Silicon carbon negative electrode material, preparation method of silicon carbon negative electrode material and lithium ion battery

A negative electrode material, silicon carbon technology, used in battery electrodes, circuits, electrical components, etc., can solve the problems of reduced battery life, electrode material shedding, serious volume expansion, etc., to improve electrical conductivity, long cycle life, reduce Effects of volume expansion and mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a silicon-carbon negative electrode material, comprising:

[0025] A) Mix and react organosilicon compound with reducing agent to obtain silicon-pyrolysis material;

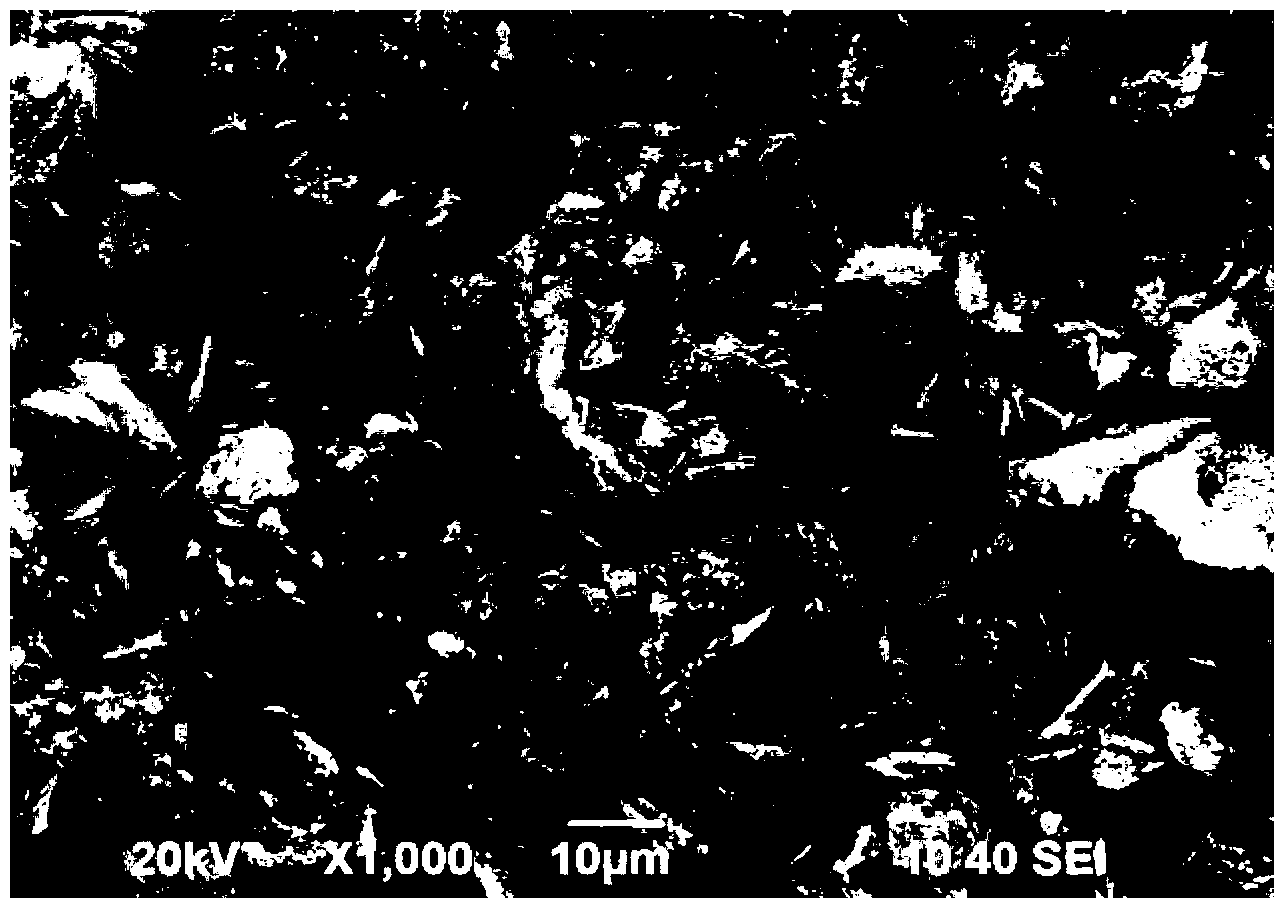

[0026] B) mixing the silicon-pyrolysis material obtained in step A) with graphite ball milling to obtain a silicon-pyrolysis carbon material;

[0027] C) Etching the silicon-pyrolytic carbon material obtained in step B) in an acid solution, and then mixing it with a salt solution containing metal ions to deposit metal and its oxide to obtain a silicon-carbon negative electrode material.

[0028] In the present invention, the organosilicon compound is firstly mixed and reacted with a reducing agent to obtain a silicon-pyrolytic material; then it is mixed with a graphite ball mill to obtain a silicon-pyrolytic carbon material; Etching is carried out, and then mixed with a salt solution containing metal ions to deposit metals and their oxides to obtain silicon-ca...

Embodiment 1

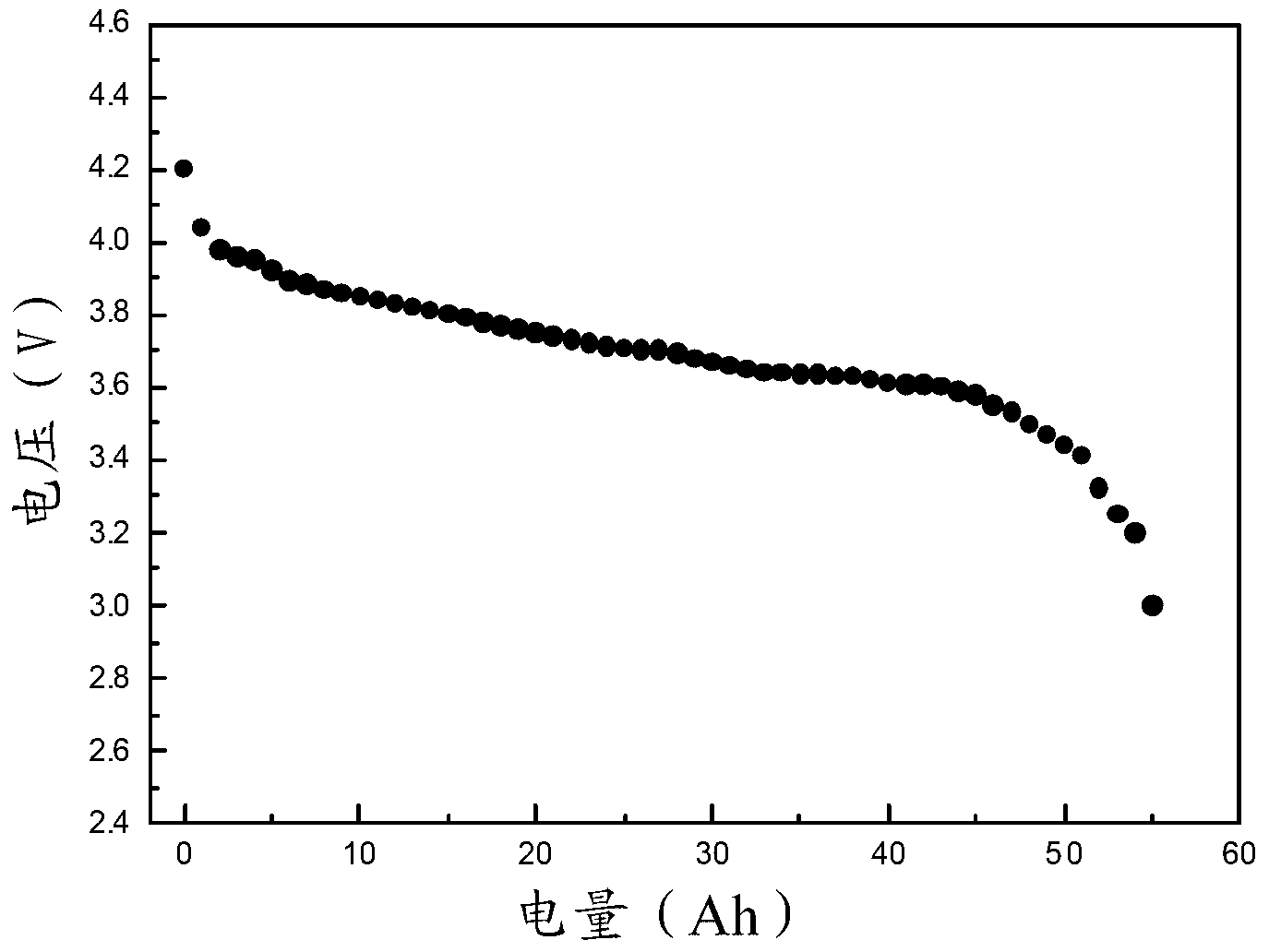

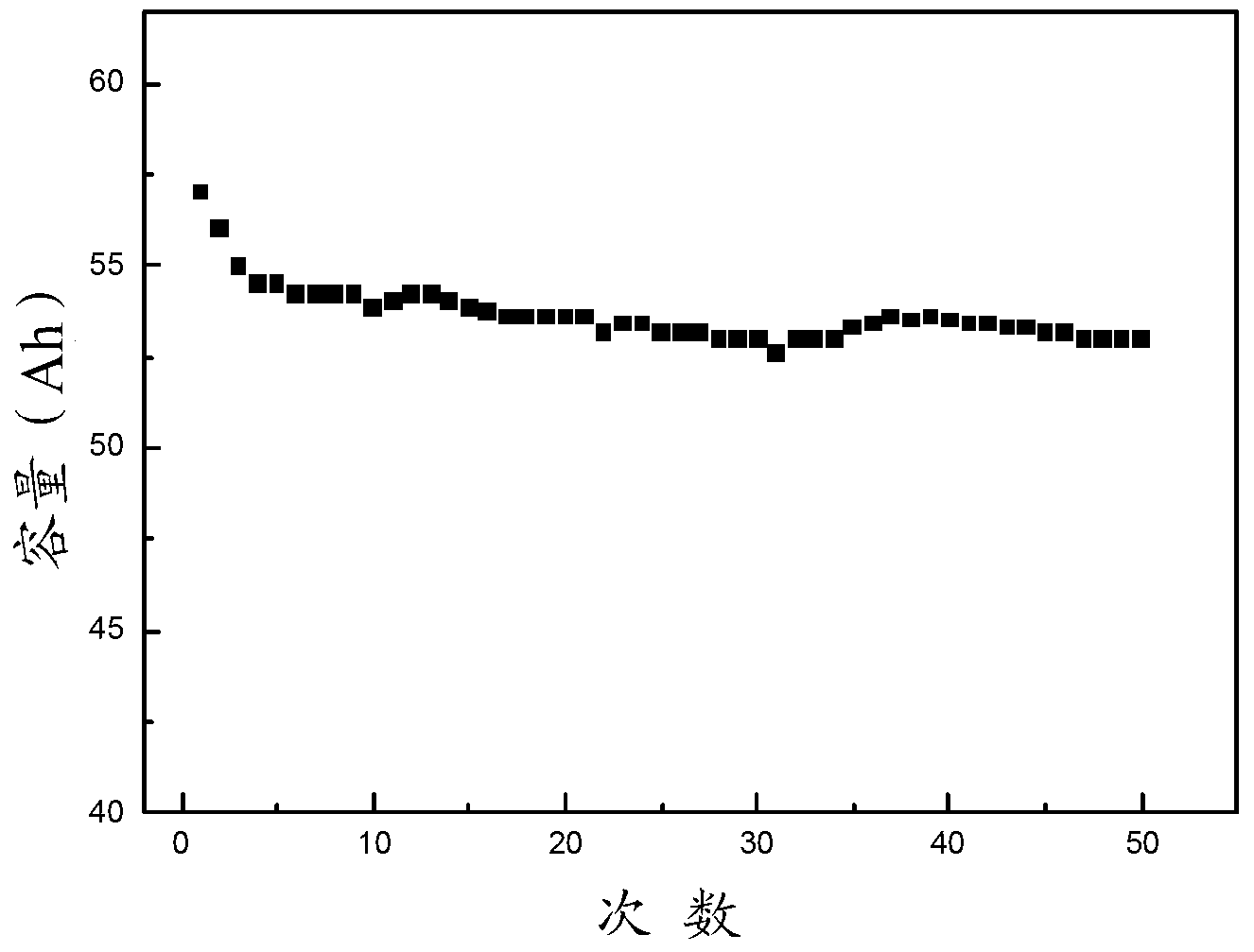

[0043] Mix 1 g of silane coupling agent with 0.05 g of nickel-based catalyst, stir evenly, and heat reaction at 800°C for 3 hours under the protection of nitrogen to obtain silicon-pyrolysis material; 1 g of silicon-pyrolysis material obtained After mixing uniformly with 1.5g of graphite in a ball mill, a silicon-pyrolytic carbon material was obtained; the obtained silicon-pyrolytic carbon material was dispersed in an acid solution and etched for 4 minutes, and the acid solution was 65wt with a mass ratio of 10:30:60 % hydrofluoric acid, 50wt% nitric acid and water mixed solution, after ultrasonic vibration etching for 4min, the material was ultrasonically cleaned with distilled water to remove the surface acid solution, filtered to obtain a solid, and the obtained solid was dispersed in sulfurous acid with a concentration of 2mol / L In iron solution, Fe and Fe 2 o 3 deposited on the surface of the silicon-pyrolytic carbon material, and then heated at 400° C. for 1 h in a mixe...

Embodiment 2

[0048] Mix 1 g of silane coupling agent with 0.05 g of nickel-based catalyst, stir evenly, and heat reaction at 800°C for 3 hours under the protection of nitrogen to obtain silicon-pyrolysis material; 1 g of silicon-pyrolysis material obtained After uniformly mixing with 1.5g of graphite in a ball mill, a silicon-pyrolytic carbon material is obtained; the obtained silicon-pyrolytic carbon material is dispersed in an acid solution, and ultrasonic vibration is etched for 10min, and the acid solution is a mass ratio of 10:30: 60 mixed solution of hydrofluoric acid, nitric acid and water, after etching for 10 minutes, the material was ultrasonically cleaned with distilled water, filtered to obtain a solid, and the obtained solid was dispersed in a tin sulfate solution with a concentration of 2mol / L to make Sn and SnO is deposited on the surface of the silicon-pyrolytic carbon material, and then heated at 800° C. for 1 h in a mixed gas of hydrogen and nitrogen at a volume ratio of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com