Armature, starting motor and method for manufacturing armature

An armature and armature shaft technology, which is applied to electric components, electrical components, electromechanical devices, etc., can solve problems such as large changes, accelerated motor temperature rise, deformation of bushing 126, etc., to reduce expansion and internal stress, The effect of reducing internal stress and reducing the interference volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

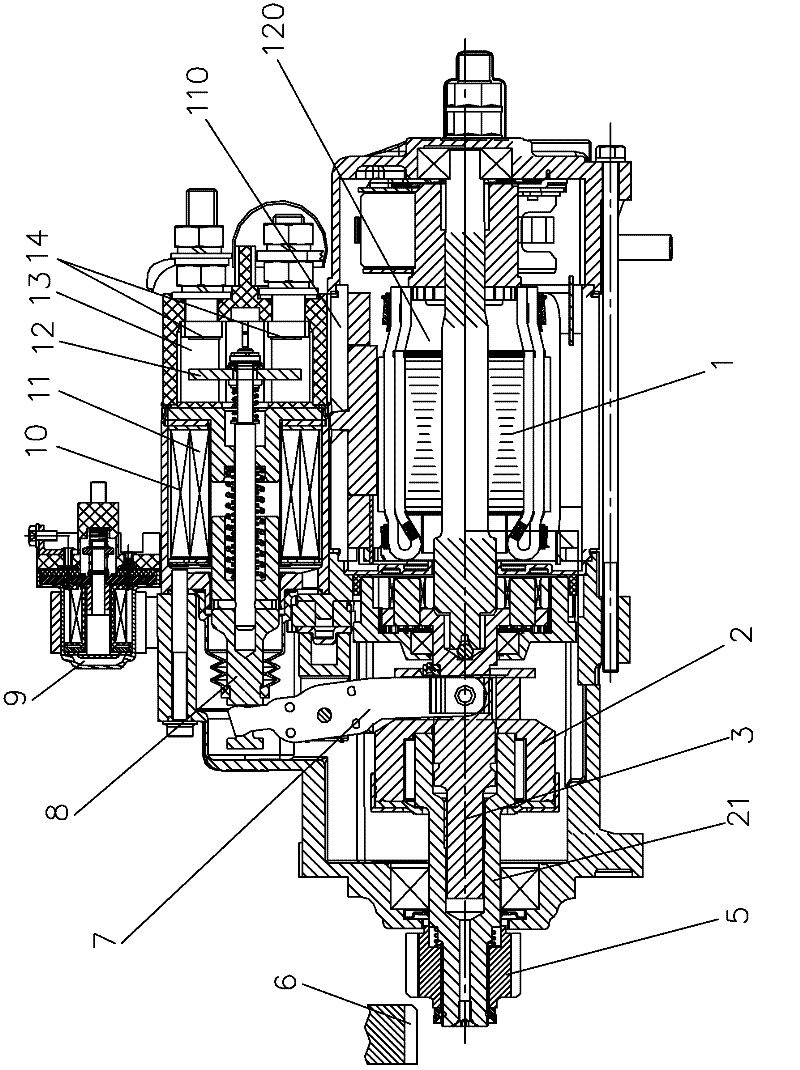

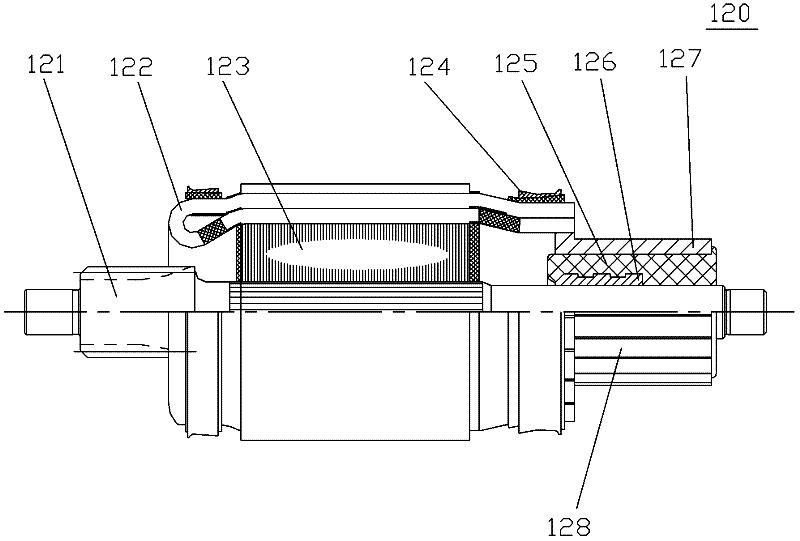

[0056] refer to figure 2 and refer to image 3 , the armature 120 of the present invention includes: an armature shaft 121, an armature wire 122, an armature core lamination 123, a binding ring 124 and a commutator 128, and the commutator is axially penetrated and arranged on the armature shaft 121 as The armature wire 122 shunts the power supply, the armature iron core lamination 123 is axially penetrated and fixed on the armature shaft 121, the armature wire 122 is inserted in the armature iron core lamination 123 and connected with the commutator, and the binding ring 124 is connected to the electric The pivot line 122 acts as a radial fixation. The commutator 128 includes an insulating filler 125, a bushing 126, and a plurality of commutator segments 127 that are evenly distributed around the axis of the armature shaft 121 and are not connected to each other. The sleeve 126 is fixed as a whole, and the bushing 126 is in interference fit with the armature shaft 121 to en...

no. 2 example

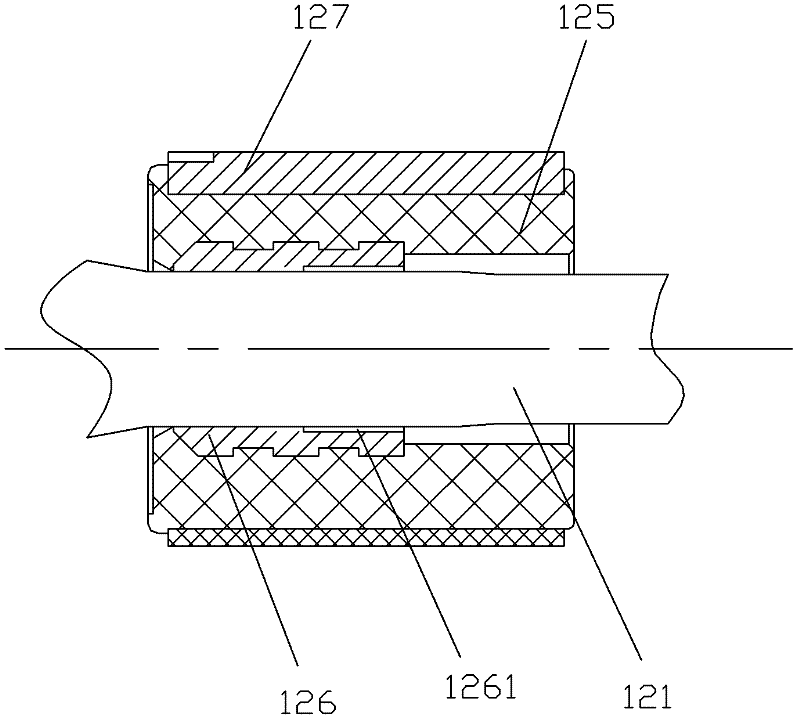

[0059] refer to Figure 4 A partial sectional view of the armature of the second embodiment of the present invention. In this embodiment, the structure of the armature is substantially the same as that in the first embodiment. The difference is that in this embodiment, the annular groove 1261 is arranged on the lining The annular groove 1261 extends from the left end surface of the bushing 126 to the middle of the bushing along the bushing axis but does not go through the whole bushing.

[0060] Regarding other structures of this embodiment, since they are the same as those of the first embodiment, details will not be repeated here.

no. 3 example

[0062] refer to Figure 5 A partial cross-sectional view of the armature of the third embodiment of the present invention. In this embodiment, the structure of the armature is roughly the same as that in the first embodiment. The difference is that in this embodiment, the number of annular grooves is Two, one annular groove 1261 is arranged on the inner wall of the bushing away from the armature core laminations, and the other annular groove 1262 is arranged on the inner wall of the bushing near the armature iron core laminations.

[0063] Regarding other structures of this embodiment, since they are the same as those of the first embodiment, details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com