A kind of prestressed fiber reinforced c/sibcn ceramic composite material and preparation method thereof

A ceramic composite material and composite material technology are applied in the field of prestressed fiber reinforced C/SiBCN ceramic composite materials and their preparation, which can solve the influence of preform volume and internal expansion stress, surface cracks of large composite materials, and low melting point of metals. requirements, etc., to solve the premature cracking of the matrix, improve the mechanical performance, and avoid the effect of interlayer damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

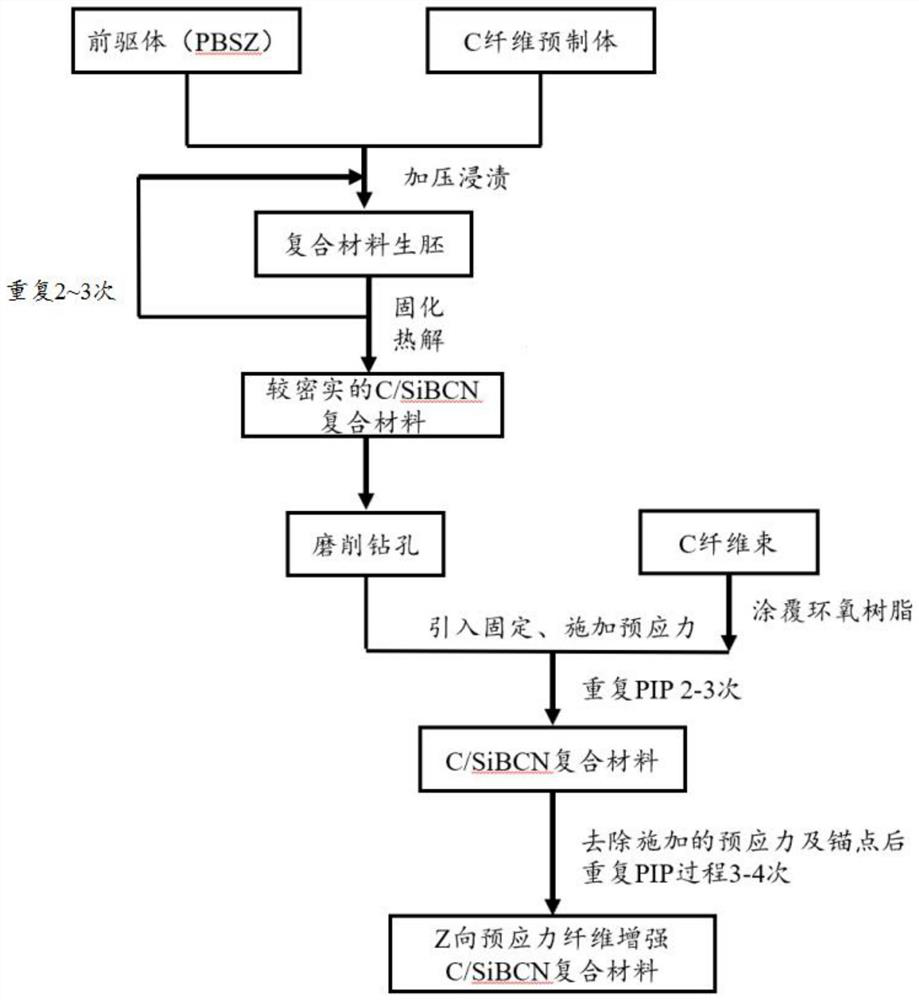

[0031] The invention provides a preparation method of a prestressed fiber reinforced C / SiBCN ceramic composite material, comprising the following steps:

[0032] The carbon fiber preform is pressurized and immersed in the polysilaborazane precursor to obtain a green embryo;

[0033] The green embryo is cross-linked and solidified to obtain a solidified body;

[0034] The solidified body is pyrolyzed to obtain a SiBCN ceramic matrix;

[0035] repeating the process of pressure impregnation-cross-linking curing-pyrolysis for the SiBCN ceramic substrate in sequence 2-3 times to obtain a C / SiBCN composite material;

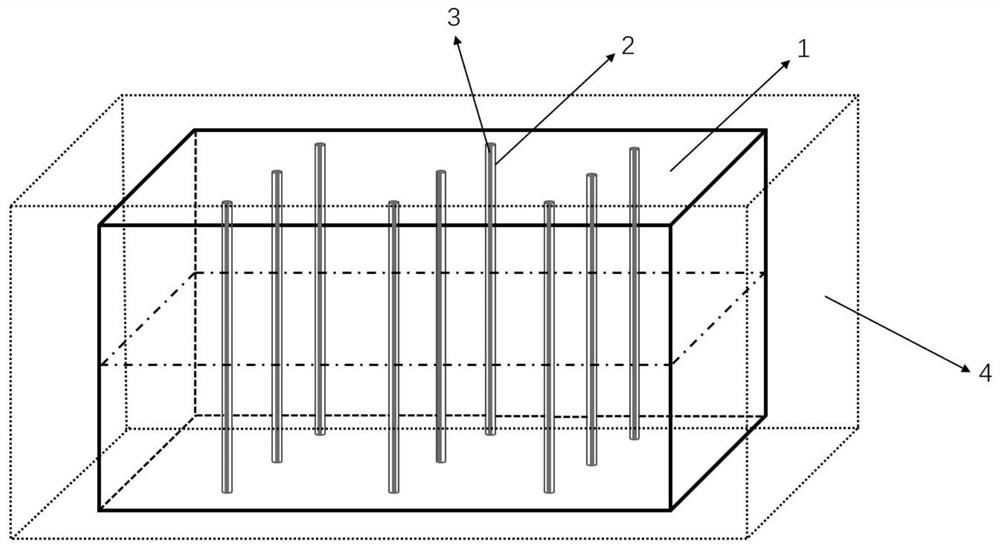

[0036] Grinding and drilling the C / SiBCN composite material from the upper surface to the lower surface to form through holes;

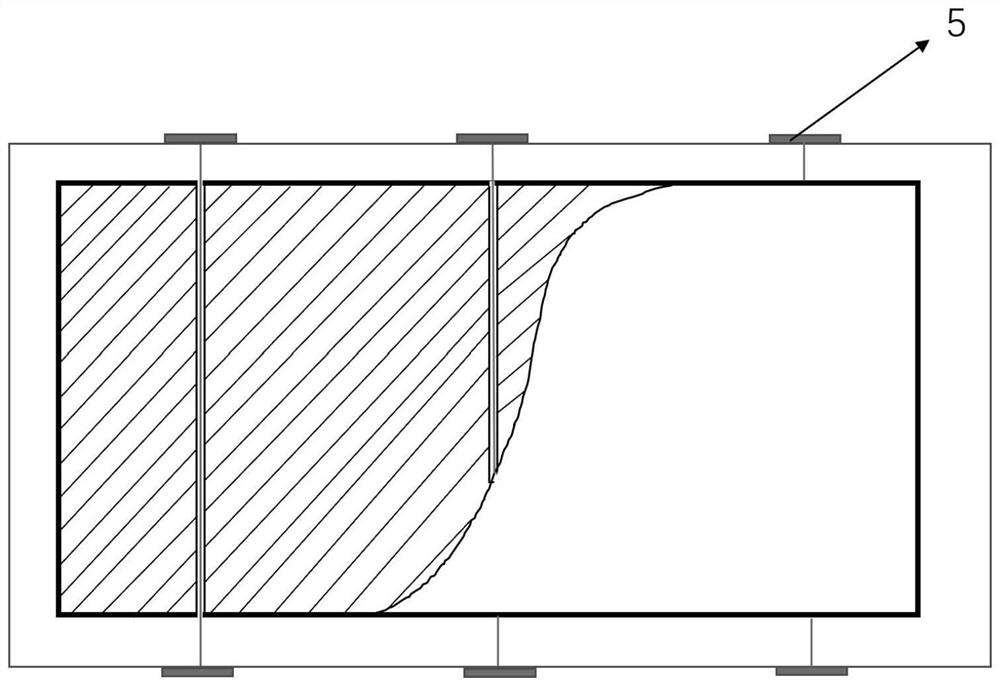

[0037] The carbon fiber bundles coated with epoxy resin are introduced into the through holes, the two ends of the obtained composite are fixed with anchor points, and a Z-direction stress is applied to one end of the anchor points, and the...

Embodiment 1

[0068] The 2.5D carbon fiber preform (woven from T300-1K, with a porosity of 60%, a fiber diameter of 5 μm, a cylindrical shape, a bottom diameter of 75 mm and a height of 100 mm) is cut to a length of 100 mm × width 53 mm × height 53 mm The size of the reactor is placed in a pressure reactor, the air in the reactor is evacuated by an external vacuum pump, and PBSZ immersion solution is added to the reactor until it is completely immersed, using N 2 Pressurized impregnation in an atmosphere, the applied pressure is 1 MPa, and the dipping time is 4 h to obtain green embryos; the temperature in the pressure reaction kettle is raised to 170 ° C (the pressure of the whole system is still maintained at 1 MPa), and cross-linking and curing are carried out. The time is 2h, the heating device is turned off, and the reaction kettle is cooled to room temperature; the sample is taken out from the kettle, transferred to a high-temperature tube furnace, 2Under protective atmosphere conditi...

Embodiment 2

[0072] The three-dimensional (3D) carbon fiber preform (made from T300-1K, the volume fraction of carbon fiber is 32%, and the fiber diameter is 6μm) is cut to a size of 100mm × width 53mm × height 53mm and placed in a pressure reaction kettle. External vacuum pump Dry the air in the kettle, add PBSZ immersion solution to the reactor until it is completely immersed, and use N 2 Pressurized impregnation in an atmosphere, the applied pressure is 1 MPa, and the dipping time is 4 h to obtain green embryos; the temperature in the pressure reaction kettle is raised to 170 ° C (the pressure of the whole system is still maintained at 1 MPa), cross-linking and curing are carried out, and curing is carried out. The time is 2h, the heating device is turned off, and the reaction kettle is cooled to room temperature; 2 Under protective atmosphere conditions, pyrolysis was carried out at 1000 °C for 2 h, and the process of pressure impregnation-crosslinking curing and pyrolysis (PIP) was re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com