Patents

Literature

35results about How to "Reduce expansion stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

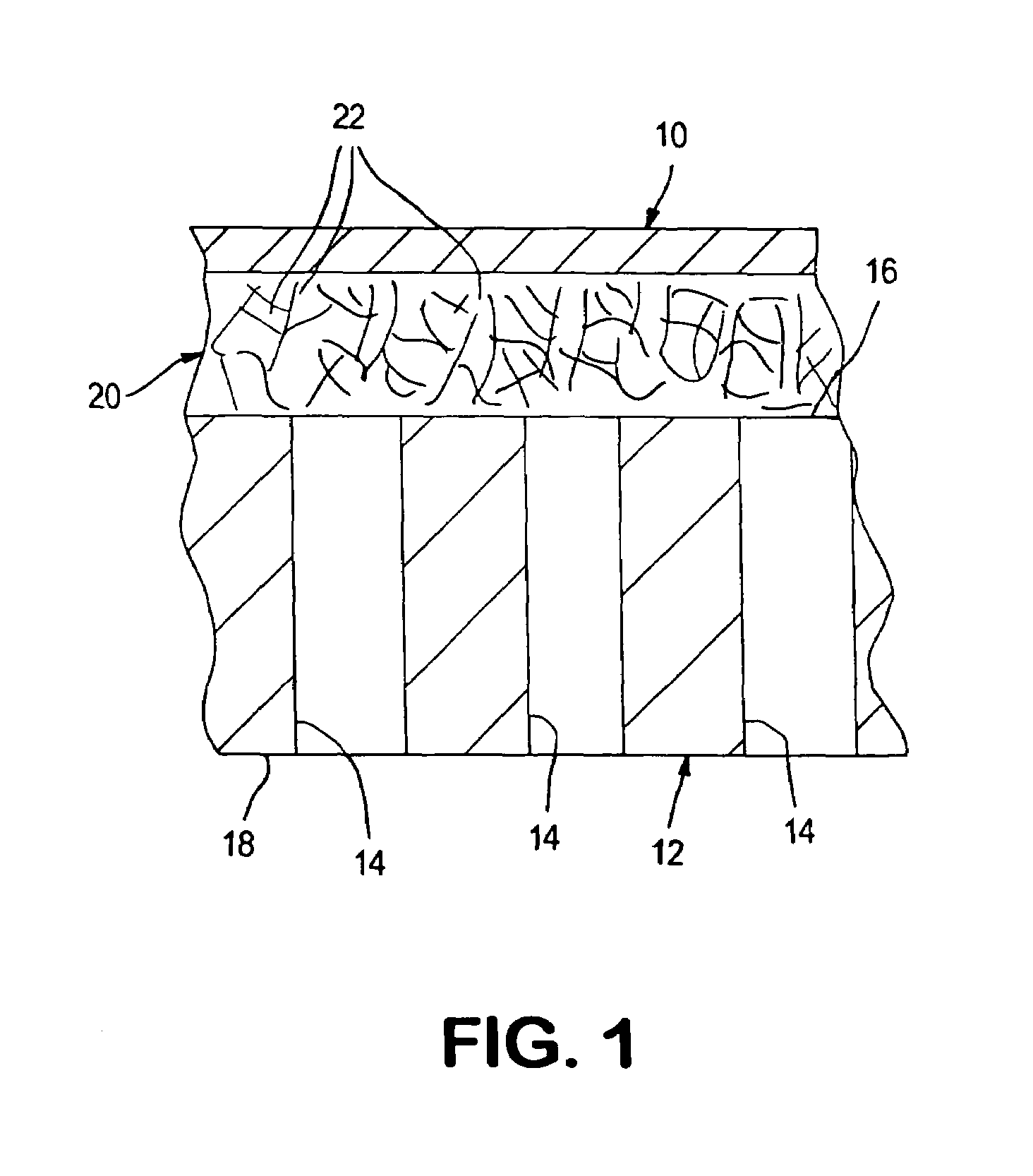

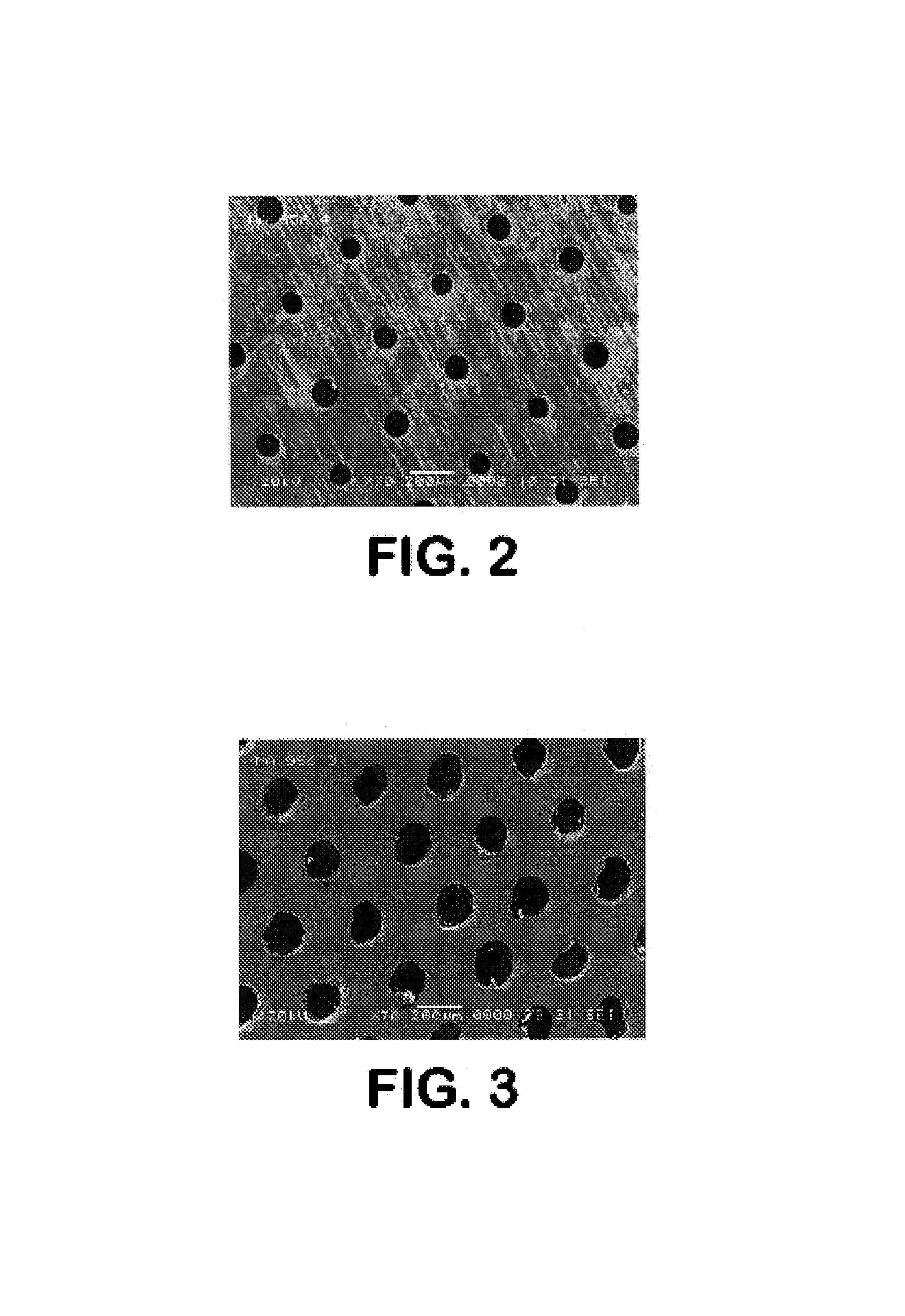

Composite oxygen ion transport element

ActiveUS20050061663A1Reduce expansion stressHigh degree of toughnessLayered productsIsotope separationLayered structureMixed conductor

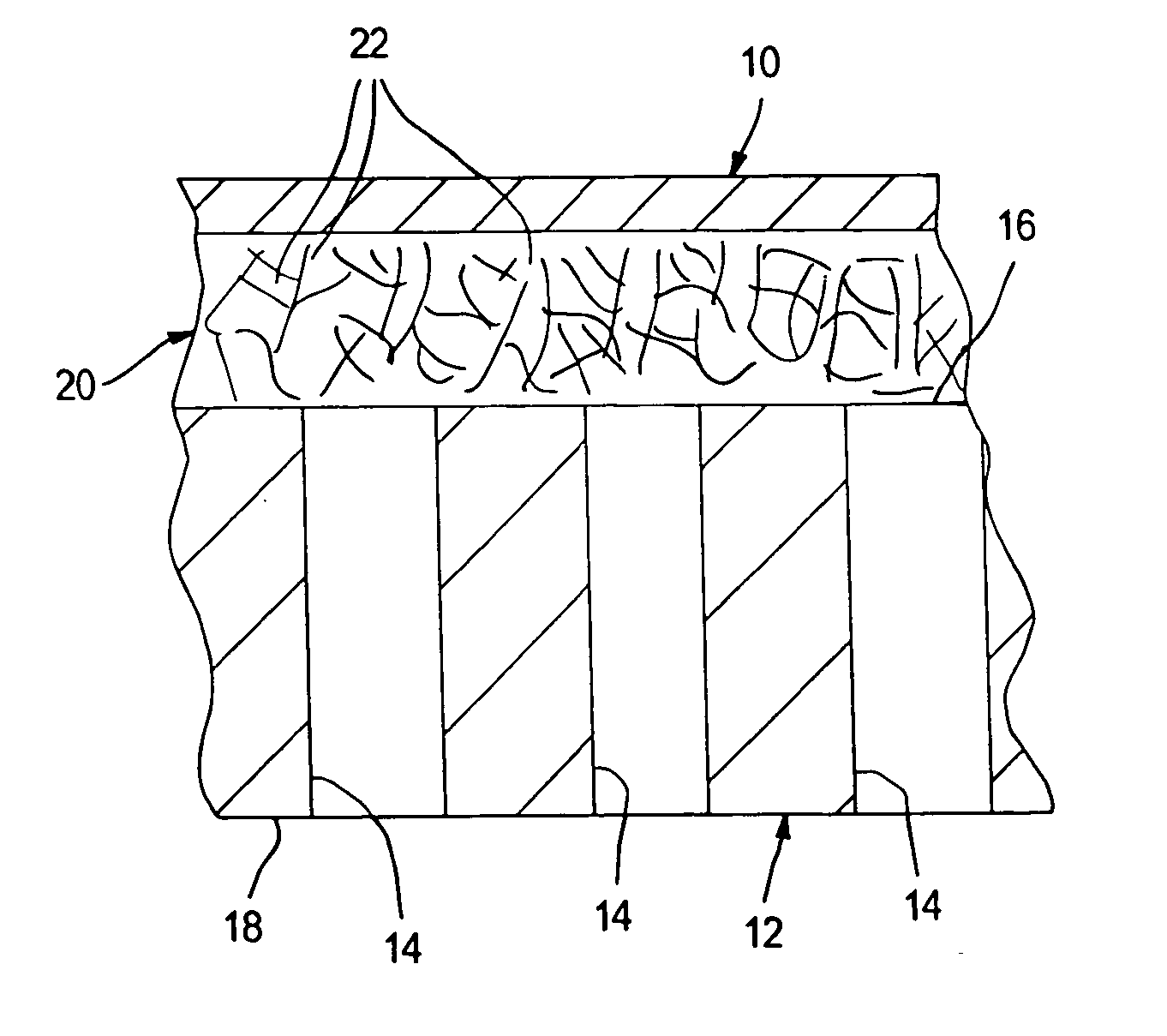

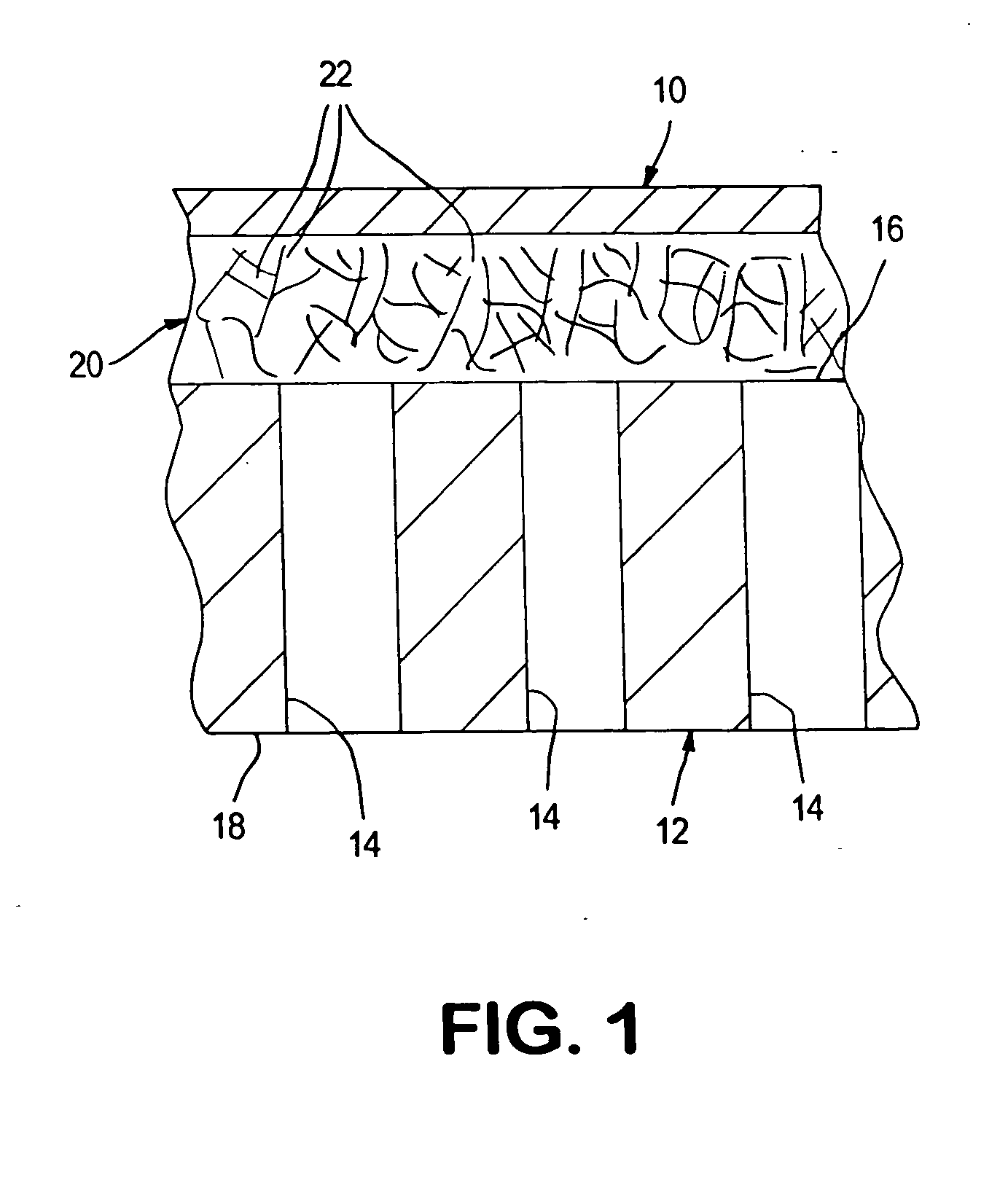

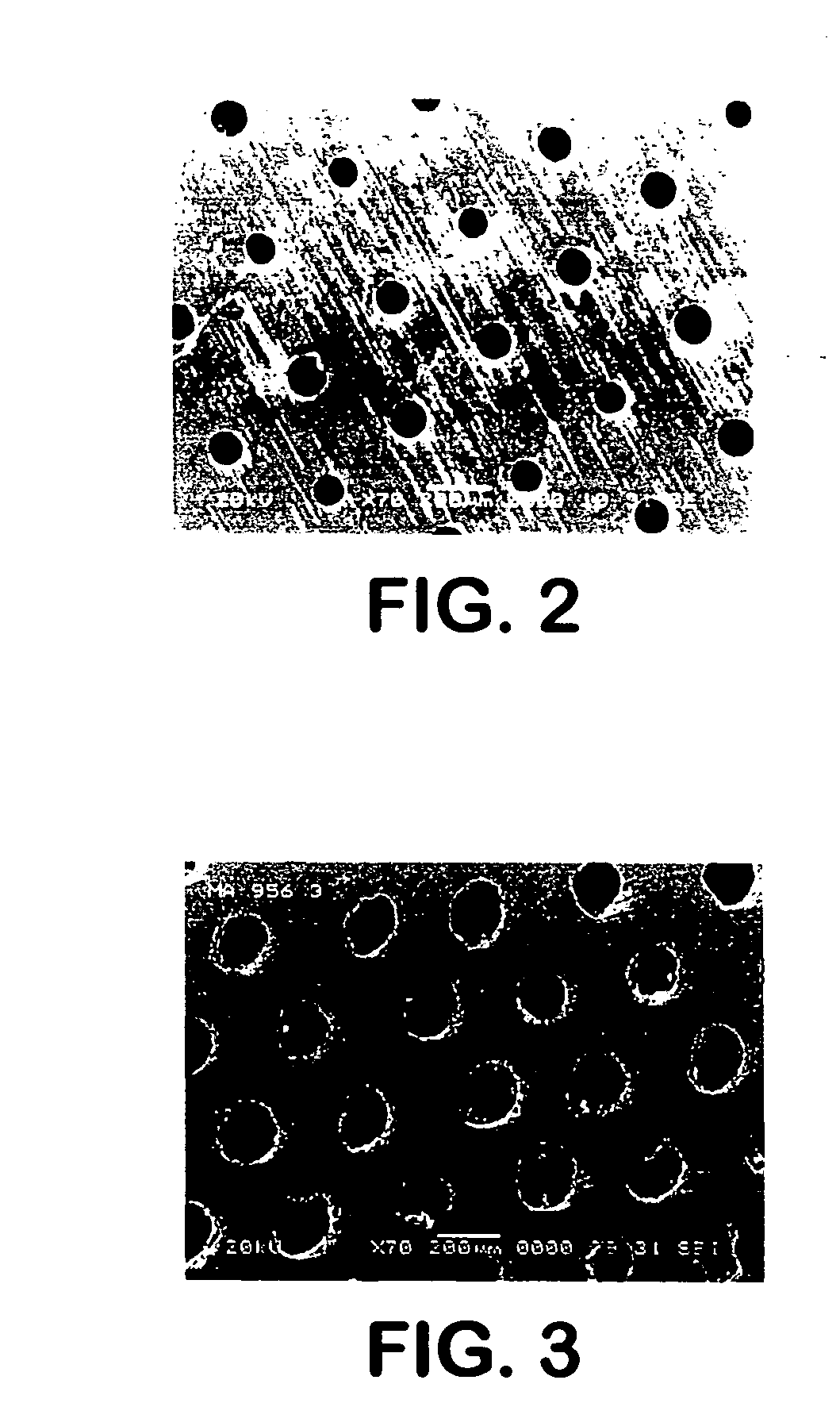

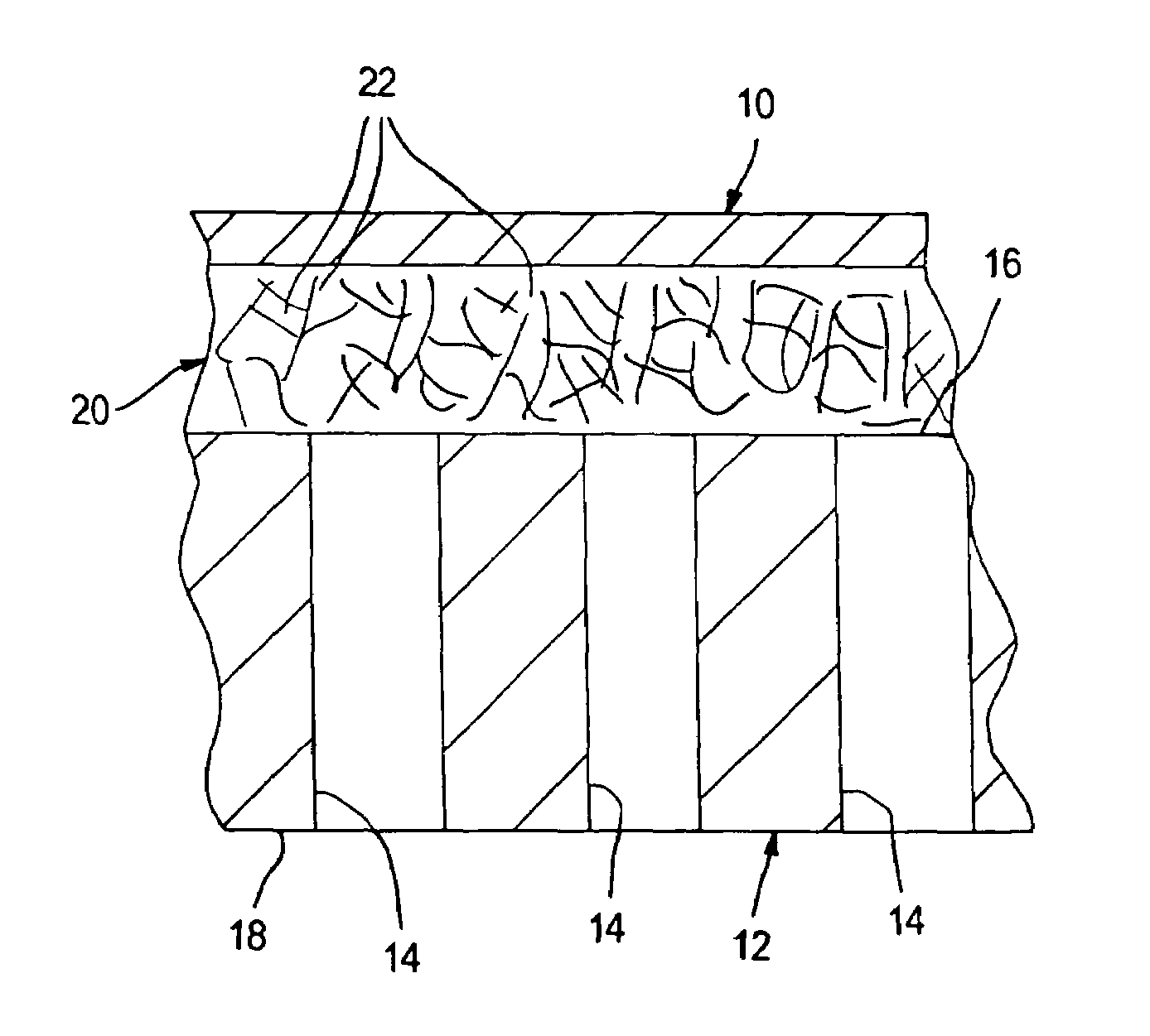

A composite oxygen ion transport element that has a layered structure formed by a dense layer to transport oxygen ions and electrons and a porous support layer to provide mechanical support. The dense layer can be formed of a mixture of a mixed conductor, an ionic conductor, and a metal. The porous support layer can be fabricated from an oxide dispersion strengthened metal, a metal-reinforced intermetallic alloy, a boron-doped Mo5Si3-based intermetallic alloy or combinations thereof. The support layer can be provided with a network of non-interconnected pores and each of said pores communicates between opposite surfaces of said support layer. Such a support layer can be advantageously employed to reduce diffusion resistance in any type of element, including those using a different material makeup than that outlined above.

Owner:PRAXAIR TECH INC +1

Composite oxygen ion transport element

ActiveUS7229537B2Improve flux performanceImprove toughnessLayered productsIsotope separationElectrical conductorDiffusion resistance

A composite oxygen ion transport element that has a layered structure formed by a dense layer to transport oxygen ions and electrons and a porous support layer to provide mechanical support. The dense layer can be formed of a mixture of a mixed conductor, an ionic conductor, and a metal. The porous support layer can be fabricated from an oxide dispersion strengthened metal, a metal-reinforced intermetallic alloy, a boron-doped Mo5Si3-based intermetallic alloy or combinations thereof. The support layer can be provided with a network of non-interconnected pores and each of said pores communicates between opposite surfaces of said support layer. Such a support layer can be advantageously employed to reduce diffusion resistance in any type of element, including those using a different material makeup than that outlined above.

Owner:PRAXAIR TECH INC +1

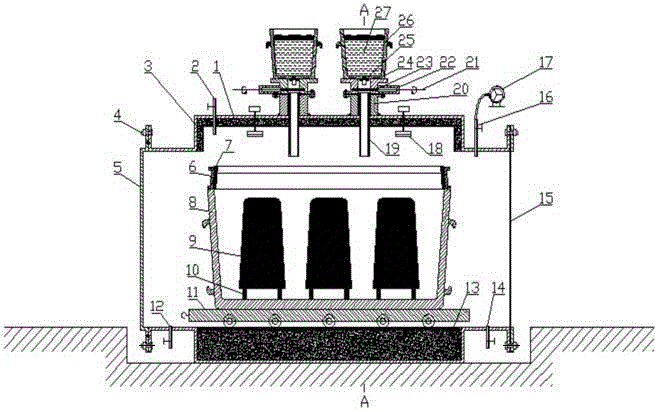

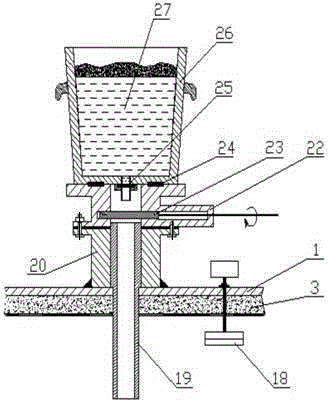

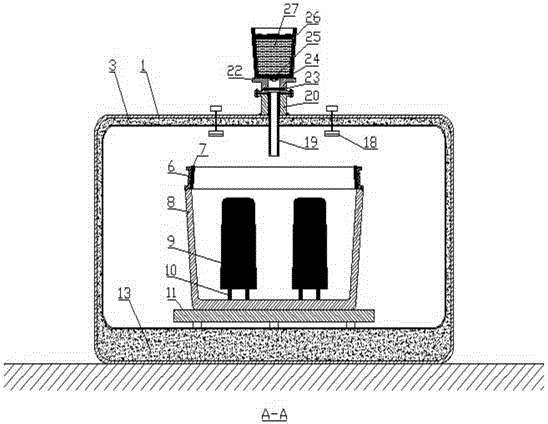

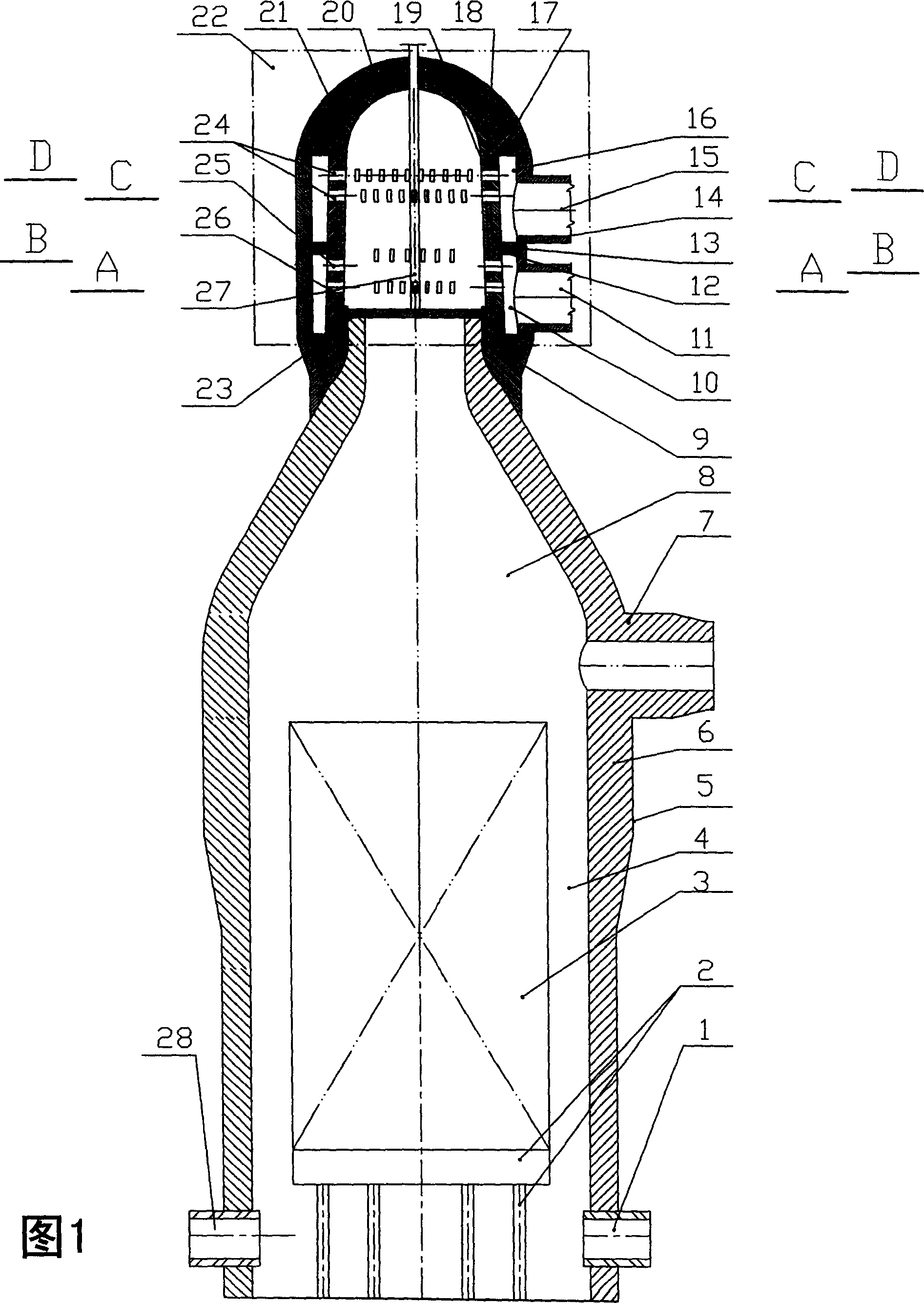

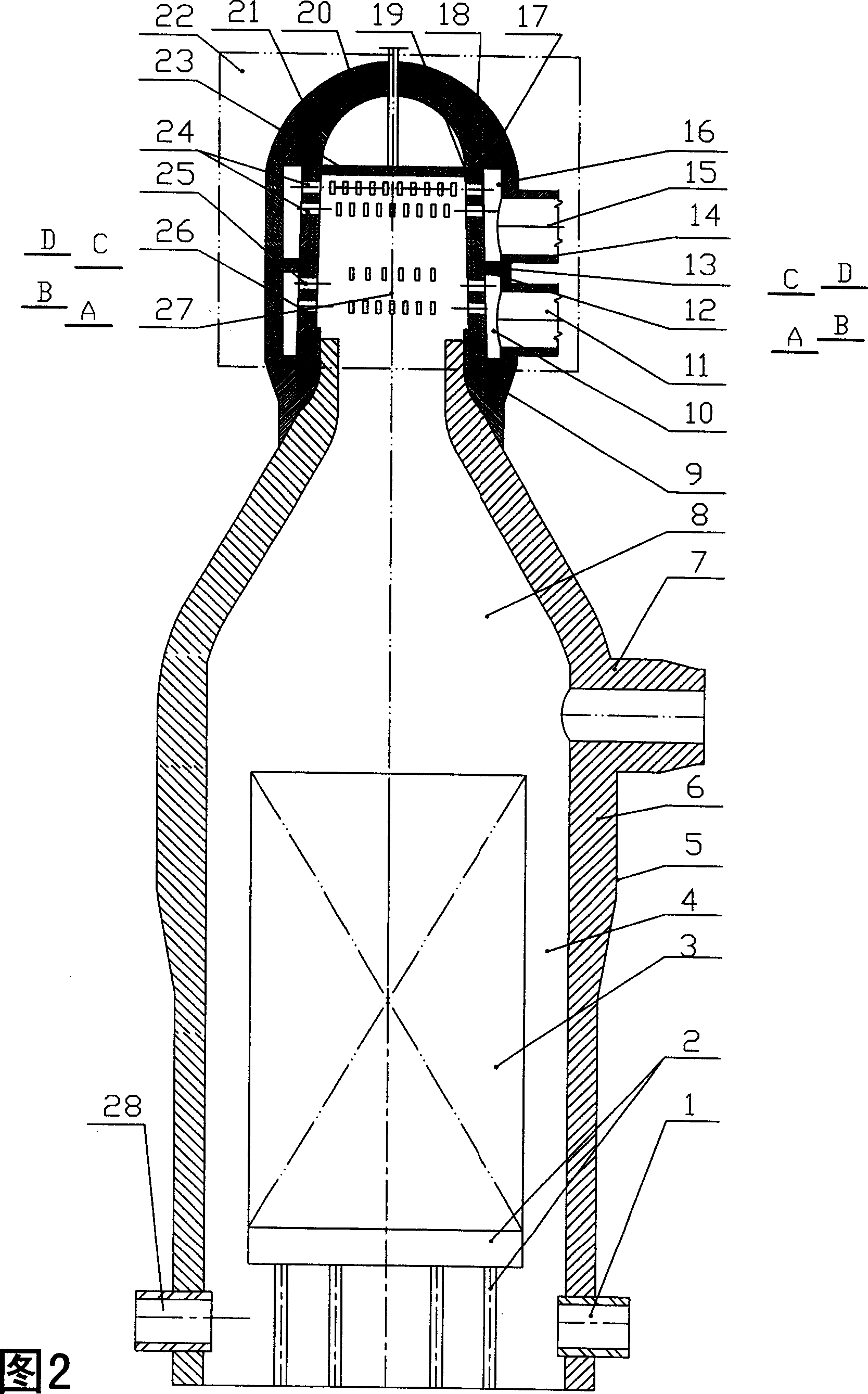

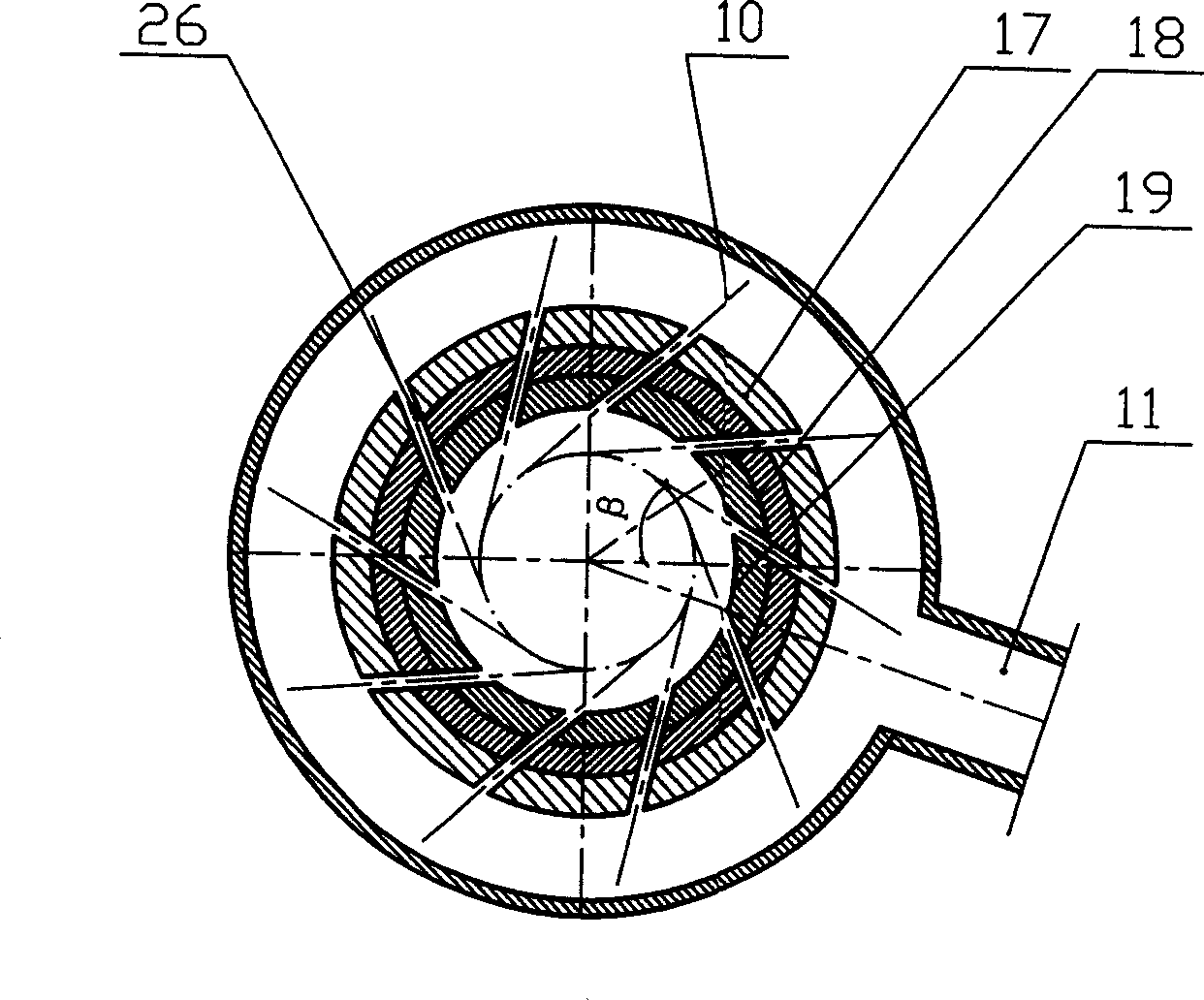

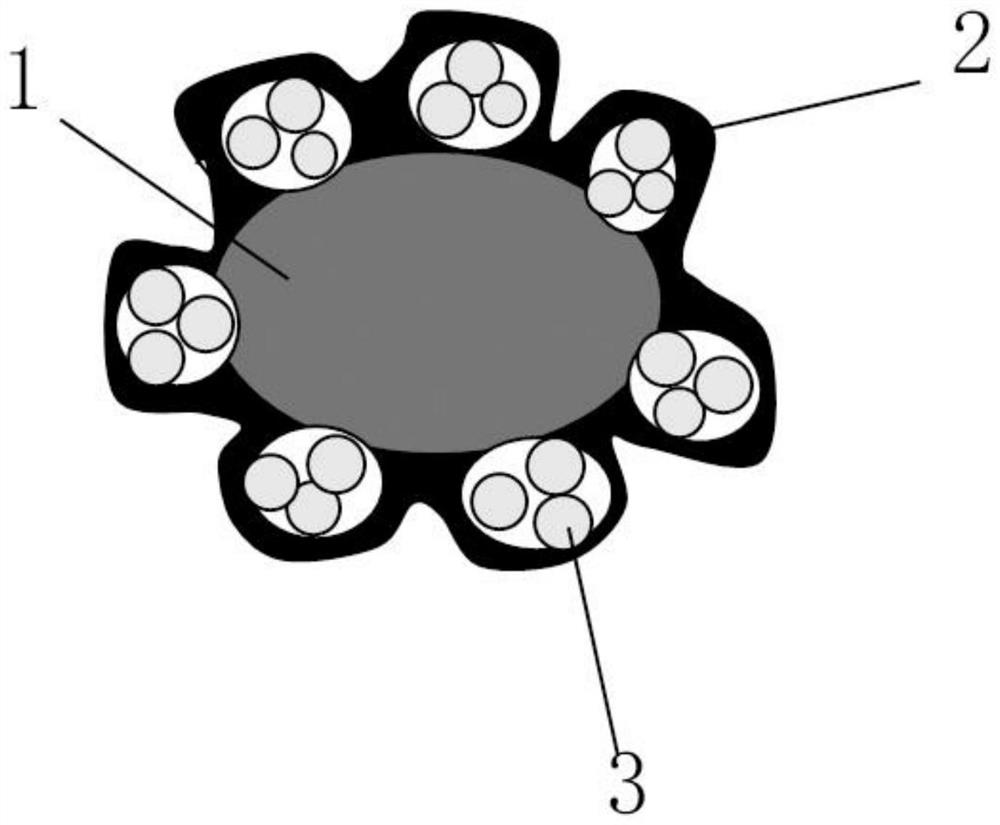

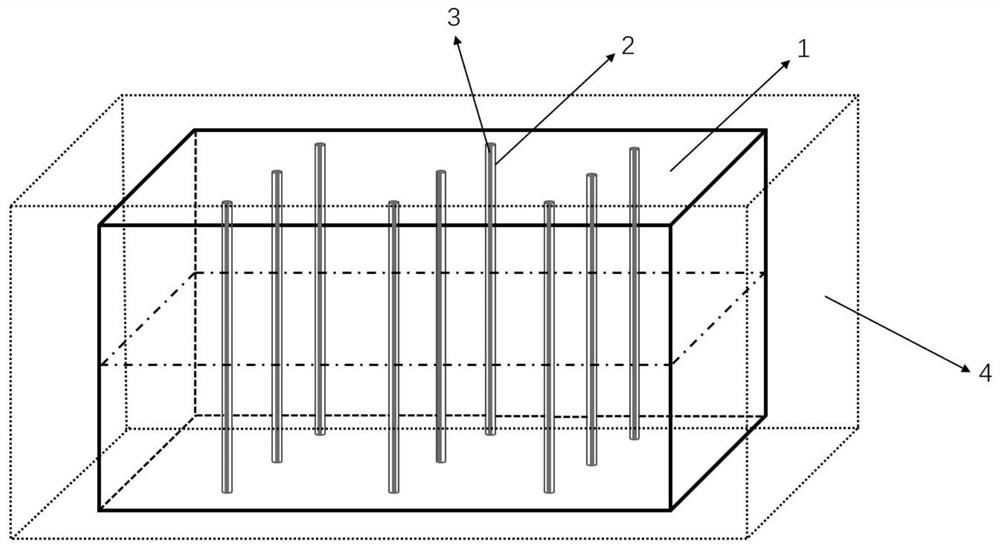

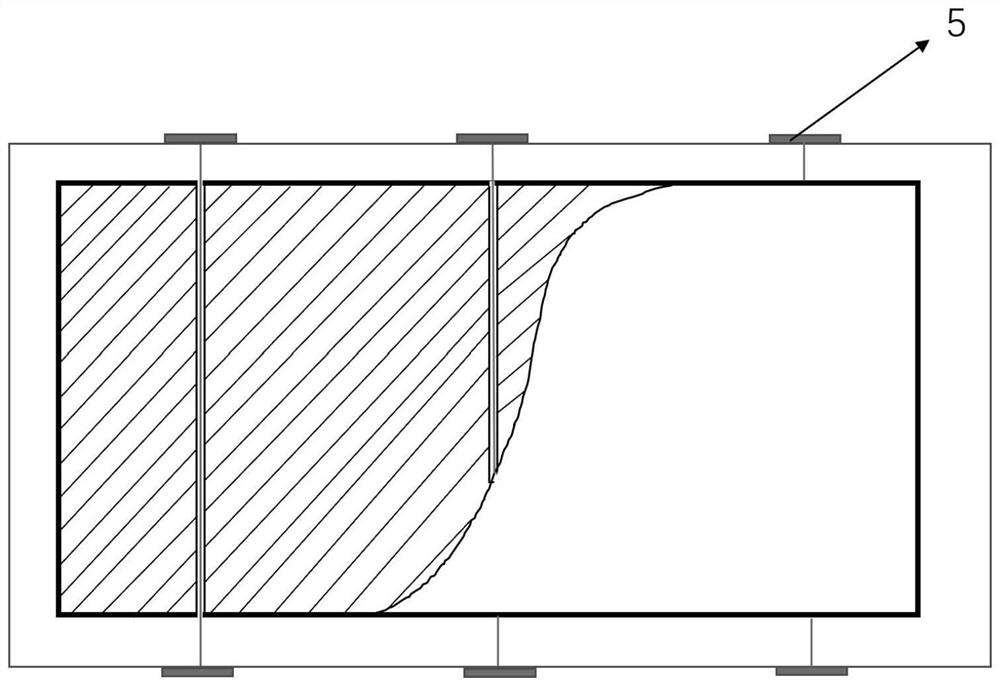

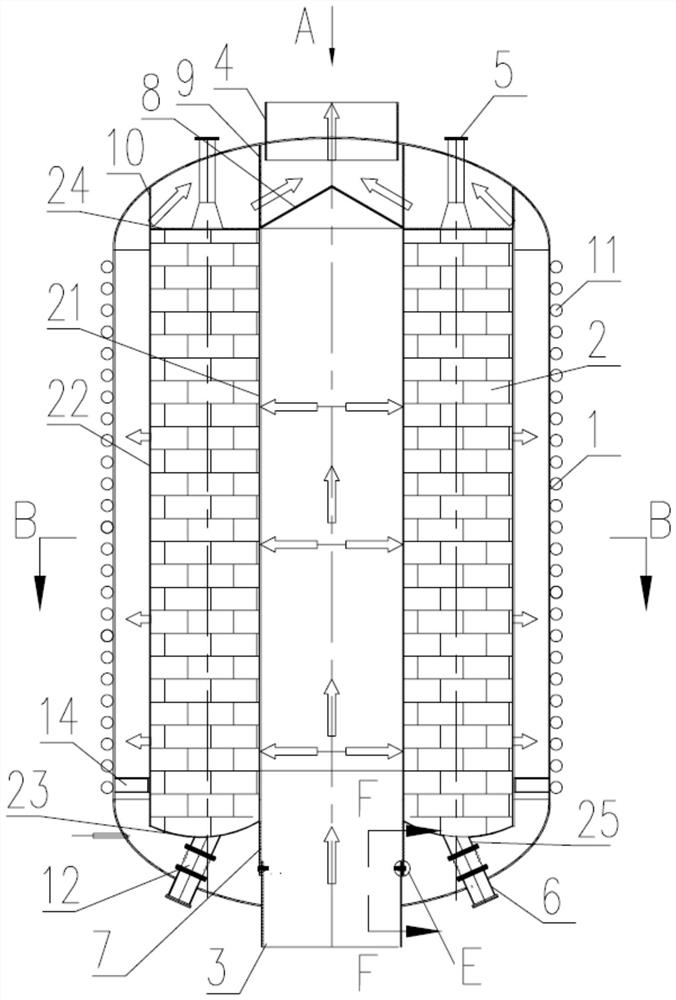

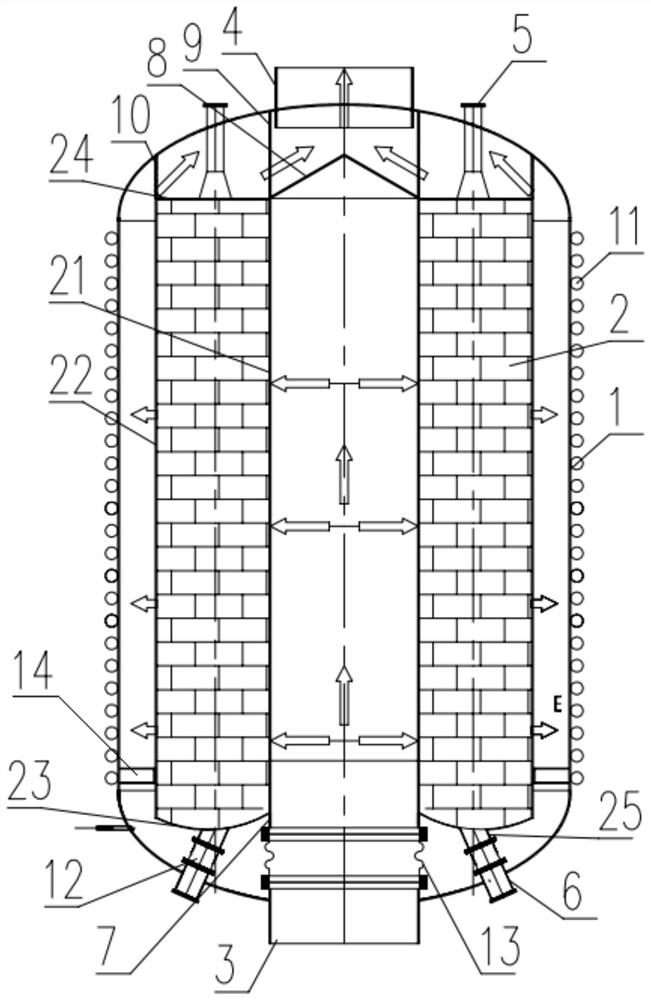

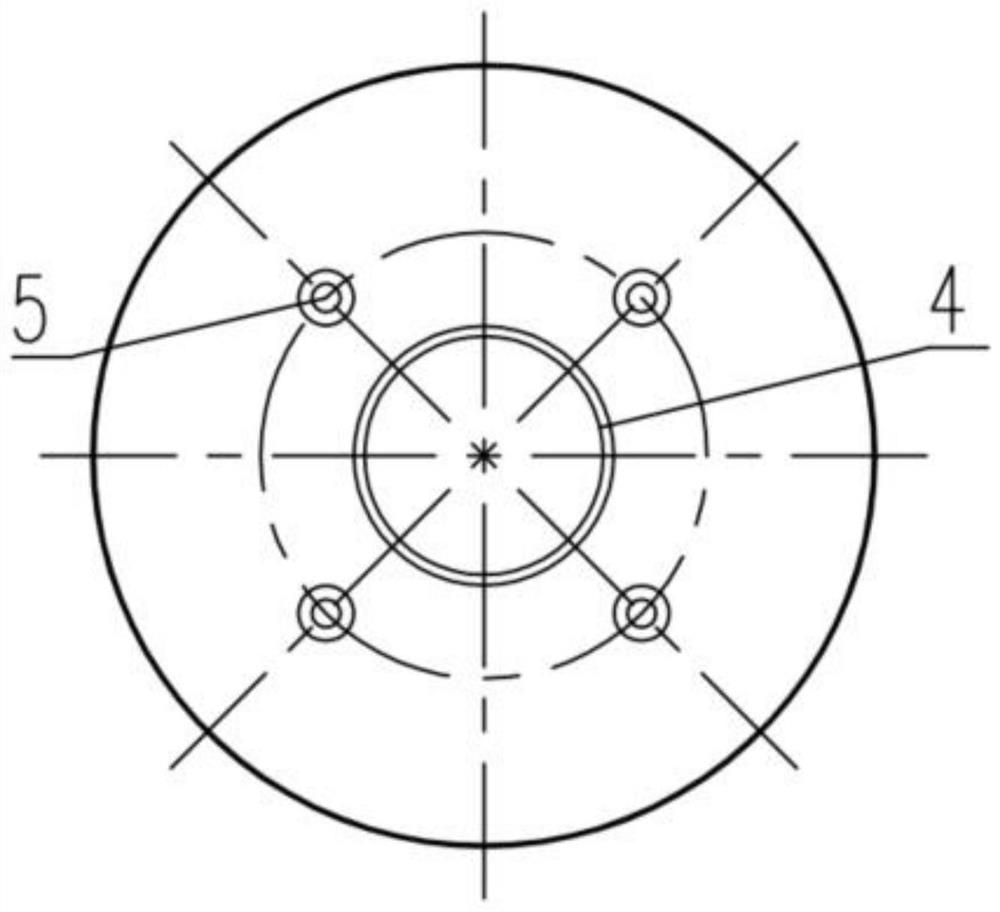

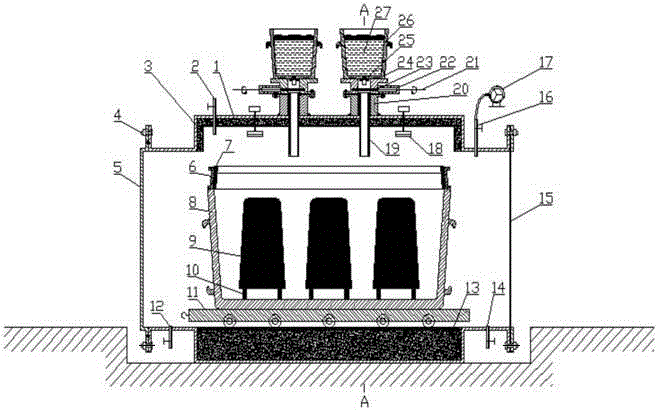

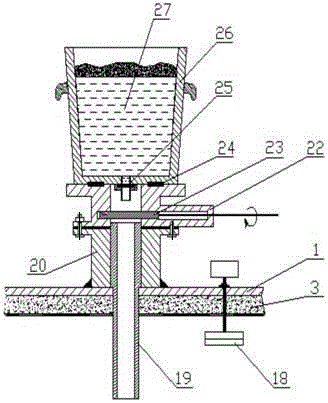

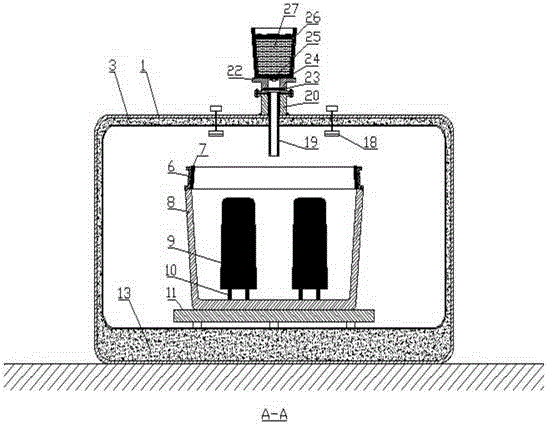

Multi-core reducing multi-ladle co-casting method and device for casting large composite steel ingots

The invention discloses a multi-core reducing multi-ladle co-casting method and device for composite casting large composite steel ingots. The multi-core reducing multi-ladle co-casting method comprises the steps of selecting core blanks, regulating the temperatures of the core blanks, re-removing scales on the surfaces of the core blanks, assembling the core blanks and ingot molds, reducing oxide scales on the surfaces of the core blanks, casting and compositing and cooling composite ingots. The device adopted by the method comprises a tank body, a reducing gas inlet, a heat preservation layer, bolts, a bin door, risers, heat insulation plates, the steel ingot molds, the core blanks, shims, a trolley, an inert gas inlet, a bottom heat insulation layer, an exhaust port, an explosion-proof end cap, a vacuum exhaust valve, a vacuum pump, circulating fans, riser bricks, casting channels, sealing valve rods, sealing valve bodies, sealing valve plates, sealing asbestos, sliding nozzles and steel ladles. Large and ultra-large molded steel ingots which cannot be produced by means of an orthodox casting method can be manufactured. The steel ingots manufactured by means of the multi-core reducing multi-ladle co-casting method and device has the advantages of being low in production cost, high in solidification speed, small in internal segregation, even in components and high in finished product rate.

Owner:佛山市金禾精密模具有限公司

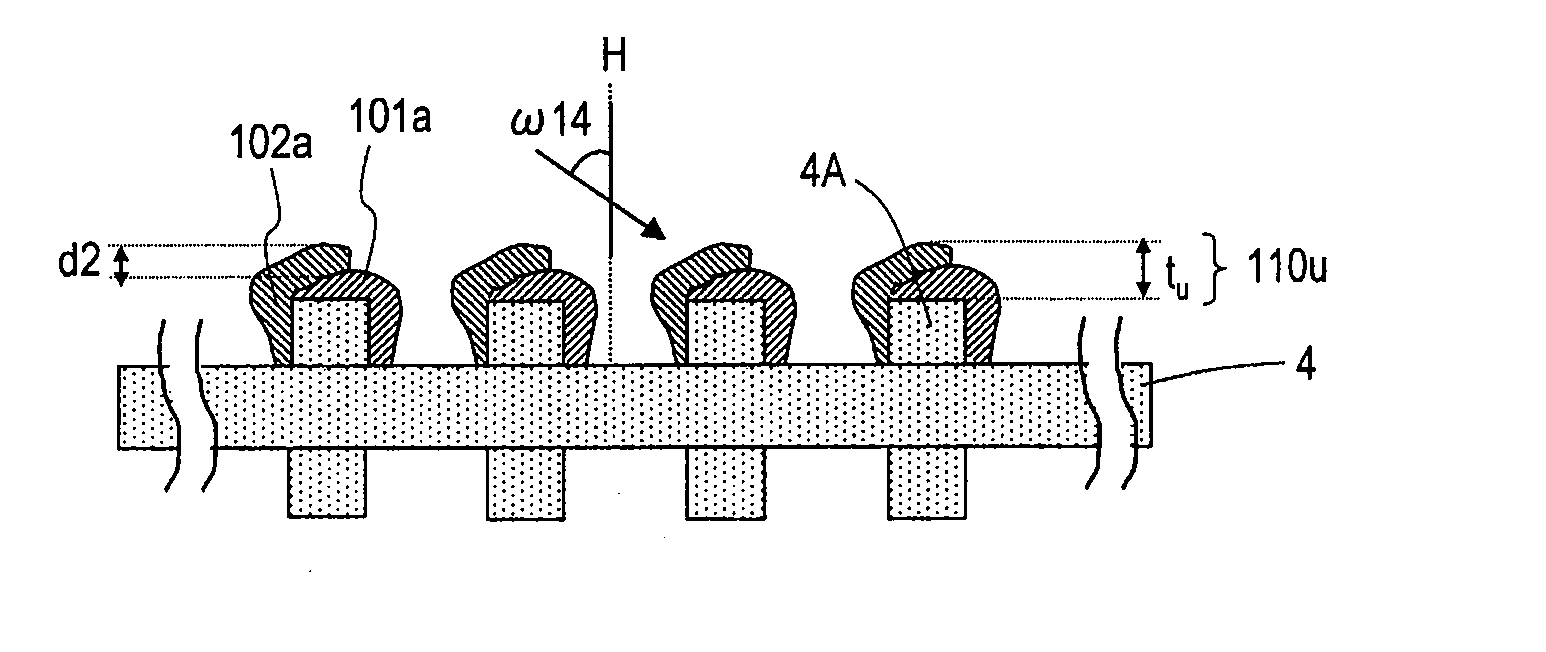

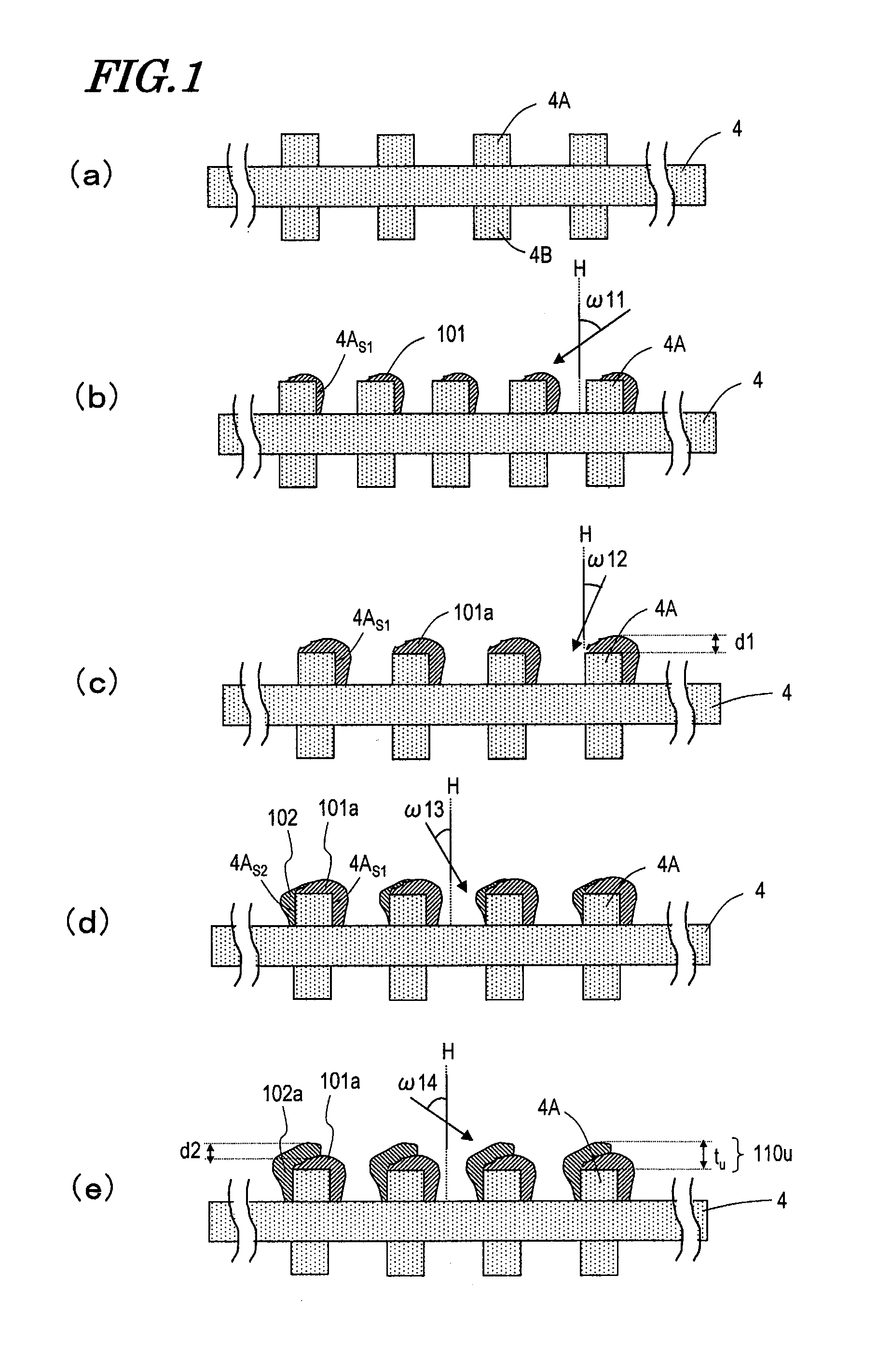

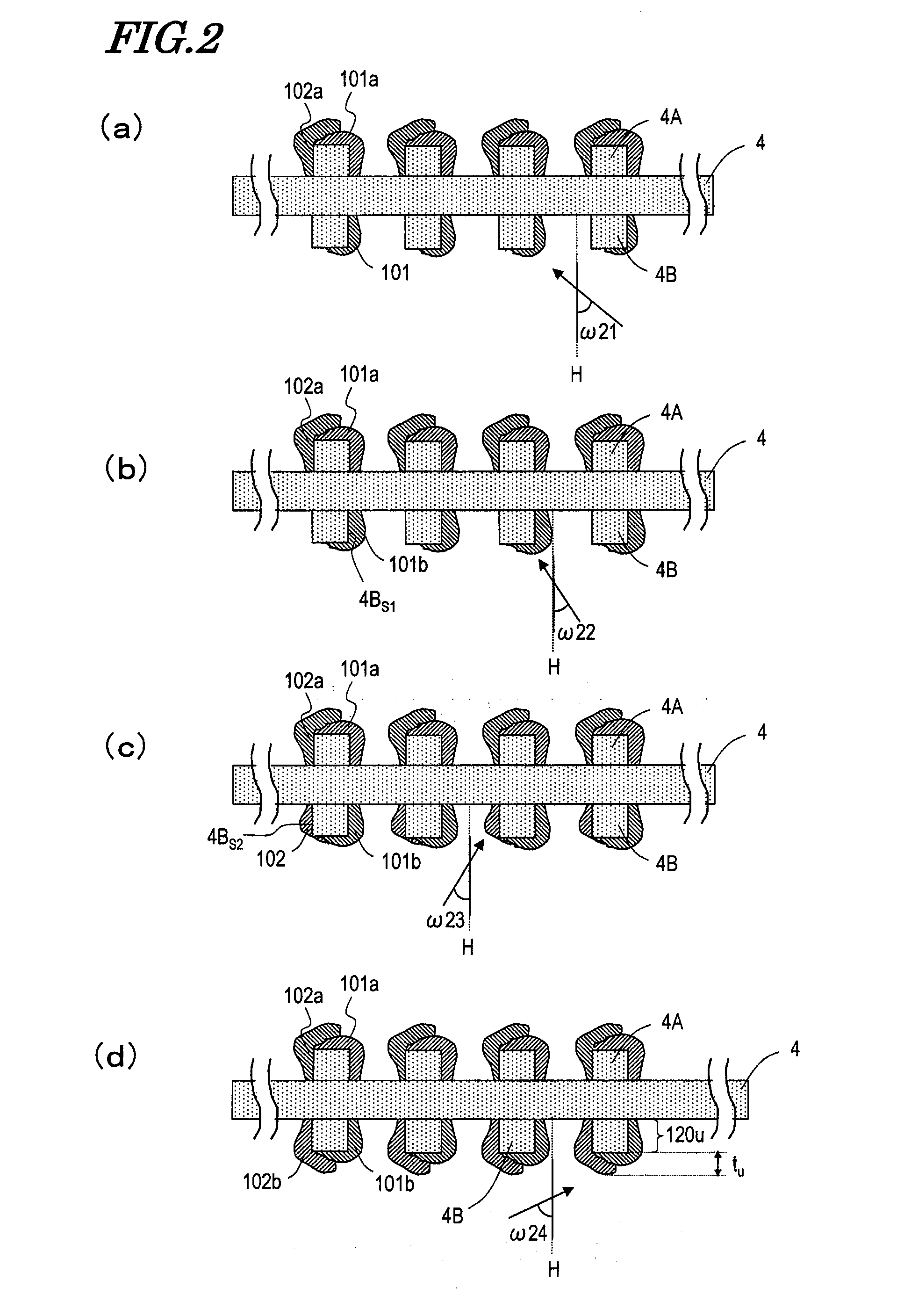

Method for manufacturing electrochemical element electrode

InactiveUS20100330420A1Reduce the amount requiredReduce expansion stressElectrode carriers/collectorsActive material electrodesElectrochemistryAtomic physics

Includes the steps of preparing a sheet-like current collector 4 having a plurality of bumps 4A on a surface thereof, the plurality of bumps having a height of 3 μm or greater and 10 μm or less; and forming an active material body having a stacked structure on each of the bumps 4A of the current collector 4. The step of forming the active material body includes a first layer vapor deposition step of causing a vaporized vapor deposition material to be incident on the surface of the current collector 4 in a direction inclined with respect to the normal H to the current collector 4 to form a first layer 101a of the active material body on each bump 4A, the first layer 101a being located closest to the current collector; and a second layer vapor deposition step of causing the vaporized vapor deposition material to be incident on the surface of the current collector 4 in a direction inclined, with respect to the normal H to the current collector 4, opposite to the incidence direction of the vapor deposition material in the first layer vapor deposition step to form a second layer 102a on at least a part of the first layer 101a. In the first layer vapor deposition step, vapor deposition is performed while moving the current collector 4 in a direction in which the incidence angle ω of the vapor deposition material with respect to the normal H to the current collector 4 is decreased.

Owner:PANASONIC CORP

Silicon carbon negative electrode material, preparation method of silicon carbon negative electrode material and lithium ion battery

InactiveCN103199225AImprove conductivityImprove cycle lifeCell electrodesSodium-ion batteryLithium-ion battery

The invention relates to a silicon carbon negative electrode material, a preparation method of the silicon carbon negative electrode material and a lithium ion battery. The preparation method comprises the steps of firstly mixing an organosilicon compound with a reducing agent, and reacting the organosilicon compound and the reducing agent to obtain a silicon pyrolysis material; then mixing the silicon pyrolysis material with graphite nodules to obtain a silicon pyrolysis carbon material; and etching the obtained silicon pyrolysis carbon material in a acid solution, mixing the etched silicon pyrolysis carbon material with a saline solution containing metal ions, and depositing metal and metal oxides to obtain the silicon carbon negative electrode material. According to the preparation method, the organosilicon, which is cheap and is easily available, is taken as a raw material, and the surface of the prepared composite silicon carbon material is covered with a metal layer with favorable electric conductivity and a metal oxide layer to form a conductive network, so that the electric conductivity of the silicon carbon negative electrode material is improved. Meanwhile, the metal and the metal oxides used for packing can efficiently lower the volume expansion and the mechanical stress in the charge and discharge processes of lithium ions, thereby prolonging the cycle life of the prepared composite material.

Owner:上海乾视通信技术有限公司

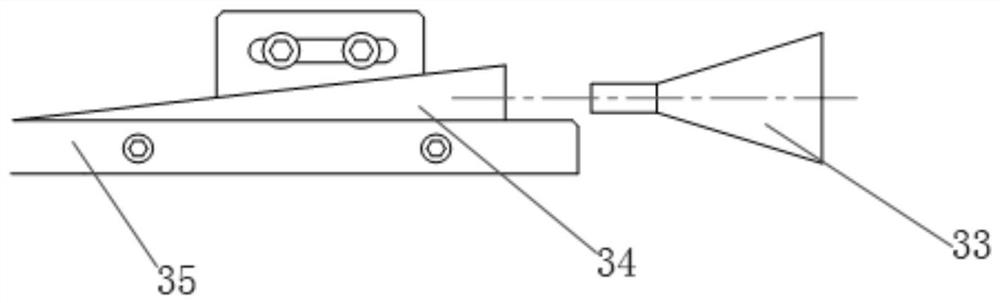

Submerged arc welding process

The invention discloses a process for carrying out submerged arc welding on two plates with thicknesses of no more than 14 mm. The process comprises the following steps: after one part to be welded forms a groove, checking an assembling clearance between the two plates and making the assembling clearance satisfy requirements, fixing a gasket on the back face of an abutted part; enabling a variable speed submerged arc welding trolley to move along a welding joint at a constant speed; controlling a welding wire to swing backwards relative to the trolley in a reciprocating way at a constant speed in the direction of the welding joint when the welding wire on the trolley moves at the constant speed with the trolley; controlling the swinging amplitude of the welding wire, so that the swinging arc of the welding wire always falls within a range of a molten pool; and adjusting the height of the welding wire so as to guarantee that an electric arc can directly act upon the root of the groove when the welding wire is positioned at a swinging arc front point. According to the invention, the desired welding current is reduced, linear energy is also reduced, the expansion stress of the welding joint is reduced and cracks are uneasy to generate on a welding joint terminal; moreover, as the two sides of the side wall of the groove can be continuously heated by the electric arc, the deposition rate is increased, the production efficiency is increased, the electric quantity and the consumption of the welding material are reduced and the production cost is reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

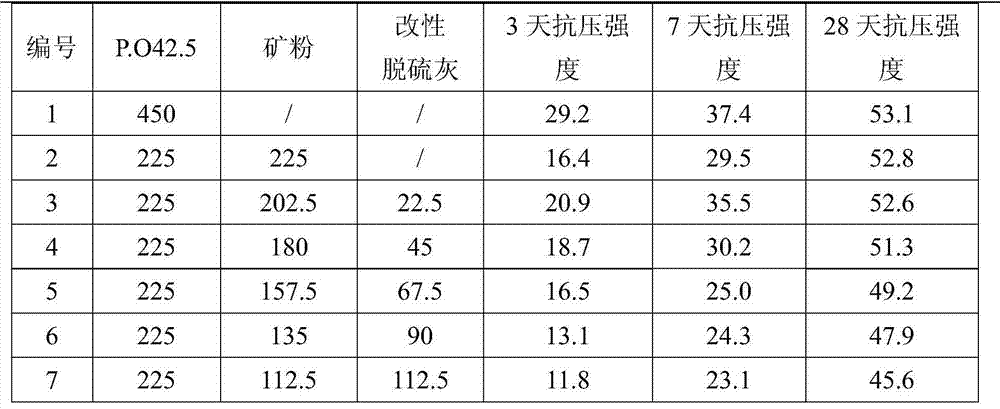

Modified desulfurization ash for cement and concrete and preparation method thereof

InactiveCN103803828AImprove early compressive strengthNo reduction in compressive strengthAcetic acidCompressive strength

The invention discloses modified desulfurization ash for cement and concrete and a preparation method of the modified desulfurization ash. The modified desulfurization ash for cement and concrete is prepared from desulfurization ash and an oxidizing agent through mixing at normal temperature, wherein the oxidizing agent comprises the following components by weight percentage: 70-80% of manganese dioxide, 5-10% of acetic acid and 10-25% of desulfuration residue, the conversion rate of CaSO4.2H2O in the modified desulfurization ash is 95-98%, the mixing amount of the modified desulfurization ash in cement and concrete is 5-25% (by weight percentage). The modified desulfurization ash has early compressive strength improved remarkably when being added into the cement and the concrete, has the compressive strength hardly reduced after being solidified completely, and has little swelling stress.

Owner:武汉武新新型建材股份有限公司

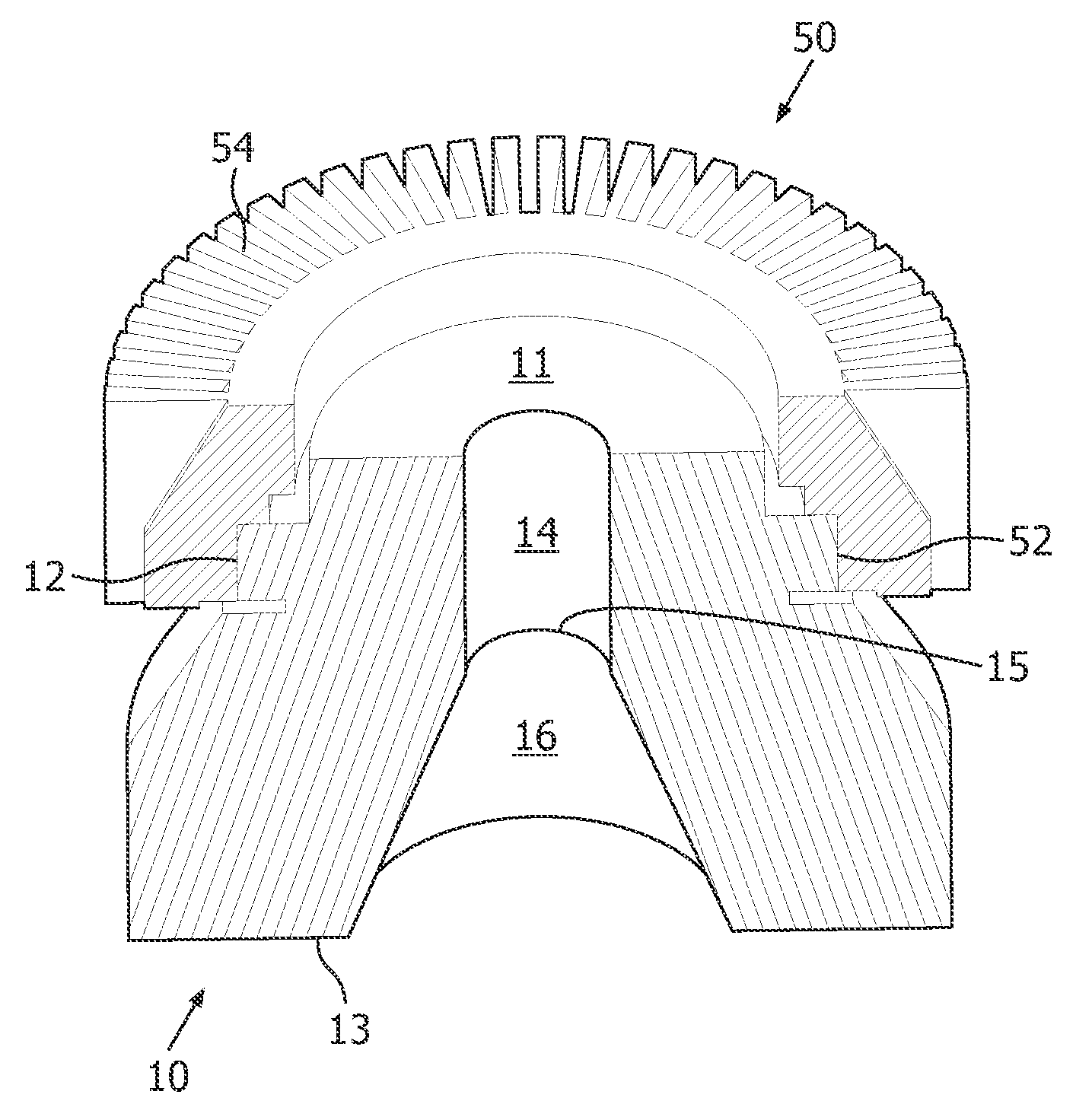

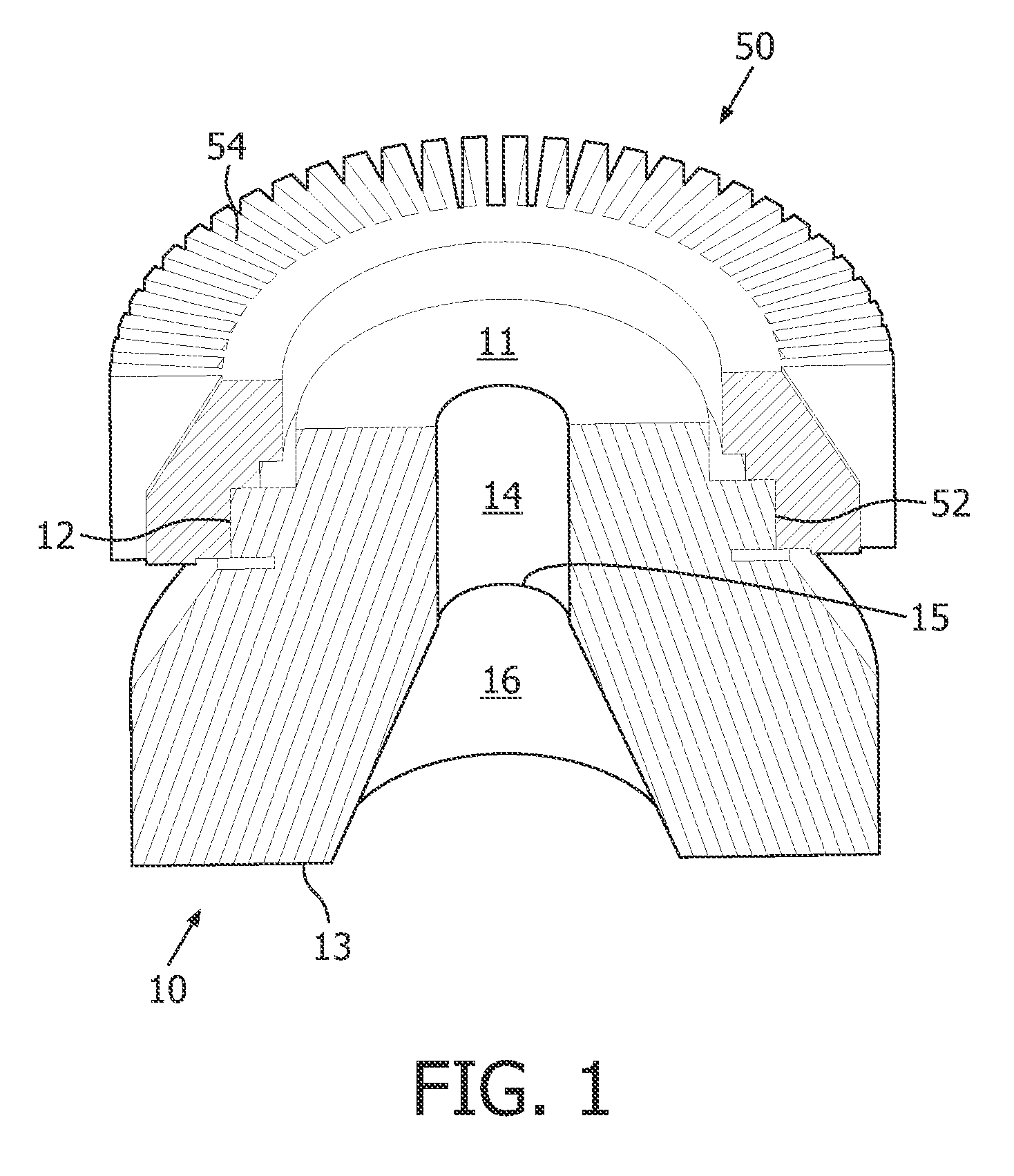

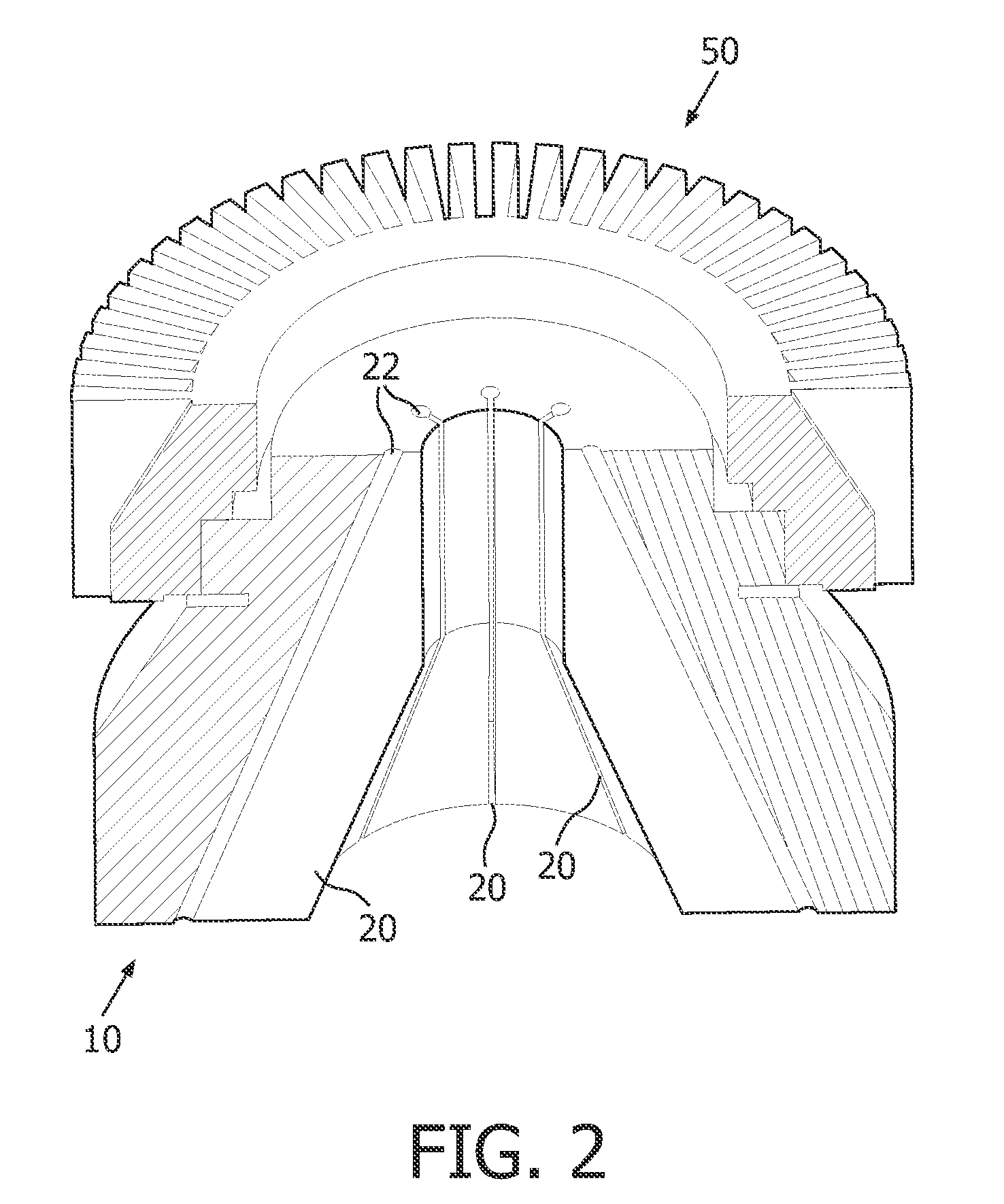

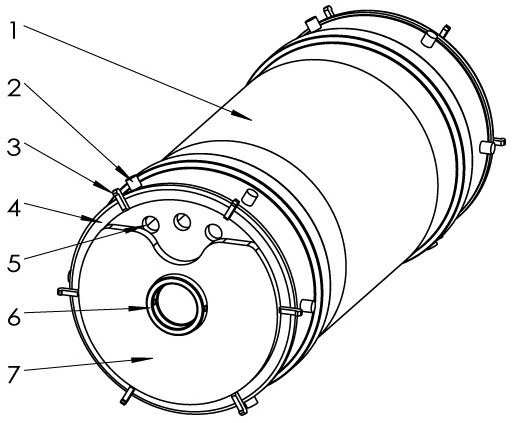

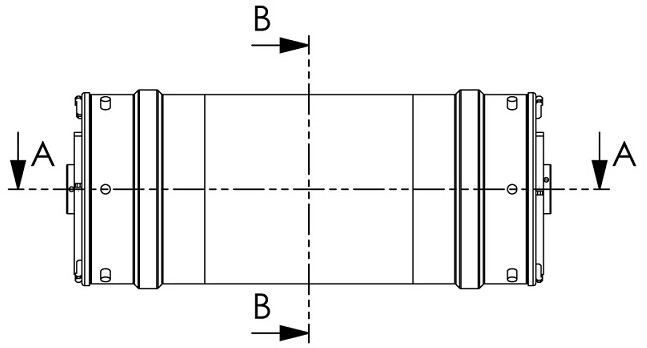

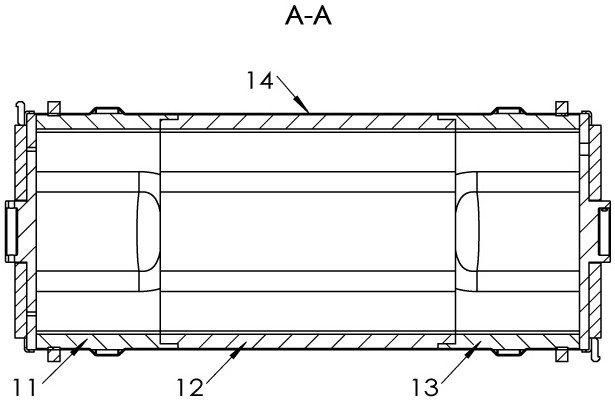

Scattered electron collector

ActiveUS20100278309A1Reduce compressive stressReduce expansion stressX-ray tube electrodesX-ray tube vessels/containerMechanical engineeringElectron

Scattered electron collector comprising a heat absorbing member having a first end, a second end, an outer periphery and a central bore (14, 16), wherein the central bore is formed in longitudinal direction through the heat absorbing member from the first end to the second end, and a cooling element (50) having an outer periphery and an inner periphery (52). The outer periphery (12) of the heat absorbing member is adapted to be in contact with the inner periphery of the cooling element. Further, at least one slot (20) is formed from the central bore in the direction to the outer periphery of the heat absorbing member to reduce compression stress within the heat absorbing member.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

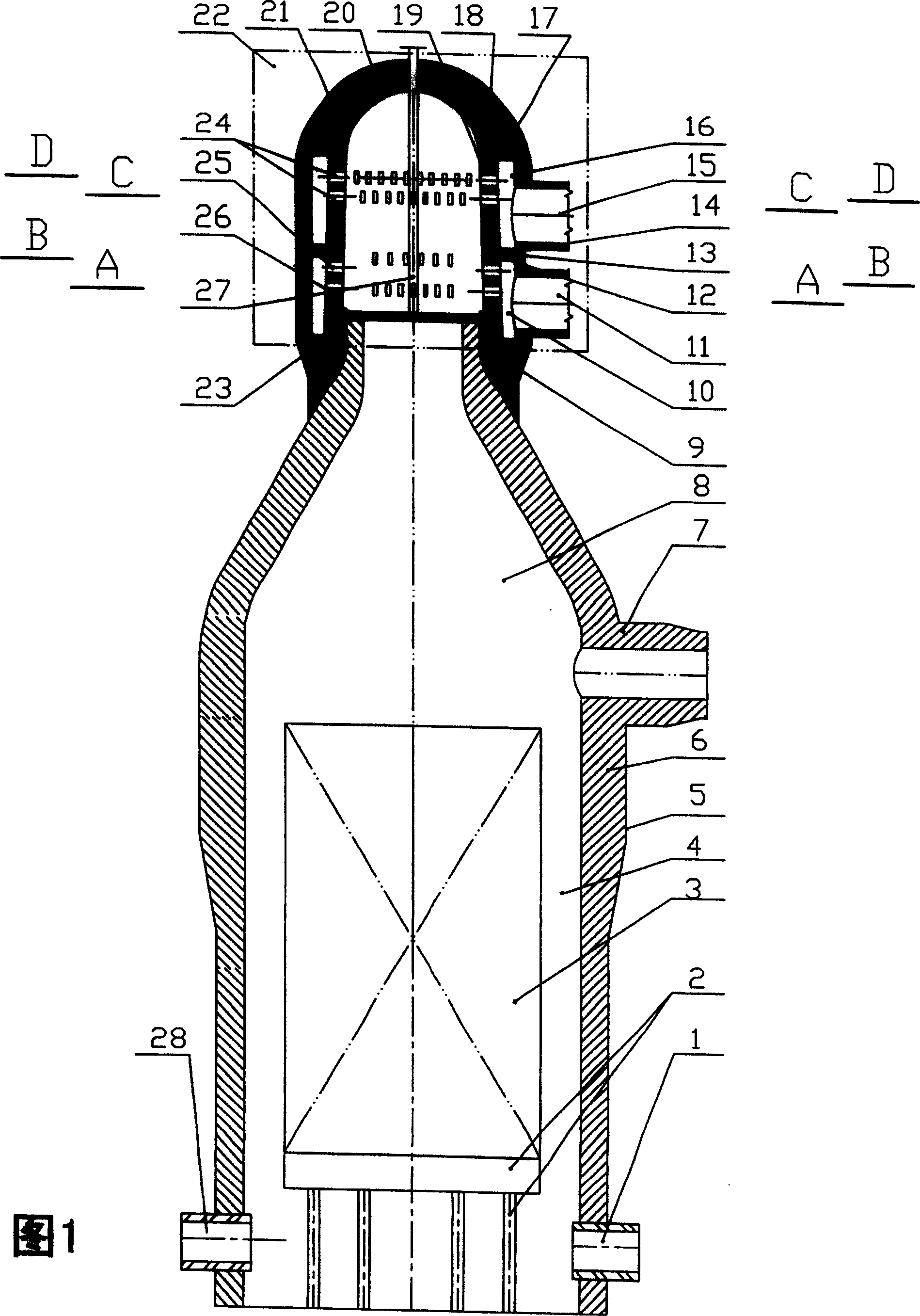

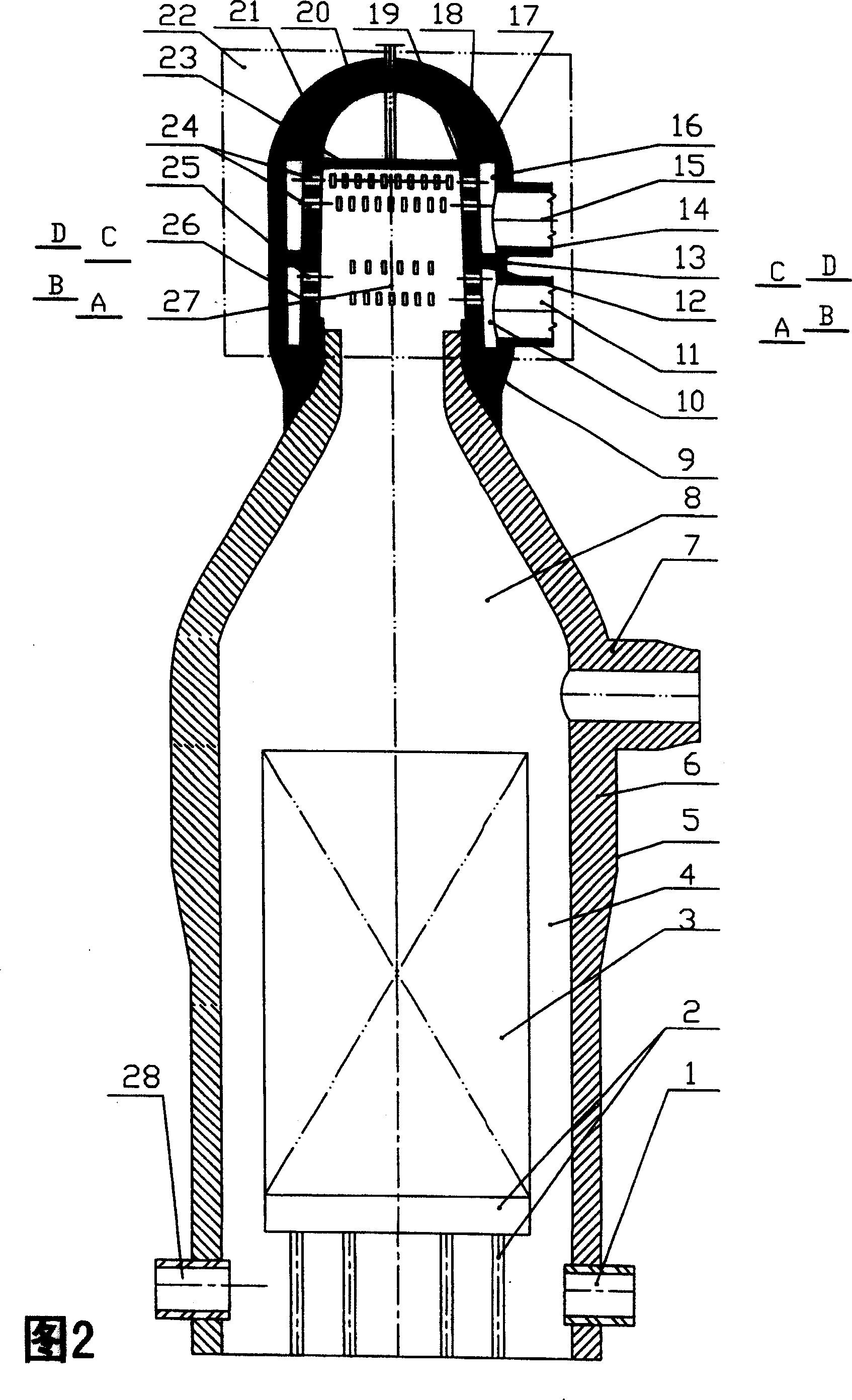

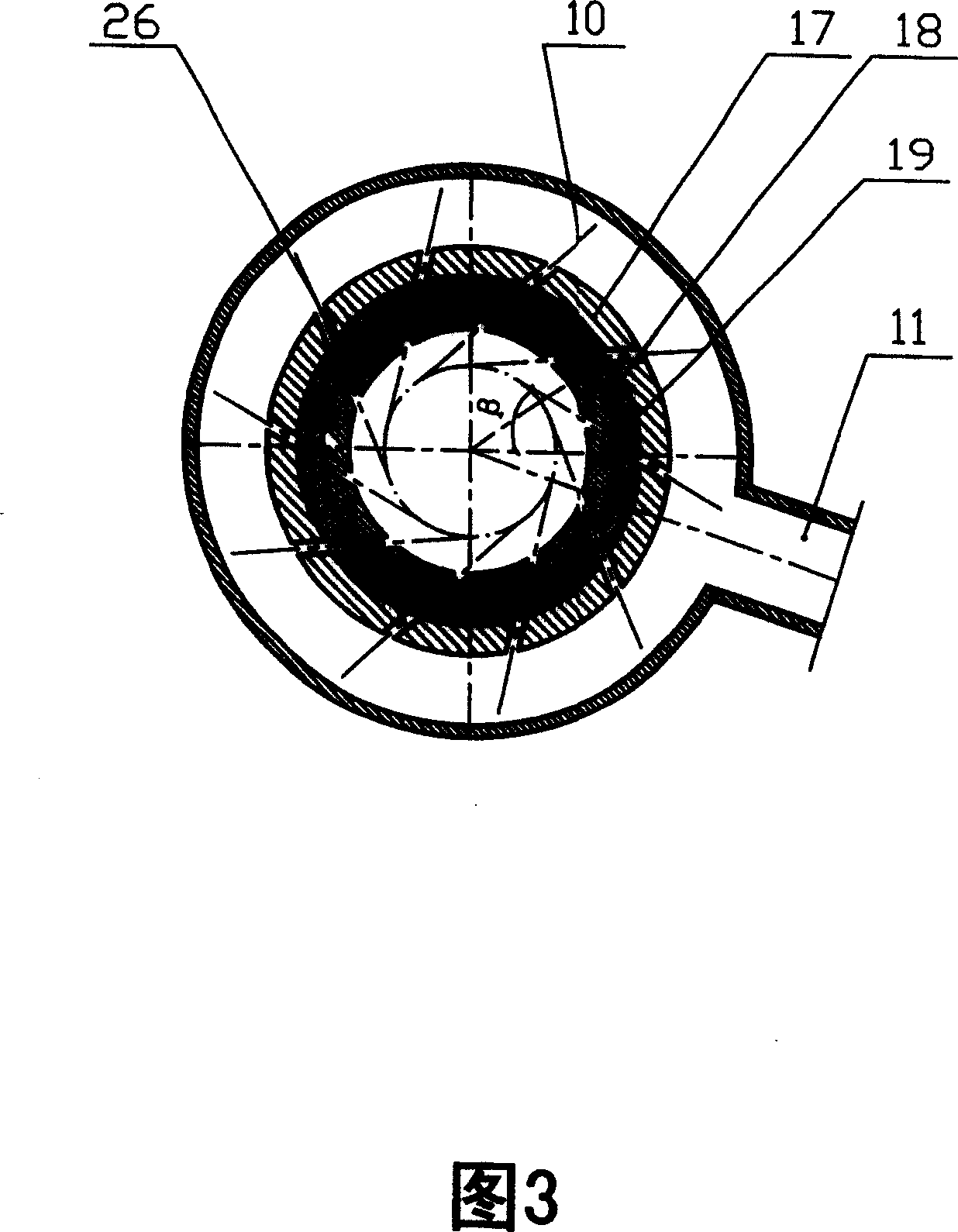

Top burning type hot blast stove with thermal insulation layer in precombustion chamber

ActiveCN1727498AReduce expansion stressReduce thermal stressBrick-hot blast stovesBlast furnace detailsCombustion chamberThermal insulation

A top combustion type hot air furnace with thermally isolating layer for preburning chamber features that said thermally isolating layer can prevent the transfer of heat from preburning chamber to the internal walls of annular gas cavity and annular air cavity to lower their temp and decrease their temp stress and thermal expansion, so elongating the service life of hot air furnace. A heat isolating layer is also arranged in the second liner between annular gas and air cavities. A movable heat isolating cover is arranged between preburning and burning chambers.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

Efficient soundless cracking agent and production method thereof

The invention discloses an efficient soundless cracking agent and a production method thereof. The cracking agent product is prepared from the following mineral components by weight percentage: 55-75%of fCaO, 8-22% of C2S, 10-20% of C4AF+C2F, 5-10% of CaSO4, 85-95 parts of an expansion clinker, 5-15 parts of a sulphoaluminate cement clinker, 0.1-0.4 part of a retarder, and 0.1-0.7 part of a waterreducing agent. The invention solves the problem of low working efficiency of existing product, i.e. the cracking agent is fast in early hydration reaction and the temperature rise is fast, the stonestrength is low, spray holes are easily generated, or slow increase of expansion stress causes long crushing time and the like, by adjusting mineral components of the expansion clinker, the calcination temperature is lowered, the efficient soundless cracking agent has the characteristics of reduction of clinker heat consumption, reduction of the emission of nitric oxide, sulfur oxide, CO2 and thelike, and is beneficial to environmental protection.

Owner:JIAHUA SPECIAL CEMENT

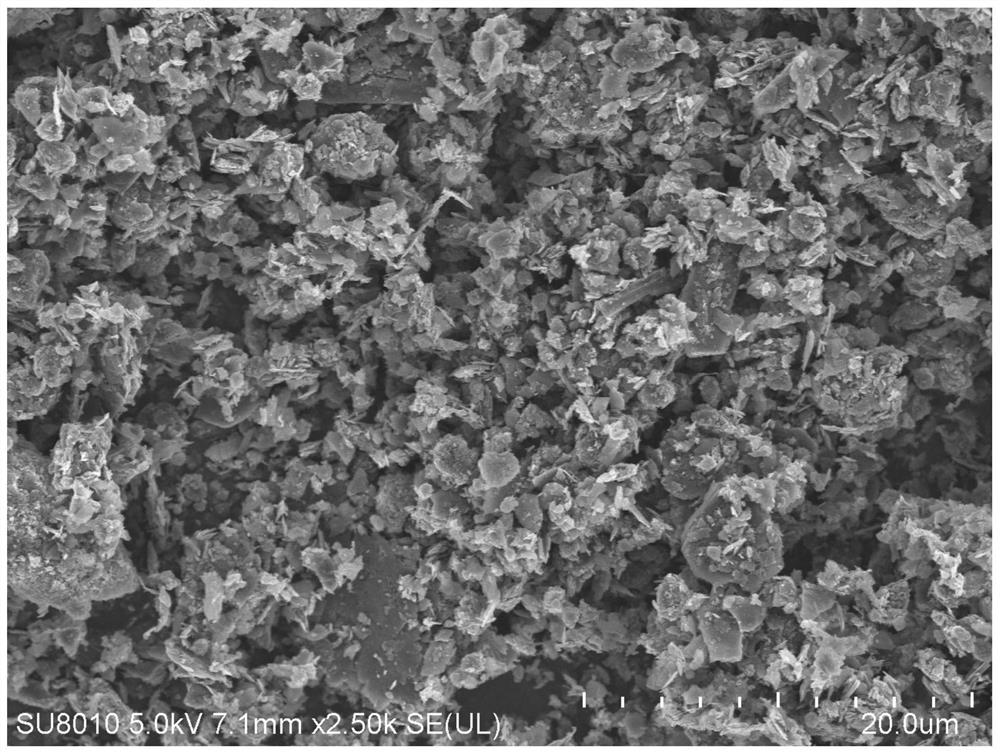

Negative electrode material for lithium batteries and preparation method thereof

InactiveCN112133894ADynamic properties of small particle size particlesHomosexualSecondary cellsNegative electrodesCarbon compositesNano silicon

The invention discloses a negative electrode material for lithium batteries and a preparation method thereof. The negative electrode material comprises graphite, silicon and an adhesive, and the adhesive is asphalt. The mass ratio of the graphite to the silicon is 3: 1 to 20: 1. The method comprises the following steps of: treating graphite particles of which the particle size D50 is less than orequal to 1 [mu]m at 2600-3200 DEG C for 30-120 minutes to obtain artificial graphite; adding micron silicon powder into a dispersing agent, grinding to form uniformly dispersed nano silicon dispersionliquid, and drying the nano silicon dispersion liquid in nitrogen to obtain amorphous nano silicon powder; and mixing the artificial graphite and the amorphous nano silicon powder according to the ratio of 3: 1 to 20: 1 to form an artificial graphite nano silicon mixture. The silicon-carbon composite material prepared by the method has good small-particle-size particle dynamic performance and relatively small material expansion stress, and the silicon-carbon composite material particles are good in isotropy and dispersion uniformity, so that the silicon-carbon negative electrode material is small in embedded volume expansion and good in capacity and cycle performance.

Owner:深圳石墨烯创新中心有限公司

Process for strengthening and toughening bearing titanium alloy

The invention discloses a process for strengthening and toughening a bearing titanium alloy, belonging to alloy strengthening and toughening processes. The process specifically comprises the following steps of: a, grinding and polishing a titanium alloy bearing, subsequently putting the titanium alloy bearing into an electric heating furnace at the room temperature, and vacuumizing the electric heating furnace; b, introducing argon into the electric heating furnace till the pressure in the electric heating furnace is 0.01-0.015MPa, and stopping introducing the argon; c, powering on the electric heating furnace to heat up till the temperature is 400-600 DEG C, reserving the temperature for 15-25 minutes, pumping out the argon when the temperature is reserved, introducing oxygen of which the purity is 99.99% in an oxygen supply velocity of 10-60SLM, and keeping the pressure of the oxygen inside the electric heating furnace be 0.01-0.015MPa; d, raising the temperature of the electric heating furnace to be 950-1,250 DEG C; e, reserving the temperature for 0.5-5 hours; f, decreasing the temperature in a velocity of 4-6 DEG C / min till the temperature is 500 DEG C; g, stopping introducing the oxygen, and closing a gas supply valve and a heating power supply of the electric heating furnace; and h, taking out the titanium alloy bearing when the temperature of the electric heating furnace is decreased to be the room temperature. The process has the advantages that the titanium alloy bearing is high in surface hardness, the thickness of an oxidation layer is controllable, and the titanium alloy bearing is good in abrasive resistance.

Owner:CHINA UNIV OF MINING & TECH

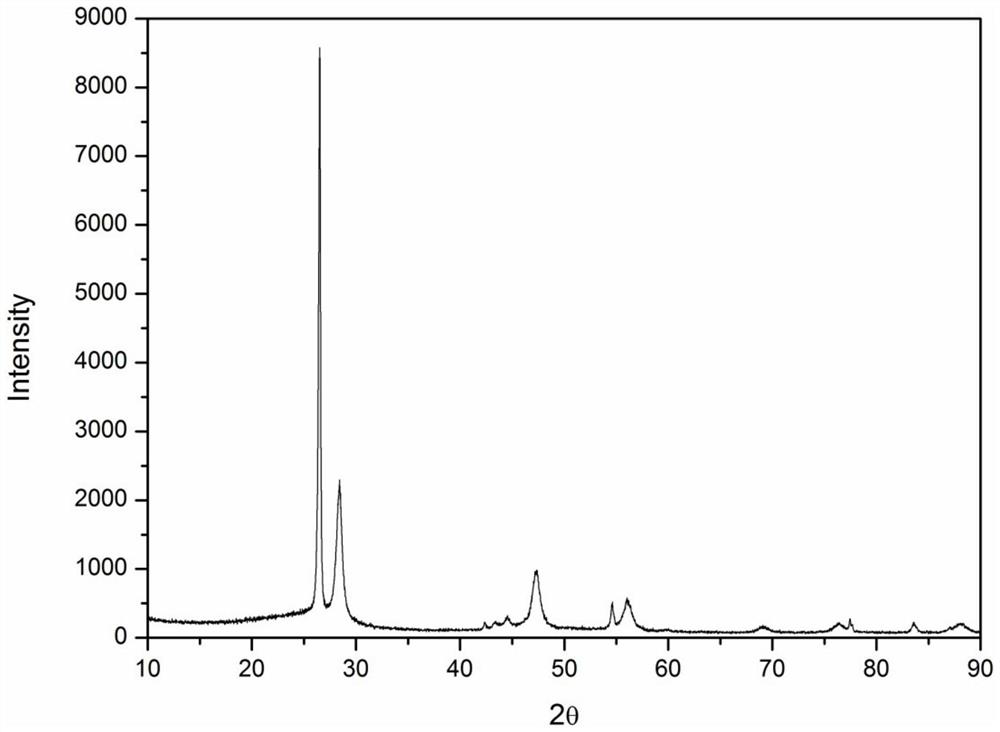

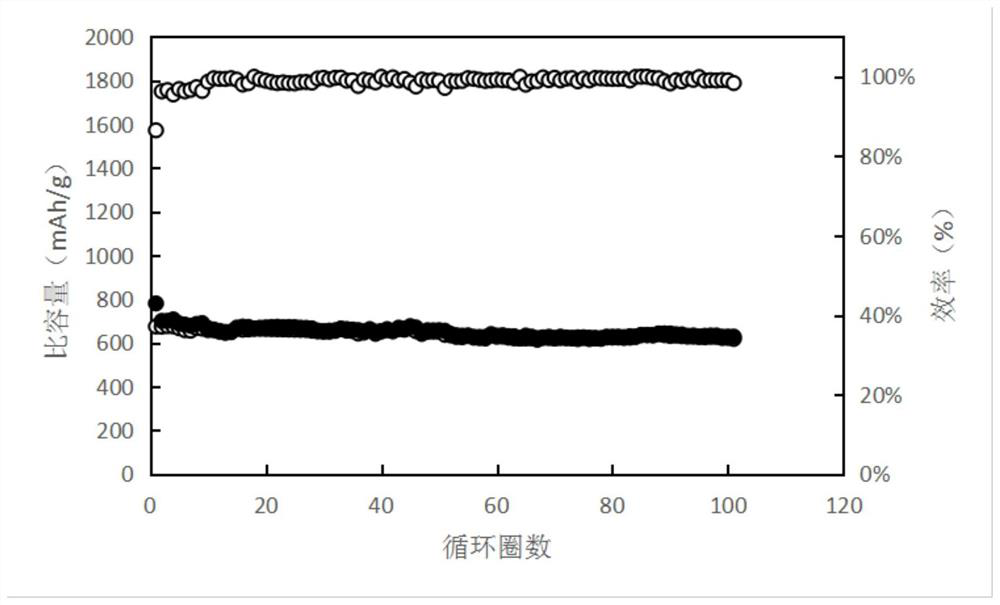

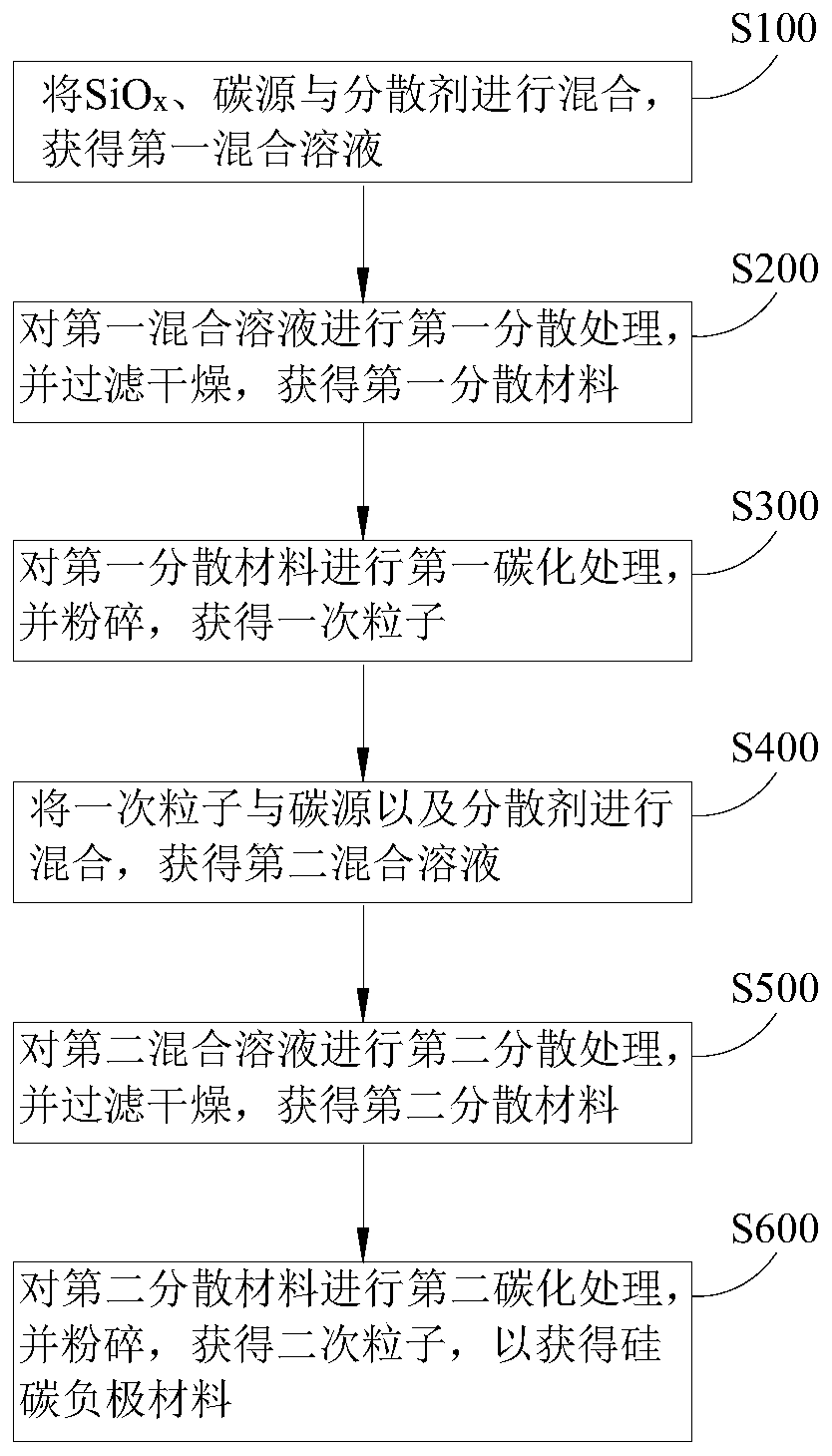

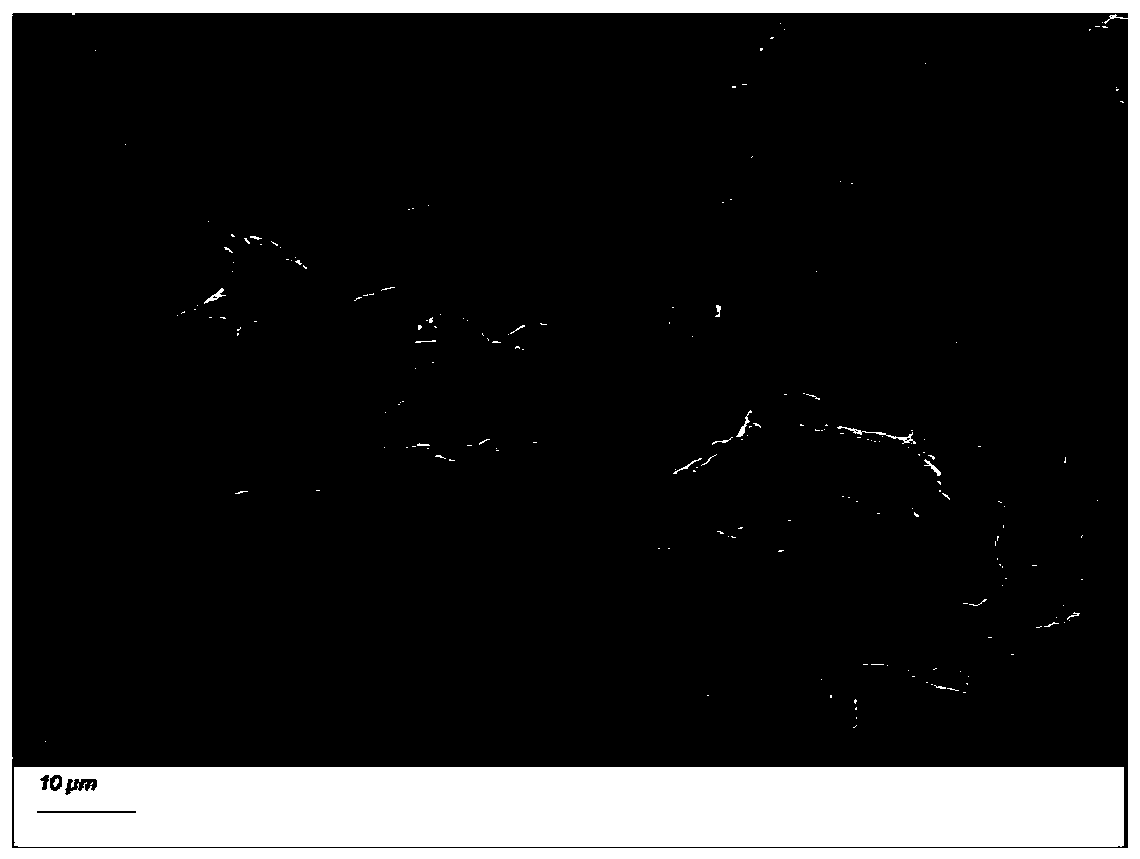

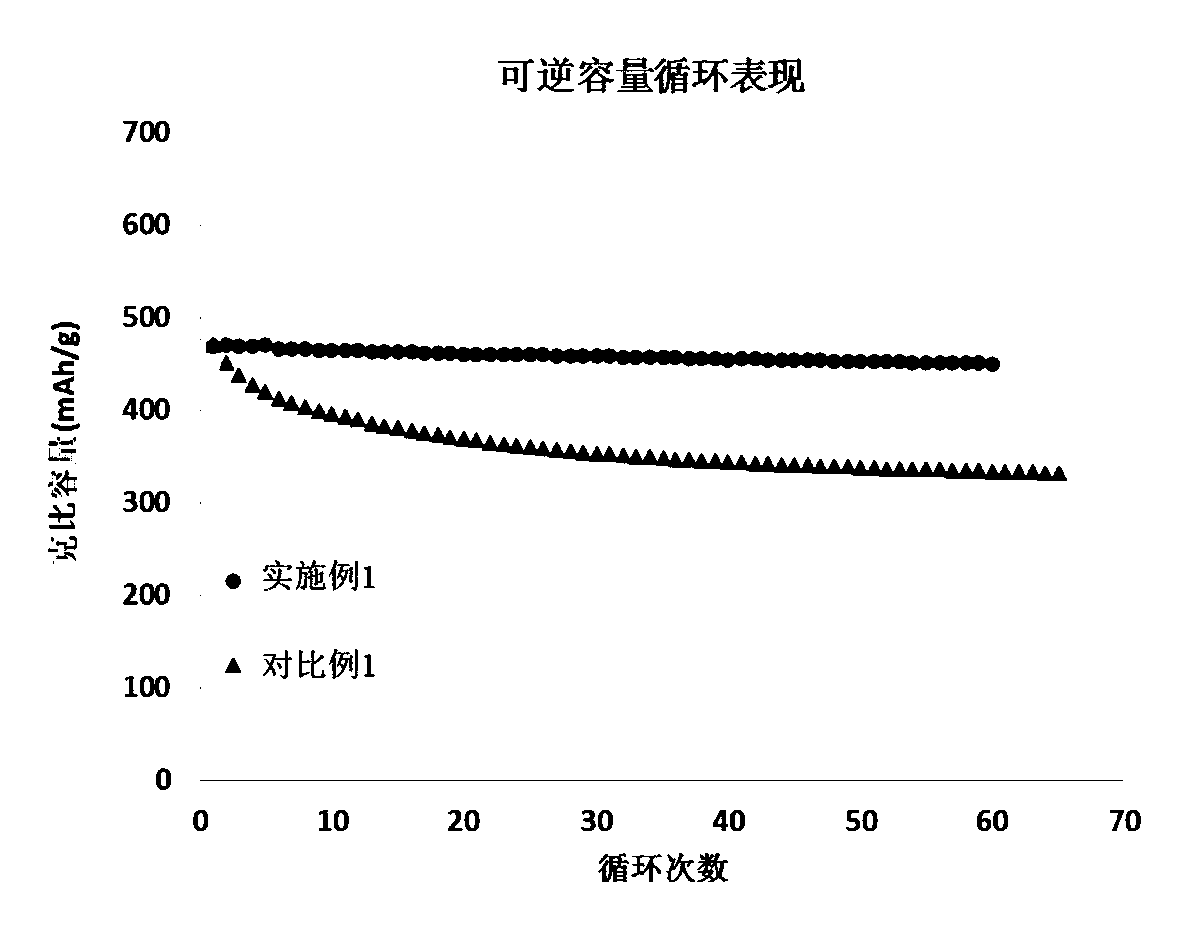

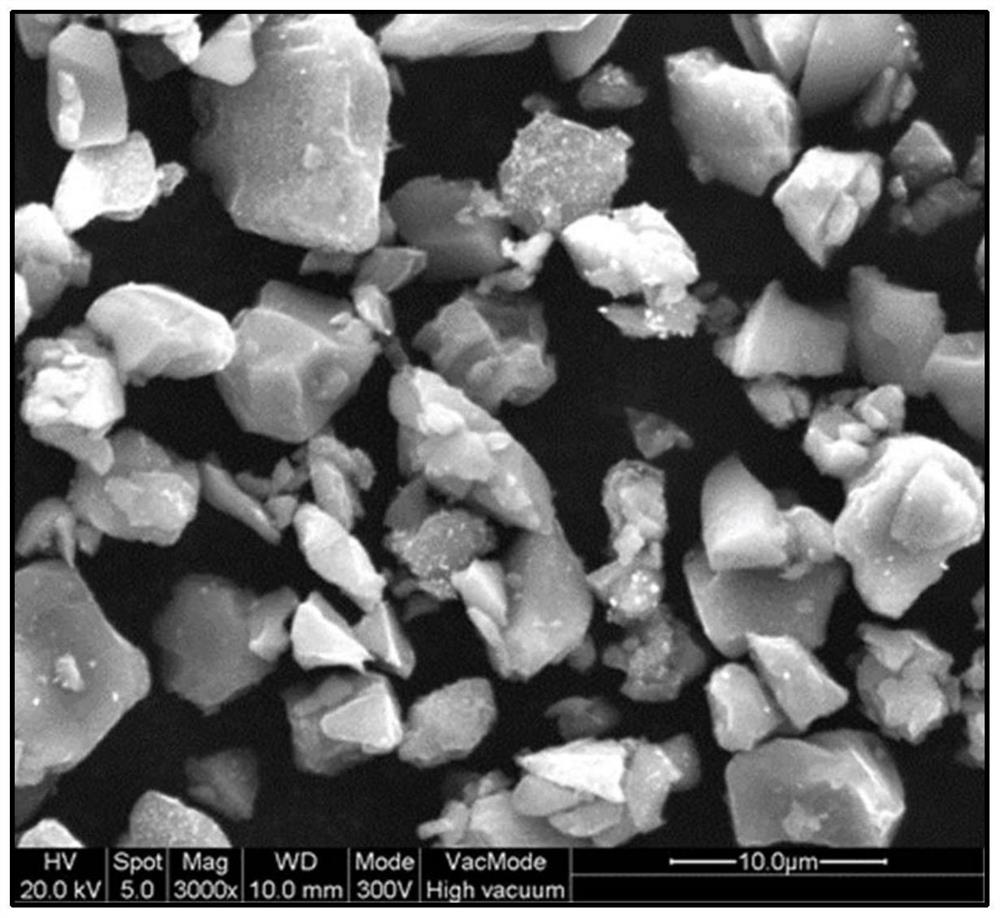

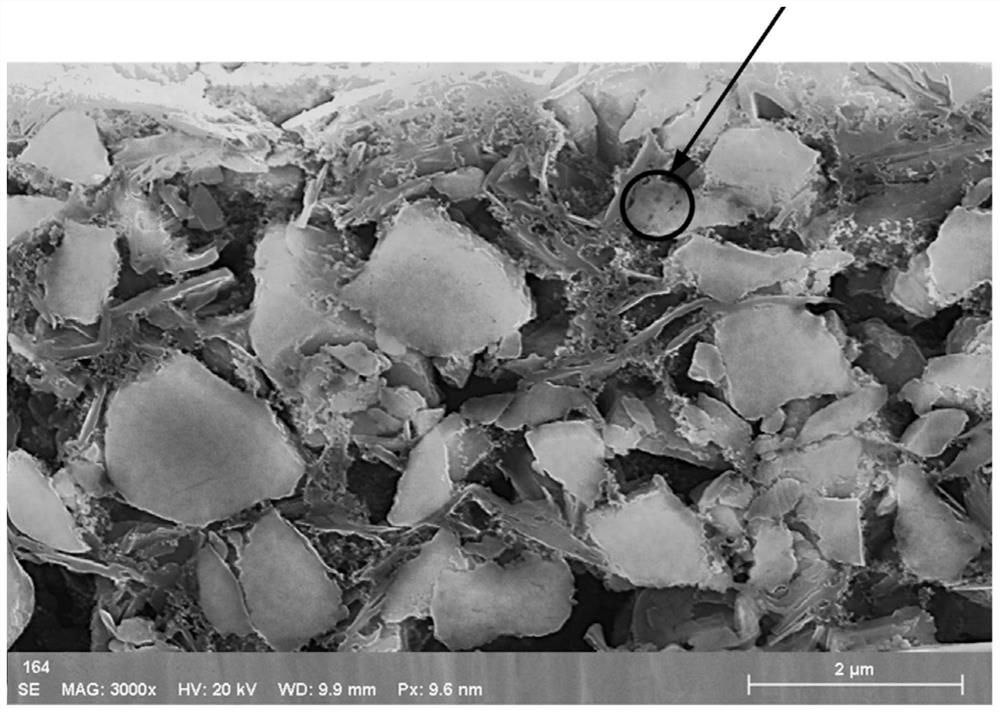

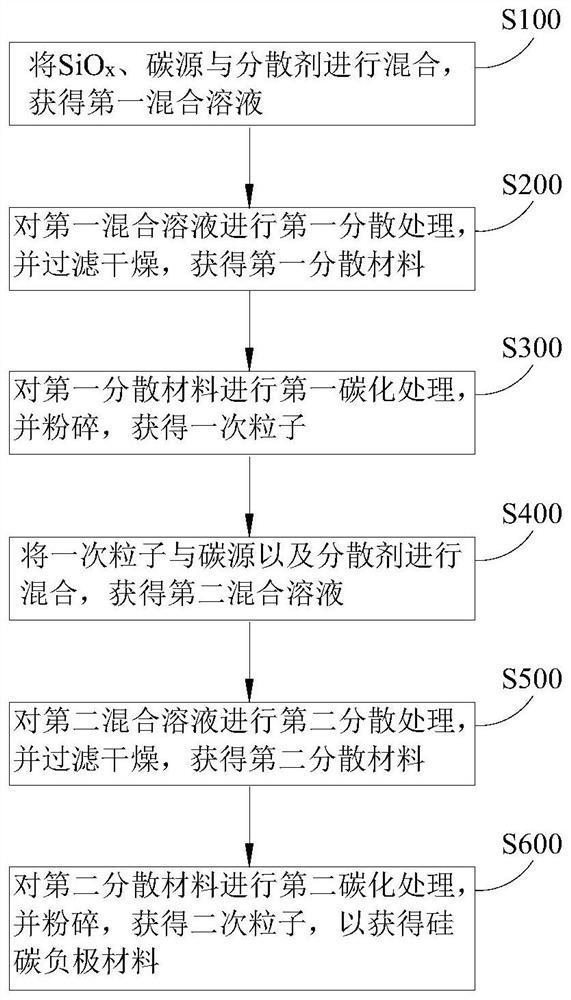

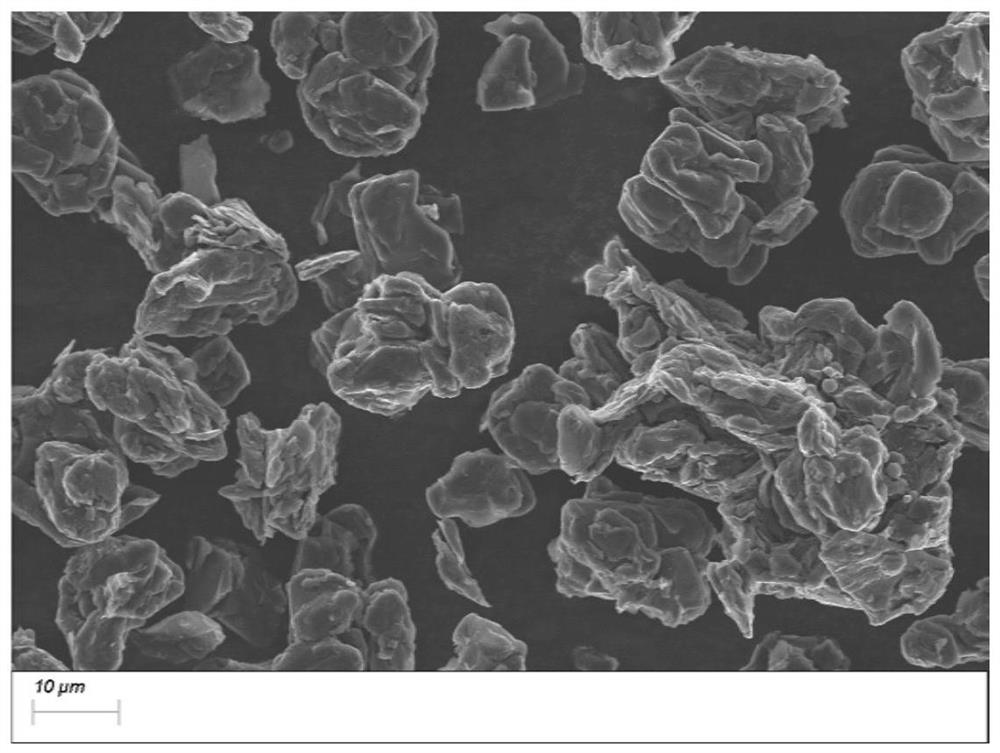

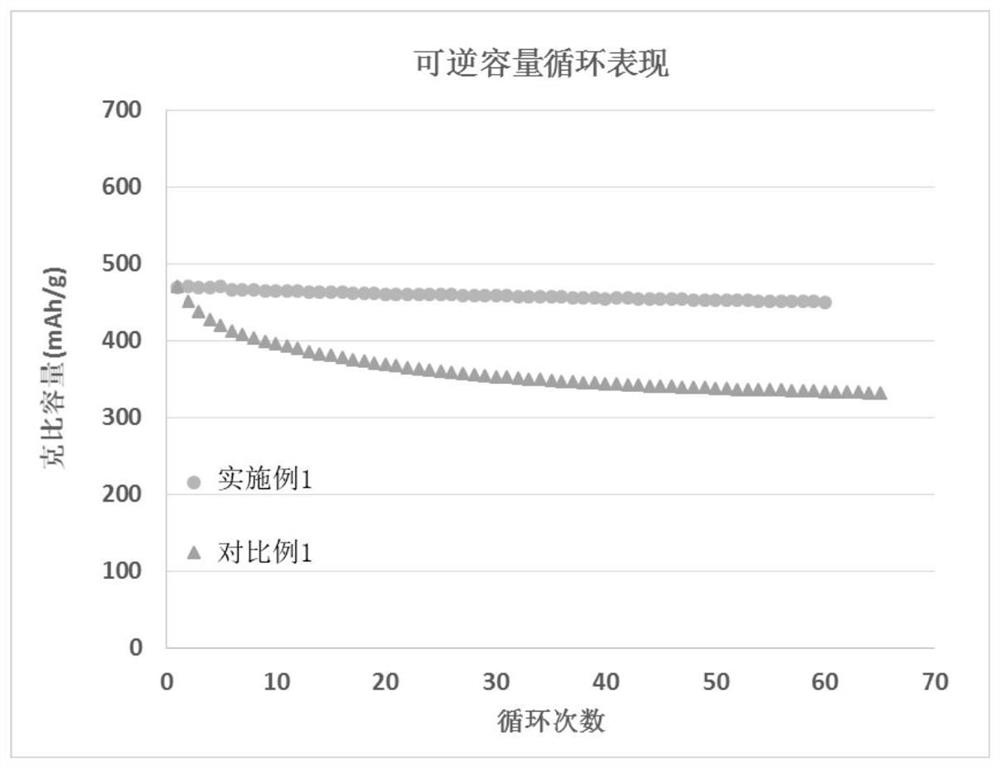

Silicon-carbon negative electrode material, preparation method and lithium ion battery

ActiveCN109713280AReduce expansion stressImprove dynamic performanceCell electrodesSecondary cellsCarbonizationSodium-ion battery

The invention provides a silicon-carbon negative electrode material, a preparation method and a lithium ion battery. The method for preparing the silicon-carbon negative electrode material comprises the steps: mixing SiOx, a carbon source and a dispersing agent to obtain first mixed solution, wherein x is equal to 0.5-1; 1.0; carrying out first dispersion treatment of the first mixed solution, andperforming filtering and drying to obtain a first dispersion material; carrying out first carbonization treatment of the first dispersion material, and performing crushing to obtain primary particleswith the particle size of 0.5-1 micron; mixing the primary particles with the carbon source and the dispersing agent to obtain second mixed solution; carrying out second dispersion treatment of the second mixed solution, and performing filtering and drying to obtain a second dispersion material; carrying out second carbonization treatment of the second dispersion material, performing crushing toobtain secondary particles with the particle size of 10-15 microns, and obtaining a silicon-carbon negative electrode material. According to the method disclosed by the invention, the finally obtainedsilicon-carbon negative electrode material has a relatively small volume expansion and a good cycle performance.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

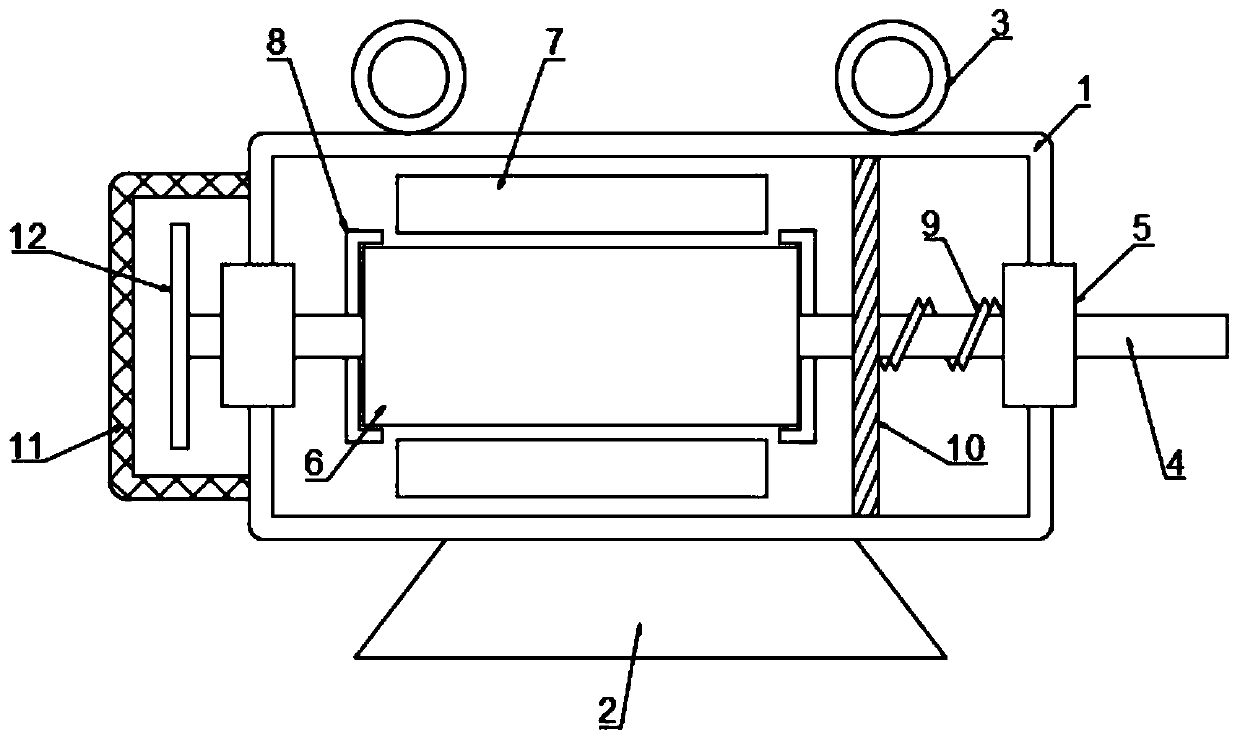

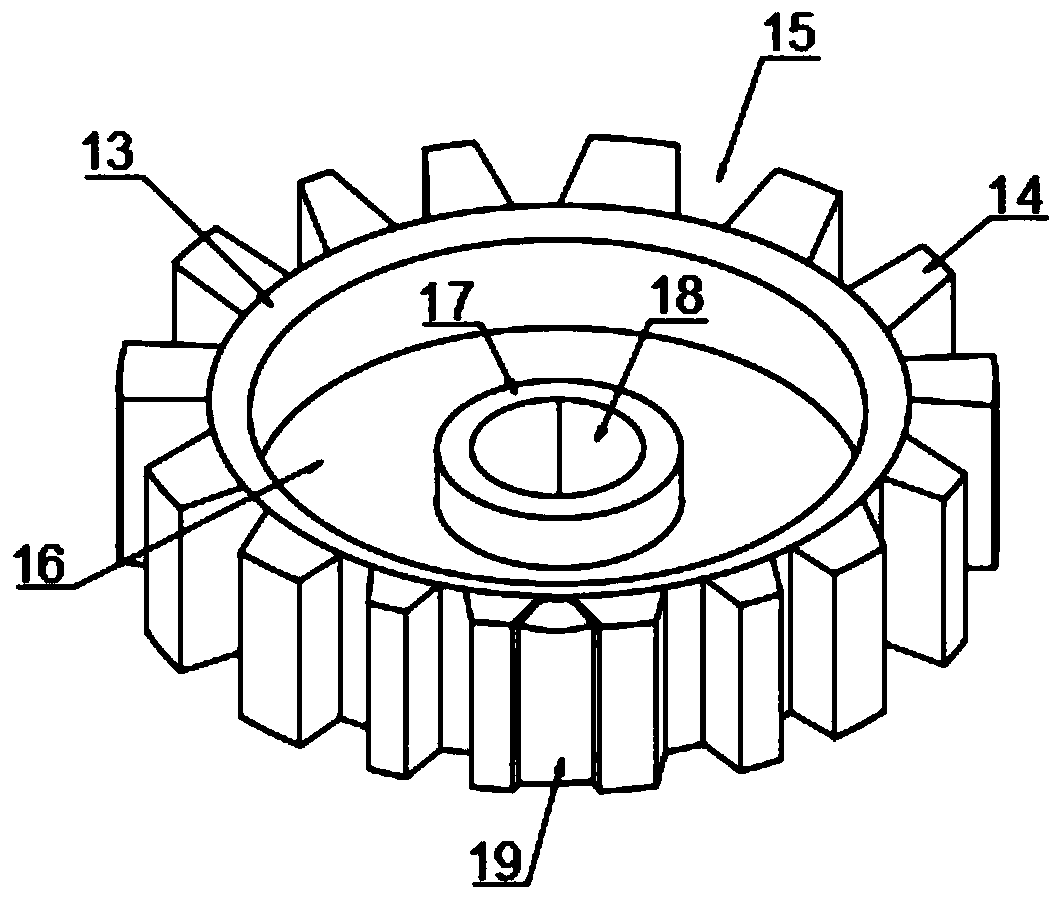

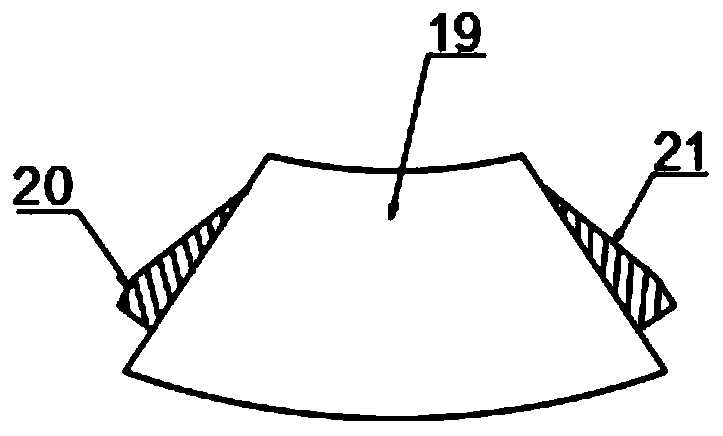

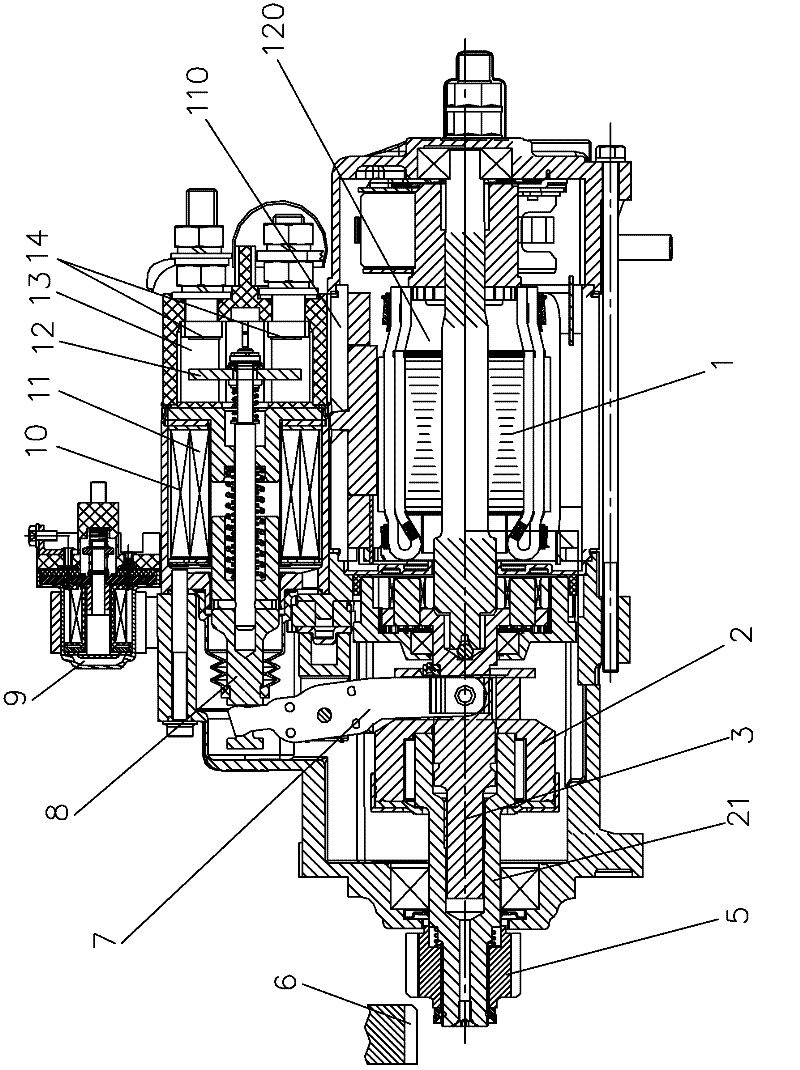

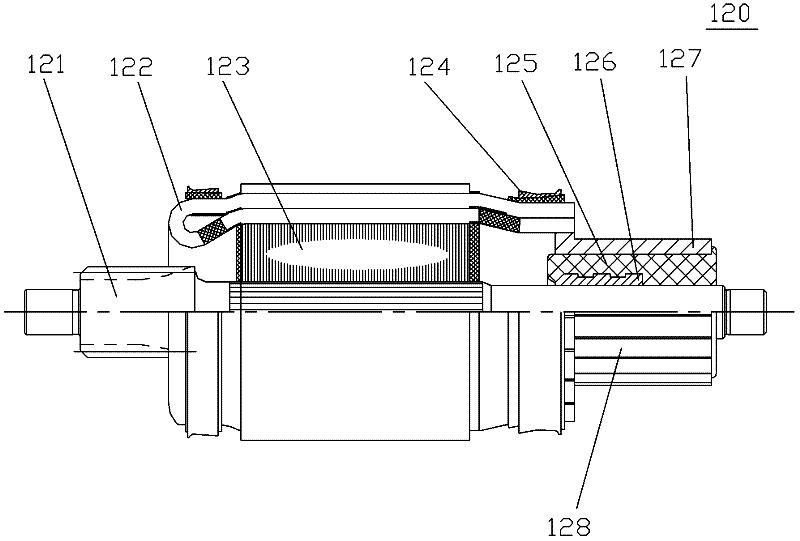

Winding type asynchronous motor and manufacturing method

InactiveCN110365142AWon't breakWill not cause breakageMagnetic circuit rotating partsManufacturing stator/rotor bodiesInduction motorControl engineering

The invention belongs to the technical field of motors and particularly relates to a winding type asynchronous motor and a manufacturing method. The problems of expansion stress difference between aniron core and a rotating shaft, magnetic short circuit and autorotation of a rotor after a power failure in an existing asynchronous motor are solved. The provided motor comprises a housing; a base isintegrally formed on the lower side wall of the housing; two hanging rings are welded to the upper side wall of the housing; a rotating shaft is arranged in the housing in a penetrating mode; a rotoris fixed to the outer wall of the rotating shaft; a stator arranged on the outer wall of the rotor in a winding mode is fixed in the housing; a mounting opening is formed in the connecting position of the housing and the rotating shaft; and a bearing is fixed in the mounting opening. By arranging the annular iron core, the motor is prevented from contacting the rotating shaft and expansion stressis reduced; by arranging mounting grooves and partition blocks, magnetic contact is avoided, and the electromagnetic performance is guaranteed; and by setting a magnetic plate and a reset spring, therotor is fixed during the power failure, and the safety performance is greatly improved.

Owner:徐州亚泰电机有限公司

Heat-resistant pottery and manufacturing method thereof

The invention discloses a heat-resistant pottery. The heat-resistant pottery comprises the following components in percentage by weight: 46-49.5% of silicon dioxide, 35.5-38.5% of aluminum oxide, 0-5%of ferric oxide, 0-2% of calcium oxide, 0-2% of magnesium oxide, 0.8-1.8% of potassium oxide, 0-1.5% of sodium oxide, 0-2% of titanium dioxide and 7-9% of ignition loss parts. The invention also discloses a manufacturing method of the heat-resistant pottery. According to the heat-resistant pottery manufactured by the manufacturing method, aluminum oxide and silicon dioxide in a pottery blank aremutually combined during high-temperature firing at 1145-1230 DEG C to generate mullite with thermal stability, so that thermal stability of the product after firing is improved, the pottery finishedproduct can be used for cooking by open fire heating, and the service life is prolonged.

Owner:贺晓东

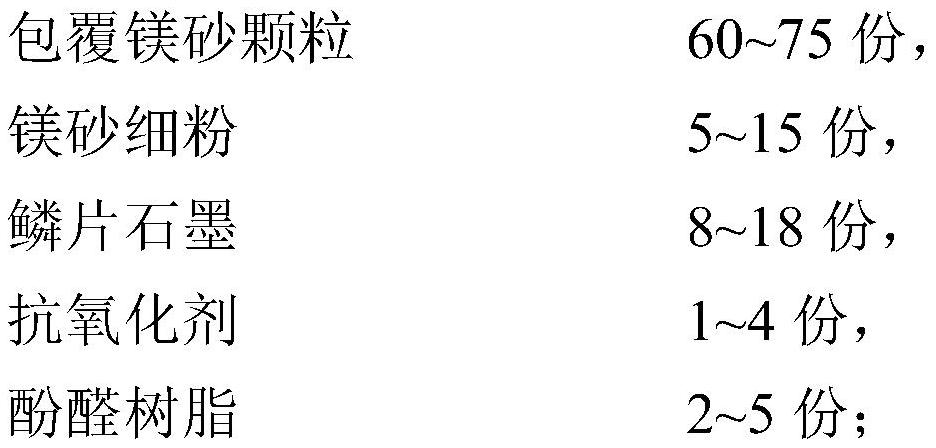

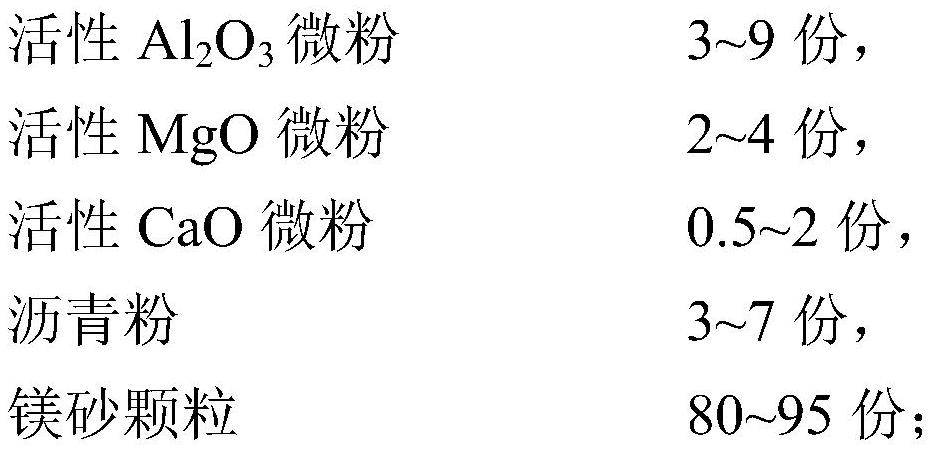

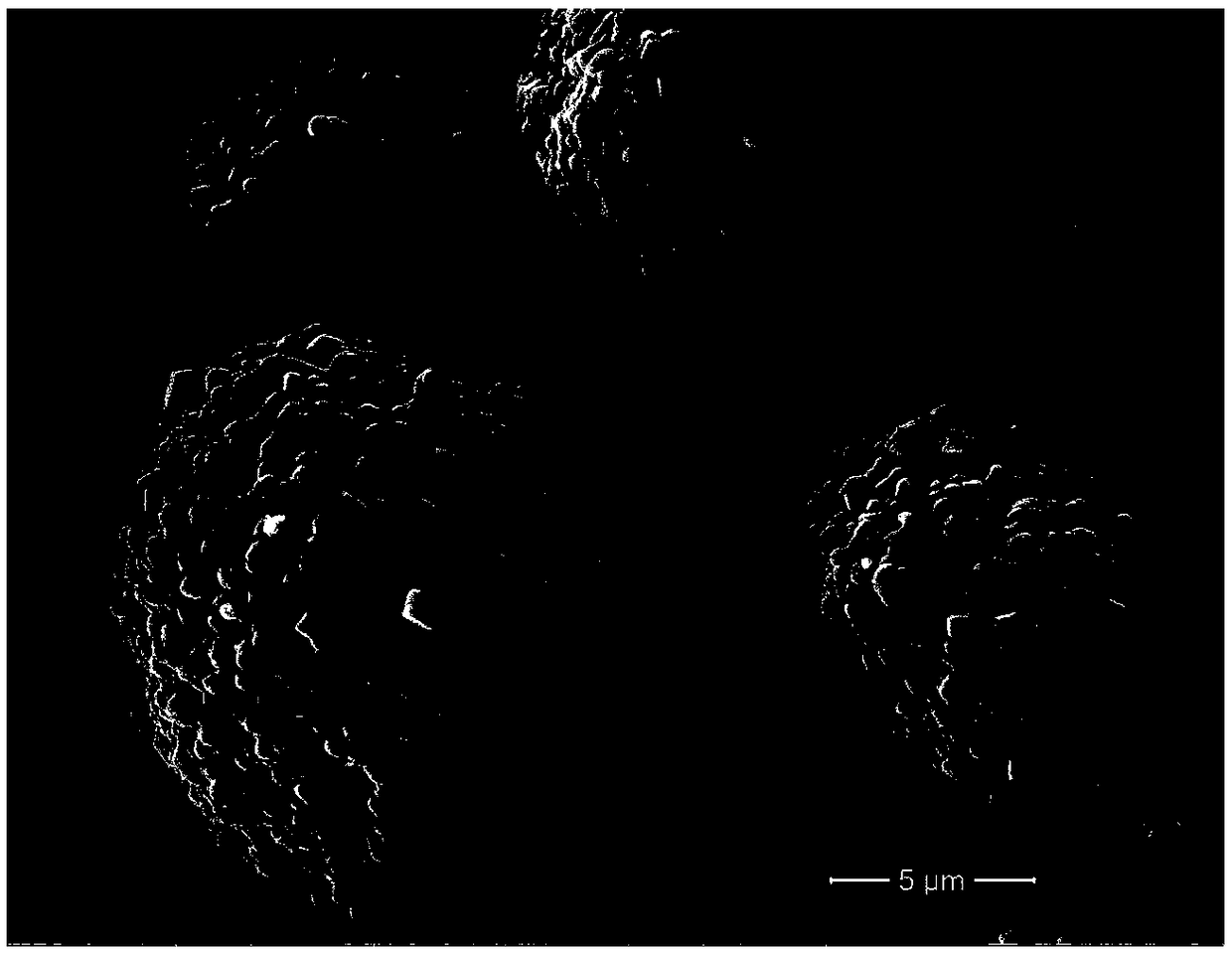

High-corrosion-resistance and low-expansion magnesia carbon brick and preparation method thereof

The invention discloses a high-corrosion-resistance and low-expansion magnesia carbon brick and a preparation method thereof. The high-corrosion-resistance and low-expansion magnesia carbon brick comprises the following raw materials in parts by mass: 60-75 parts of coated magnesia particles, 5-15 parts of fine magnesia powder, 8-18 parts of crystalline flake graphite, 1-4 parts of an antioxidant and 2-5 parts of phenolic resin. The coated magnesia particles comprise the following raw materials in parts by mass: 3-9 parts of active Al2O3 micro powder, 2-4 parts of active MgO micro powder, 0.5-2 parts of active CaO micro powder, 3-7 parts of asphalt powder and 80-95 parts of magnesia particles. The preparation method of the coated magnesia particles comprises the steps of: well mixing the raw materials of the coated magnesia particles in a mixing mill in a hot state at 150-300 DEG C, and cooling to obtain the coated magnesia particles. The preparation method of the high-corrosion-resistance and low-expansion magnesia carbon brick comprises the steps of: well mixing the raw materials of the high-corrosion-resistance and low-expansion magnesia carbon brick, pressing the mixture into a green body, and baking the green body at 150-220 DEG C for 6-12 hours to obtain the high-corrosion-resistance and low-expansion magnesia carbon brick.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

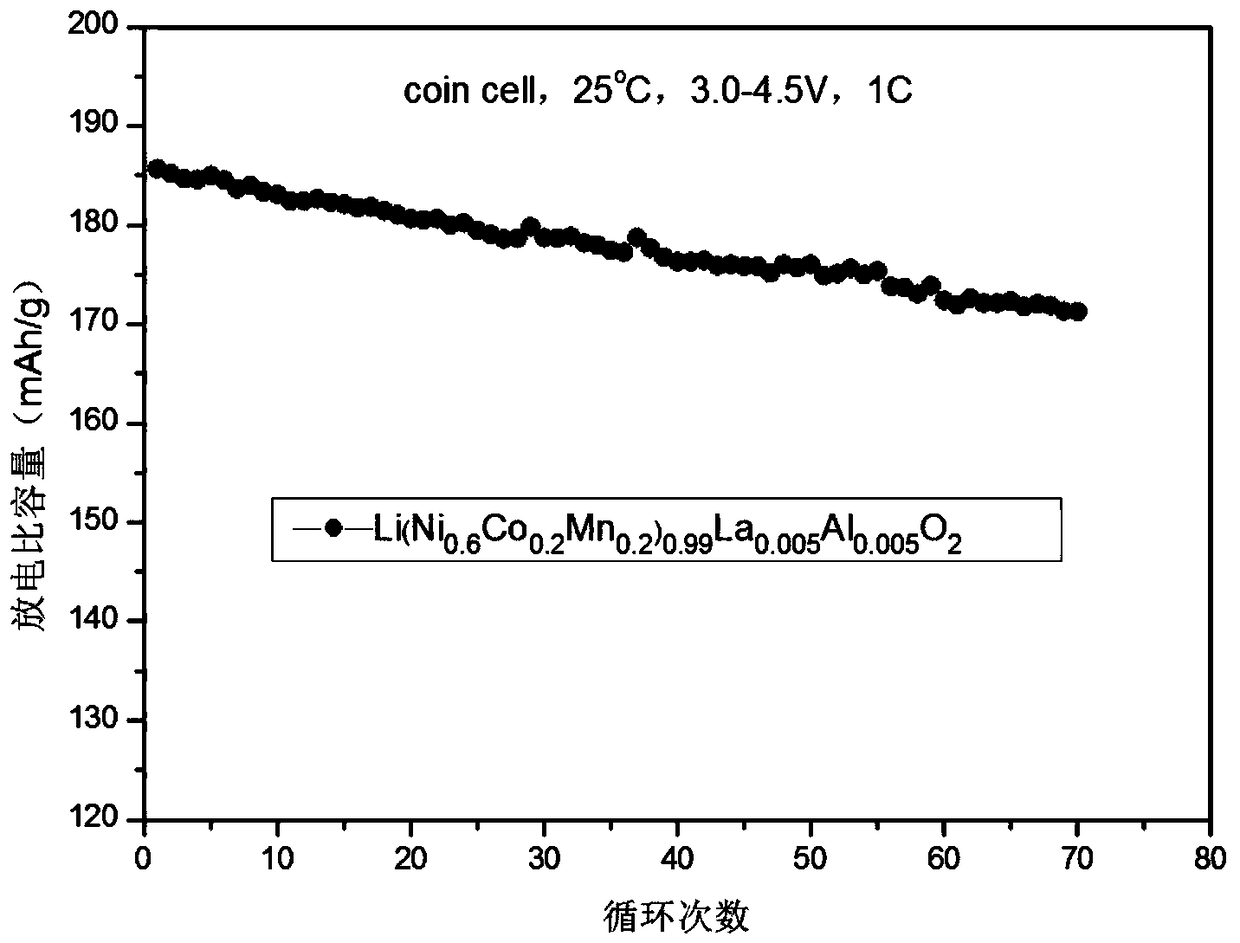

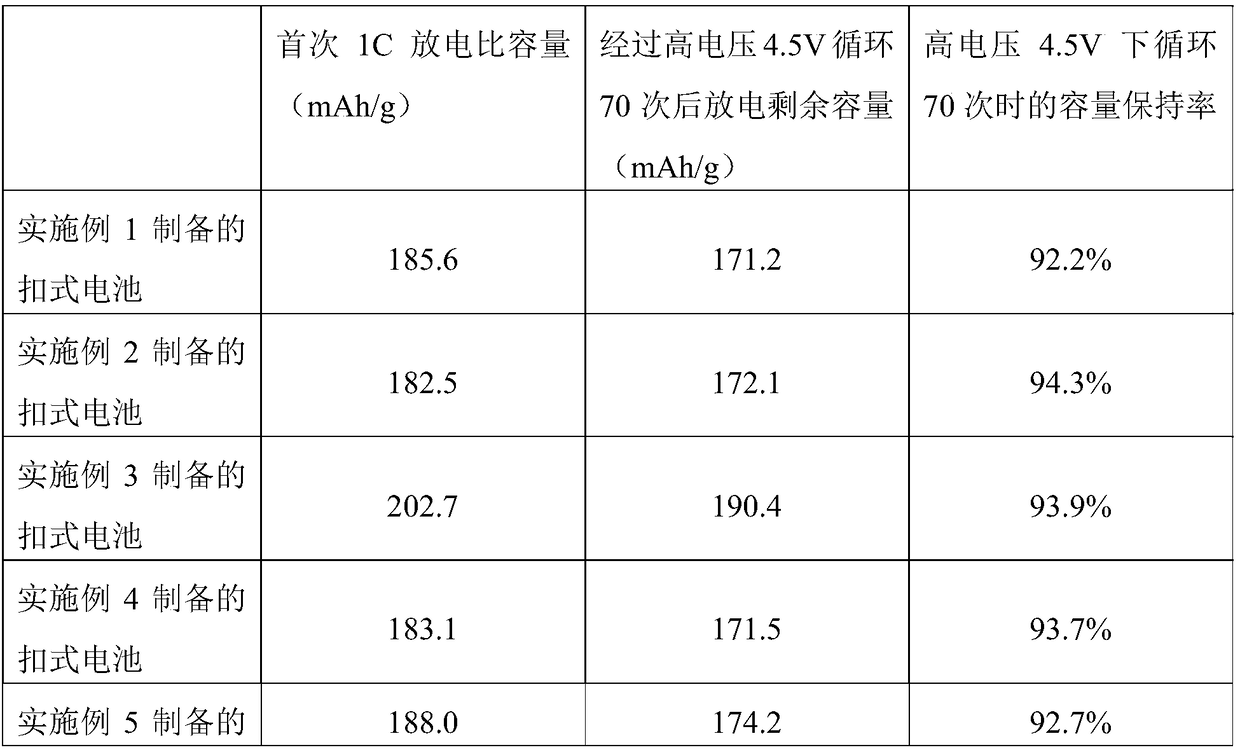

Nickel-cobalt lithium manganate positive electrode material applied to high-voltage lithium ion batteries and preparation method thereof

InactiveCN108807975ASolve the problem of rapid capacity decayPromote migrationCell electrodesSecondary cellsManganateLanthanum

The invention discloses a nickel-cobalt lithium manganate positive electrode material applied to high-voltage lithium ion batteries. The chemical formula of nickel-cobalt lithium manganate is Li(NixCoyMn1-x-y)1-a-bLaaAlbO2, wherein a is greater than or equal to 0 and is less than or equal to 0.05, b is greater than or equal to 0 and is less than or equal to 0.1, x is greater than or equal to 0.3 and is less than or equal to 0.8, and y is greater than or equal to 0.05 and is less than or equal to 0.4. A preparation method of the nickel-cobalt lithium manganate positive electrode material comprises the following steps: carrying out ball milling and mixing a nickel-cobalt-manganese precursor, a lanthanum source, an aluminum source and lithium salt in a horizontal ball mill, then pre-sinteringthe obtained mixture in a muffle furnace, then carrying out secondary ball milling and mixing the obtained mixture in the horizontal ball mill, and finally sintering the obtained mixture in a high-temperature tubular furnace to obtain a final product which is nickel-cobalt lithium manganate used as a positive electrode material. According to the nickel-cobalt lithium manganate positive electrodematerial, La and Al are co-doped in the nickel-cobalt lithium manganate positive electrode material; the interplanar crystal spacing can be increased, so that the migration of lithium ions can be accelerated; the stability of the lithium-free state of the crystal structure under high voltage can be improved; meanwhile, the crystal lattice volume and the stress expansion can be effectively reduced;the nickel-cobalt lithium manganate positive electrode material has the characteristics of high capacity and excellent cycle performance under high voltage; the disordered-ordered phase change underhigh voltage of the nickel-cobalt lithium manganate positive electrode material can be effectively inhibited; the problem of rapid capacity attenuation of the material in cycle under high voltage is solved, so that the service life of the lithium ion batteries can be prolonged.

Owner:ETRUST POWER ETP GRP LTD

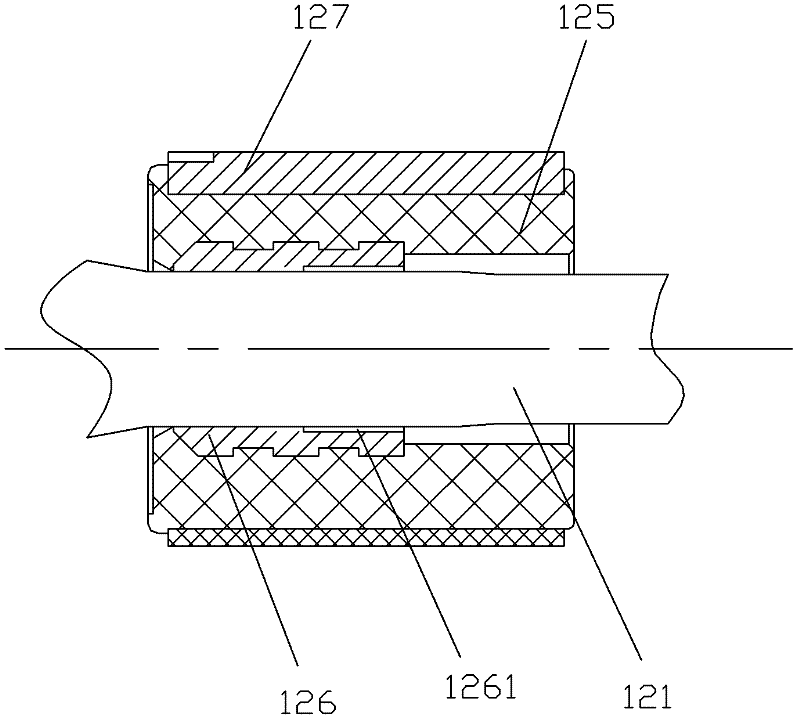

Armature, starting motor and method for manufacturing armature

InactiveCN102255407AReduced interference volumeHigh strengthMagnetic circuit rotating partsManufacturing stator/rotor bodiesInterference fitEngineering

The invention discloses an armature and a starting motor containing the armature, and also discloses a method for manufacturing the armature, relating to the technical field of motors. The armature comprises an armature shaft, an armature line, an armature core lamination and a commutator, wherein the armature core lamination is fixed on the armature shaft; the armature line is inserted into the armature core lamination and connected with the commutator; the commutator comprises multiple commutating segments which are uniformly distributed around the axis of the armature shaft and not connected with each other; a bush is arranged on the armature shaft in an interference fit mode; the commutating segments and the bush are fixed into a whole; the inner wall of the bush is provided with at least one annular groove; and the bush forms fit clearance between the annular groove position and the armature shaft. According to the invention, the annular groove arranged on the inner wall of the bush can reduce the internal stress of the armature, thus the smooth working condition of the surface of the commutator can be ensured, the service life of a starter can be prolonged and the possibility of the starter failure can be reduced.

Owner:PRESTOLITE ELECTRIC BEIJING

Top burning type hot blast stove with thermal insulation layer in precombustion chamber

ActiveCN100344772CReduce expansion stressReduce thermal stressBrick-hot blast stovesBlast furnace detailsCombustion chamberThermal insulation

A top combustion type hot air furnace with thermally isolating layer for preburning chamber features that said thermally isolating layer can prevent the transfer of heat from preburning chamber to the internal walls of annular gas cavity and annular air cavity to lower their temp and decrease their temp stress and thermal expansion, so elongating the service life of hot air furnace. A heat isolating layer is also arranged in the second liner between annular gas and air cavities. A movable heat isolating cover is arranged between preburning and burning chambers.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

A kind of graphite/silicon/carbon composite negative electrode material and preparation method thereof

ActiveCN112366294BImprove adsorption capacityUniform adsorptionSecondary cellsNegative electrodesCarbon compositesSilicon oxide

The present invention relates to the field of negative electrode materials for lithium ion batteries, in particular to a graphite / silicon / carbon composite negative electrode material and a preparation method thereof, comprising the following steps: (1) pretreatment of graphite; (2) pretreatment of silicon dioxide; 3) Mix the two to make silica evenly adsorbed on the graphite surface, and the outer layer is coated with carbon source to obtain graphite / silicon dioxide / carbon composite material; (4) Perform magnesia thermal reduction to obtain graphite / silicon / carbon composite negative electrode Material. The present invention combines graphite and silicon dioxide by electrostatic adsorption, improves the uniformity of silicon dioxide dispersion on the graphite surface, improves the distribution uniformity of silicon on the graphite surface after magnesia thermal reduction, and reduces the expansion stress of silicon , improve the cycle stability and prolong the service life; at the same time, there is a buffer space between the graphite and the carbon that can accommodate the volume expansion of silicon, which further improves the cycle stability of the present invention and prolongs the service life.

Owner:WANXIANG 123 CO LTD

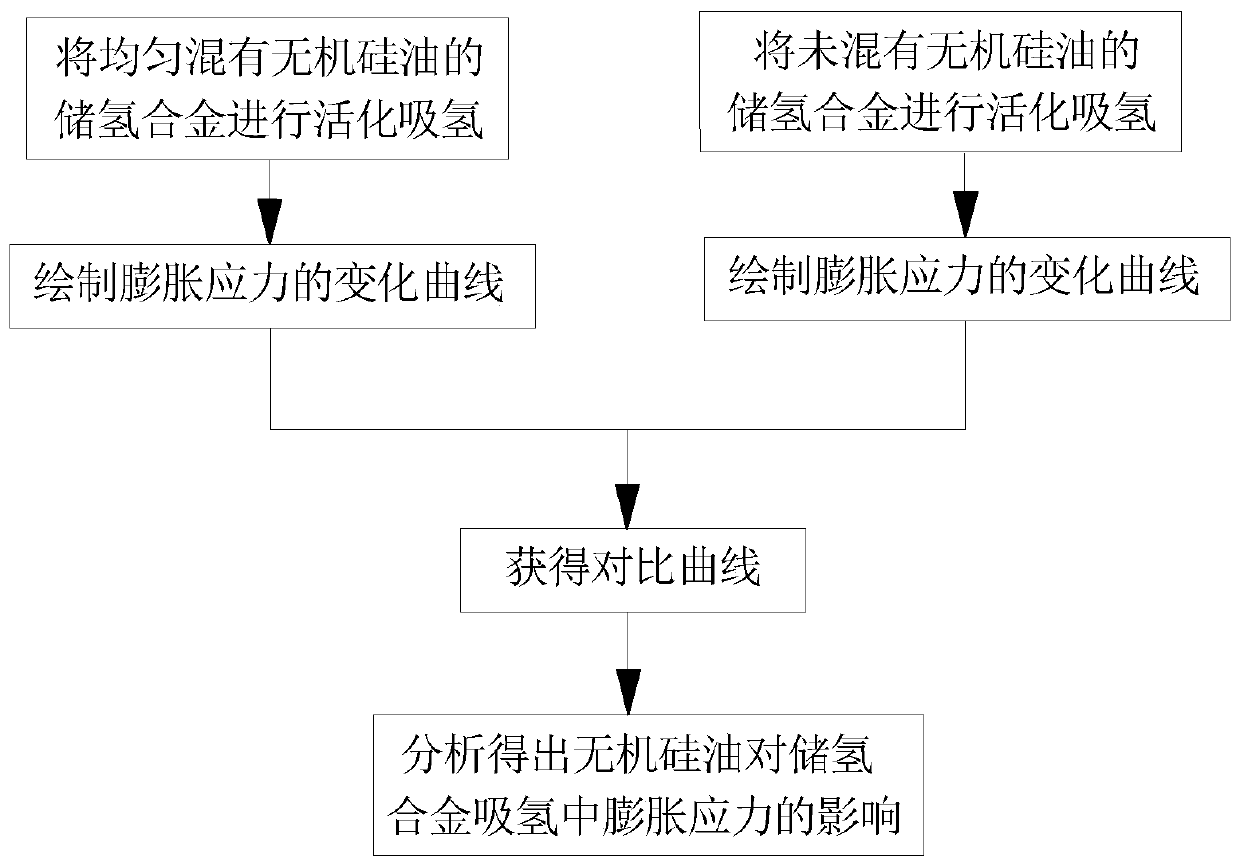

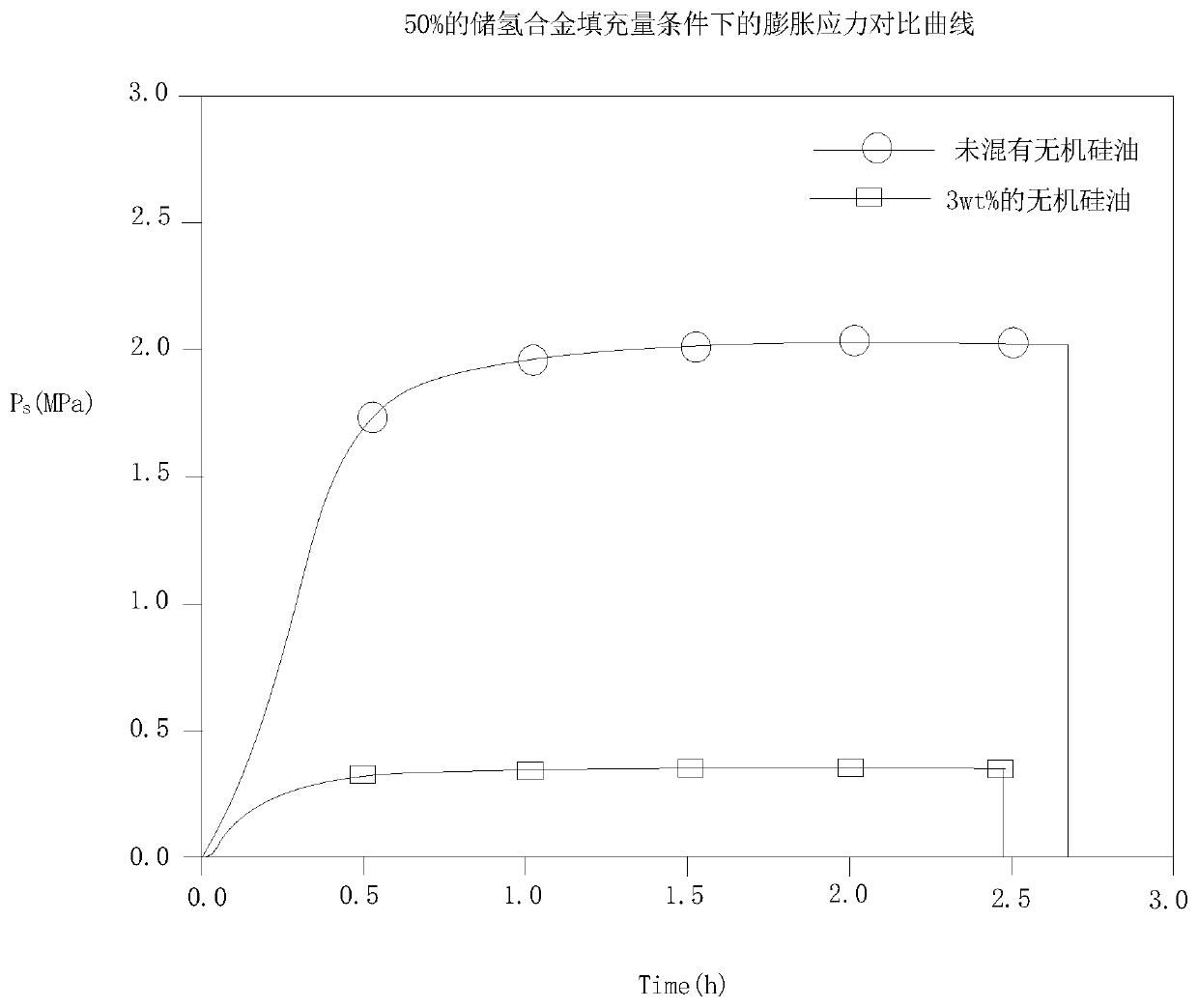

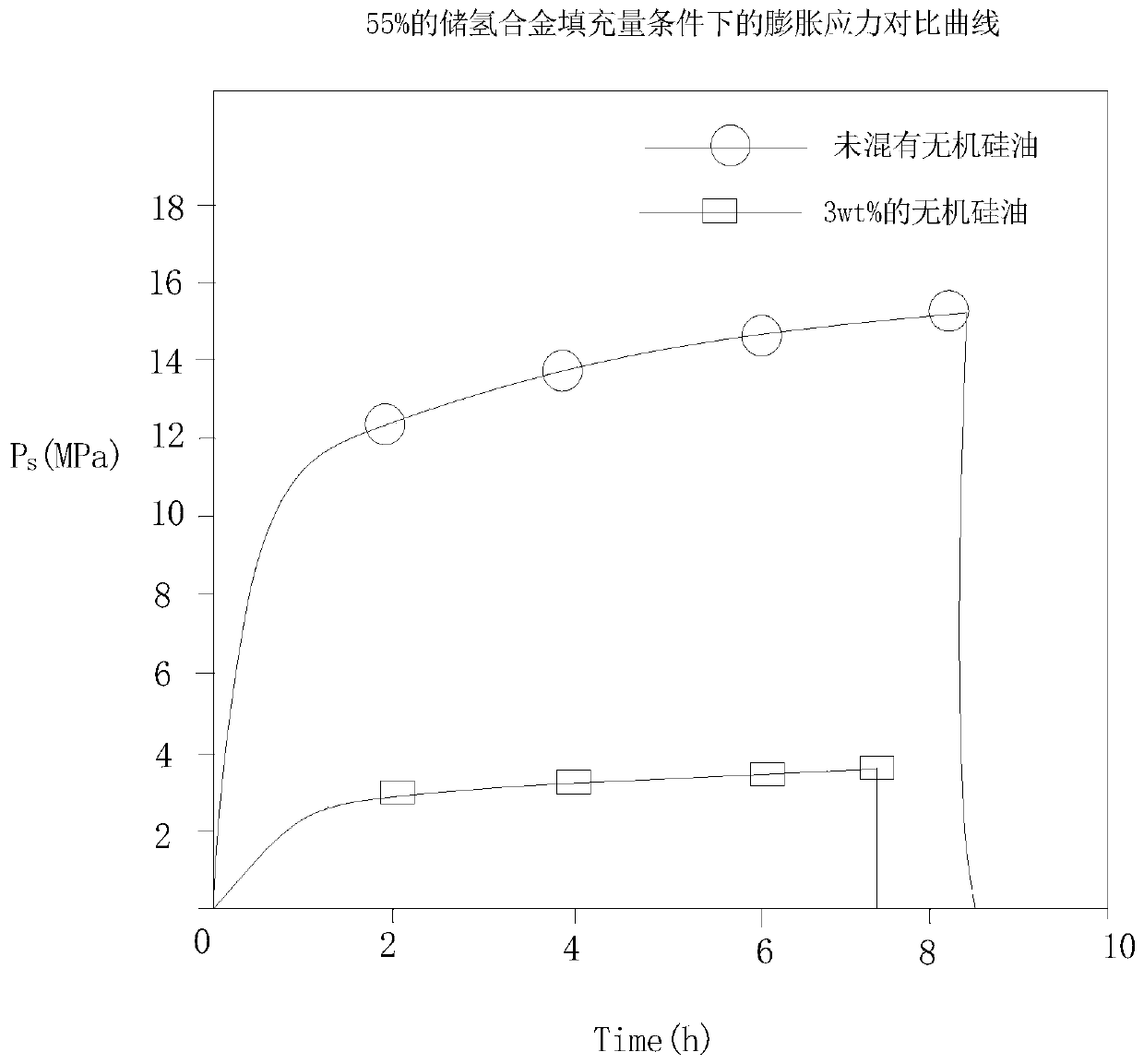

Experimental method for reducing hydrogen absorption expansion stress of hydrogen storage alloy powder

InactiveCN109975167AReduce hydrogen absorption expansion stressImprove efficiencyMaterial analysisExperimental methodsSilicone oil

The invention discloses an experimental method for reducing hydrogen absorption expansion stress of hydrogen storage alloy powder. The experimental method comprises the steps of: S1, performing an experiment 1 and verifying an interaction relationship between inorganic silicone oil and expansion stress generated in the hydrogen absorption process of the hydrogen storage alloy powder; S2, and conducting an experiment 2 based on the S1, and verifying to obtain an inorganic silicone oil percentage with the optimized effect on the expansion stress generated in the hydrogen absorption process of the hydrogen storage alloy powder, wherein the inorganic silicone oil percentage is a weight ratio of the inorganic silicone oil to the hydrogen storage alloy powder. Through adopting the experimental method for reducing the hydrogen absorption expansion stress of the hydrogen storage alloy powder, an effective measure for reducing the hydrogen absorption expansion stress of the hydrogen storage alloy powder is obtained, and is applied to the actual production operation, thereby increasing the efficiency and safety of the actual production operation.

Owner:CHINA JILIANG UNIV

Rolling sagger and powder sintering method

PendingCN114353535ANot easy to scatterDischarge in timeCharge supportsTunnel kilnStructural engineering

The invention discloses a rolling sagger and a powder sintering method, and relates to the technical field of high-temperature sintering kilns. The rolling sagger comprises a sagger main body, the sagger main body is a hollow cylinder forming an inner cavity in a surrounding mode and is provided with at least one rotation axis, the two ends of the sagger main body are detachably connected with fixed cover plates, the fixed cover plates are provided with through exhaust holes, and the exhaust holes are communicated with the inner cavity of the sagger main body; a fixed shaft and a movable cover plate are arranged on the outer side of the fixed cover, the movable cover plate is in close fit with the outer side of the fixed cover plate and enables part of the exhaust holes to be in a blocked state, a notch is formed in the movable cover plate, the notch corresponds to at least one exhaust hole and enables the exhaust hole to be in a communicated state, and the movable cover plate can rotate around the fixed shaft. According to the rolling sagger and the powder sintering method, when the rolling sagger rolls in the tunnel kiln, waste gas can be discharged while powder is reserved.

Owner:JIANGSU JITRI MOLECULAR ENG INST CO LTD

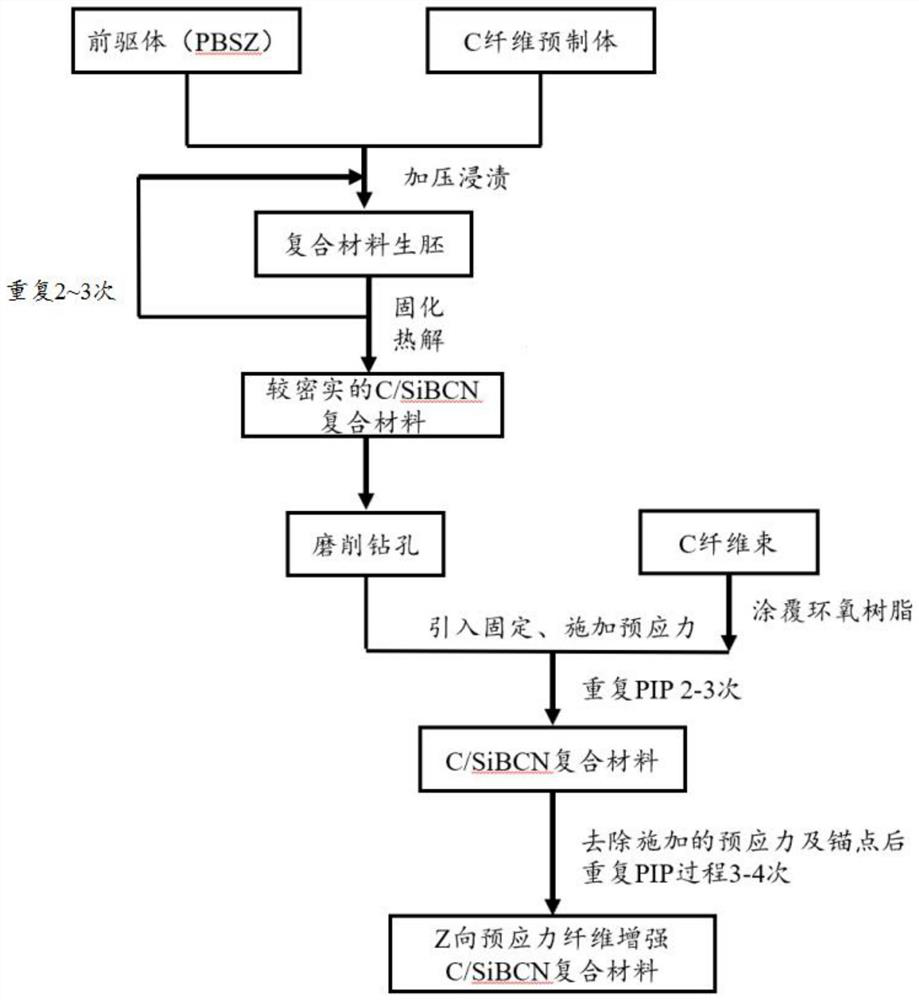

A kind of prestressed fiber reinforced c/sibcn ceramic composite material and preparation method thereof

The invention provides a prestressed fiber reinforced C / SiBCN ceramic composite material and a preparation method thereof, belonging to the technical field of ceramic matrix composite materials. The invention improves the interlayers of the fiber preform in the process of repeating the PIP, introduces Z-direction prestressed fibers along the direction perpendicular to the interlayer of the fiber preform, and introduces the Z-direction prestressed fibers into the SiBCN ceramic matrix by grinding and drilling holes. The prestressed fibers perpendicular to the axial direction can offset the internal stress from the inside to the outside of the composite material during the process of PIP impregnation and pyrolysis to prepare thicker samples, improve the mechanical properties of structural ceramics, and avoid excessive fiber pull-out and layering. Moreover, the Z-direction fibers can enhance the mechanical properties of the material along the axial direction, which not only reduces the internal stress of the composite material, but also improves the bonding state of the matrix and the reinforcement fibers, which solves the problem of continuous carbon fiber reinforced SiBCN ceramic matrix. The problem of premature cracking between the layers of the composite matrix.

Owner:SHANGHAI UNIV +1

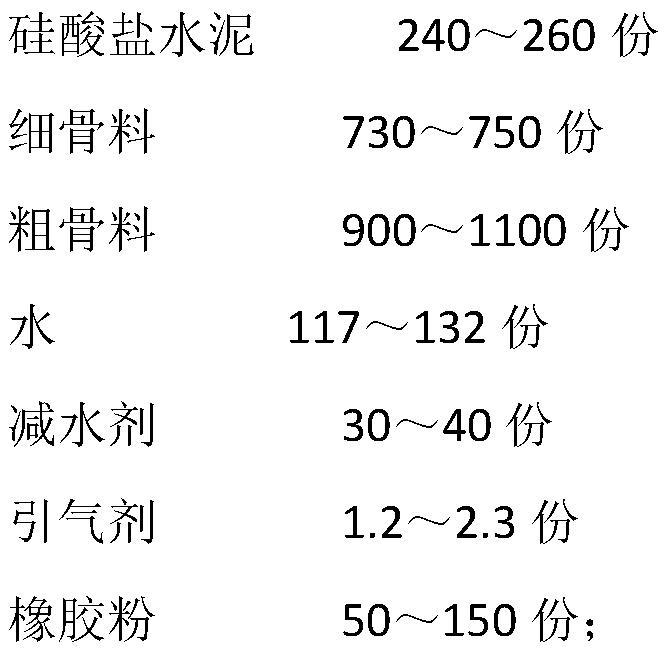

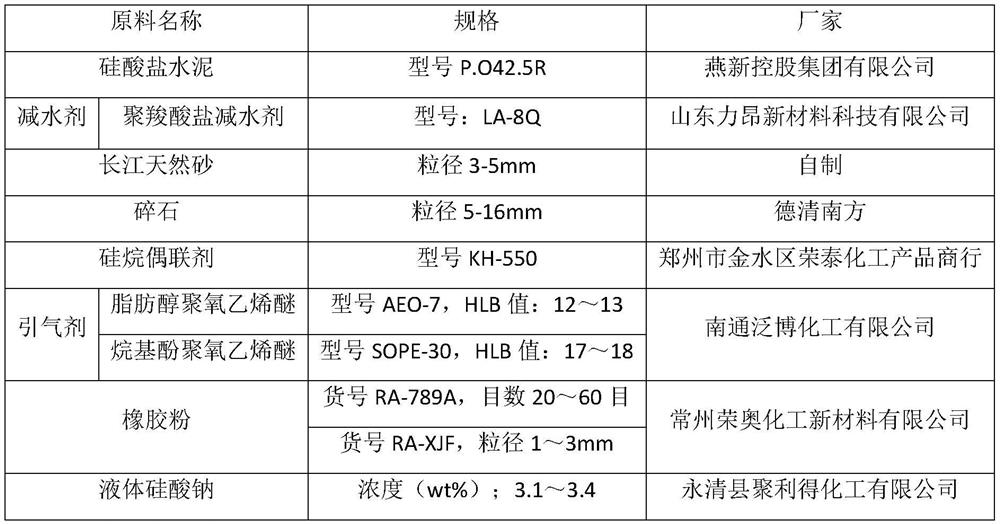

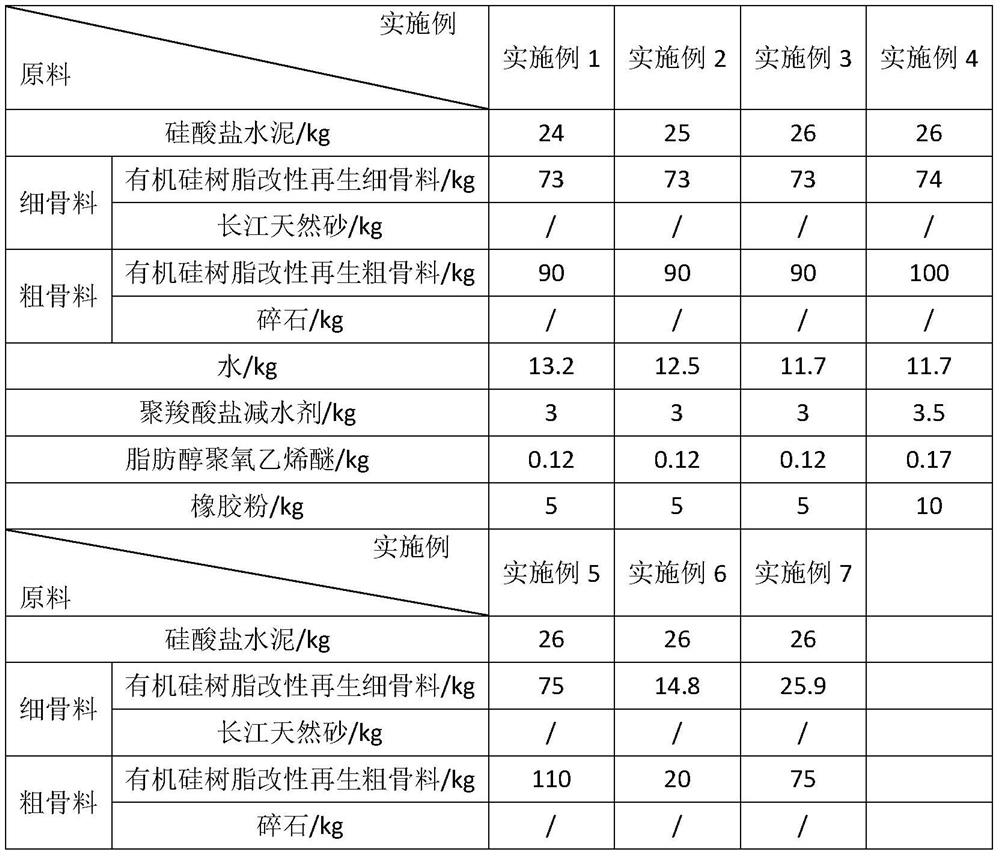

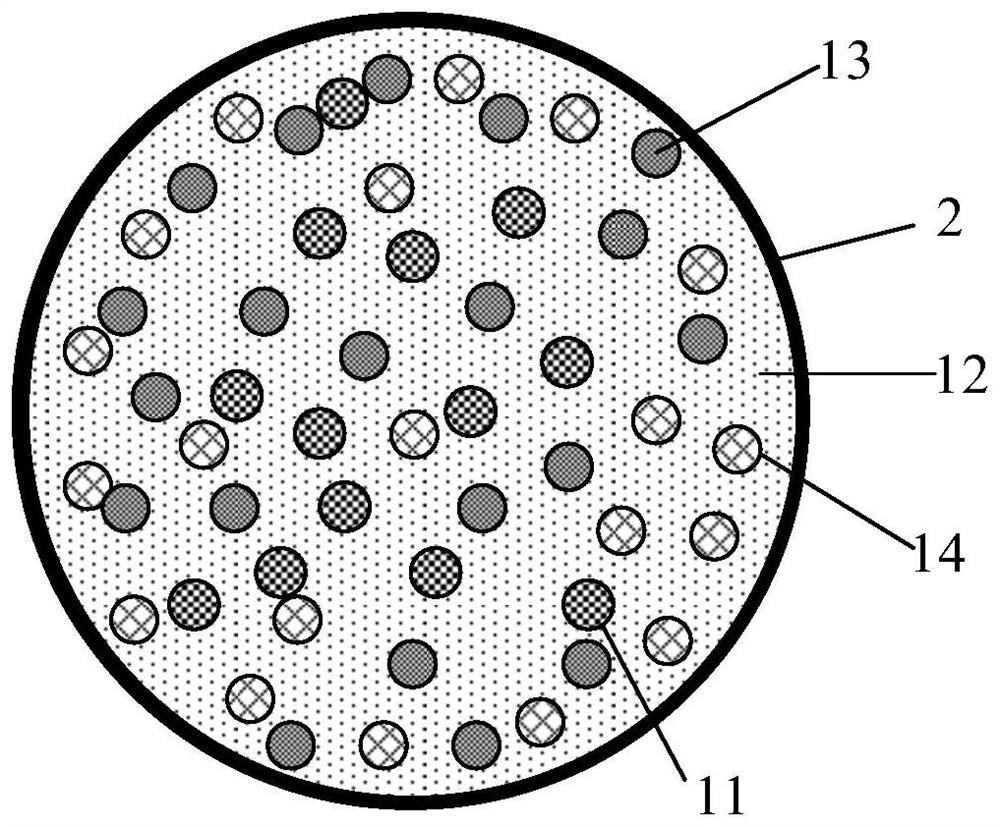

Antifreeze-thaw cycle recycled concrete and preparation method thereof

ActiveCN113429178BImprove freeze-thaw resistanceHigh compressive strengthSolid waste managementFreeze thawingCompressive resistance

The invention discloses a freezing-thawing cycle recycled concrete and a preparation method thereof. A kind of anti-freezing and thawing recycled concrete, which is prepared from the following raw materials: Portland cement, fine aggregate, coarse aggregate, water, water reducing agent, air-entraining agent, rubber powder, and the fine aggregate includes organic Silicone resin modified recycled fine aggregate, the coarse aggregate includes organosilicon resin modified recycled coarse aggregate; in this application, rubber powder and air-entraining agent provide expansion space for the expansion of free water in recycled concrete, reducing the internal At the same time, silicone resin is used to coat the surface of recycled aggregates to reduce the water absorption of recycled aggregates, improve the freeze-thaw resistance of recycled concrete, and the modified recycled aggregates are closely connected with the cement gel system , making the interior of the recycled concrete dense, and enhancing the compressive strength of the recycled concrete.

Owner:崇德建材集团有限公司

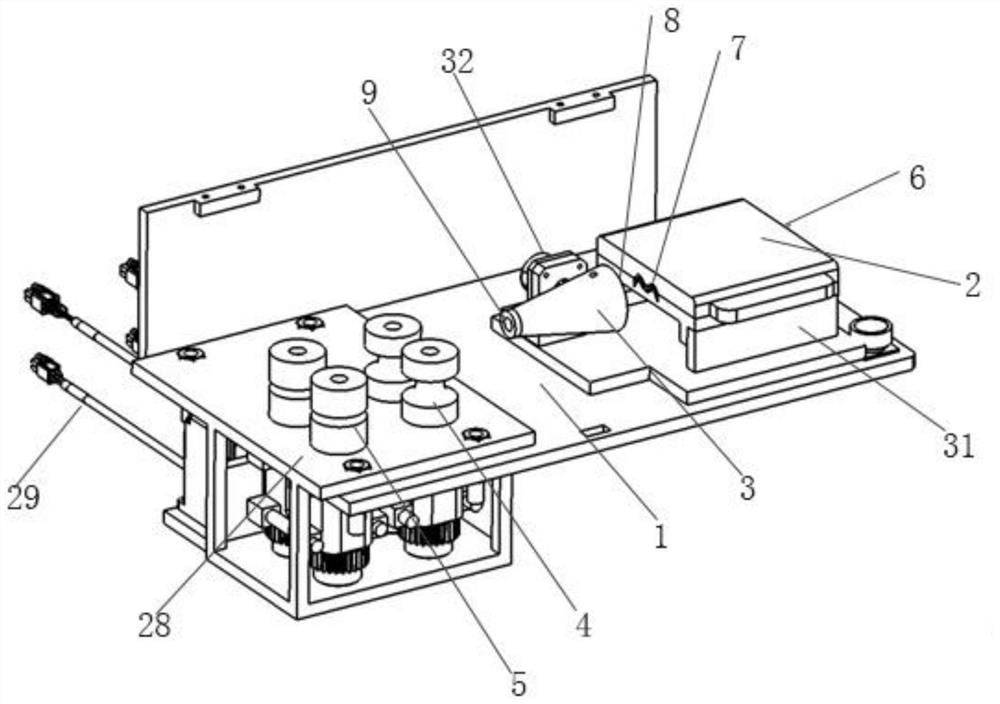

Filter stick material pre-folding and collecting device

PendingCN114176253AComply with workmanship standardsImprove appearance qualityTobacco smoke filtersEngineeringPower apparatus

The filter stick material pre-folding and collecting device comprises a rack, a paper guide device, a conical barrel, a first-stage forming wheel and a second-stage forming wheel are sequentially installed on the rack from upstream to downstream, a paper guide channel is formed in the paper guide device, and the paper guide channel is gradually shrunk from the inlet end to the outlet end; a conical channel is formed in the conical barrel, the large opening end of the conical channel faces the paper guide device, and the small opening end of the conical channel faces the first-stage forming wheel; the first-stage forming wheel and the second-stage forming wheel are each composed of a fixed wheel and a separation wheel, the distance between the fixed wheels and the separation wheels is the wheel distance, the wheel distance of the first-stage forming wheel is larger than the wheel distance of the second-stage forming wheel, and the diameter of the small opening end of the conical channel is larger than the wheel distance of the first-stage forming wheel. The first-stage forming wheel and the second-stage forming wheel are driven by a power device to rotate. The bundling device can enable the end face hole of the cooling base rod to meet the technological standard, the roundness index meets the technological standard, and the cigarette rejecting amount is reduced by more than 50%.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

A secondary doped silicon-based negative electrode material and preparation method thereof

ActiveCN112751011BImprove the first Coulombic efficiencyReduce consumptionNegative electrodesSecondary cellsSilicic acidSilicon oxide

The present application provides a secondary doped silicon-based negative electrode material and a preparation method thereof, wherein the secondary doped silicon-based negative electrode material includes: an inner core including silicon, silicon oxide, and silicic acid of the first metal element Salt and silicate of a second metal element, wherein the general formula of the silicon oxide is SiOx, 0<x<2, the activity of the first metal element is lower than that of the second metal element; The coating covers the surface of the inner core. The secondary doped silicon-based negative electrode material and the preparation method of the technical solution of the present application can improve the first-time Coulombic efficiency and capacity retention rate of the secondary battery.

Owner:SHANGHAI SHANSHAN TECH CO LTD

A submerged arc welding process

ActiveCN103008852BAvoid crackingIncrease productivityArc welding apparatusElectrical currentConstant speed

The invention discloses a process for carrying out submerged arc welding on two plates with thicknesses of no more than 14 mm. The process comprises the following steps: after one part to be welded forms a groove, checking an assembling clearance between the two plates and making the assembling clearance satisfy requirements, fixing a gasket on the back face of an abutted part; enabling a variable speed submerged arc welding trolley to move along a welding joint at a constant speed; controlling a welding wire to swing backwards relative to the trolley in a reciprocating way at a constant speed in the direction of the welding joint when the welding wire on the trolley moves at the constant speed with the trolley; controlling the swinging amplitude of the welding wire, so that the swinging arc of the welding wire always falls within a range of a molten pool; and adjusting the height of the welding wire so as to guarantee that an electric arc can directly act upon the root of the groove when the welding wire is positioned at a swinging arc front point. According to the invention, the desired welding current is reduced, linear energy is also reduced, the expansion stress of the welding joint is reduced and cracks are uneasy to generate on a welding joint terminal; moreover, as the two sides of the side wall of the groove can be continuously heated by the electric arc, the deposition rate is increased, the production efficiency is increased, the electric quantity and the consumption of the welding material are reduced and the production cost is reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Silicon carbon negative electrode material and preparation method, lithium ion battery

ActiveCN109713280BReduce expansion stressImprove dynamic performanceCell electrodesSecondary cellsLithium-ion batteryBattery cell

The invention provides a silicon-carbon negative electrode material, a preparation method and a lithium ion battery. The method for preparing silicon carbon negative electrode material comprises: SiO x 1. Mixing the carbon source and the dispersant to obtain the first mixed solution, x=0.5-1.0; performing the first dispersion treatment on the first mixed solution, filtering and drying to obtain the first dispersed material; performing the first carbonization on the first dispersed material processing, crushing to obtain primary particles, the particle size of the primary particles is 0.5-1 μm; mixing the primary particles with carbon source and dispersant to obtain the second mixed solution; performing the second dispersion treatment on the second mixed solution, filtering and drying to obtain The second dispersion material: performing a second carbonization treatment on the second dispersion material, pulverizing to obtain secondary particles, the particle size of the secondary particles is 10-15 μm, and obtaining a silicon carbon negative electrode material. The method of the present invention can make the finally obtained silicon-carbon negative electrode material have small volume expansion and good cycle performance.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Moving bed gas-solid radial reactor

ActiveCN113509894AReduce expansion stressPass smoothlyChemical/physical processesBulk chemical productionThermodynamicsPtru catalyst

The invention relates to a moving bed gas-solid radial reactor, and belongs to the field of catalysis devices. The moving bed gas-solid radial reactor comprises a shell and a catalyst chamber, and the catalyst chamber is defined by an inner ring plate, an outer ring plate, a bottom arc plate and a top sealing plate; the upper ends of the inner ring plate and the outer ring plate are correspondingly hung at the top of the shell through an inner ring hanging plate and an outer ring hanging plate, so that a certain distance is formed between the bottom arc plate at the bottom end of the catalyst chamber and the inner surface of the bottom of the shell; a gas bottom sealing plate is connected to the lower port of the inner ring plate serving as a gas collecting pipe and is connected with a gas inlet pipe penetrating through the bottom of the shell; and the inner ring plate and the outer ring plate are each of a composite structure formed by stacking grating plates on a Johnson net, and the Johnson net is located on the catalyst side. The reactor is uniform in flow field, low in pressure drop, and capable of ensuring that the side wall of the catalyst chamber is not unstable under the conditions of large diameter and high bed layer, the service lives of the inner ring plate and the outer ring plate are longer in a corrosive gas environment, and the catalyst is not easy to block meshes, so that the flowing smoothness of reaction gas is ensured.

Owner:CISDI ENG CO LTD +2

A method and device for multi-core reduction and multi-package co-casting composite casting of large steel ingots

The invention discloses a multi-core reducing multi-ladle co-casting method and device for composite casting large composite steel ingots. The multi-core reducing multi-ladle co-casting method comprises the steps of selecting core blanks, regulating the temperatures of the core blanks, re-removing scales on the surfaces of the core blanks, assembling the core blanks and ingot molds, reducing oxide scales on the surfaces of the core blanks, casting and compositing and cooling composite ingots. The device adopted by the method comprises a tank body, a reducing gas inlet, a heat preservation layer, bolts, a bin door, risers, heat insulation plates, the steel ingot molds, the core blanks, shims, a trolley, an inert gas inlet, a bottom heat insulation layer, an exhaust port, an explosion-proof end cap, a vacuum exhaust valve, a vacuum pump, circulating fans, riser bricks, casting channels, sealing valve rods, sealing valve bodies, sealing valve plates, sealing asbestos, sliding nozzles and steel ladles. Large and ultra-large molded steel ingots which cannot be produced by means of an orthodox casting method can be manufactured. The steel ingots manufactured by means of the multi-core reducing multi-ladle co-casting method and device has the advantages of being low in production cost, high in solidification speed, small in internal segregation, even in components and high in finished product rate.

Owner:佛山市金禾精密模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com