Nickel-cobalt lithium manganate positive electrode material applied to high-voltage lithium ion batteries and preparation method thereof

A technology for nickel-cobalt lithium manganate and lithium-ion batteries, which is applied in the field of lithium-ion battery cathode materials and their preparation, can solve the problems of poor structural stability, rapid capacity decay of nickel-cobalt lithium manganate cathode materials, etc., and achieves a reduction in lattice volume. and stress expansion, promoting Li+ migration, and increasing the effect of interplanar spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

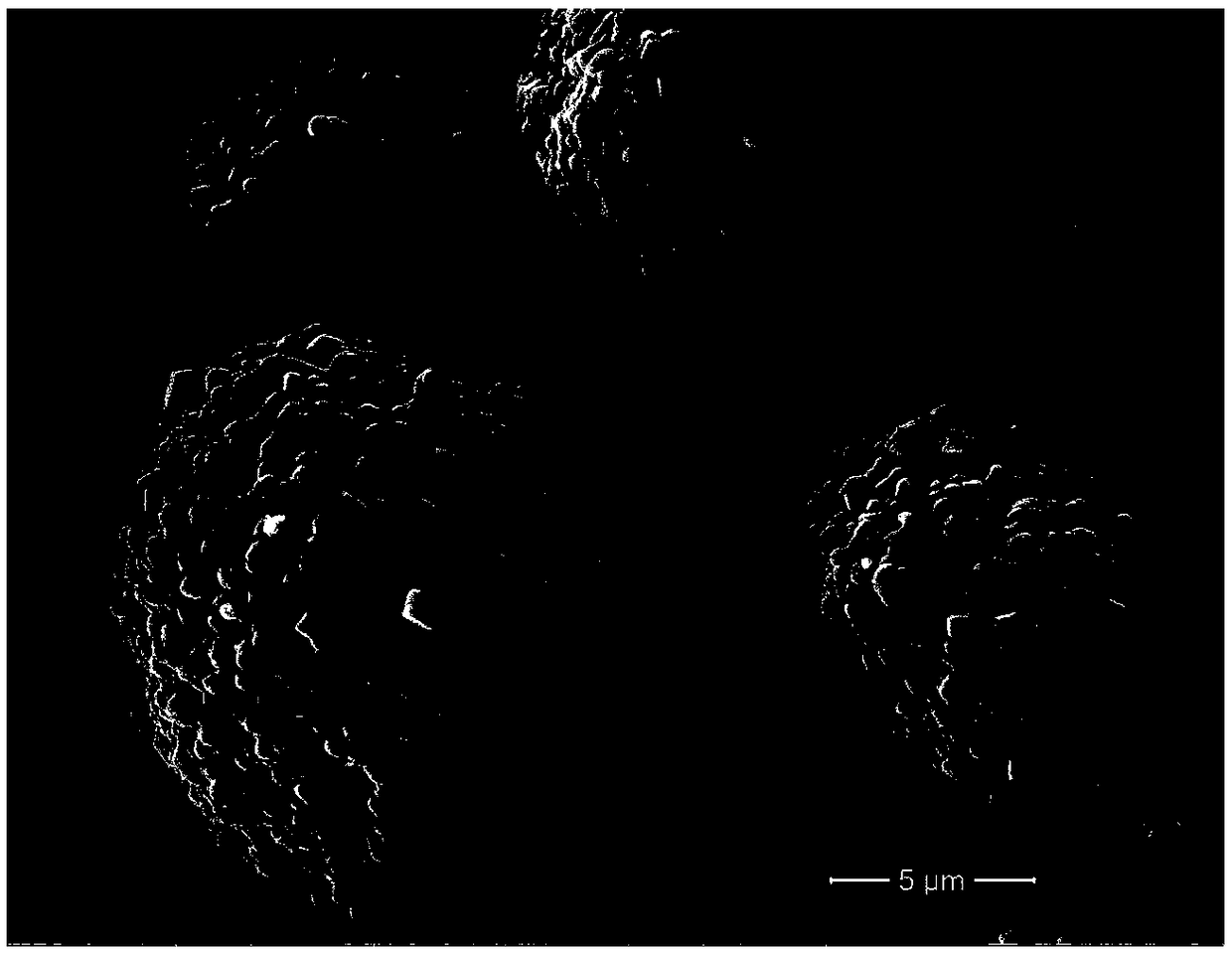

Image

Examples

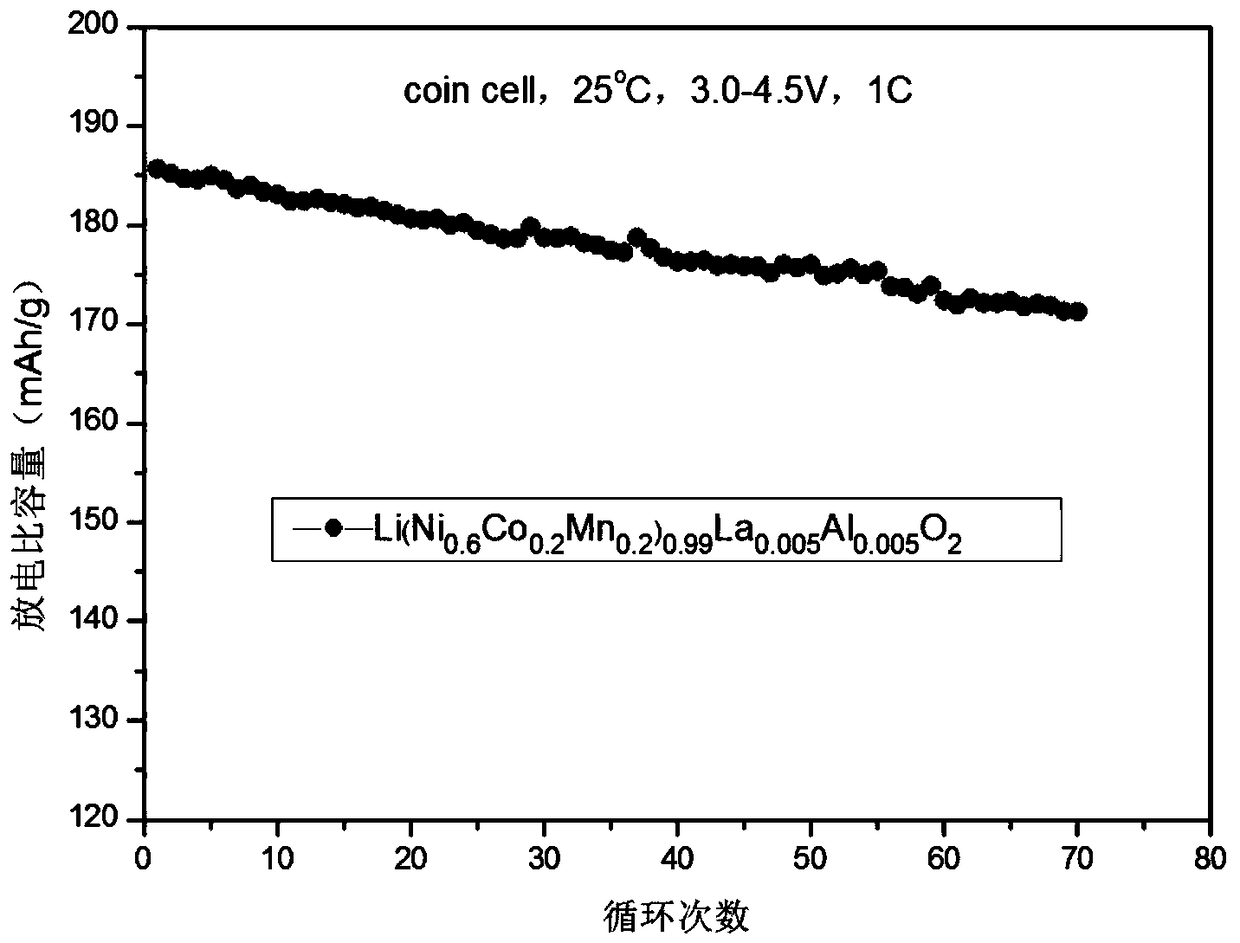

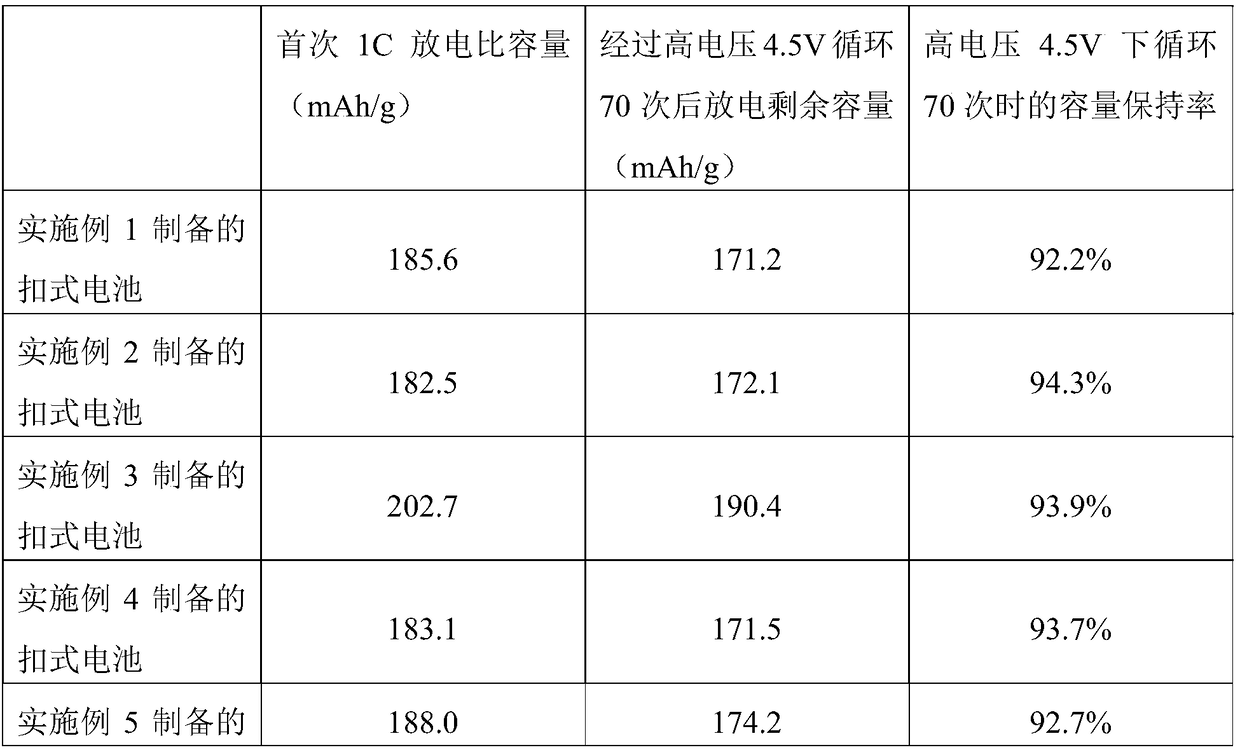

Embodiment 1

[0028] A method for preparing a positive electrode material of nickel-cobalt lithium manganese oxide for a high-voltage lithium-ion battery comprises the following steps.

[0029] Step 1: Massage Molebi Ni 0.6 co 0.2 mn 0.2 (OH) 2 : La 2 o 3 :Al(OH) 3 : Li 2 CO 3 = 1:0.0025:0.005:0.54, weigh the nickel-cobalt-manganese precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 and La 2 o 3 , Al(OH) 3 , Li 2 CO 3 , placed in a horizontal ball mill for ball milling and mixing, the speed of the horizontal ball mill is 200r / min, and the ball milling time is 2.5 hours.

[0030] Step 2: pre-calcine the mixture obtained in step 1 in a muffle furnace, the pre-calcination temperature is 550° C., and the pre-calcination time is 8 hours.

[0031] Step 3: Put the material obtained in Step 2 into a horizontal ball mill for secondary ball milling and mixing. The rotating speed of the horizontal ball mill is 200 r / min, and the ball milling time is 2.5 hours.

[0032] Step 4: Sinter the mixture ...

Embodiment 2

[0034] A method for preparing a positive electrode material of nickel-cobalt lithium manganese oxide for a high-voltage lithium-ion battery comprises the following steps.

[0035] Step 1: Massage Molebi Ni 0.5 co 0.2 mn 0.3 (OH) 2 : La 2 o 3 :Al(OH) 3 : Li 2 CO 3 = 1:0.0025:0.005:0.54, weigh the nickel-cobalt-manganese precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 and La 2o 3 , Al(OH) 3 , Li 2 CO 3 , placed in a horizontal ball mill for ball milling and mixing, the speed of the horizontal ball mill is 200r / min, and the ball milling time is 2.5 hours.

[0036] Step 2: pre-calcine the mixture obtained in step 1 in a muffle furnace, the pre-calcination temperature is 600° C., and the pre-calcination time is 8 hours.

[0037] Step 3: Put the material obtained in Step 2 into a horizontal ball mill for secondary ball milling and mixing. The rotating speed of the horizontal ball mill is 300 r / min, and the ball milling time is 2 hours.

[0038] Step 4: Sinter the mixture obt...

Embodiment 3

[0040] A method for preparing a positive electrode material of nickel-cobalt lithium manganese oxide for a high-voltage lithium-ion battery comprises the following steps.

[0041] Step 1: Massage Molebi Ni 0.8 co 0.1 mn 0.1 (OH) 2 : La 2 o 3 :Al(OH) 3 : LiOH=1:0.0025:0.005:1.08, weigh the nickel cobalt manganese precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 and La 2 o 3 , Al(OH) 3 , LiOH, placed in a horizontal ball mill for ball milling and mixing, the speed of the horizontal ball mill is 200r / min, and the ball milling time is 2.5 hours.

[0042] Step 2: pre-calcine the mixture obtained in step 1 in a muffle furnace, the pre-calcination temperature is 500° C., and the pre-calcination time is 8 hours.

[0043] Step 3: Put the material obtained in Step 2 into a horizontal ball mill for secondary ball milling and mixing. The rotating speed of the horizontal ball mill is 200 r / min, and the ball milling time is 2.5 hours.

[0044] Step 4: Sinter the mixture obtained in Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com