Ferrosilicon composite negative electrode material and preparation method thereof

A negative electrode material, a technology of ferrosilicon alloy, applied in the field of ferrosilicon composite negative electrode material and its preparation, can solve the problems of low effective specific capacity, high cost of nanometerization, poor cycle performance, etc., to reduce the average particle size, improve the preparation efficiency, The effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

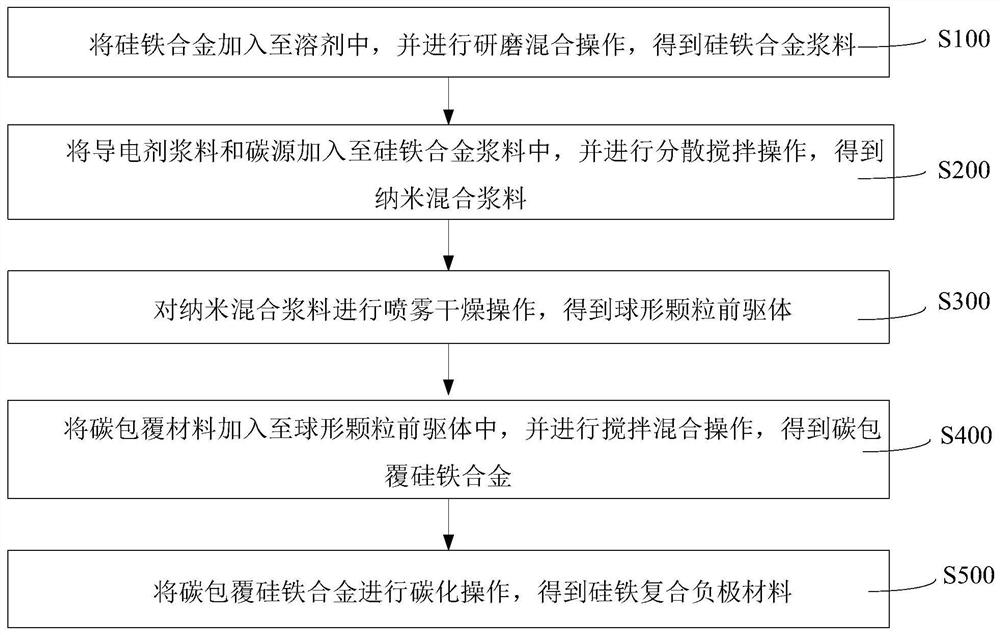

[0033] The present application provides a preparation method of ferrosilicon composite negative electrode material, comprising the following steps: adding ferrosilicon alloy to a solvent, and performing grinding and mixing operations to obtain ferrosilicon alloy slurry; adding conductive agent slurry and carbon source to the The ferrosilicon alloy slurry is dispersed and stirred to obtain a nano-mixed slurry; the nano-mixed slurry is spray-dried to obtain a spherical particle precursor; the carbon coating material is added to the spherical particle precursor , and a stirring and mixing operation is performed to obtain a carbon-coated ferrosilicon alloy; the carbon-coated ferrosilicon alloy is subjected to a carbonization operation to obtain the ferrosilicon composite negative electrode material.

[0034] In the preparation method of the above-mentioned ferrosilicon composite negative electrode material, ferrosilicon alloy is used as the negative electrode material, and the seco...

Embodiment 1

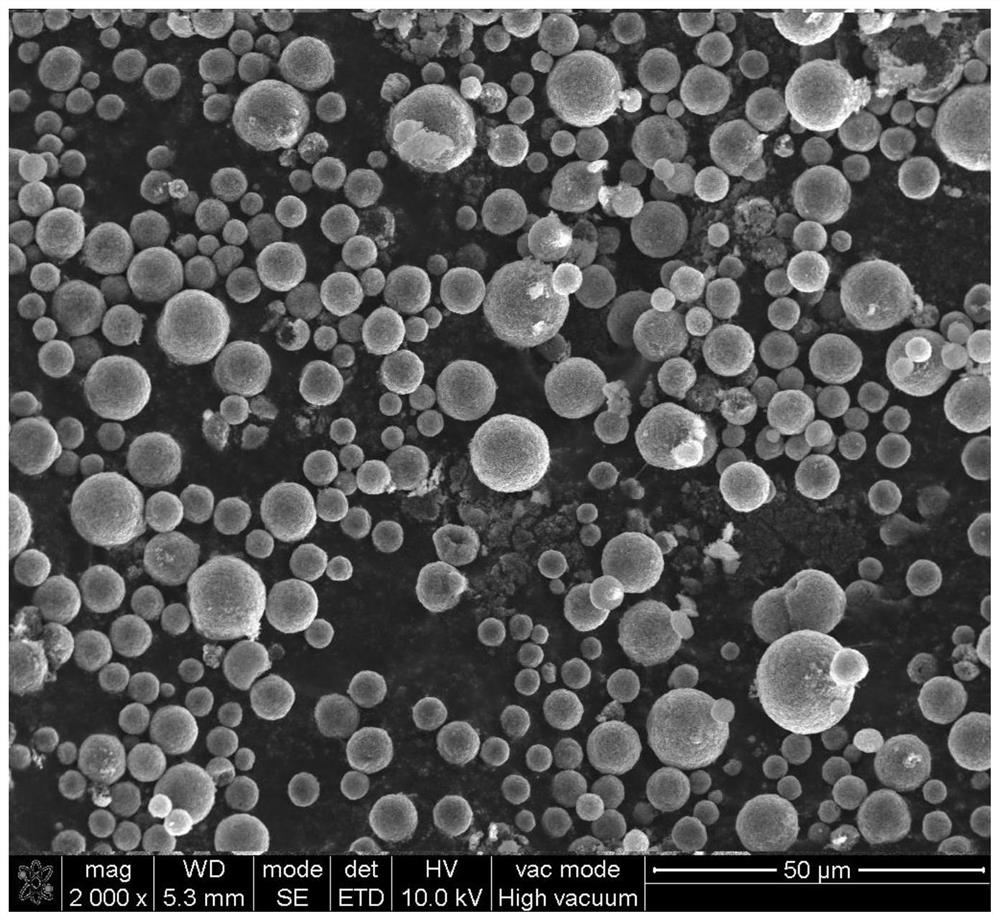

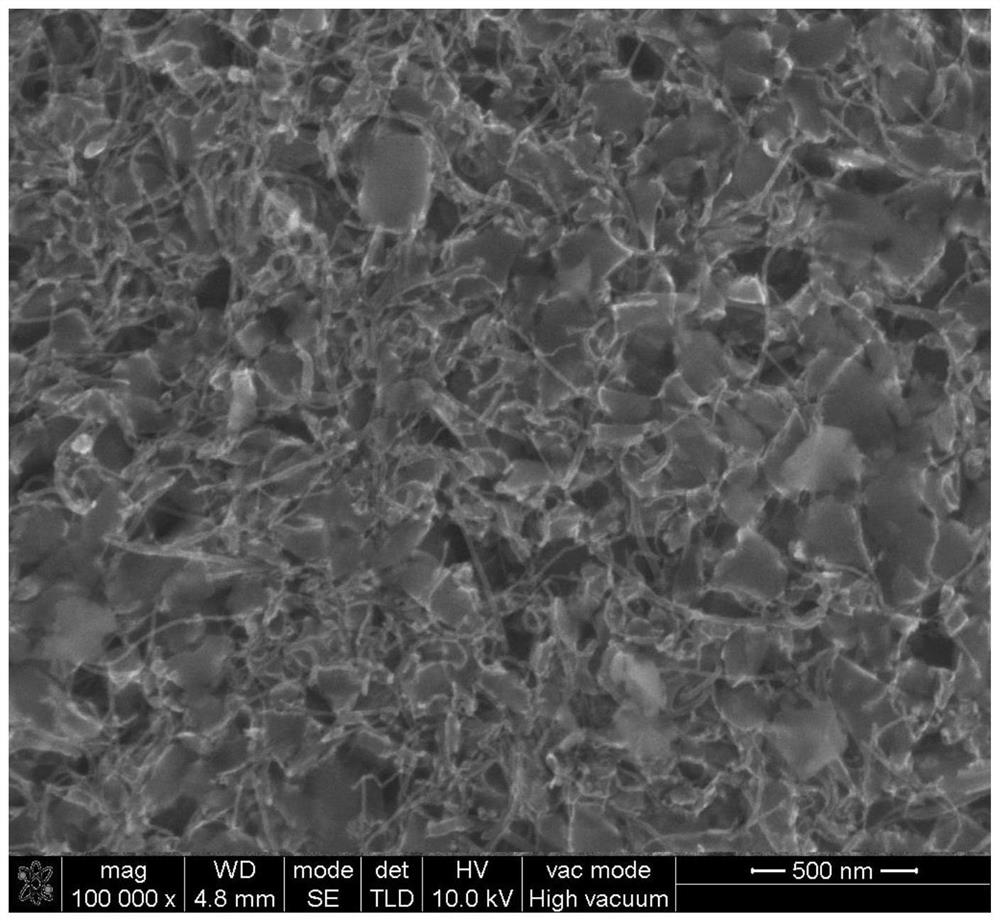

[0062] The ferrosilicon alloy was added to an ethanol solution with a liquid-solid ratio of 3:1, and ground in a sand mill for 2 hours to obtain a ferrosilicon alloy slurry. The average particle size of the particles in the slurry was 0.8 microns. 1% of carbon nanotube slurry and 5% of SBR are added to the slurry, and the mixture is uniformly dispersed for 1 hour with a vacuum high-speed dispersing mixer to obtain a uniformly dispersed nanometer mixed slurry. The nano-mixed slurry is spray-dried, and the inlet temperature of the spray-drying is adjusted to 220° C. and the outlet temperature is 80° C. to obtain spherical particle precursors. A mixture of coal tar pitch and N-methylpyrrolidone in a ratio of 20%: 80% is added to the ferrosilicon alloy precursor powder prepared in the above step, the weight ratio of the mixture to the alloy powder is 1:1, and the mixture is uniformly stirred and placed in an atmosphere furnace , dried at 200°C under argon protection, and then carb...

Embodiment 2

[0064] The ferrosilicon alloy was added to an ethanol solution with a liquid-solid ratio of 3:1, and ground in a sand mill for 2 hours to obtain a ferrosilicon alloy slurry. The average particle size of the particles in the slurry was 0.6 microns. 1.5% of carbon nanotube slurry and 10% of PVP are added to the slurry, and the mixture is uniformly mixed and dispersed for 1 hour with a vacuum high-speed dispersing mixer to obtain a uniformly dispersed nanometer mixed slurry. The nano-mixed slurry is spray-dried, and the inlet temperature of the spray-drying is adjusted to be 250° C. and the outlet temperature is 100° C. to obtain spherical particle precursors. A mixture of coal tar pitch and N-methylpyrrolidone in a ratio of 20%: 80% is added to the ferrosilicon alloy precursor powder prepared in the above step, the weight ratio of the mixture to the alloy powder is 1:1, and the mixture is uniformly stirred and placed in an atmosphere furnace , dried under argon protection at 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com