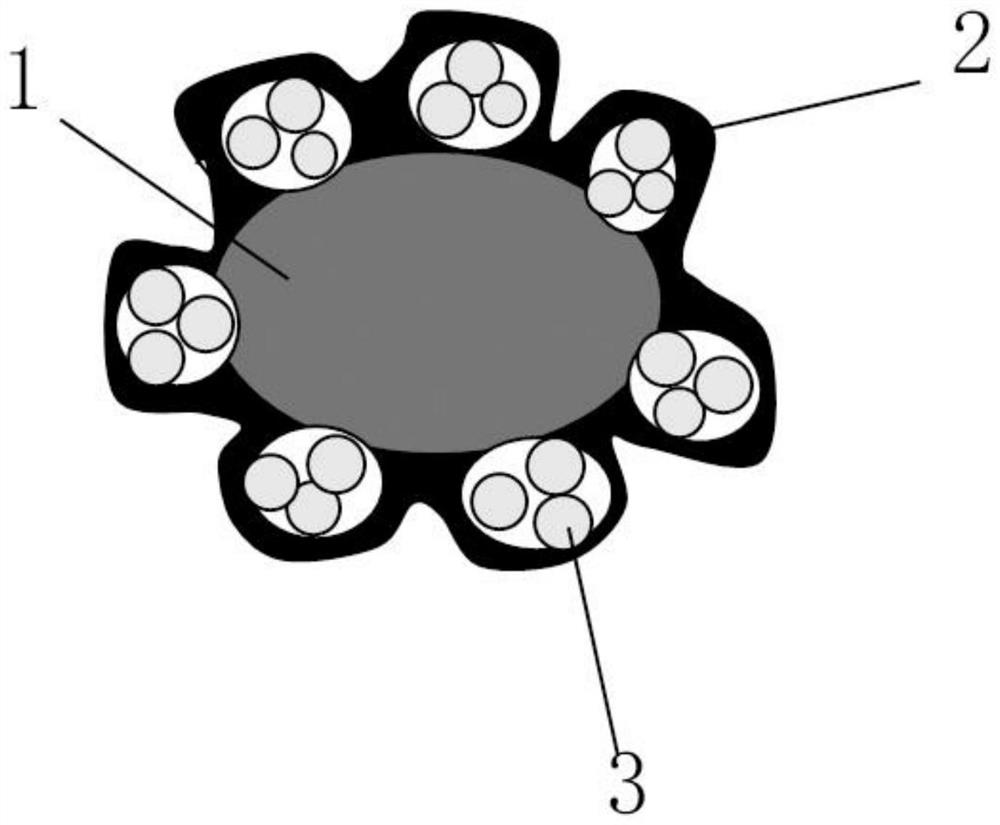

A kind of graphite/silicon/carbon composite negative electrode material and preparation method thereof

A negative electrode material, carbon composite technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of uneven distribution, low cycle stability of materials, easy agglomeration, etc., to improve distribution uniformity and improve cycle stability. The effect of improving the uniformity of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of graphite / silicon / carbon composite negative electrode material, comprising the steps of:

[0031] (1) Take 4.5g of graphite and disperse it into the sulfuric acid and nitric acid mixed solution with a volume ratio of 3:1, stir at room temperature for 24h after ultrasonication for 3h, wash, and remove the acid solution;

[0032] (2) Weigh 0.25 g of silicon dioxide and disperse it into 100 ml of pure water, add 0.5 g of 3-aminopropyltriethoxysilane, stir at room temperature for 5 hours, and wash to obtain surface amino-modified silicon dioxide;

[0033] (3) Disperse the graphite obtained in step (1) and the silica obtained in step (2) in a pure water / ethanol system, add hydrochloric acid, control the acid concentration to 0.5mol / L, stir for 24 hours, and add an appropriate amount of asphalt (According to the amount of residual carbon, ensure that the carbon content in the final prepared material is 10%), continue to stir for 24h, wash and dry to obt...

Embodiment 2

[0035] A preparation method of graphite / silicon / carbon composite negative electrode material, comprising the steps of:

[0036] (1) Take 4g of graphite and disperse it into the sulfuric acid and nitric acid mixed solution with a volume ratio of 3:1, stir at room temperature for 24h after ultrasonication for 3h, wash, and remove the acid solution;

[0037] (2) Weigh 0.5 g of silicon dioxide and disperse it into 100 ml of pure water, add 1 g of 3-aminopropyltrimethoxysilane, stir at room temperature for 5 hours, and wash to obtain surface amino-modified silicon dioxide;

[0038] (3) Disperse the graphite obtained in step (1) and the silica obtained in step (2) in a pure water / ethanol system, add hydrochloric acid, control the acid concentration to 0.5mol / L, stir for 12 hours, and add an appropriate amount of asphalt (According to the residual carbon content, ensure that the carbon content in the final prepared material is 10%), continue to stir for 12 hours, wash and dry to obta...

Embodiment 3

[0041] A preparation method of graphite / silicon / carbon composite negative electrode material, comprising the steps of:

[0042] (1) Take 4.5g of graphite and disperse it into the sulfuric acid and nitric acid mixed solution with a volume ratio of 3:1, stir at room temperature for 24h after ultrasonication for 3h, wash, and remove the acid solution;

[0043] (2) Weigh 0.25 g of silicon dioxide and disperse it into 100 ml of pure water, add 0.5 g of 3-aminopropyltriethoxysilane, stir at room temperature for 5 hours, and wash to obtain surface amino-modified silicon dioxide;

[0044] (3) Disperse the graphite obtained in step (1) and the silicon dioxide obtained in step (2) in pure water, add hydrochloric acid, control the acid concentration to 0.5mol / L, stir for 24h, add an appropriate amount of dopamine (according to residual carbon content, to ensure that the carbon content in the final prepared material is 10%), continue to stir for 24h, wash and dry to obtain graphite / silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com