High-corrosion-resistance and low-expansion magnesia carbon brick and preparation method thereof

A low-expansion, magnesia-carbon brick technology, used in the field of refractory materials for steelmaking, can solve the problems of reducing the slag erosion resistance of the material, thermal spalling of the material, and high thermal expansion rate, and improve the erosion resistance. The effect of reducing high temperature expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further illustrated in conjunction with specific embodiments. It will be appreciated that these examples are intended to illustrate the scope of the invention and are not intended to limit the scope of the invention. The method of operation no specific conditions in the examples below, are performed under routine conditions, or in accordance with the conditions recommended by the manufacturer. Unless otherwise specified, the amount of each raw material component are parts by mass.

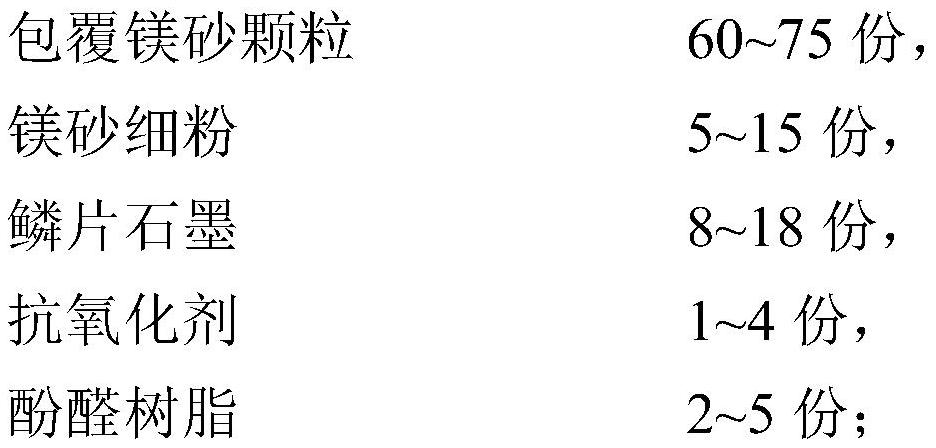

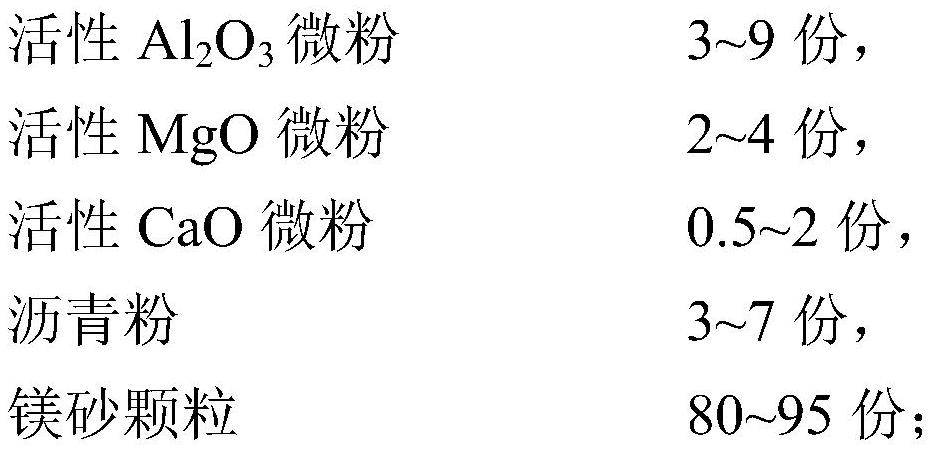

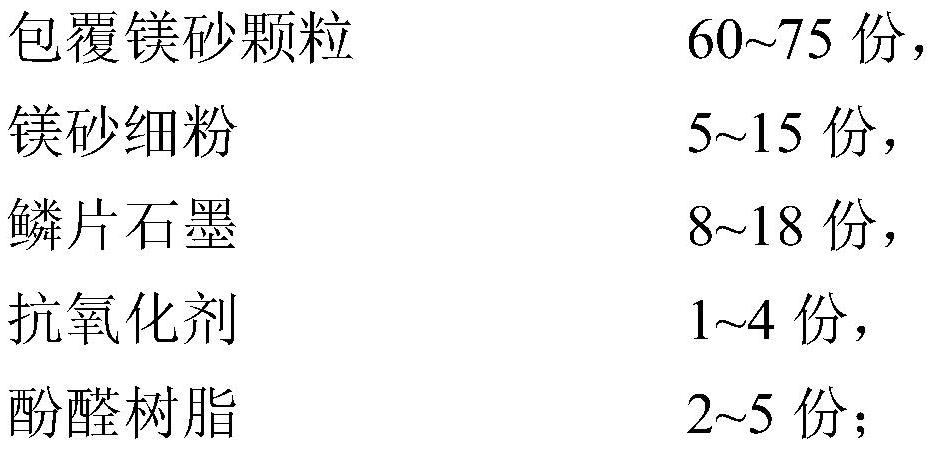

[0046] Table 1 shows the respective embodiments, the ratio of raw materials Bricks, and Table 2 shows the respective embodiments, the ratio of the raw materials involved composition coated magnesia particles, wherein:

[0047] Fused magnesia magnesia particles, chemical composition and mass percentage: MgO≥97.0wt%, CaO≤1.8wt%, SiO 2 ≤0.9 wt%.

[0048] Al activity 2 O 3 The chemical composition and mass content of fine powder is Al 2 O 3 ≥98.00 wt%, SIO 2 ≤0.4 wt%, Fe 2 O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com