Winding type asynchronous motor and manufacturing method

An asynchronous motor, winding type technology, applied in the field of motors, can solve problems such as rotation, expansion stress difference, short circuit, etc., to achieve the effect of improving safety performance, reducing expansion stress, and avoiding magnetic short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

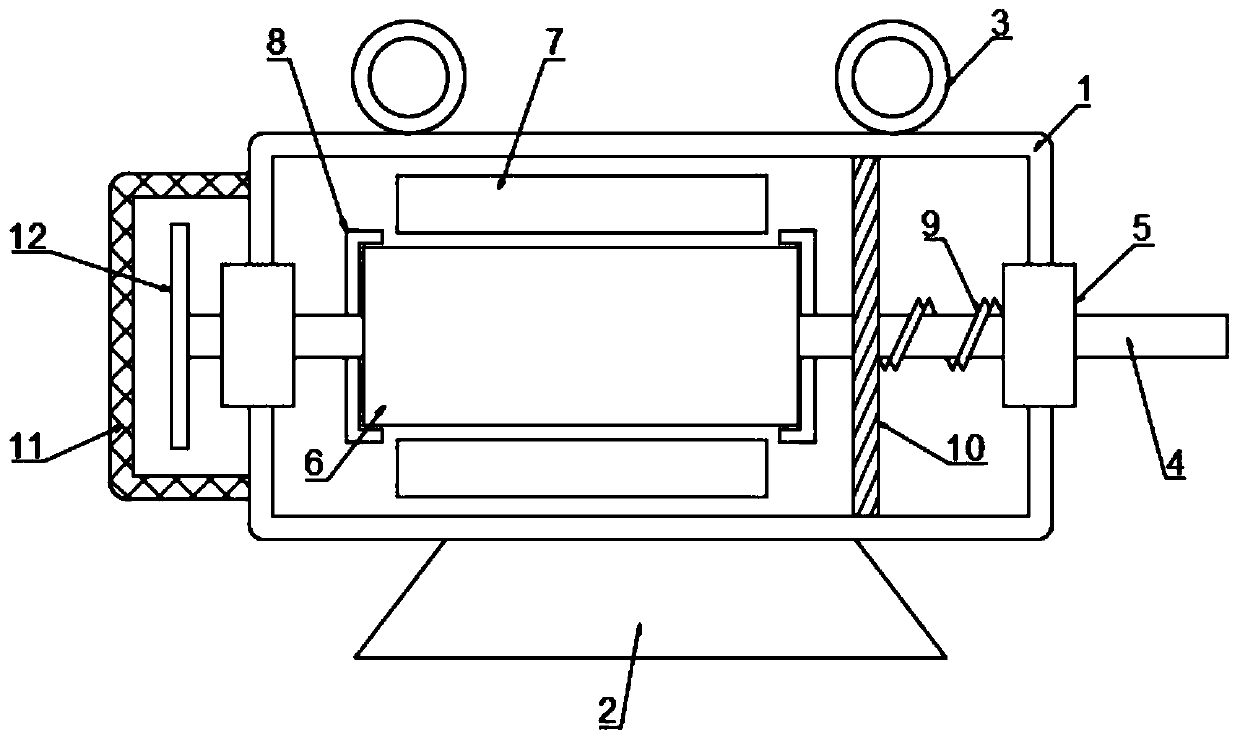

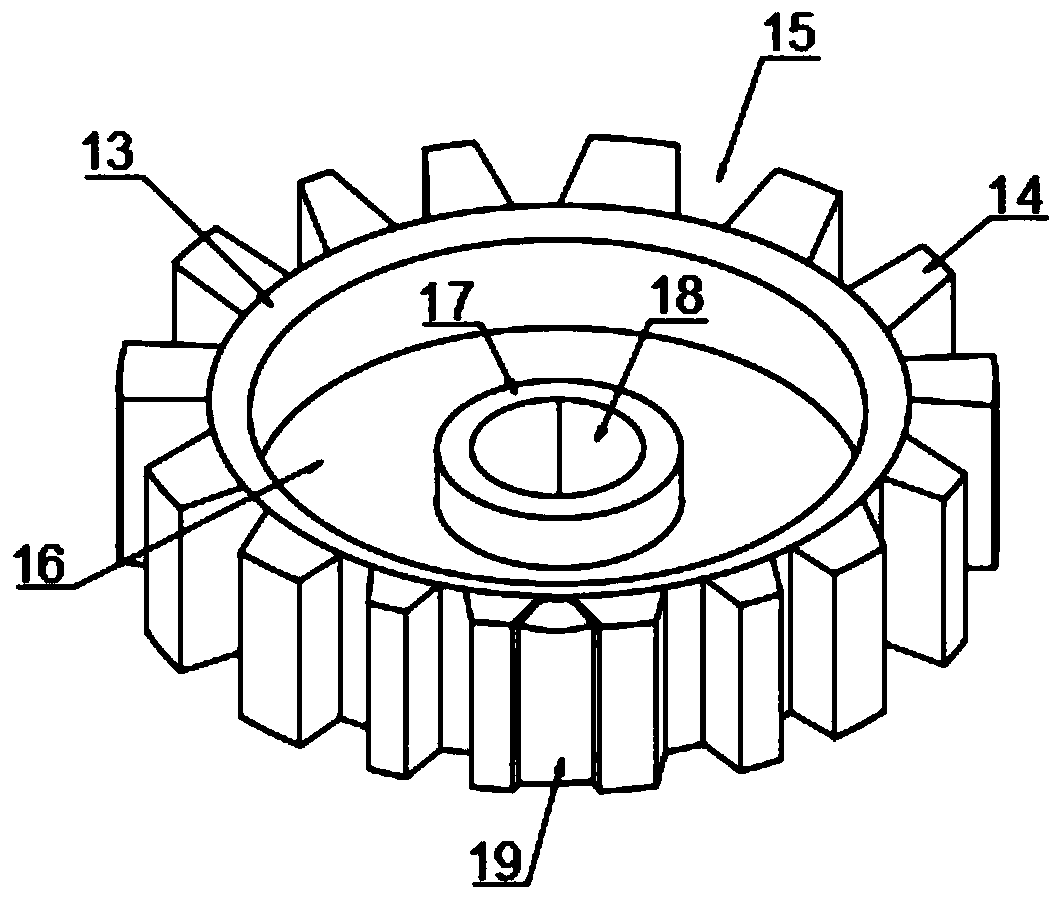

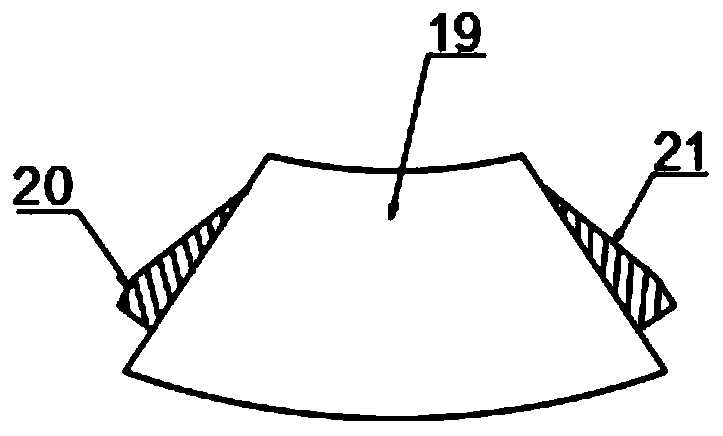

[0039] refer to Figure 1-3 , a wire-wound asynchronous motor, comprising a housing 1, the lower side wall of the housing 1 is integrally formed with a base 2, the upper side wall of the housing 1 is welded with two lifting rings 3, and the inside of the housing 1 is provided with a rotating shaft 4 A rotor 6 is fixed on the outer wall of the rotating shaft 4, and hoops 8 are fixedly sleeved on the outer walls of both ends of the rotor 6. The hoops 8 are mesh structures made of galvanized steel, which can prevent corrosion of steel. rust so as to prolong the service life of the steel, and at the same time have better mechanical performance and enhance the performance of the rotor 6. The inside of the housing 1 is fixed with a stator 7 wound on the outer wall of the rotor 6, and the connection between the housing 1 and the rotating shaft 4 is opened. There is a mounting port, and a bearing 5 is fixed in the mounting port. Both ends of the rotating shaft 4 are inserted through t...

Embodiment 2

[0048] refer to Figure 2-4 , refer to Figure 1-3 , a wire-wound asynchronous motor, comprising a housing 1, the lower side wall of the housing 1 is integrally formed with a base 2, the upper side wall of the housing 1 is welded with two lifting rings 3, and the inside of the housing 1 is provided with a rotating shaft 4 A rotor 6 is fixed on the outer wall of the rotating shaft 4, and hoops 8 are fixedly sleeved on the outer walls of both ends of the rotor 6. The hoops 8 are mesh structures made of galvanized steel, which can prevent corrosion of steel. rust so as to prolong the service life of the steel, and at the same time have better mechanical performance and enhance the performance of the rotor 6. The inside of the housing 1 is fixed with a stator 7 wound on the outer wall of the rotor 6, and the connection between the housing 1 and the rotating shaft 4 is opened. There is a mounting port, and a bearing 5 is fixed in the mounting port. Both ends of the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com