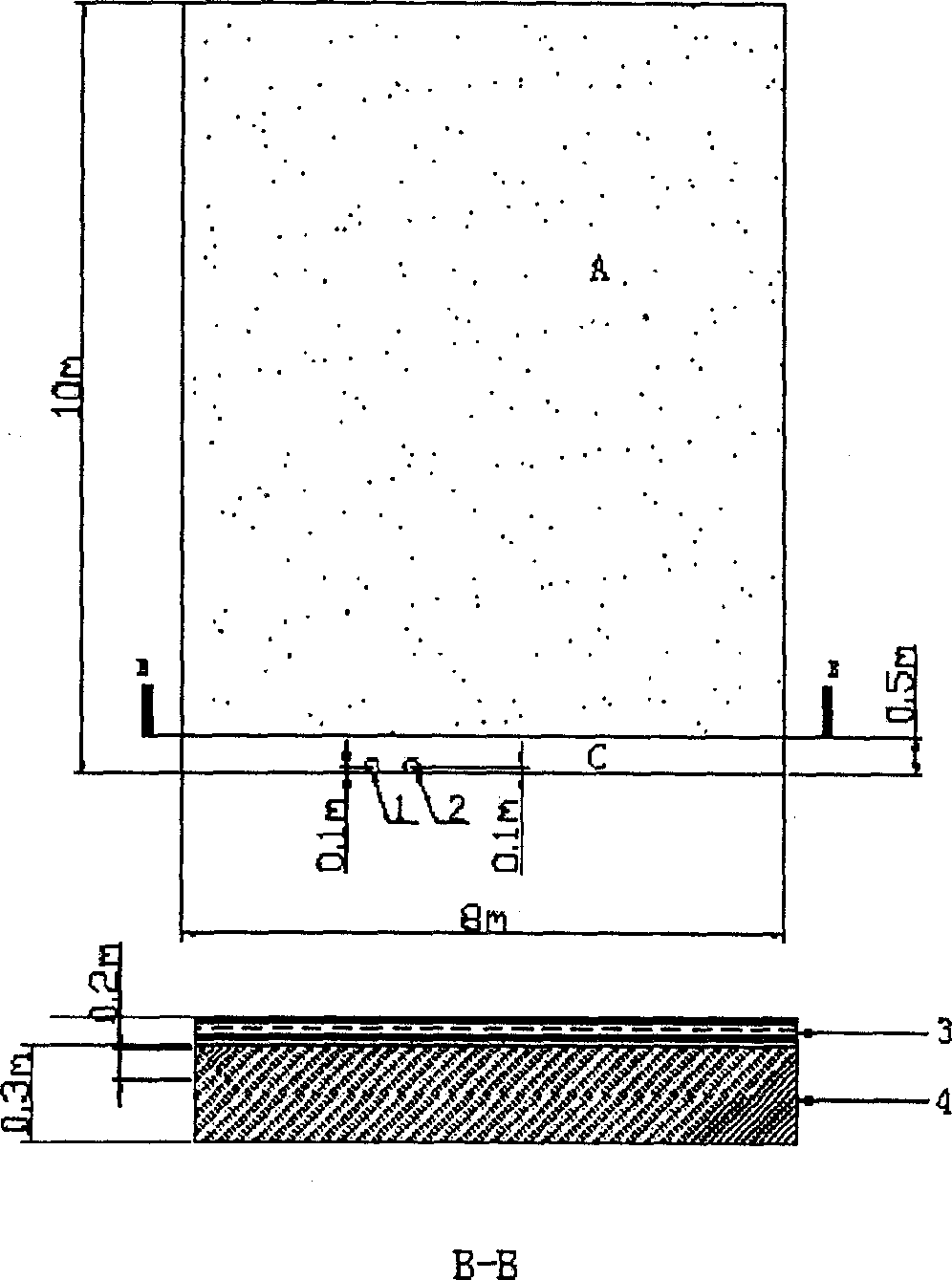

Projected closed water-atomizing nozzle

A projected closed water-atomizing nozzle for extinguishing fire is composed of water filter, water guider, sealing post, sealing ring, frame, thermosenstive element, atomized water splashing cone, splashed water collecting tray and screwed pipe.

Owner:张新国

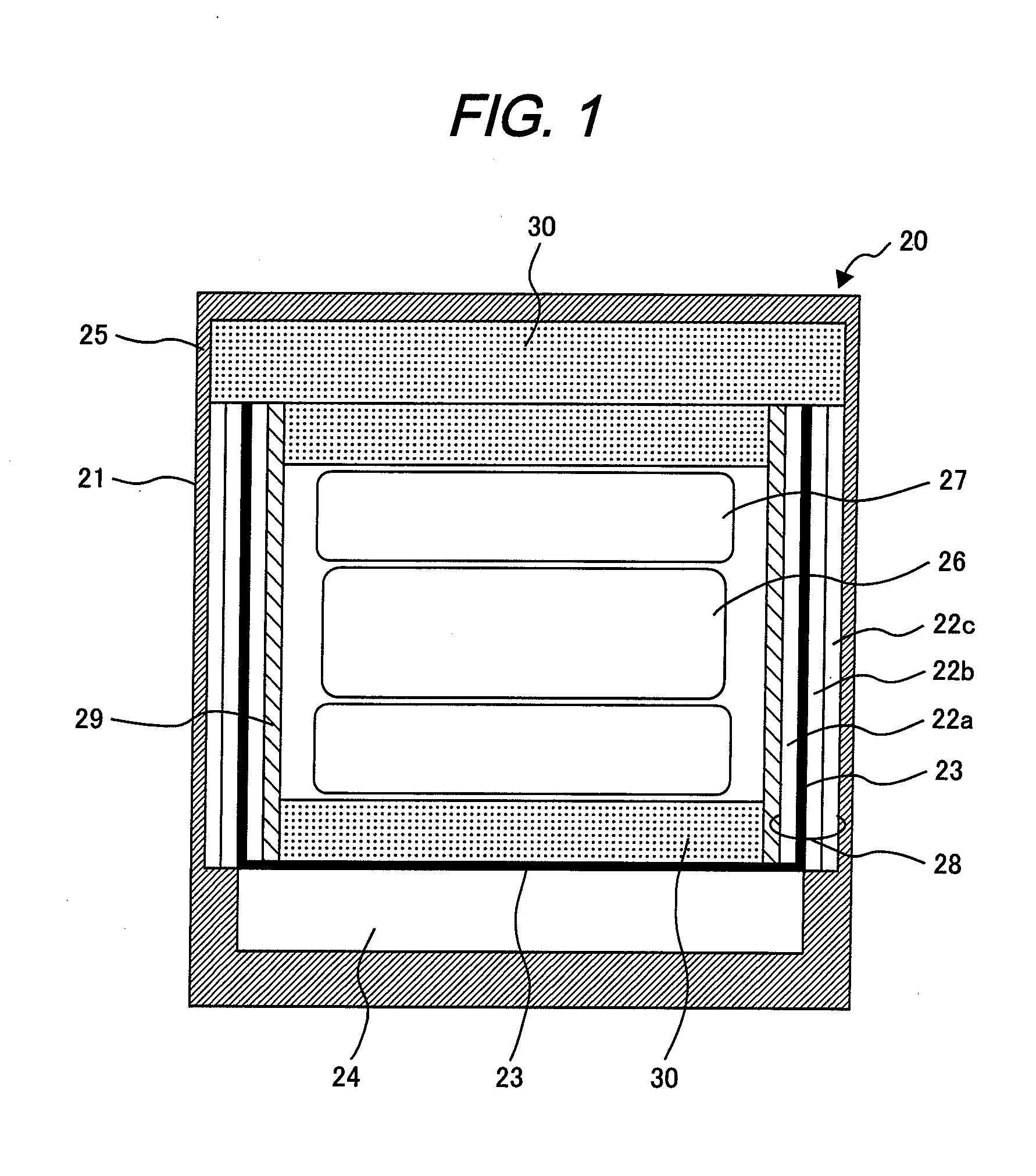

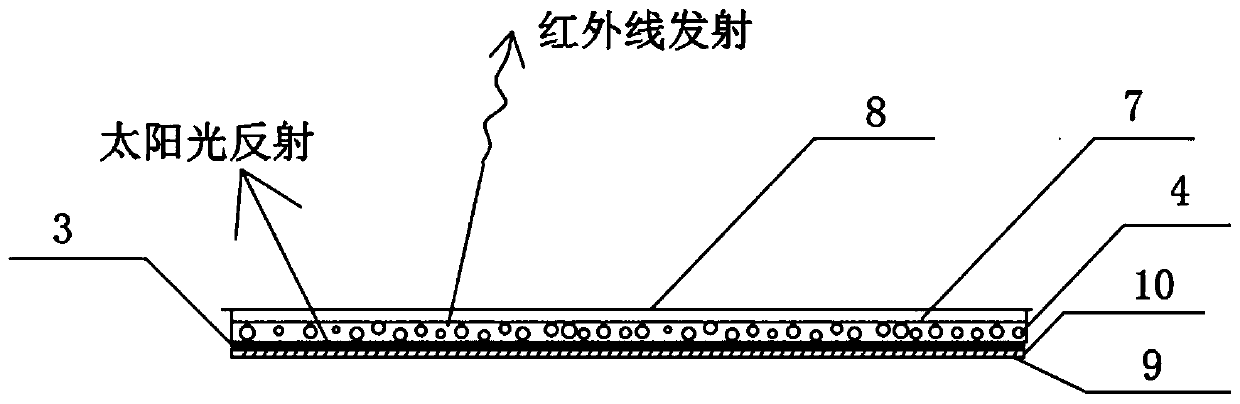

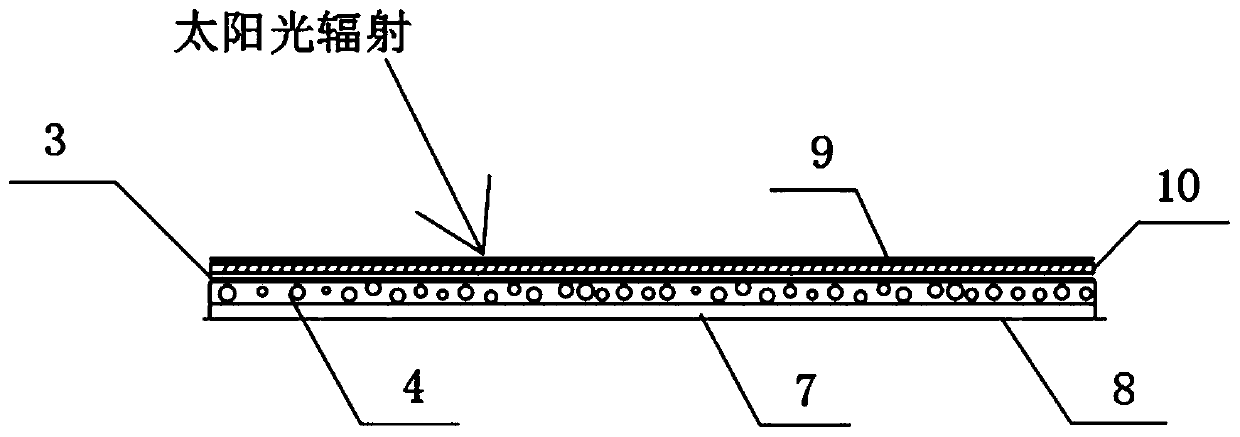

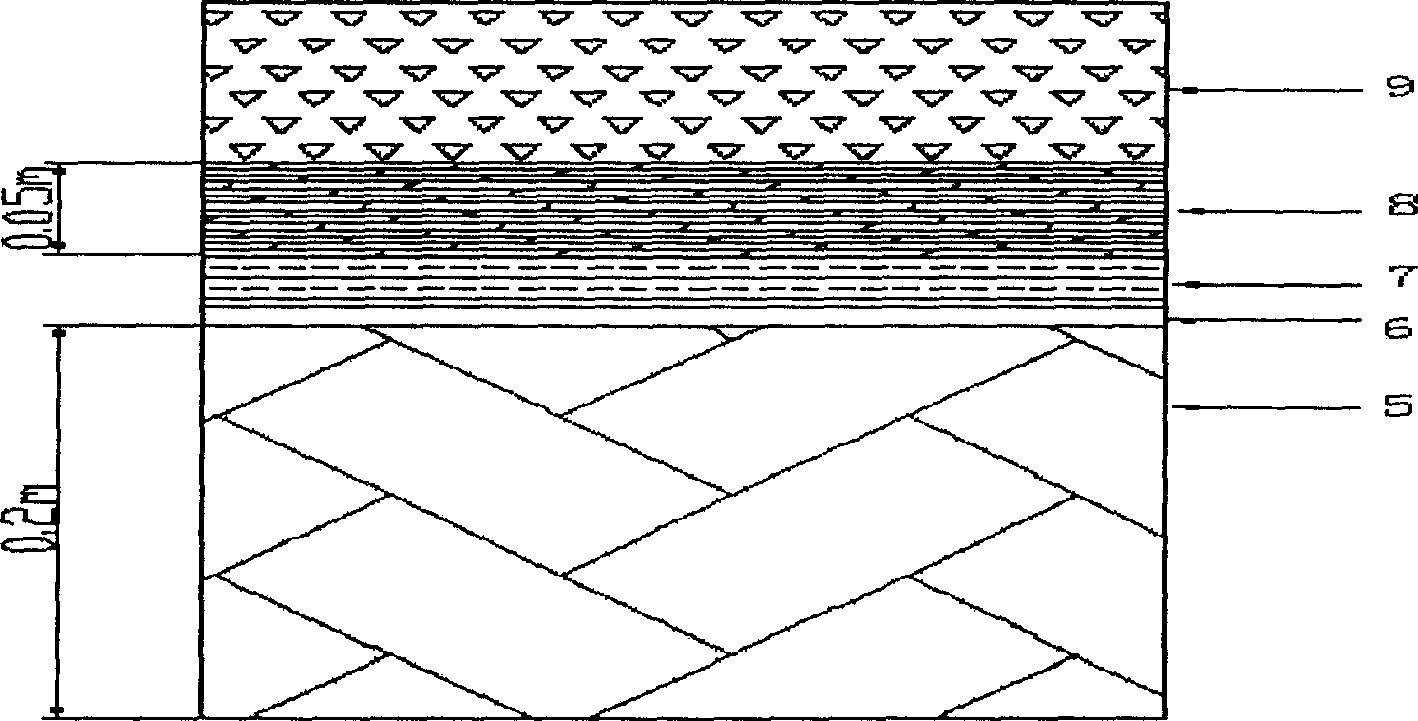

Winter and summer temperature adjusting device based on radiation cooling and solar energy utilization and construction method of winter and summer temperature adjusting device

PendingCN110567188AReduce radiant heatSolve Cooling ProblemsSynthetic resin layered productsLaminationInfraredOptoelectronics

The invention discloses a winter and summer temperature adjusting device based on radiation cooling and solar energy utilization and a construction method of the winter and summer temperature adjusting device. The winter and summer temperature adjusting device is constituted by a radiation cooling structure and a heat absorbing layer; the radiation cooling structure is composed of a reflecting layer, an emission layer and a wind screen, the emission layer is arranged between the reflecting layer and the wind screen, the wind screen is composed of an air layer and a covering material layer, andthe air layer is located between the emission layer and the covering material layer; the reflecting layer reflects sunlight out, and the emission layer emits heat in a temperature-adjusted medium outin an infrared ray mode; and the heat absorbing layer is composed of a solar heat-absorbing material layer and a metal plate, and the metal plate is located between the solar heat-absorbing materiallayer and the reflecting layer of the radiation cooling structure and is closely combined with the radiation cooling structure. The winter and summer temperature adjusting device can provide passive temperature decreasing and increasing for certain occasions and equipment, and achieves the energy saving effect.

Owner:TIANJIN UNIV

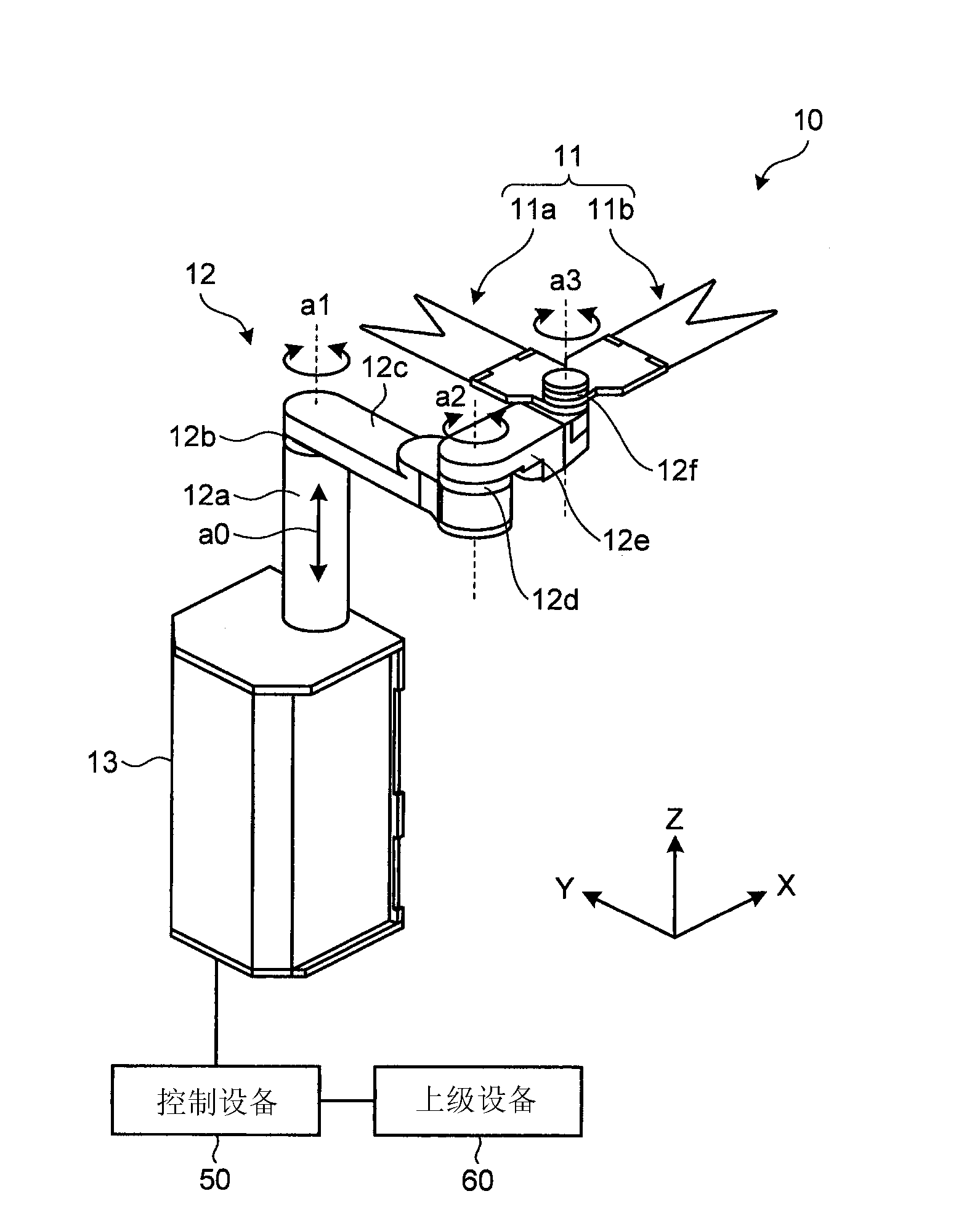

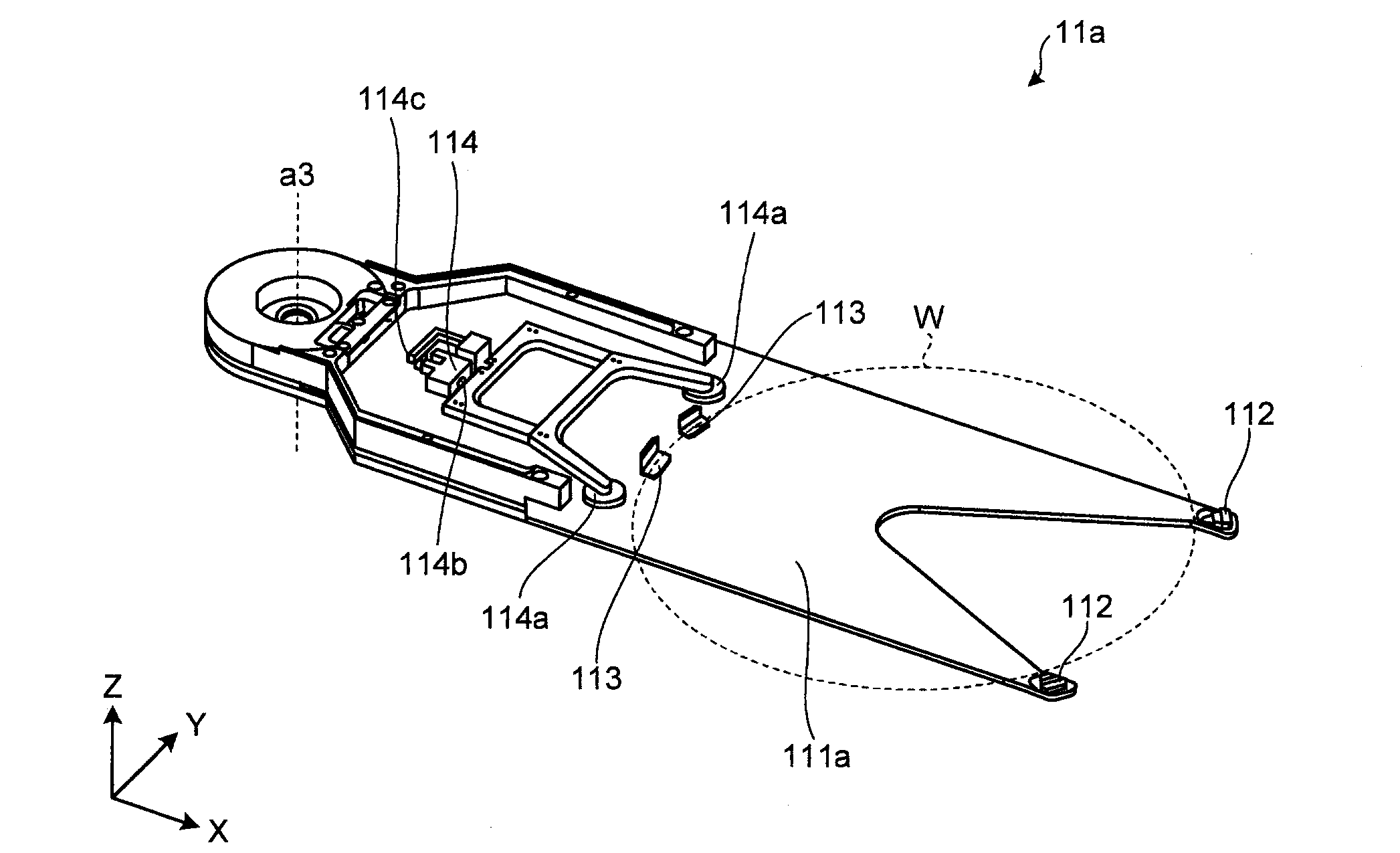

Conveying robot

InactiveCN103223674AReduce radiant heatProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingRobotic systemsIndustrial engineering

A robot system according to an aspect of the embodiments includes a plurality of work holding units and a heat insulating member. The work holding units each hold a work to be conveyed on one surface and are arranged vertically one over another in some cases during conveying of the work. The heat insulating member is provided on another surface side of at least one of the work holding units.

Owner:YASKAWA DENKI KK

Process for performing roofs virescence by using melastona dodecandrum bamboo straw

ActiveCN101116413AImprove insulation performanceWith cooling performanceCultivating equipmentsSoilless cultivationEcological environmentHeat resistance

The invention discloses a roof greening method by using callisia repens, in particular to a growing method for planting callisia repens on roof. The procedures of the method are as follows: first, a water-resistant system, a drainage system and a root resistant layer are arranged on the roof and a matrix layer is paved on the roof; second, grass seeds of the callisia repens is planted on the matrix layer by using any one method of offshoots, broadcasting sowing method, cottage or greensward transplanting and paving method; third, root fixing water is watered and N fertilizer is fertilized once every fifteen days, and lawn is formed within one to two months. As an effective measure for solving the influence of urban development on the entironment and raising the urban afforestation rate, the invention uses the callisia repens on the roof greening, which has a resultful effect on the heat resistance, virescence and disaster prevention of room surface.

Owner:广东如春生态集团有限公司

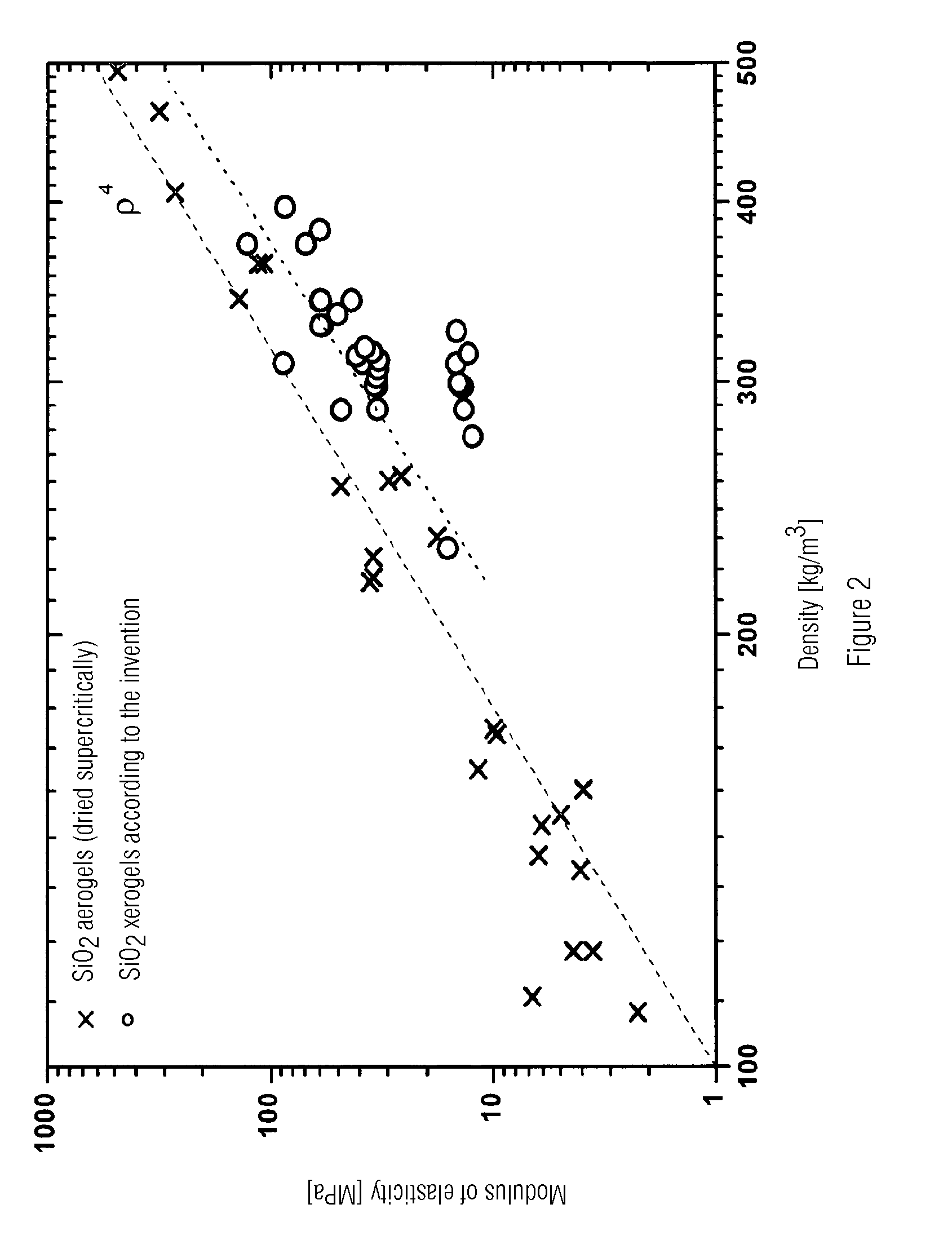

Method for producing a porous sio2-xerogel with a characteristic pore size by means of a bottom-up method using a precursor that has organic solid skeletal supports

In a method for producing a porous SiO2-xerogel starting solution containing a silicon compound is provided and organic monomers and an organically modified alkoxysilane are added to the starting solution. During gelification of the silicon compound, the organic monomers and the organically modified alkoxysilane react in situ to form organic solid skeletal supports in the silicon network. The resulting gel is dried under subcritical conditions and the solid skeletal supports removed by thermal oxidation.

Owner:BAYERISCHES ZENT FUER ANGEWANDTE ENERGIEFORSCHUNG +1

Drawing heat box device

InactiveCN1590604AReduce temperature differenceImprove air temperature control accuracyStretch-spinning methodsFiberEngineering

A heating case system for drafting tow is composed of a channel with a tow inlet, at least two air inlets, a tow outlet and an air outlet, and an air channel in which there are a centrifugal fan, an electric heater far from said channel and a static pressure box. It has high precision of air speed and air temp.

Owner:CHINA PETROLEUM & CHEM CORP +1

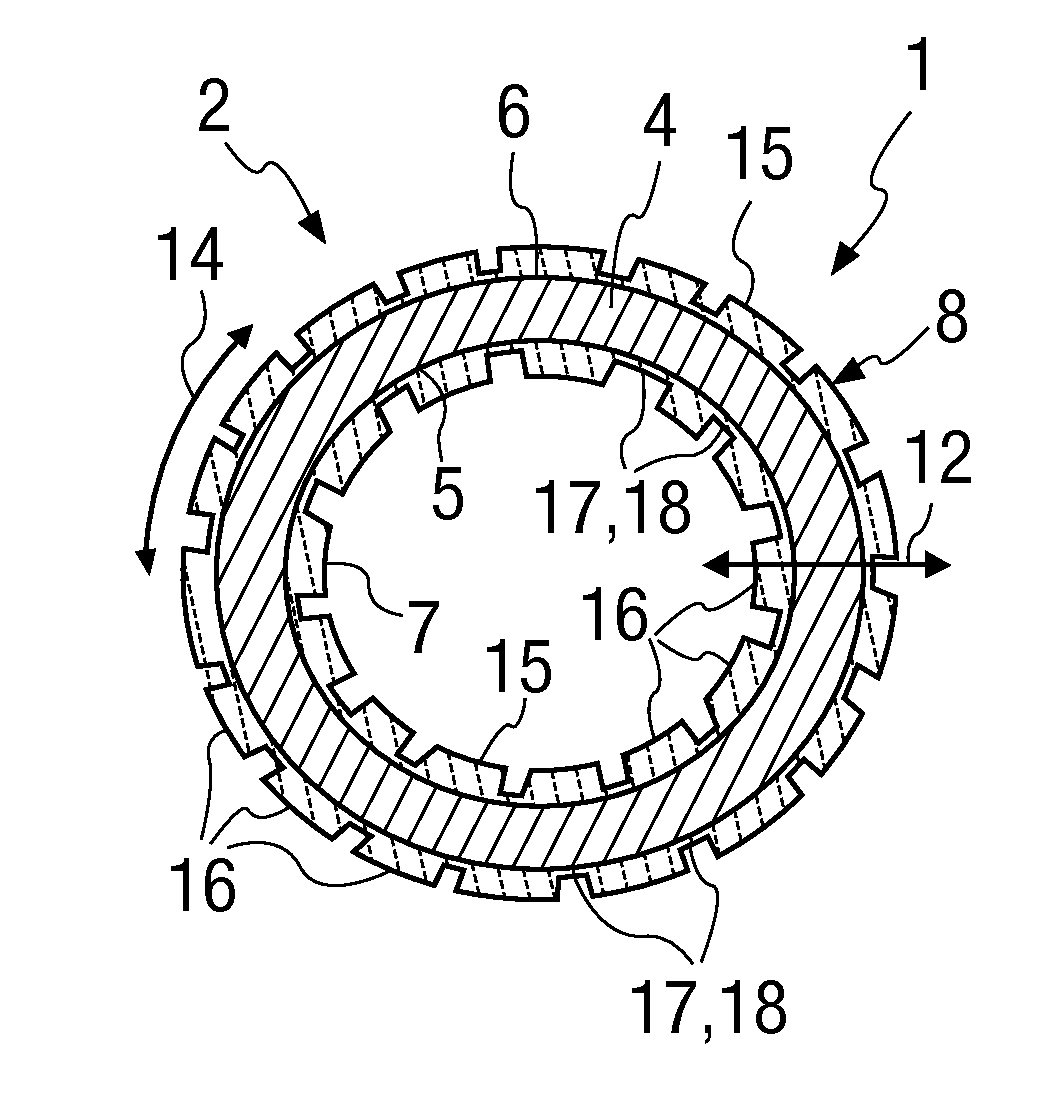

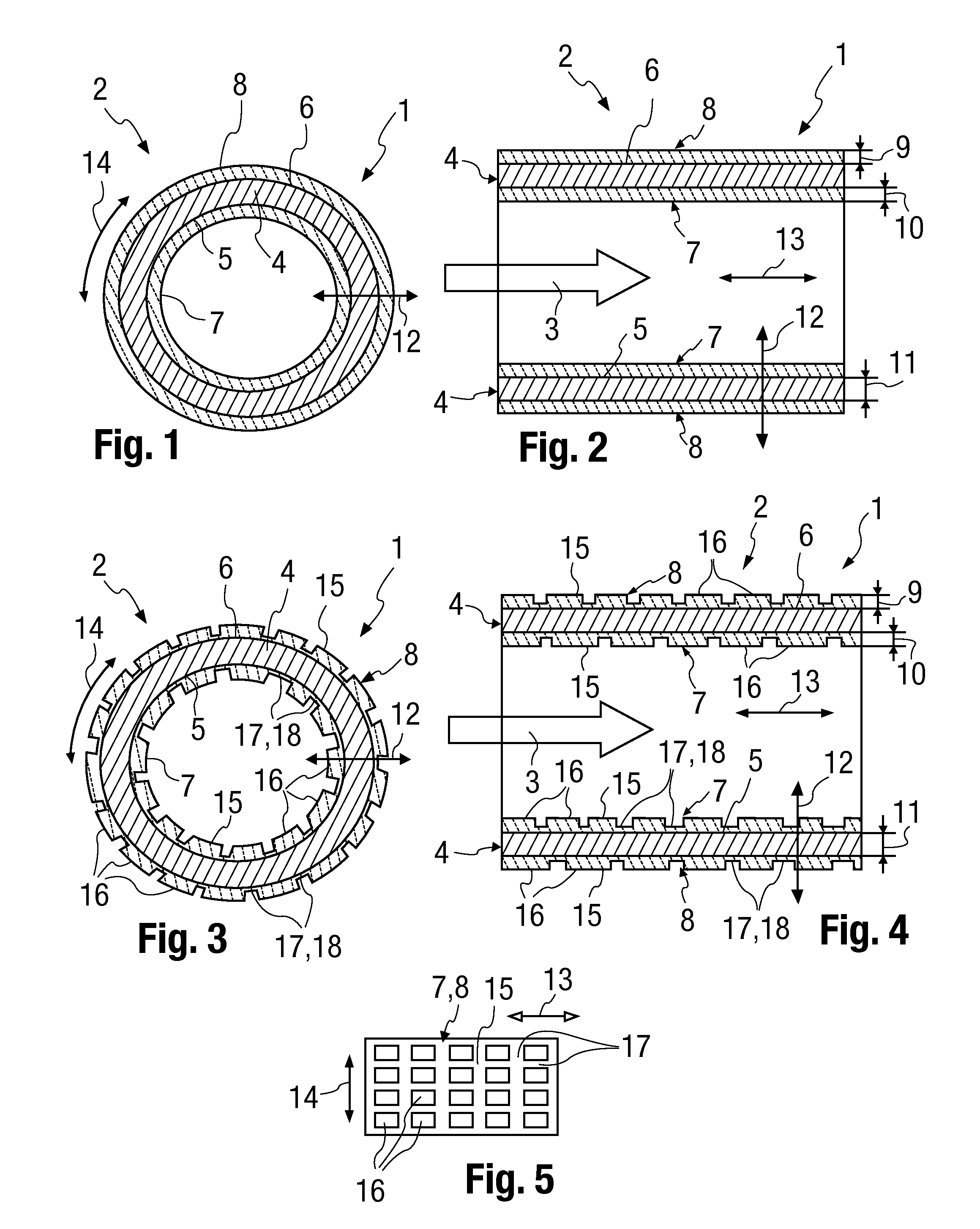

Tubular body and exhaust system

InactiveUS20110174412A1Small installation spaceReduce weightThermal insulationSilencing apparatusNanoparticleComposite ceramic

An exhaust gas-carrying tubular body (1) is provided for an exhaust system (2) of an internal combustion engine, especially of a motor vehicle. The tubular body (1) is provided on its inside (5) facing the exhaust gas and / or on its outside (6) facing away from the exhaust gas with a coating (7, 8), which is formed of a composite ceramic based on nanoparticles.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

Electronically controlled actuator

ActiveUS8978379B2Reduced life-timeReduce radiant heatDC motor speed/torque controlInternal combustion piston enginesEngineeringActuator

Owner:MITSUBISHI ELECTRIC CORP

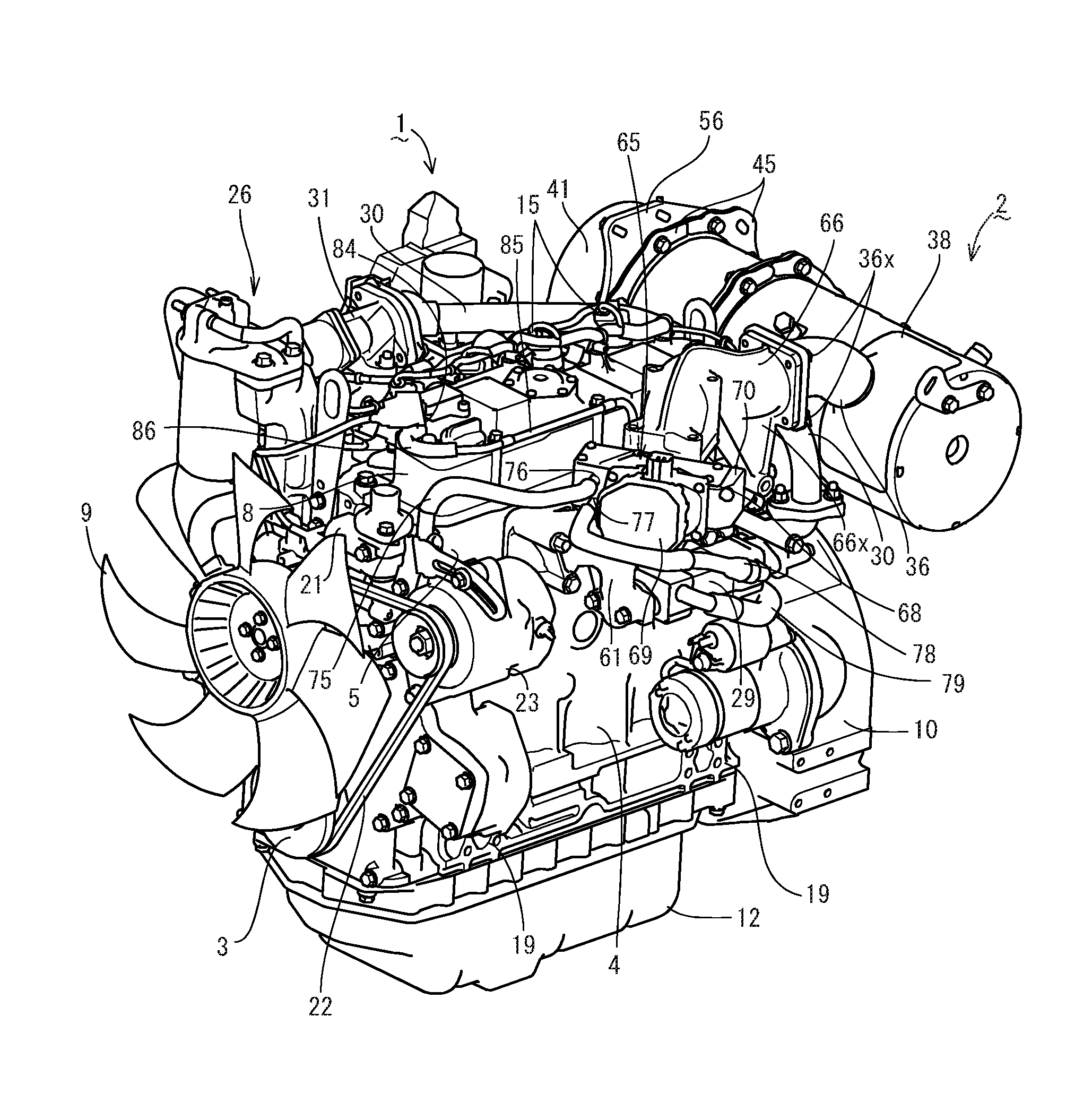

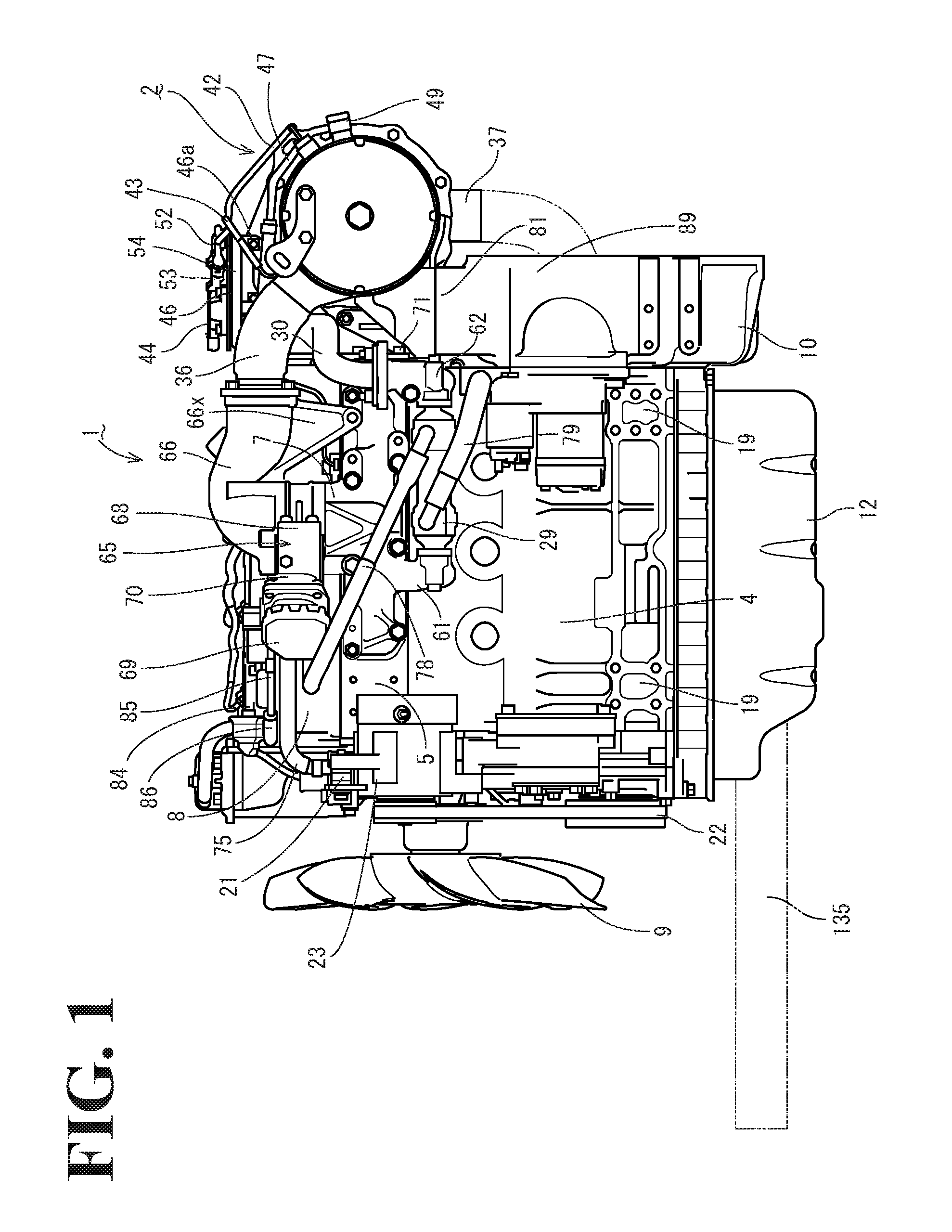

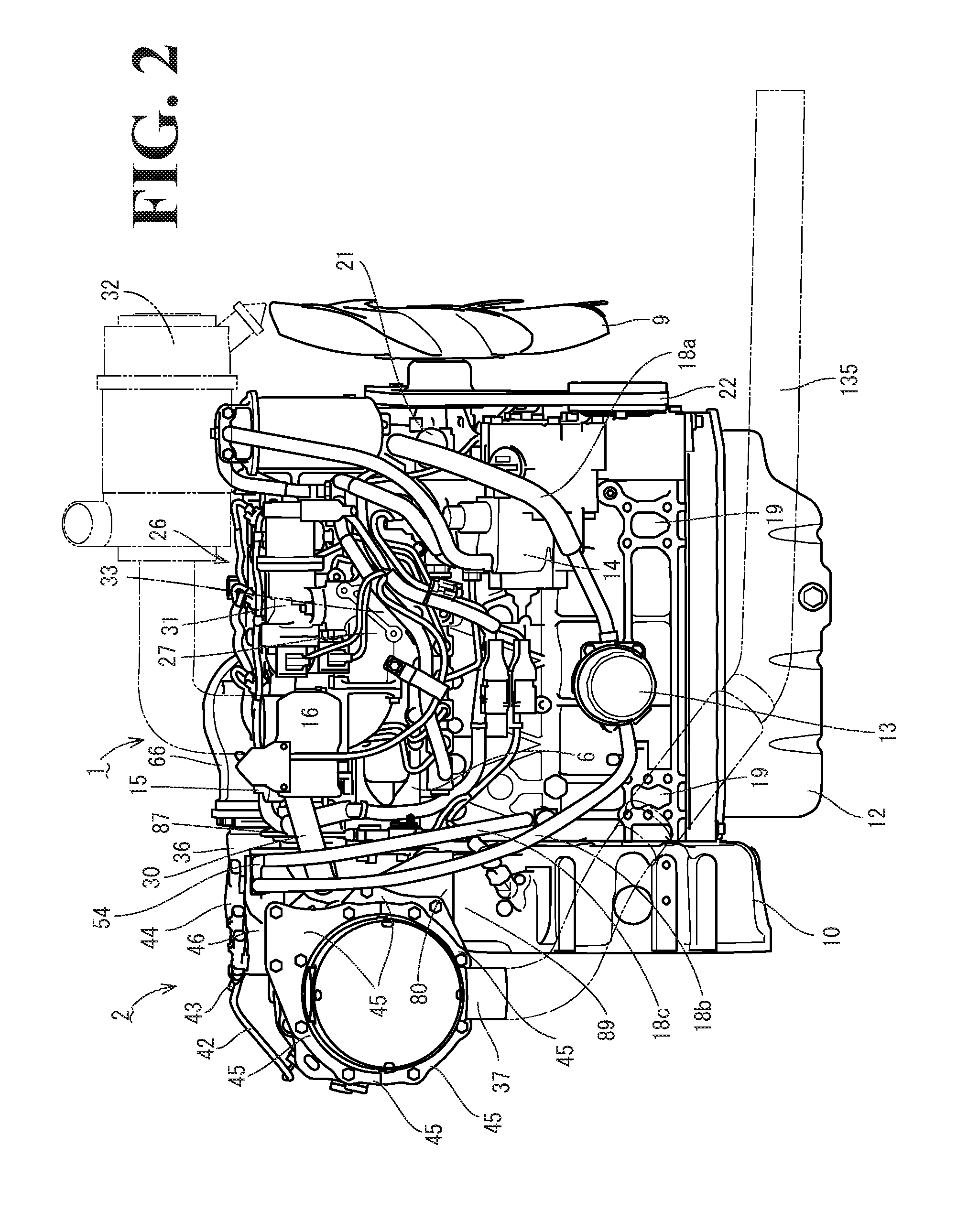

Engine device and stationary work machine having same mounted thereon

InactiveUS20170009639A1Reduce the impact of heatReduce failureLiquid coolingCoolant flow controlExhaust fumesWater circulation

An engine includes an exhaust-gas purification device. The exhaust-gas purification device purifies exhaust gas. The exhaust-gas purification device includes electrical components. The electrical components detect the states of the exhaust-gas purification device. The engine includes a cooling-water circulation mechanism for circulating cooling water for the engine. Further, a portion of the cooling water circulated by the cooling-water circulation mechanism cools the electrical components.

Owner:YANMAR POWER TECHNOLOGY CO LTD

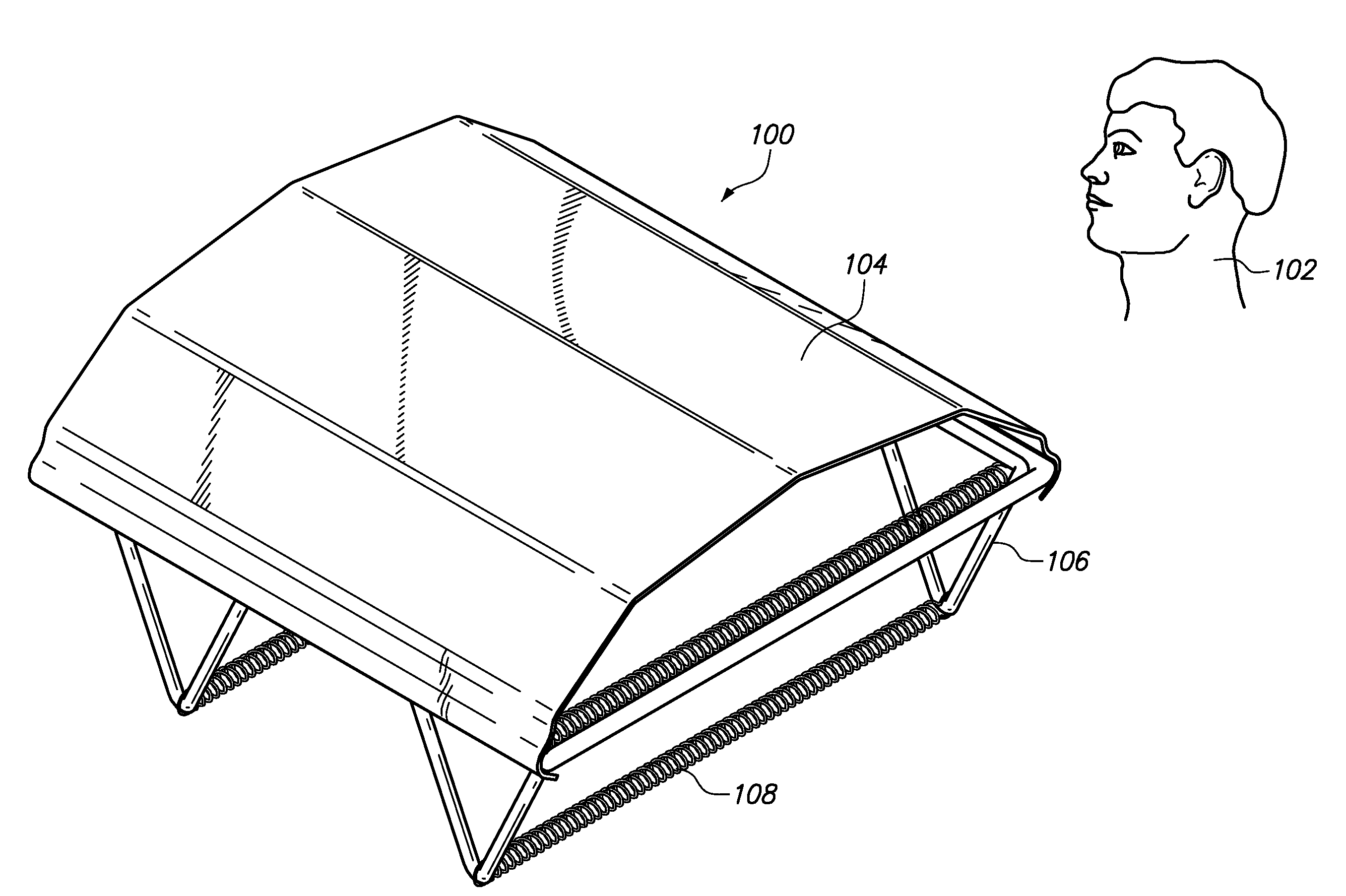

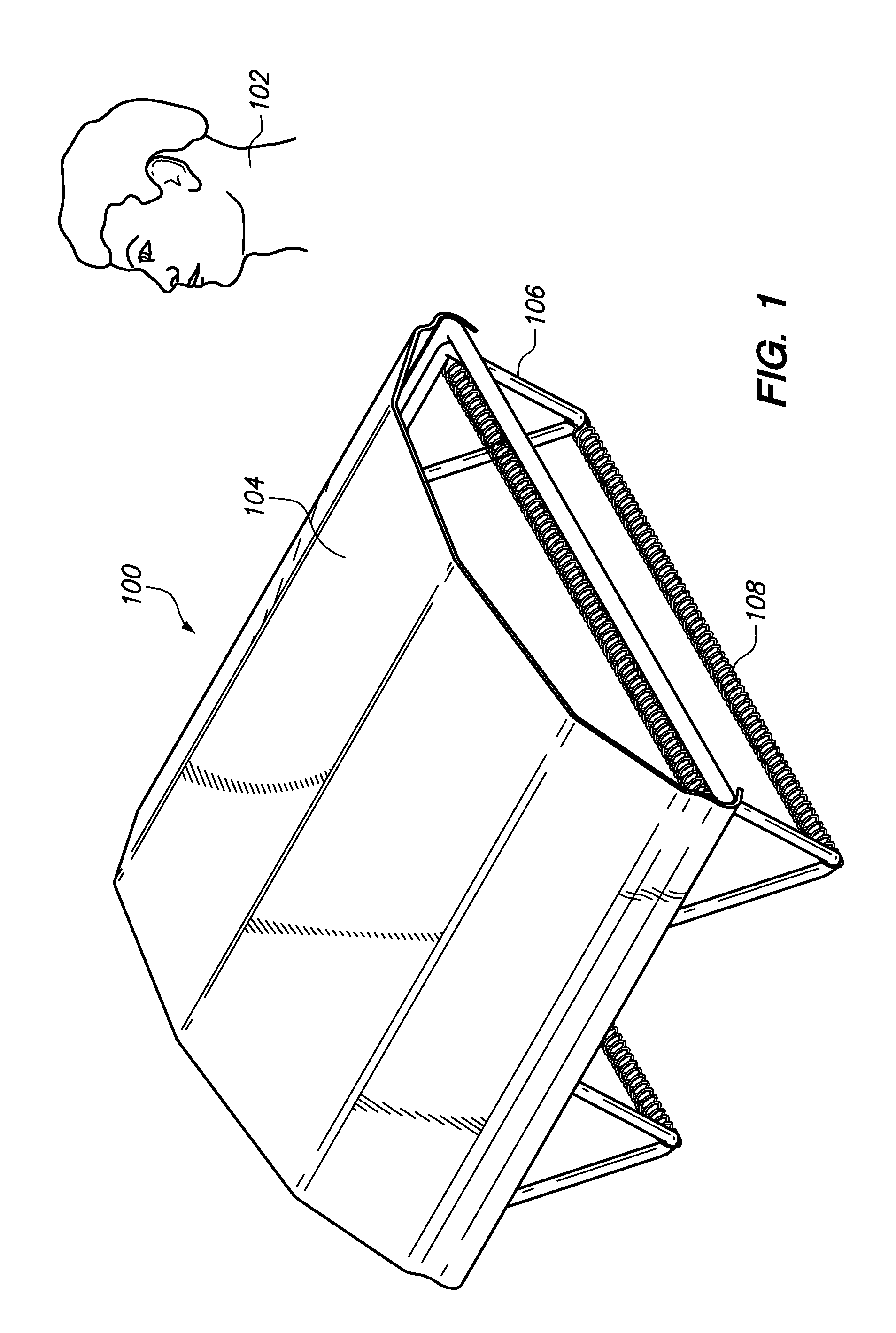

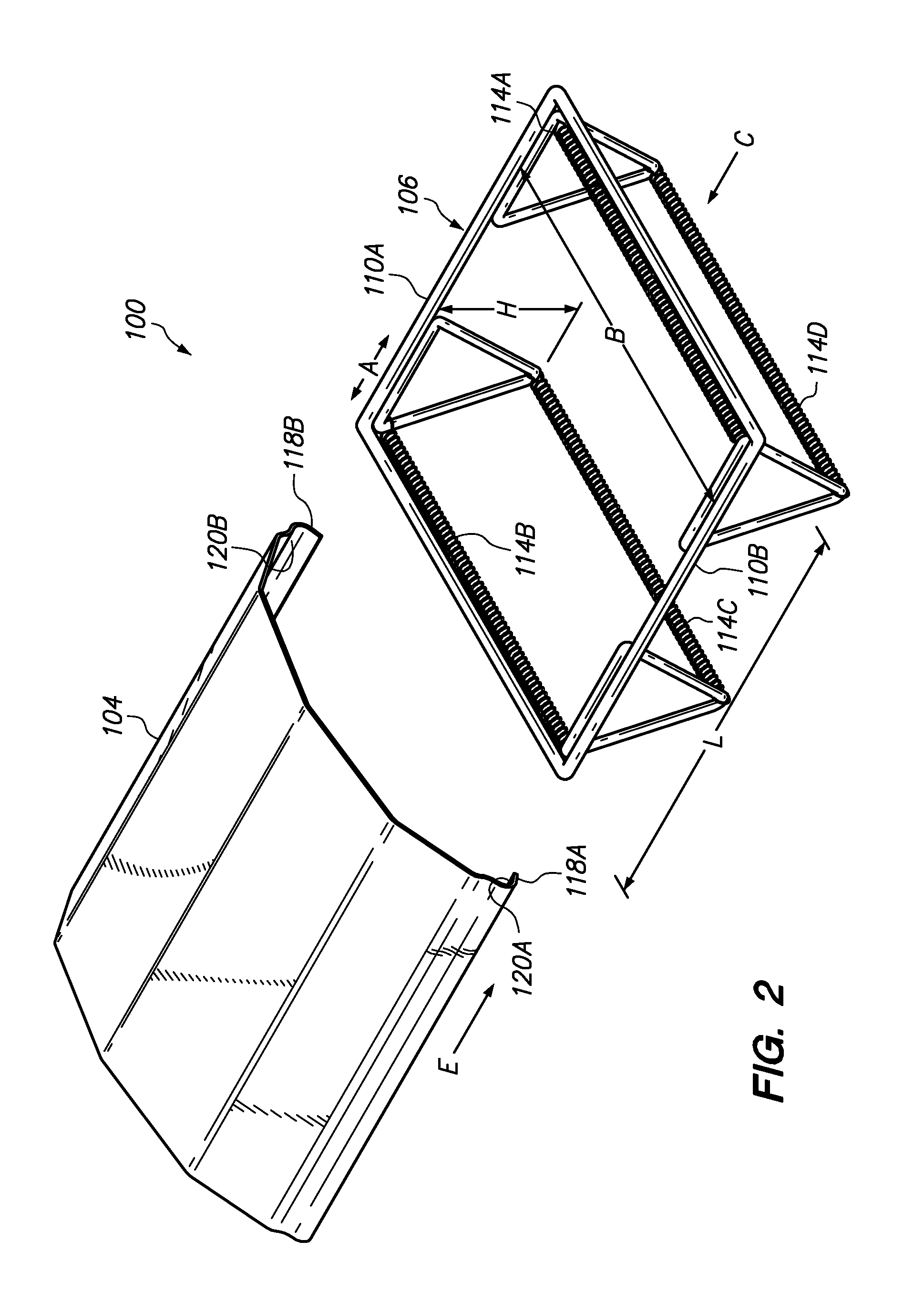

Hand shield system and method for welding

InactiveUS20120097649A1Reduce radiant heatMaximum protectionWelding/cutting auxillary devicesEngineering safety devicesSlagEngineering

A hand-held shield for welding. The shield includes a rigid metal frame for receiving a user's gloved hand. A substantially rectangular plate is detachably engaged over the rigid metal frame forming a shield to cover and protect the user's gloved hands from slags, molten flames and the like that are typically encountered during welding operations.

Owner:DAWSON RICHARD

Top burning type hot blast stove with thermal insulation layer in precombustion chamber

ActiveCN1727498AReduce expansion stressReduce thermal stressBrick-hot blast stovesBlast furnace detailsCombustion chamberThermal insulation

A top combustion type hot air furnace with thermally isolating layer for preburning chamber features that said thermally isolating layer can prevent the transfer of heat from preburning chamber to the internal walls of annular gas cavity and annular air cavity to lower their temp and decrease their temp stress and thermal expansion, so elongating the service life of hot air furnace. A heat isolating layer is also arranged in the second liner between annular gas and air cavities. A movable heat isolating cover is arranged between preburning and burning chambers.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

Method for constructing turf bed and planting lawn on water-storage type roof

InactiveCN1804335AStability is not affectedMeet moisture needsClimate change adaptationRoof drainageWater storageCoverage ratio

The invention relates to a level ground bed on the construction bed and a technique to plant lawn, to solve the problem that the water storage roof in south area is easily to be leaked by rain and the water quality is easily to be polluted, and the project that changing the water storage roof into slope roof can not realize the city heat island effect. Based on planting lawn on the water storage roof, it increases city natural underlay surface, to reduce roof heat radiation, improve green coverage ratio, reduce energy consumption of air conditioner, increase the oxygen amount and release the city heat island effect.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com