Patents

Literature

66 results about "Lithium.free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-embedding method of lithium ion super capacitor cathode

InactiveCN101252043ASimplify the assembly processCapacitor safety performance improvementElectrode manufacturing processesElectrolytic capacitorsConductive polymerLithium compound

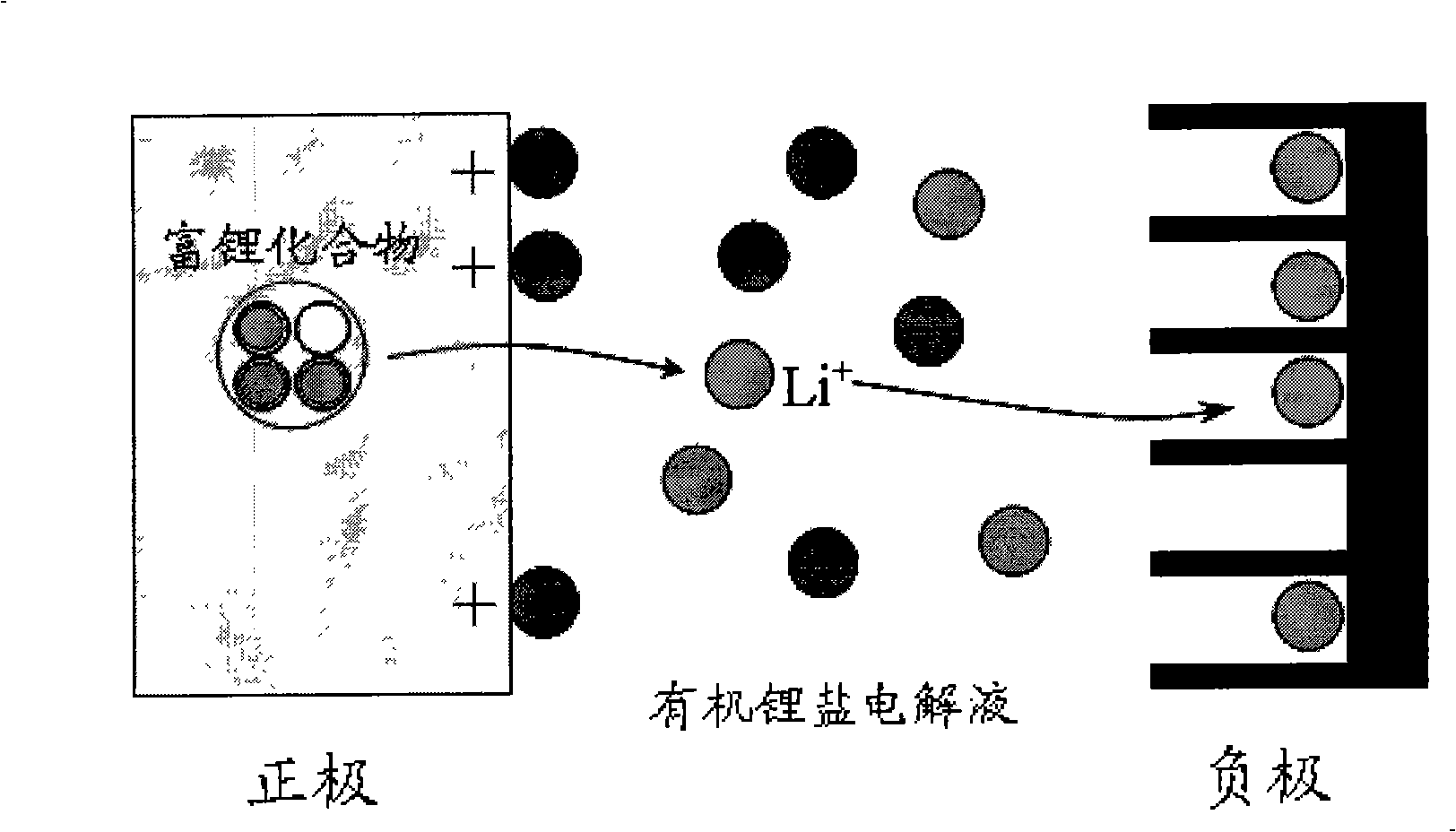

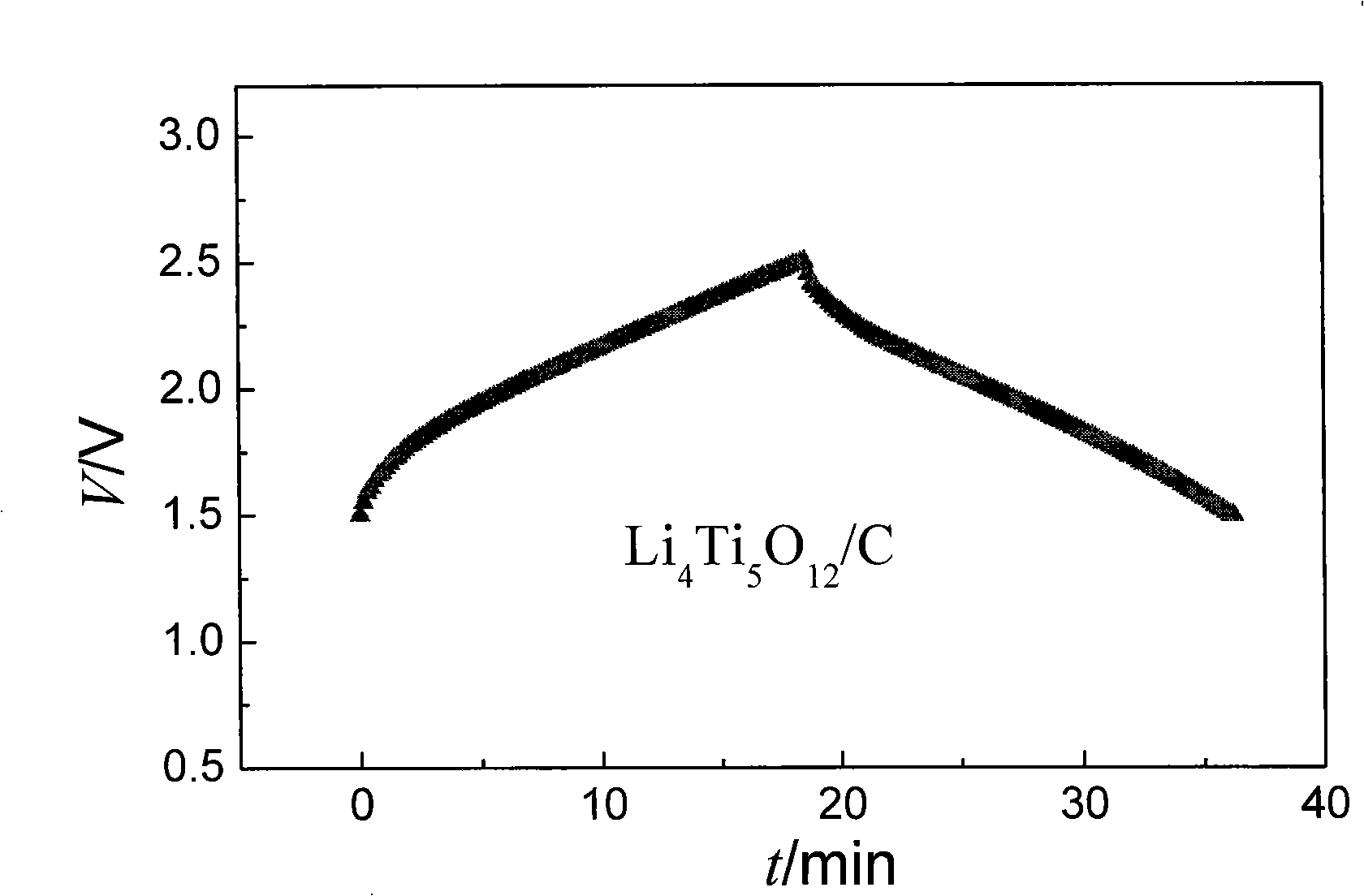

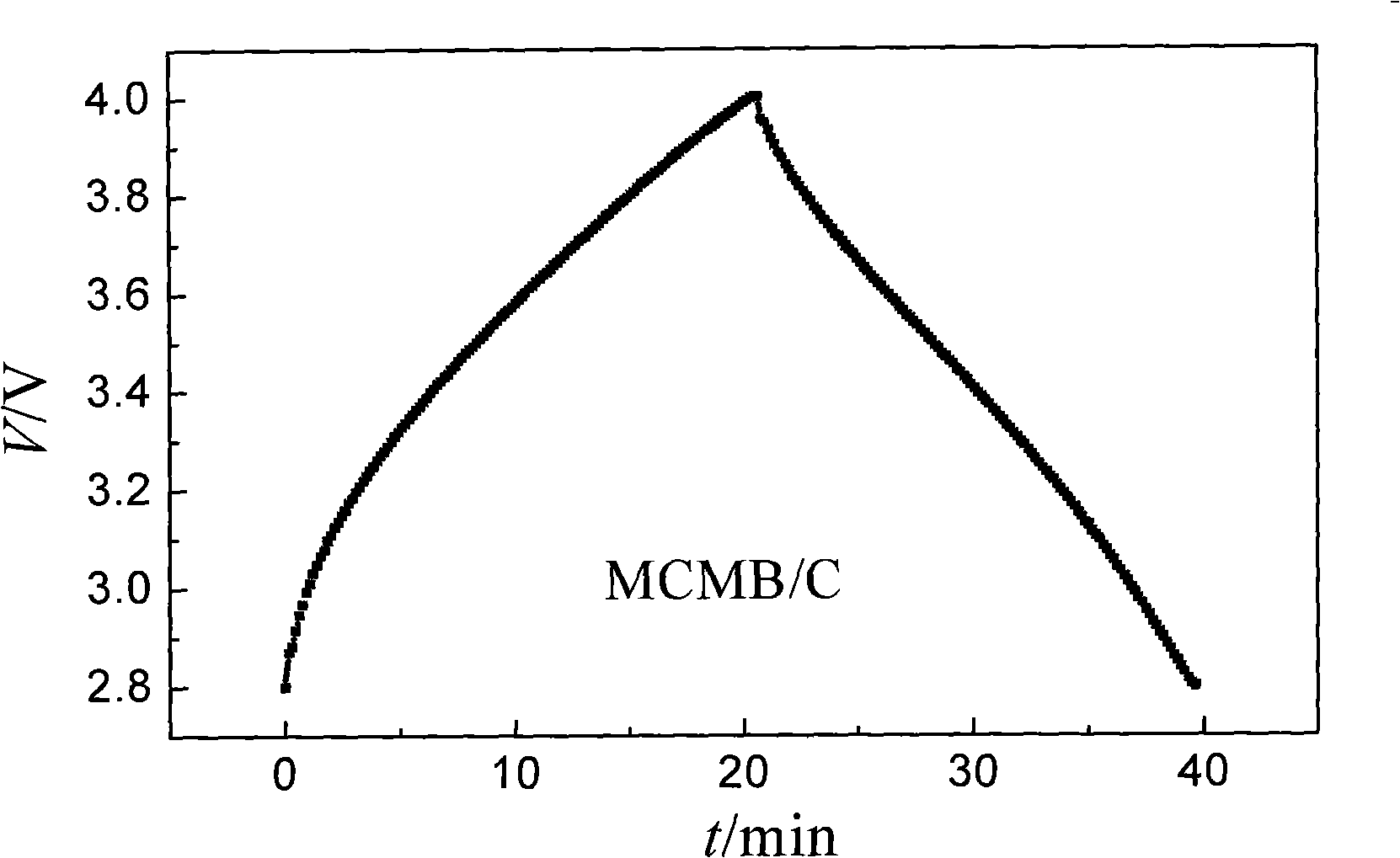

The invention discloses an easily implemented lithium pre-insertion novel method for a cathode of a lithium ion super capacitor, wherein, a nonmetal lithium third electrode is led into a novel lithium ion super capacitor system which takes porous charcoal materials, conductive polymers or compounds of the conductive polymers as an anode, lithium insertable metal oxides or charcoal lithium insertion materials as the cathode and organic lithium salt solution as electrolyte, and lithium pre-insertion processing of the cathode with a depth of 5 to 60 percent is performed so as to prevent reduction of the ion concentration of the electrolyte during the charging and discharging process and non-reversible absorption of anions on the anode and improve the charging and discharging characteristics of the capacitor. The essential component of the nonmetal lithium third electrode is lithium-rich compounds with non-reversible lithium-free property; during the preparation process of the porous charcoal material anode or the conductive polymer anode, the lithium-rich compounds of the third electrode are mixed by mass percent of 3 to 50 and can form the lithium ion super capacitor together with the lithium insertable cathode after being prepared into the electrode; during the activation process of the capacitor, lithium pre-insertion of the cathode is realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

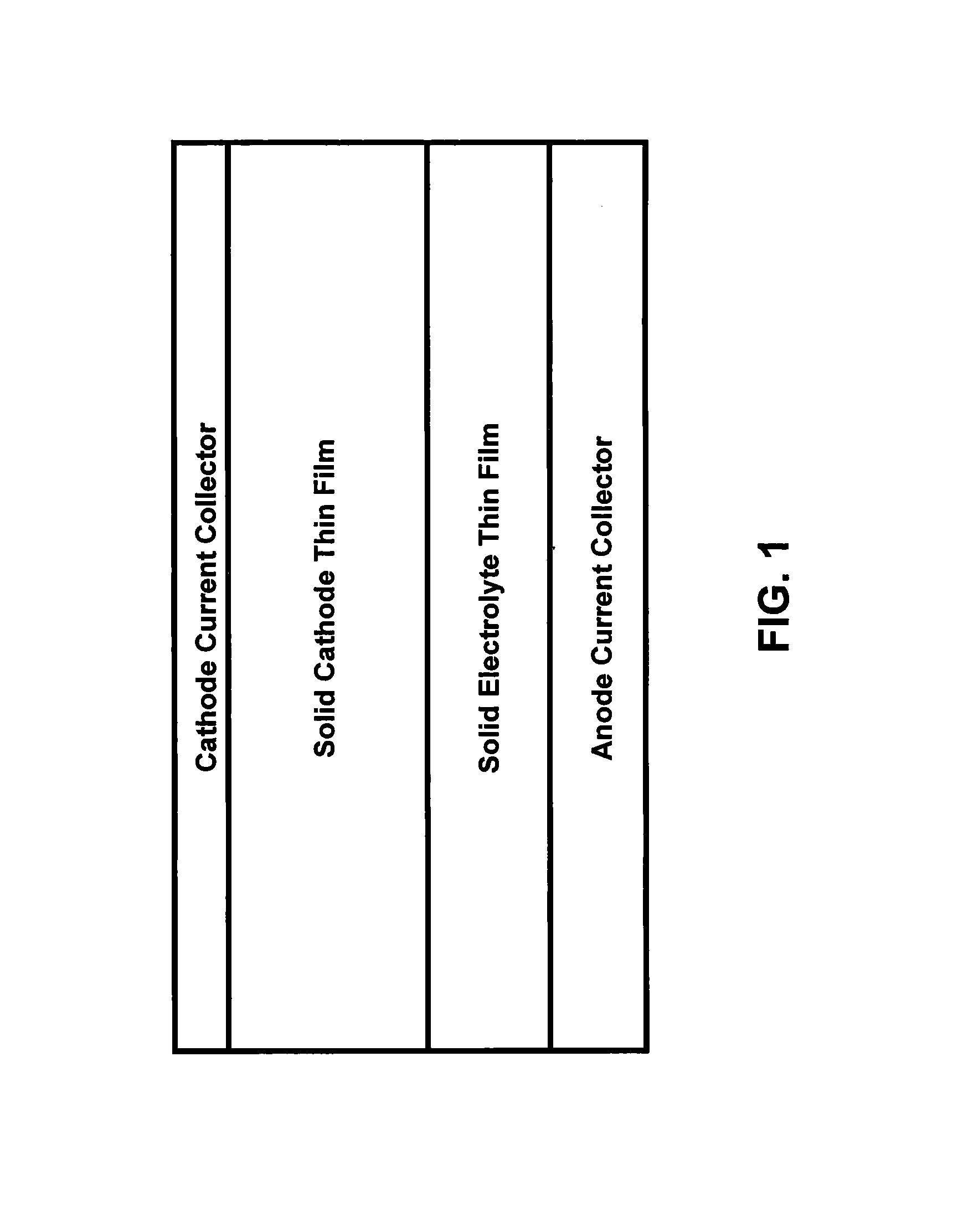

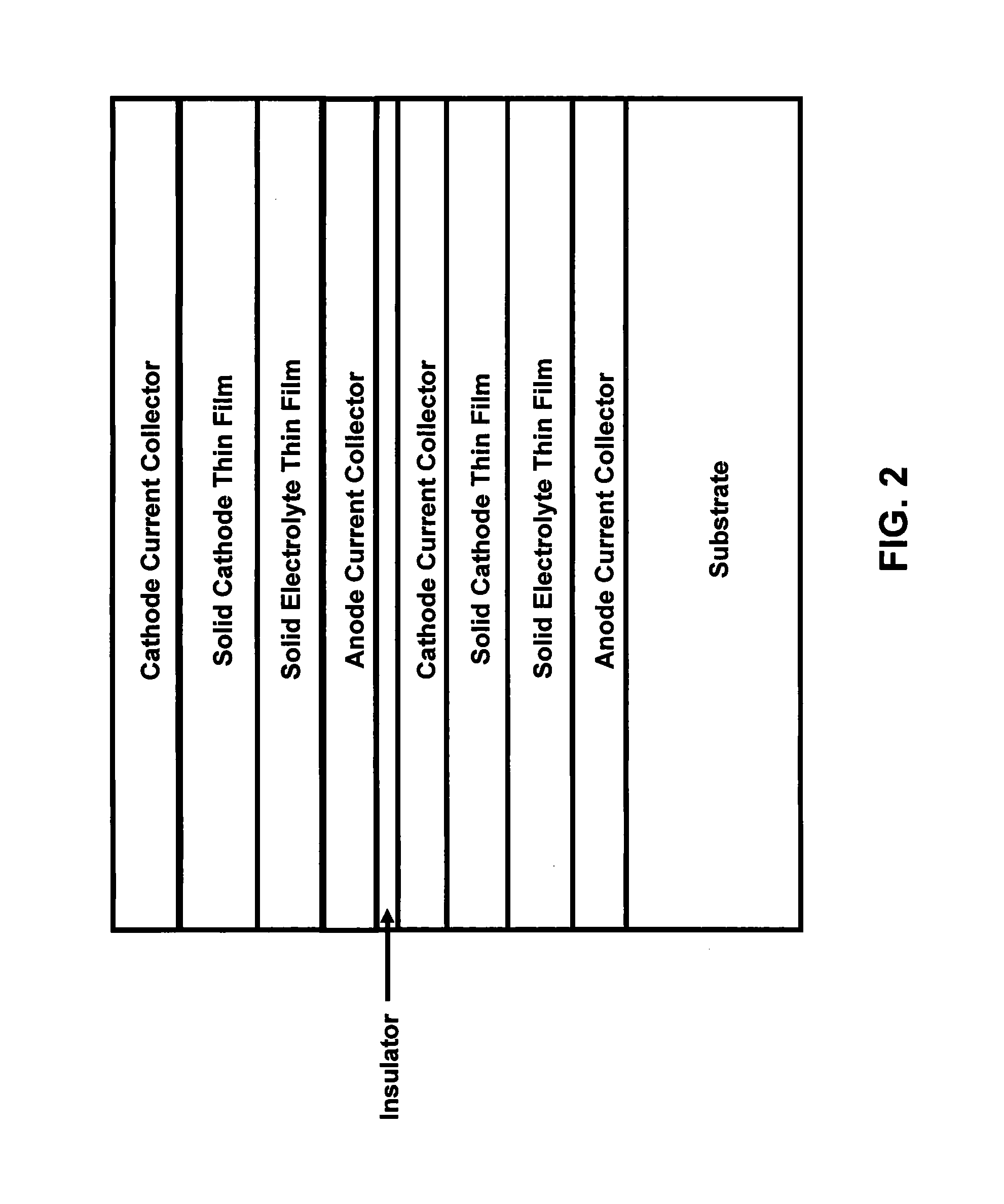

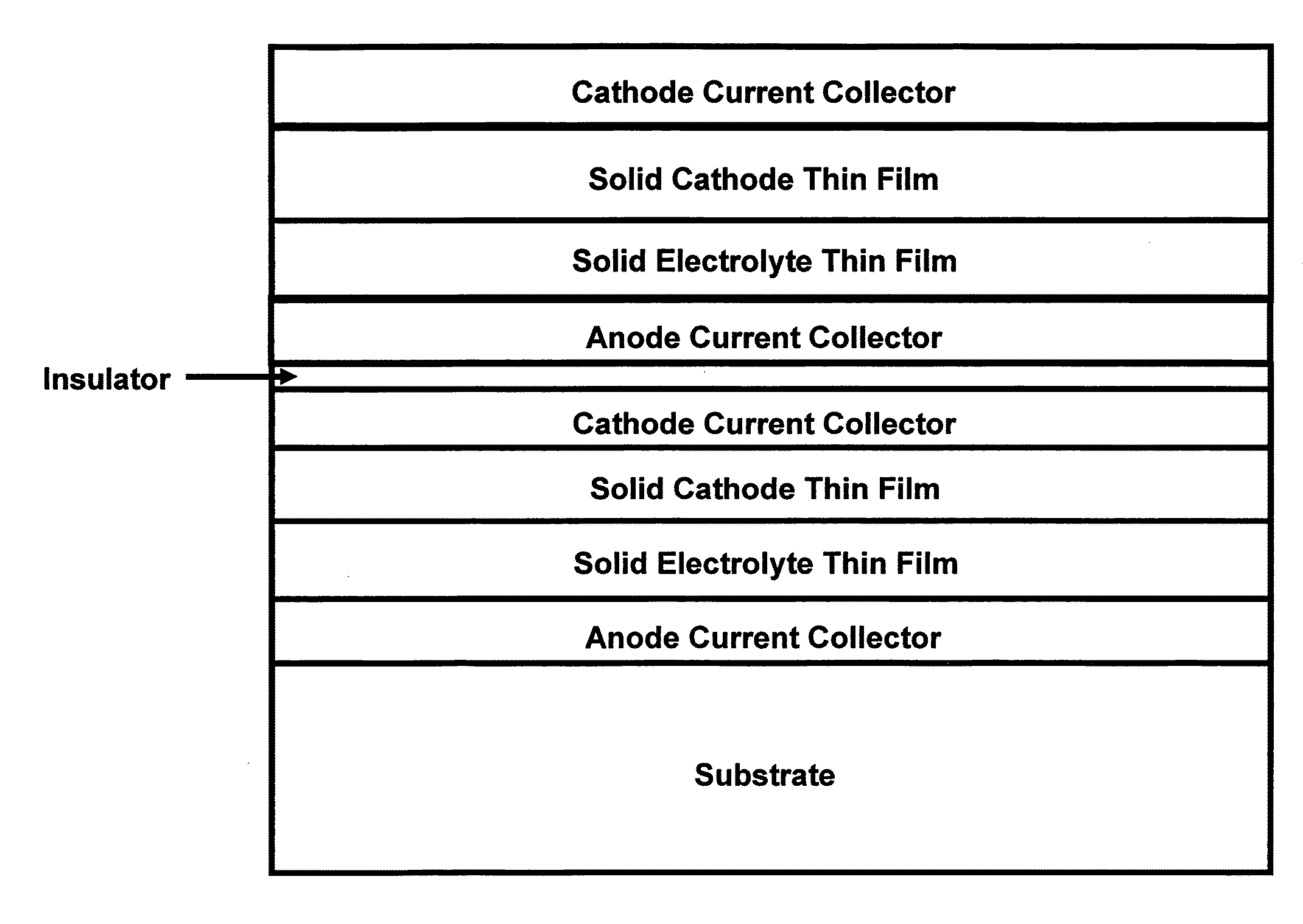

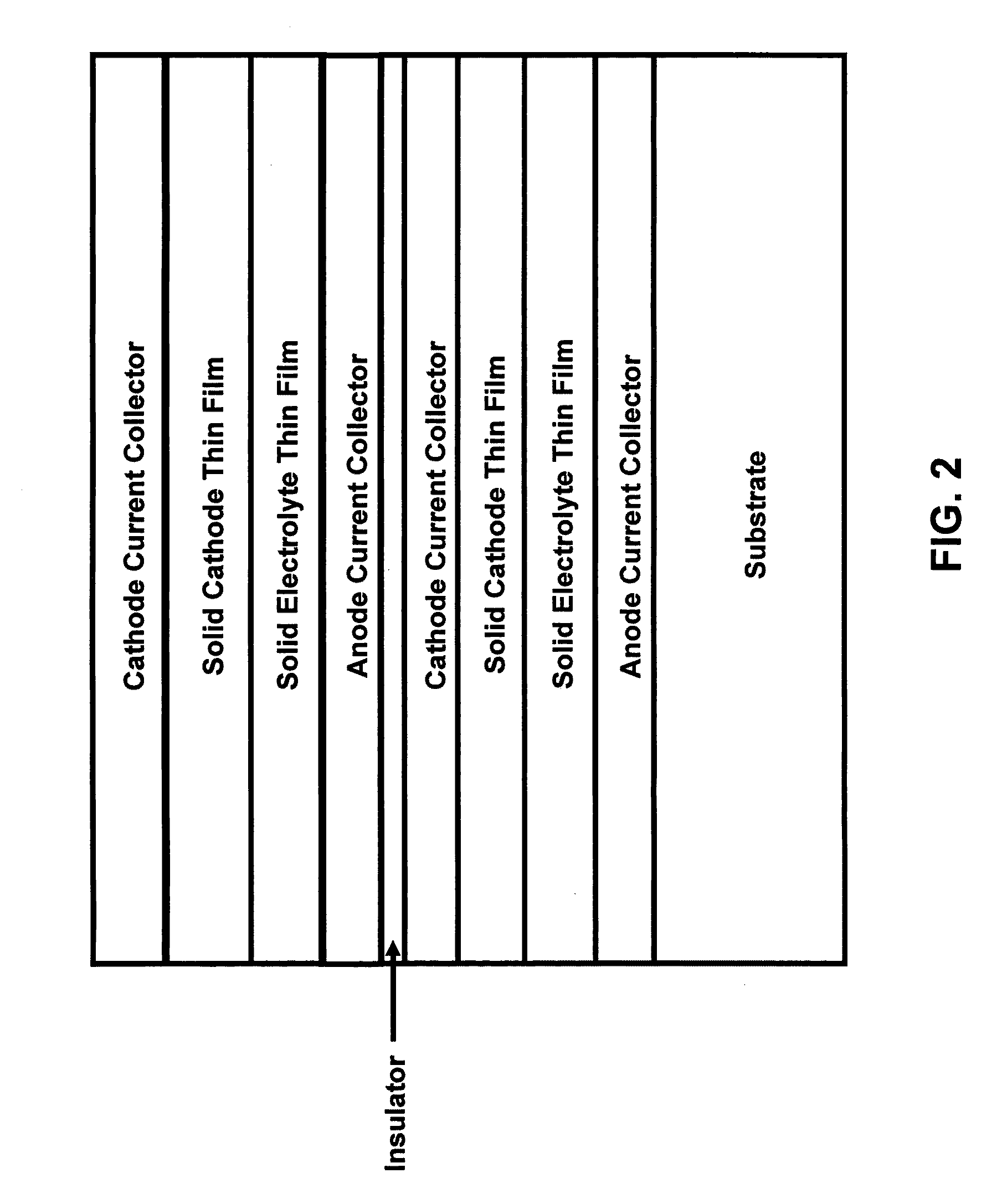

Solid-state lithium battery

ActiveUS8877388B1Low form factor requirementsIncrease powerTantalum compoundsPrinted batteriesLanthanumLithium.free

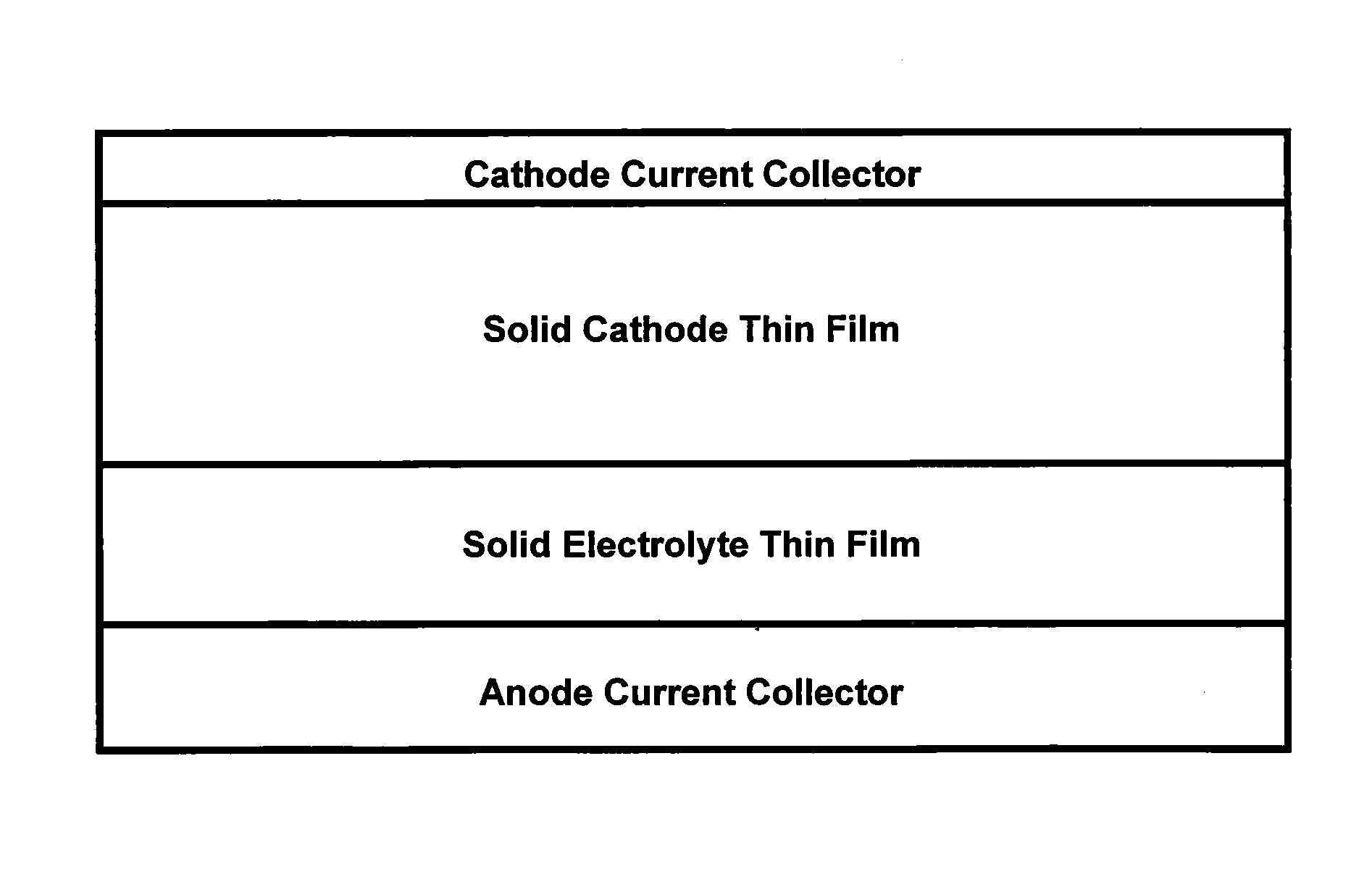

The present invention is directed to a higher power, thin film lithium-ion electrolyte on a metallic substrate, enabling mass-produced solid-state lithium batteries. High-temperature thermodynamic equilibrium processing enables co-firing of oxides and base metals, providing a means to integrate the crystalline, lithium-stable, fast lithium-ion conductor lanthanum lithium tantalate (La1 / 3-xLi3xTaO3) directly with a thin metal foil current collector appropriate for a lithium-free solid-state battery.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

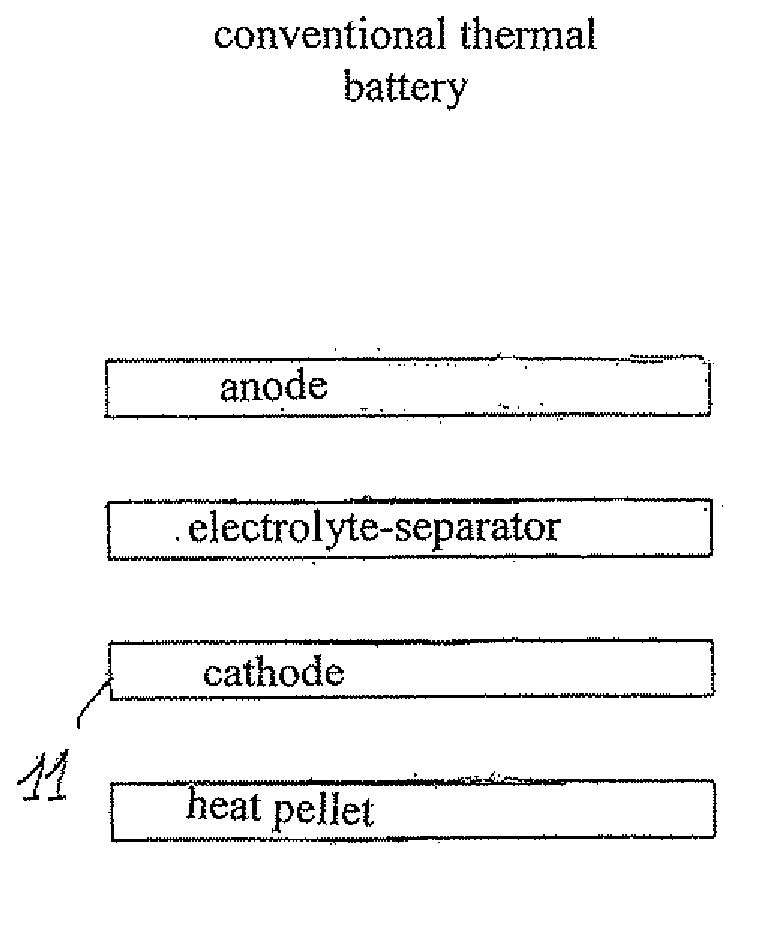

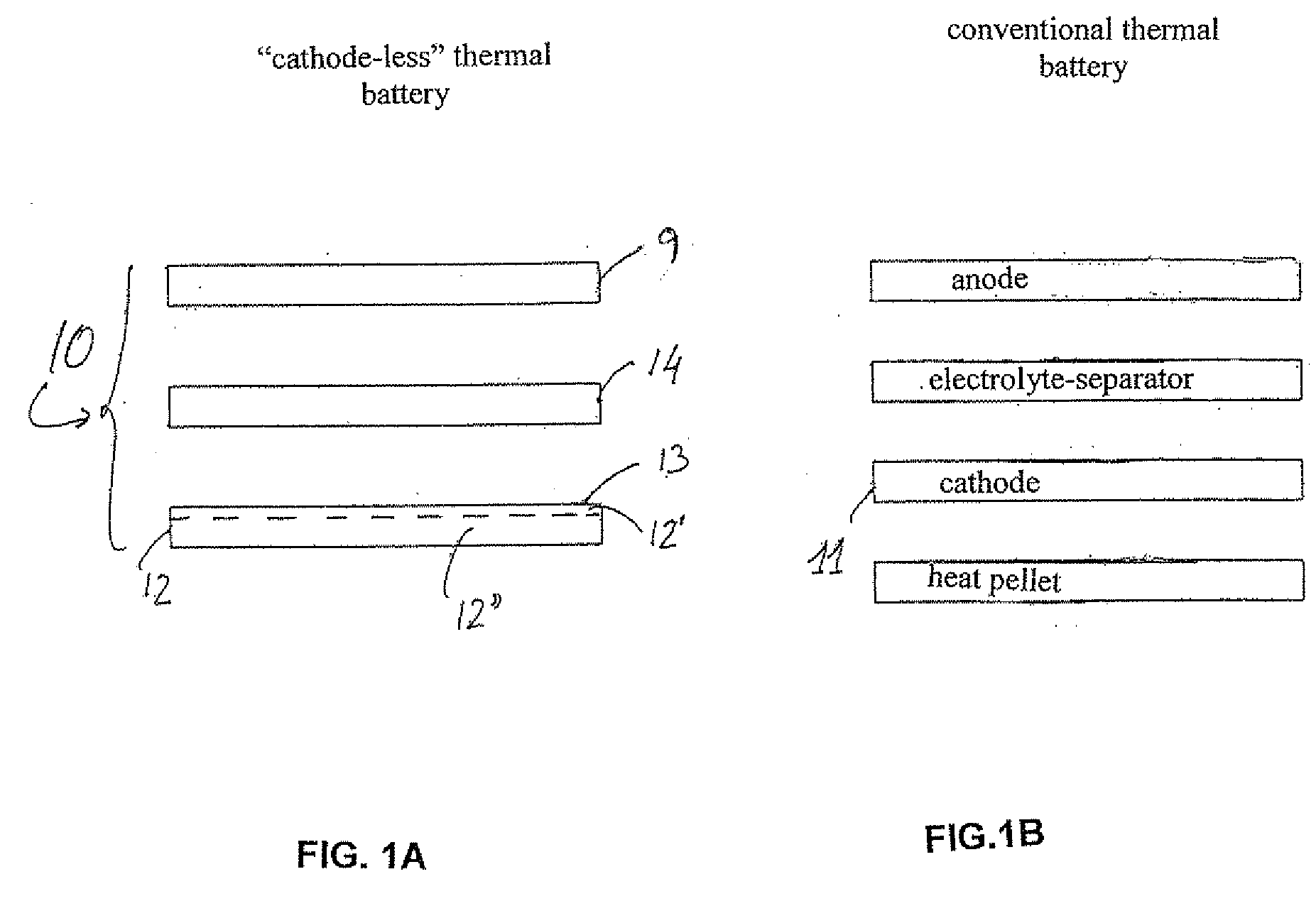

Thermal batteries using cathode-precursor pyrotechnic pellets

InactiveUS20070292748A1Extended service lifeReliable and reliableDeferred-action cellsCell electrodesPyrotechnic heat sourceLithium.free

Owner:THE STATE OF ISRAEL MINIST OF AGRI & RURAL DEV AGRI RES ORG ARO VOLCANI CENT

System of lithium ion battery containing material with high irreversible capacity

ActiveUS20060257737A1Improve securityImprove security levelCell seperators/membranes/diaphragms/spacersSecondary cellsLithium metalLithium.free

Disclosed is a cathode active material comprising a lithium-free metal oxide and a material with high irreversible capacity. A novel lithium ion battery system using the cathode active material is also disclosed. The battery, comprising a cathode using a mixture of a Li-free metal oxide and a material with high irreversible capacity, and an anode comprising carbon instead of Li metal, shows excellent safety compared to a conventional battery using lithium metal as an anode. Additionally, the novel battery system has a higher charge / discharge capacity compared to a battery using a conventional cathode active material such as lithium cobalt oxide, lithium nickel oxide or lithium manganese oxide.

Owner:LG ENERGY SOLUTION LTD

Lithium metal battery with high specific energy

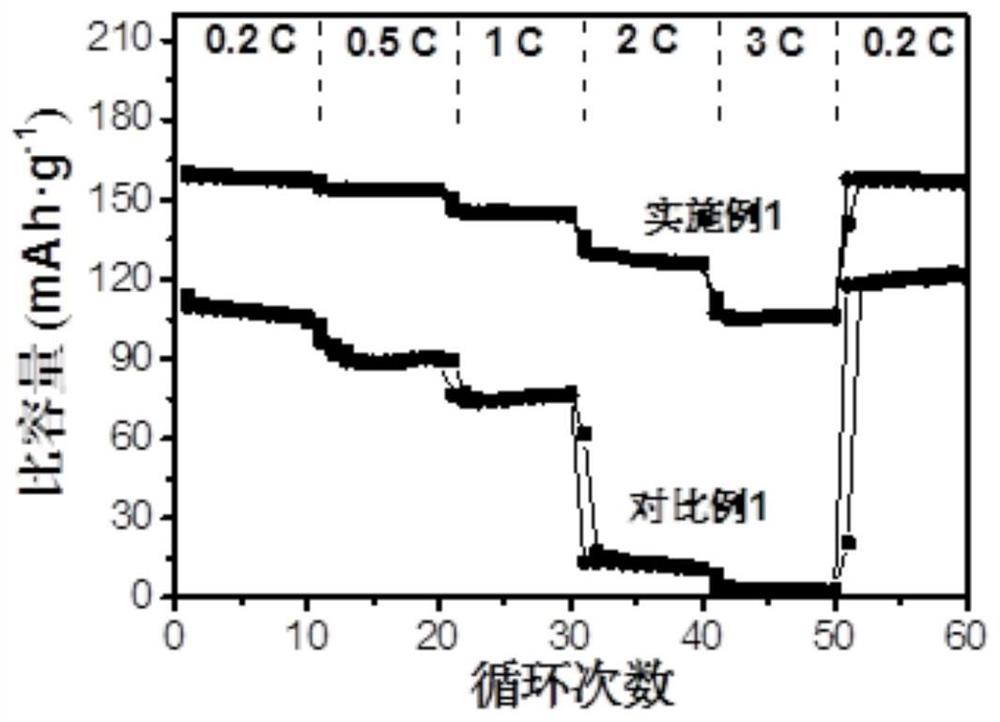

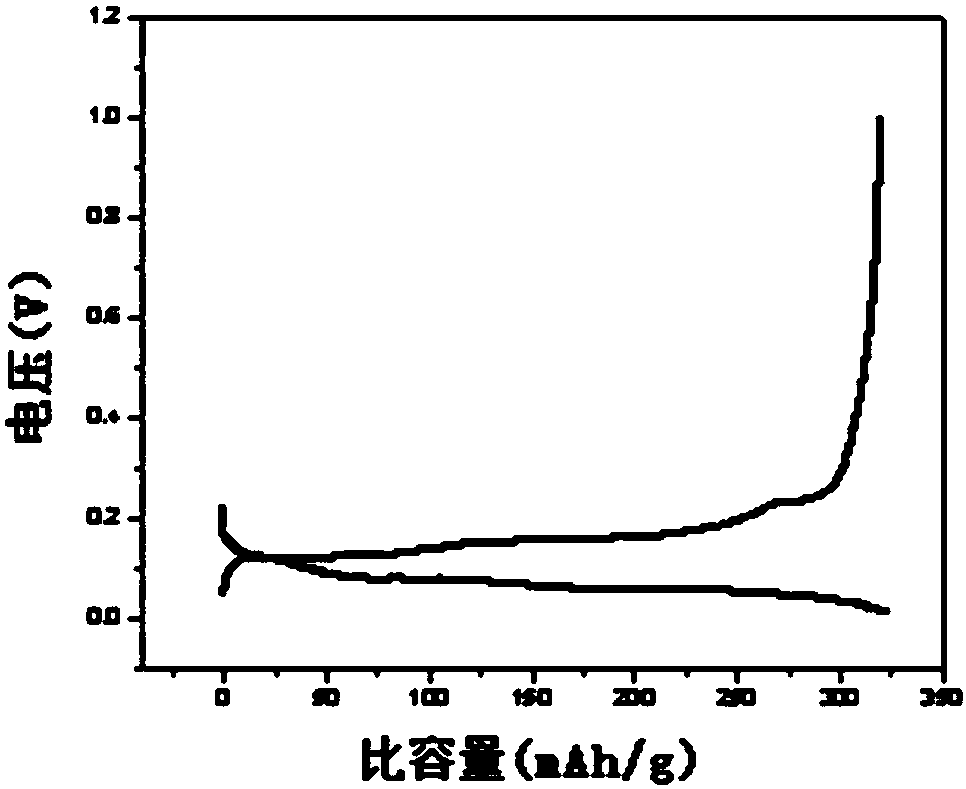

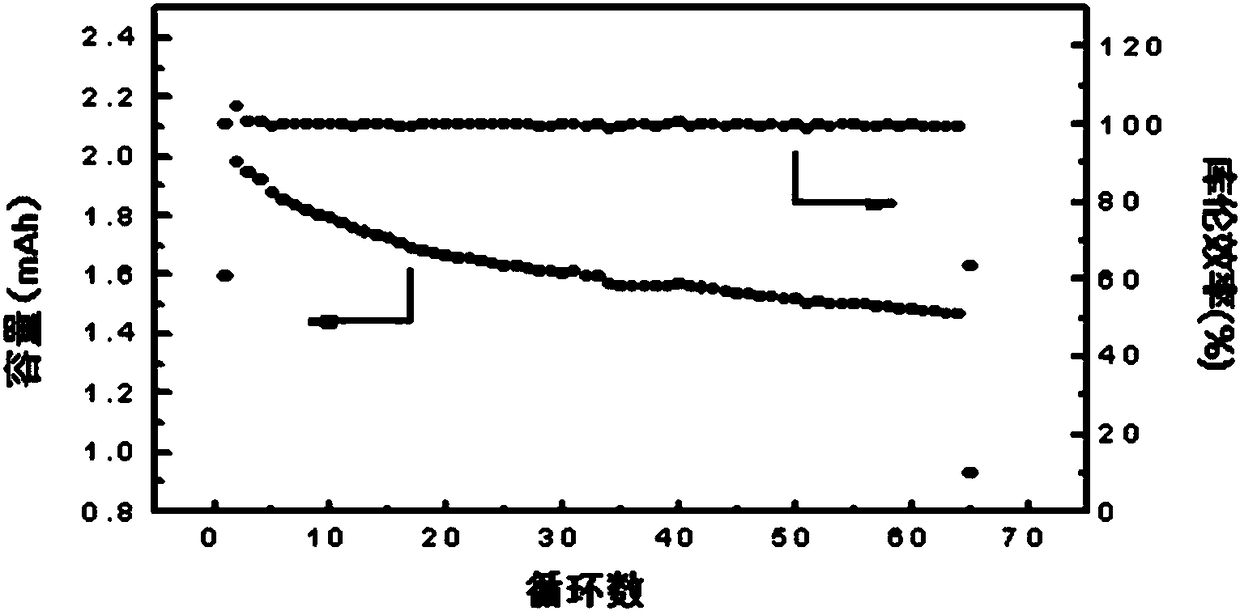

InactiveCN109728291AIncrease profitHigh deposition-dissolution efficiencyCell electrodesSecondary cellsCyclic processSolid state electrolyte

The invention discloses a lithium metal battery with high specific energy. The battery comprises a liquid system battery composed of a negative electrode, a positive electrode, an electrolyte, a diaphragm or an all-solid battery composed of a negative electrode, a positive electrode and a solid electrolyte membrane, wherein the negative electrode is a lithium-free negative electrode composed of ametal substrate and a lithiophilic metal layer covering the metal substrate and capable of inducing the uniform lithium deposition; the positive electrode is a lithium-rich positive electrode expressed as xLi2MnO3.(1-x)LiMO2, 0<x<1, M = Mn, Ni, Co. The lithiophilic metal on the surface of the lithium-free negative electrode can induce uniform lithium deposition, ensures very high deposition-dissolution efficiency of lithium metal deposited on the negative electrode current collector to obtain a high lithium utilization rate. The lithium-rich material is used as a positive electrode active material. After one cycle, the excess lithium of the positive electrode is stored in the negative electrode in the form of lithium metal in order to supplement the active lithium consumed by a side reaction in the subsequent cycles to obtain high coulombic efficiency and high cycle life. The lithium metal battery has low manufacturing cost, good safety, a long service life and high specific energy.

Owner:HARBIN INST OF TECH

Electrode active material, preparation method thereof, and electrode and lithium battery containing the same

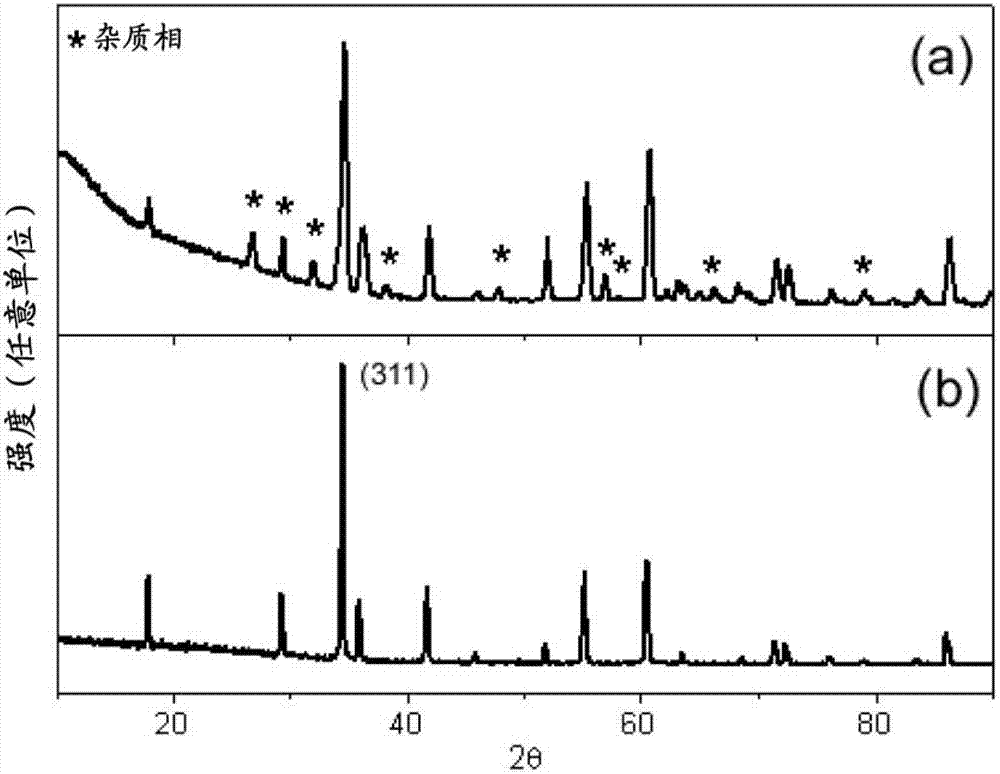

An electrode active material includes a core capable of intercalating and deintercalating lithium; and a surface treatment layer disposed on at least a portion of a surface of the core, wherein the surface treatment layer includes a lithium-free oxide having a spinel structure, and an intensity of an X-ray diffraction peak corresponding to impurity phase of the lithium-free oxide, when measured using Cu-K± radiation, is at a noise level of an X-ray diffraction spectrum or less.

Owner:SAMSUNG SDI CO LTD

Solid-state battery

ActiveCN112397762ASimple manufacturing processIncrease specific energySolid electrolytesLi-accumulatorsInterface impedanceElectrical battery

The invention discloses a solid-state battery and a preparation method thereof. The solid-state battery is composed of a positive electrode, an organic-inorganic composite solid electrolyte diaphragmand a negative electrode. The organic-inorganic composite solid electrolyte diaphragm and the positive electrode have good chemical and electrochemical stability; and the organic-inorganic composite solid electrolyte diaphragm and the negative material have relatively small interface impedance, and growth of lithium dendrites can be inhibited. The solid-state battery prepared by the method is small in interface impedance, controllable in interface side reaction, capable of being matched with various positive electrodes and negative electrodes, and free of lithium dendritic crystal growth phenomenon, so that the solid-state battery has high specific energy and long cycle life. And the preparation process of the solid-state battery designed by the invention is matched with the existing preparation process of the lithium ion battery, so that the requirement of large-scale production is met.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Solid-State Lithium Battery

InactiveUS20150030909A1Low form factorSimple materialTantalum compoundsPrinted batteriesLanthanumLithium.free

The present invention is directed to a higher power, thin film lithium-ion electrolyte on a metallic substrate, enabling mass-produced solid-state lithium batteries. High-temperature thermodynamic equilibrium processing enables co-firing of oxides and base metals, providing a means to integrate the crystalline, lithium-stable, fast lithium-ion conductor lanthanum lithium tantalate (La1 / 3-xLi3xTaO3) directly with a thin metal foil current collector appropriate for a lithium-free solid-state battery.

Owner:SANDIA

Metal lithium composite cathode as well as preparation method and application thereof

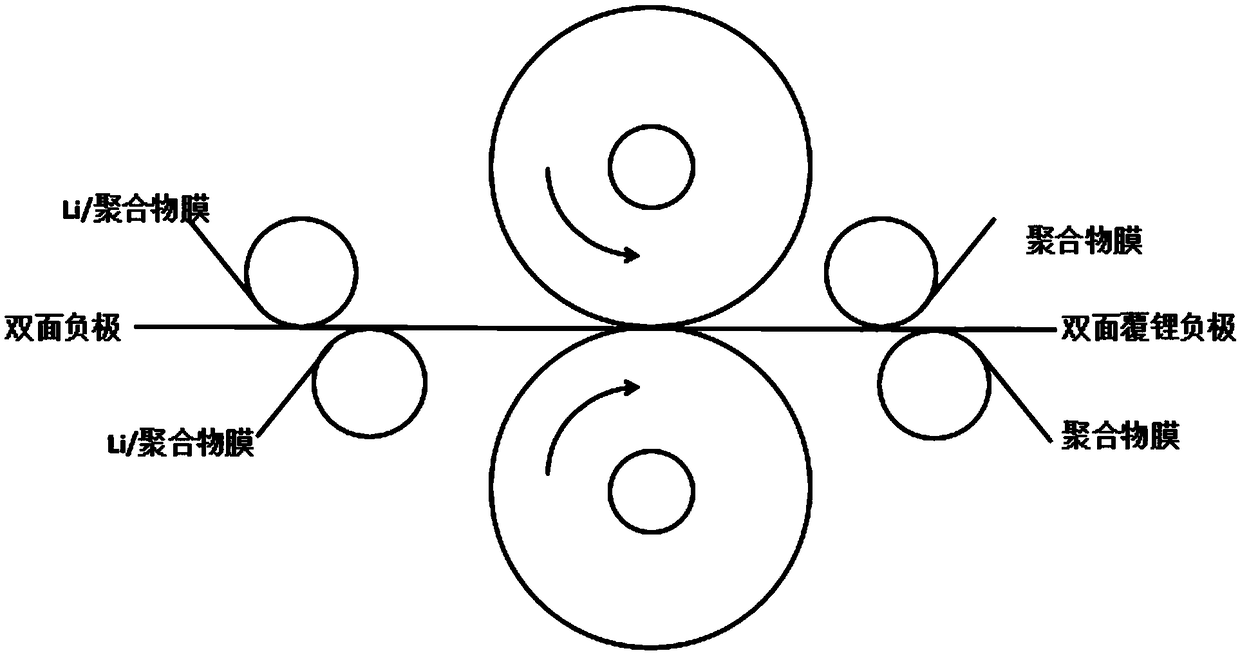

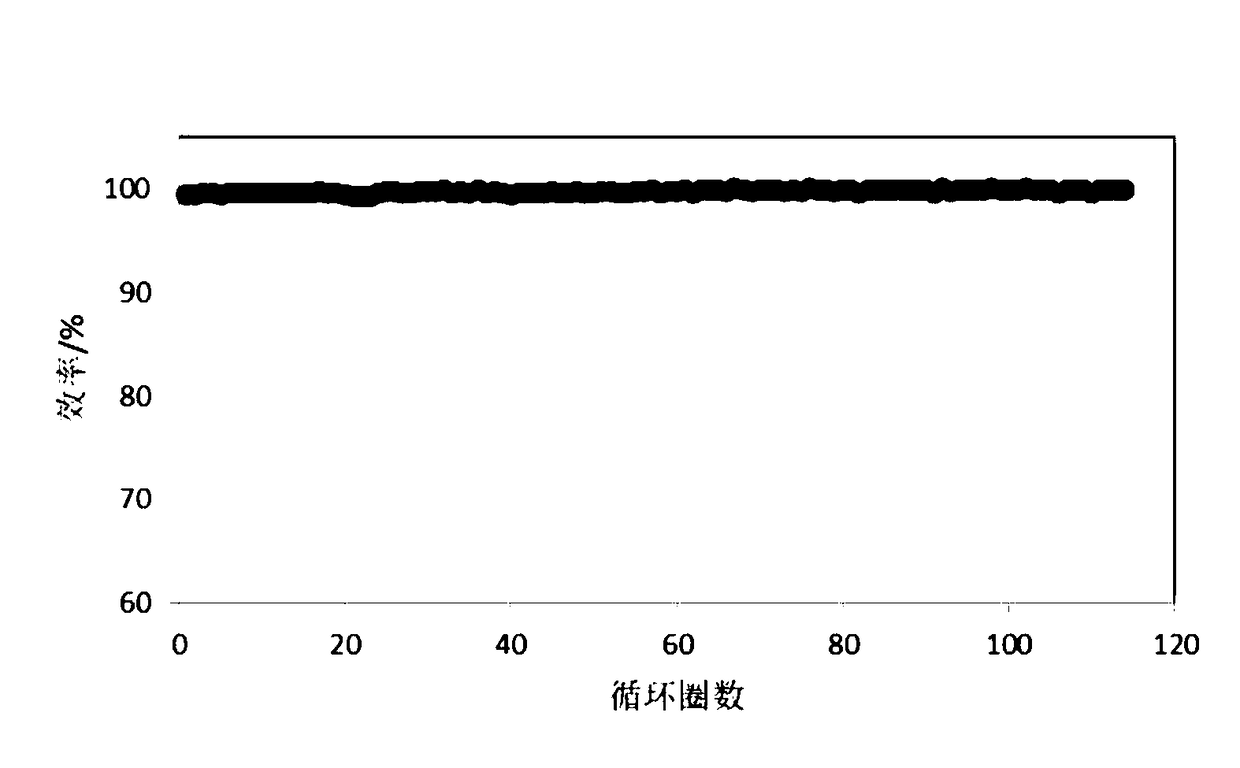

InactiveCN109411694AImprove consistencyFacilitate strippingElectrode rolling/calenderingLi-accumulatorsDischarge efficiencyComposite cathode

The invention discloses a metal lithium composite cathode as well as a preparation method and application thereof. The preparation method comprises the following steps: forming a metal lithium layer on the surface of a polymer film in a depositing manner at least by adopting a vacuum physical deposition method, and obtaining a composite band; respectively arranging one composite band at two sidesof a cathode piece, enabling the metal lithium layer in each composite band to contact the cathode piece, applying pressure to a composite structure consisting of the cathode piece and the composite band, obtaining the cathode piece with two side surfaces being respectively combined with the metal lithium layer, thus obtaining the metal lithium composite cathode. The lithium band is prepared through the vacuum physical deposition method, and a pressure-rolling process is combined, so that the metal lithium layer can be uniformly, continuously and thinly covered on the cathode, thereby obtaining a pre-lithiated cathode. The defect that the lithium band is easily broken is avoided, and at the same time the cathode is compacted, and the density of the cathode is increased. The metal lithium composite cathode is utilized to improve the first-time charge / discharge efficiency of a cathode material, can serve as a lithium-containing cathode and be matched with a lithium-free anode, and has abroad application prospect.

Owner:天齐锂业(江苏)有限公司

Modified lithium-free negative electrode, preparation method thereof and lithium ion battery with modified lithium-free negative electrode

InactiveCN109309194AImprove the first charge and discharge efficiencyImprove cycle stabilityElectrode carriers/collectorsSecondary cellsCarbon compositesSodium-ion battery

The invention discloses a modified lithium-free negative electrode, a preparation method thereof and a lithium ion battery with the modified lithium-free negative electrode. The modified lithium-freenegative electrode is prepared from a lithium-free negative electrode material and a metal lithium-framework carbon composite material, wherein the content of the metal lithium-framework carbon composite material is 2 to 20 percent by mass of the negative electrode active material. In the first charging-discharging process of the battery, metal lithium in the metal lithium-framework carbon material can supplement lithium consumed by forming an SEI layer on the surface of the lithium-free negative electrode, so that the first charging-discharging efficiency of the lithium-free negative electrode is improved.

Owner:CHINA ENERGY CAS TECH CO LTD

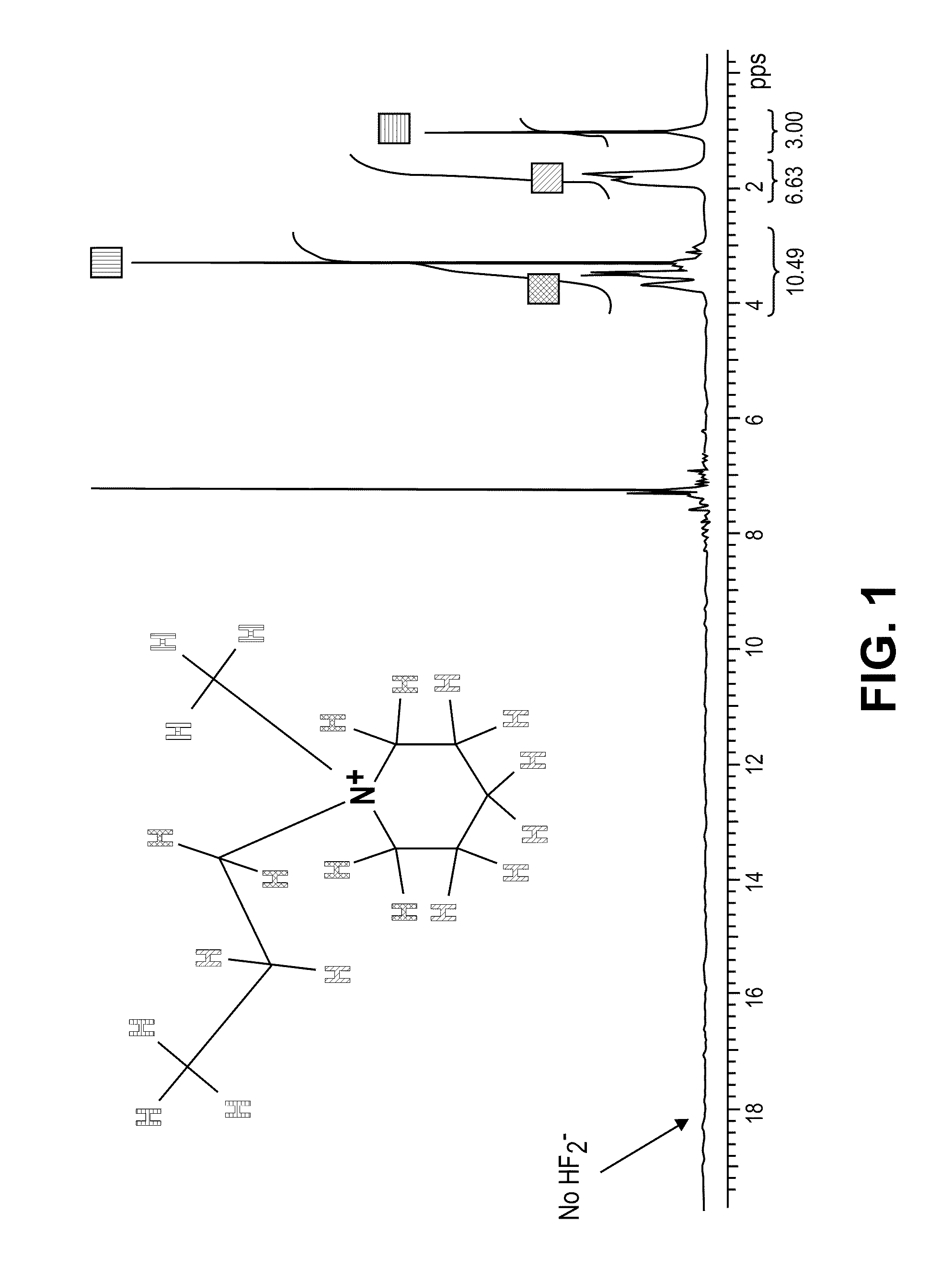

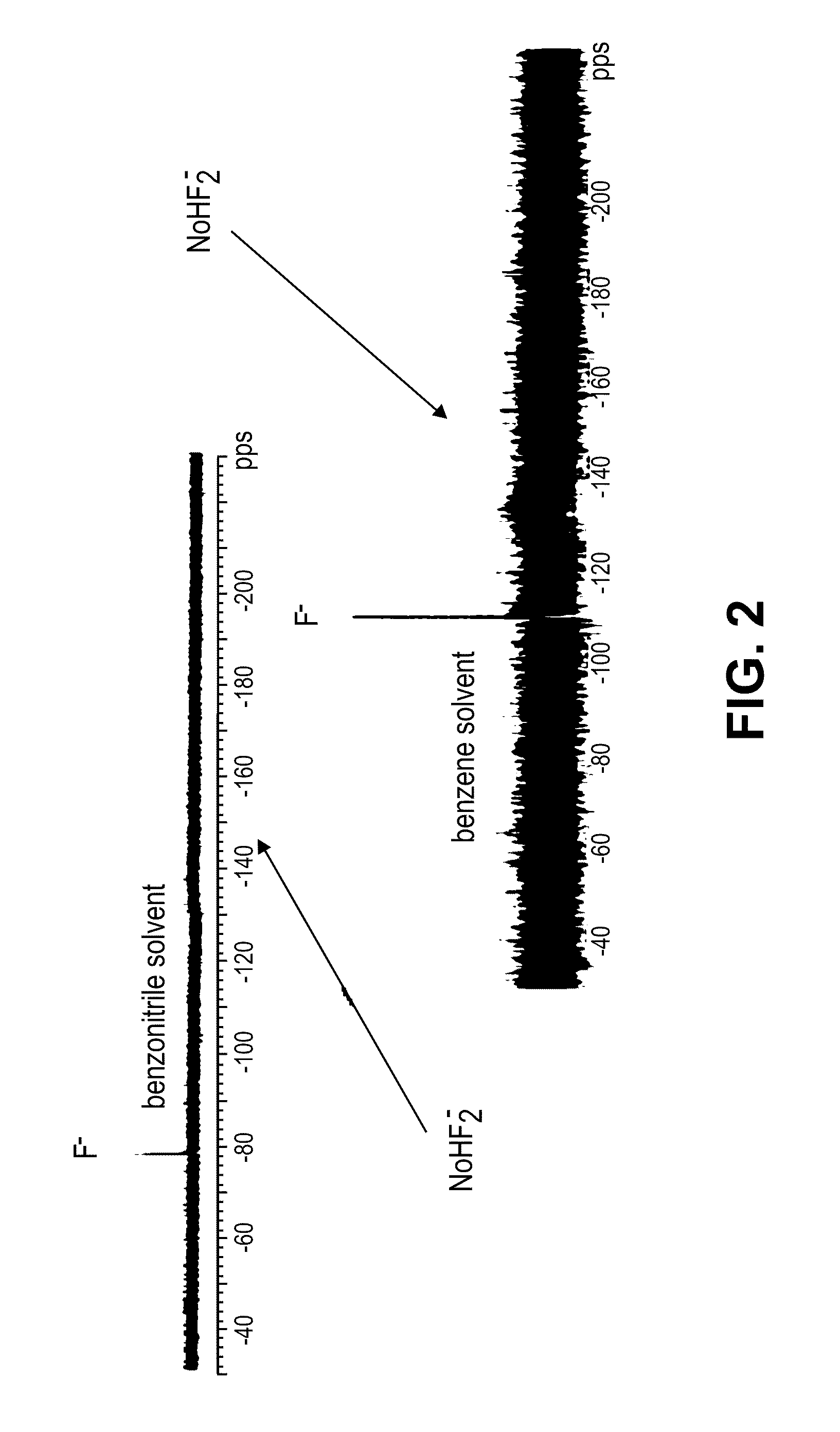

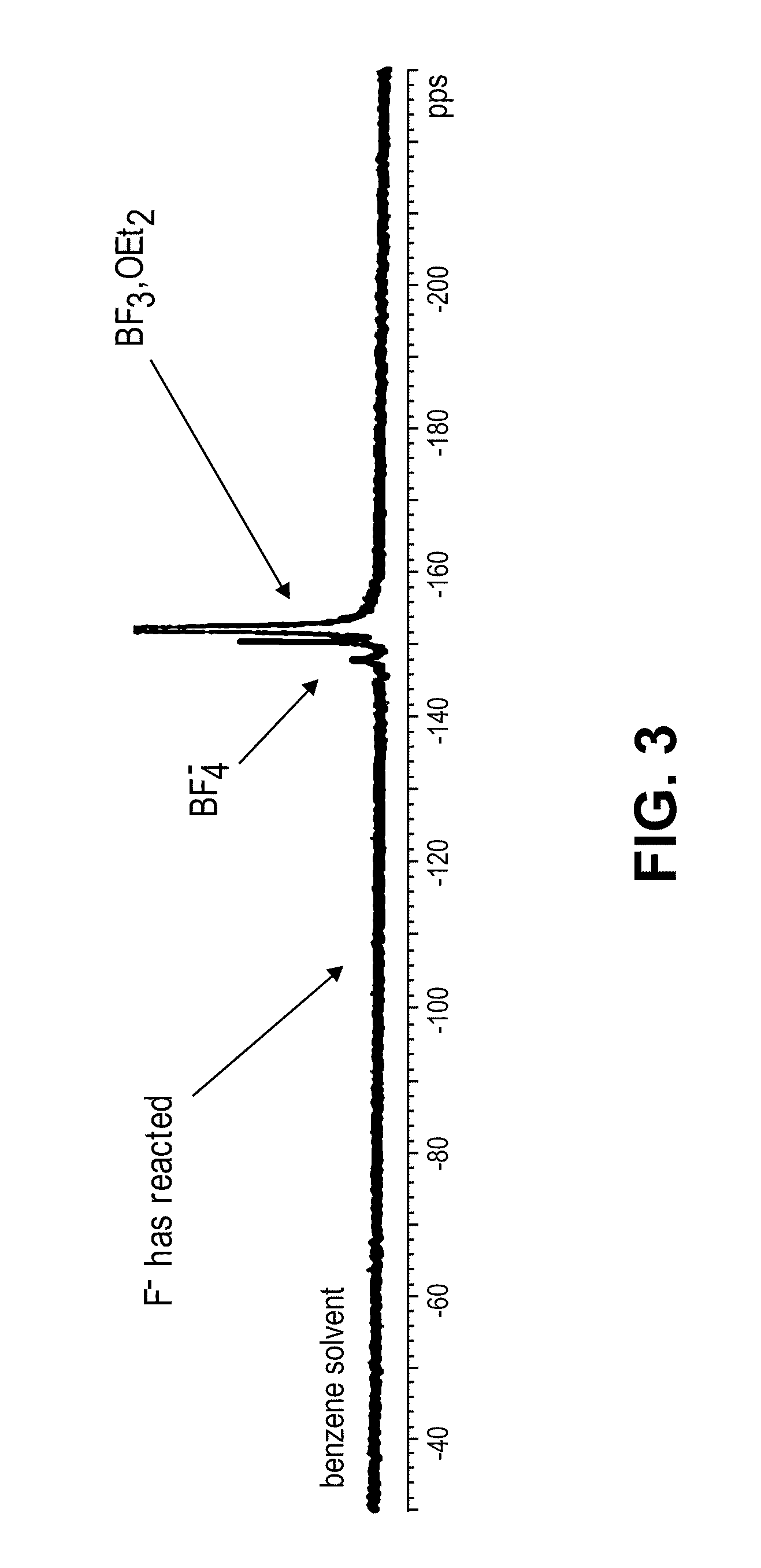

Fluoride ion battery electrolyte compositions

ActiveUS9331360B2Easily overchargedEasily overheatedOrganic chemistryCell electrodesCelsius DegreeLithium.free

Owner:CALIFORNIA INST OF TECH

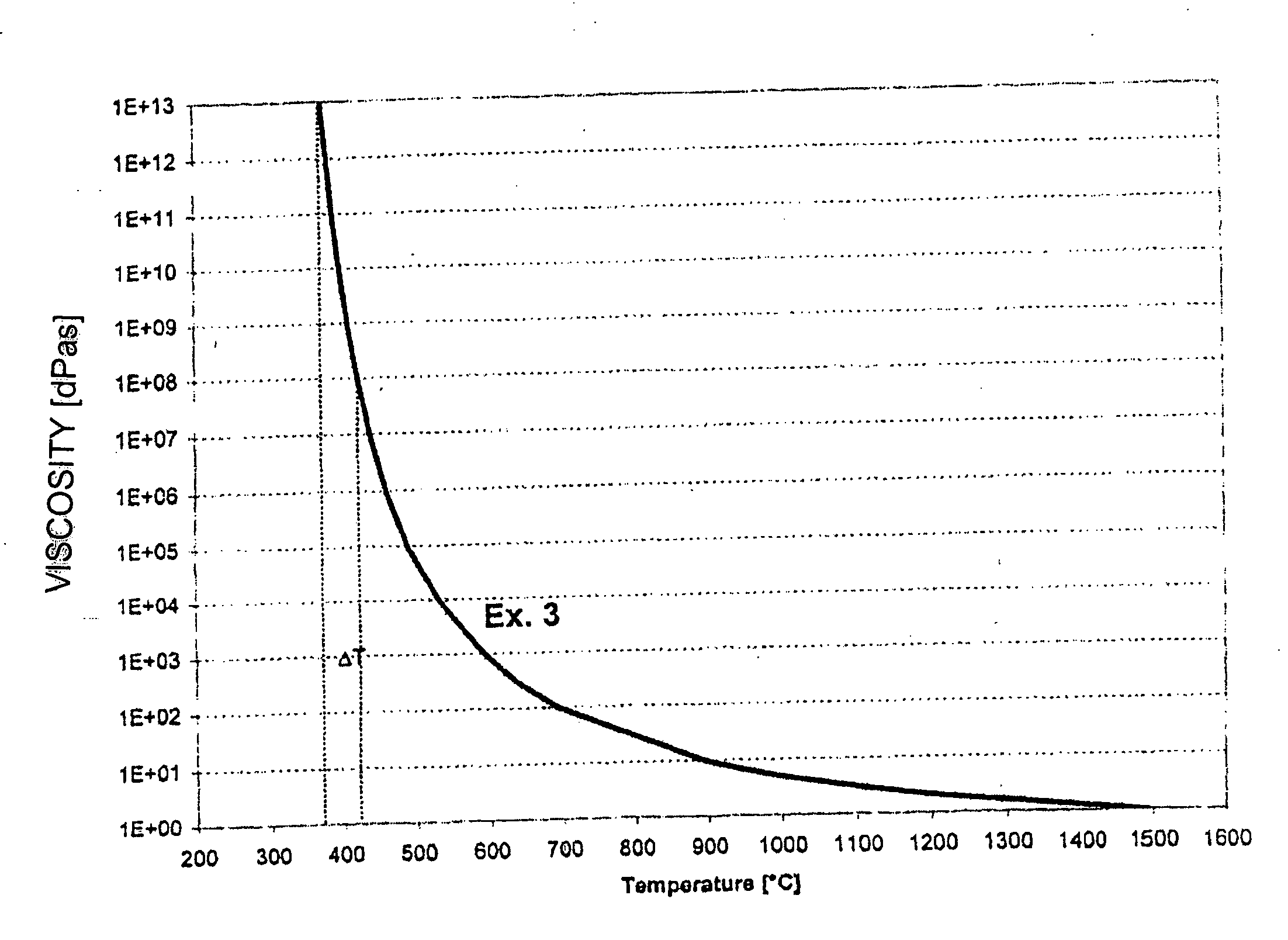

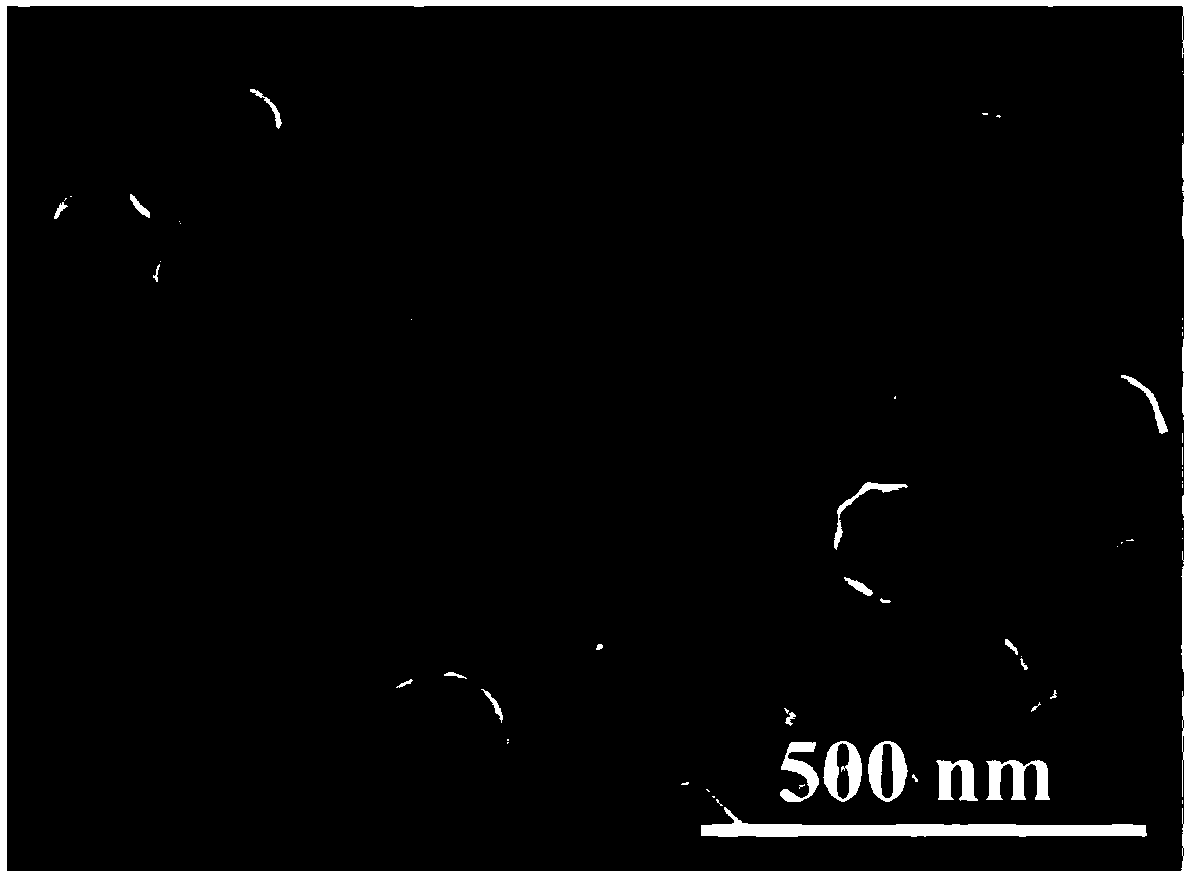

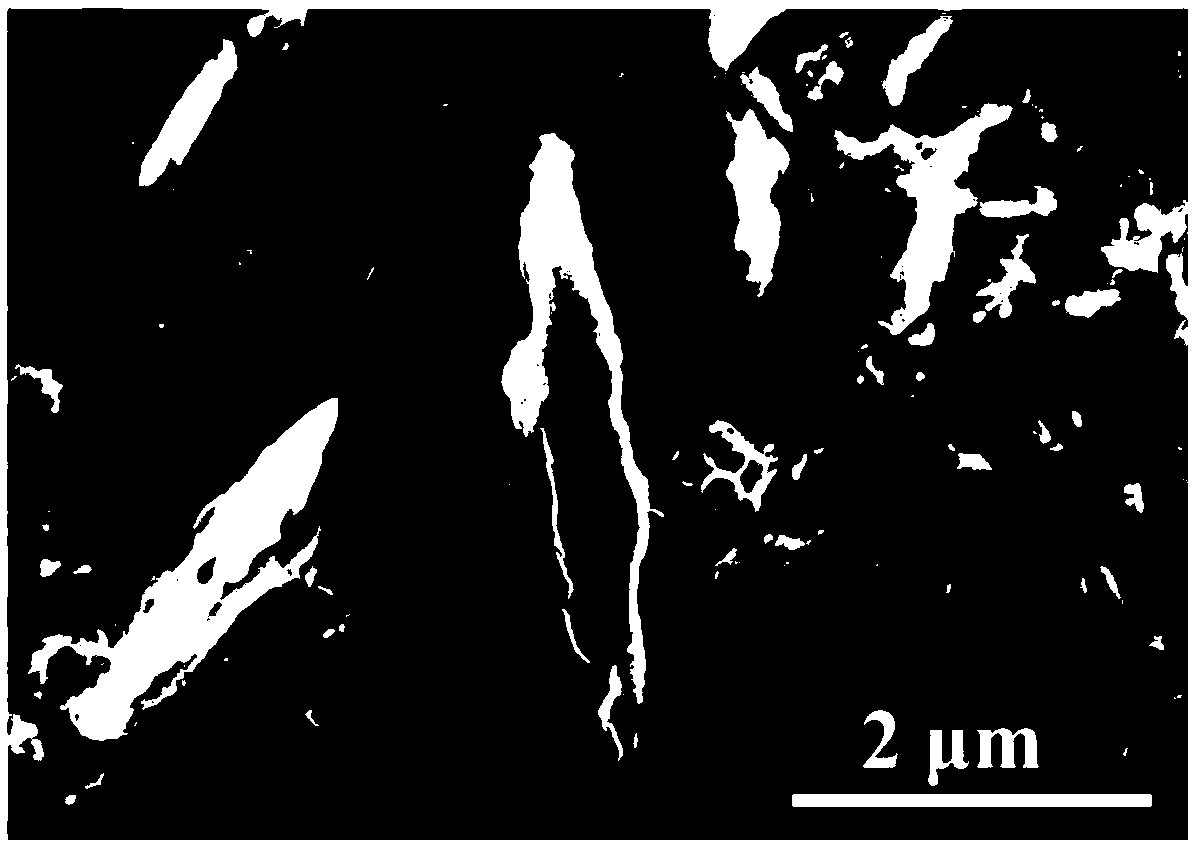

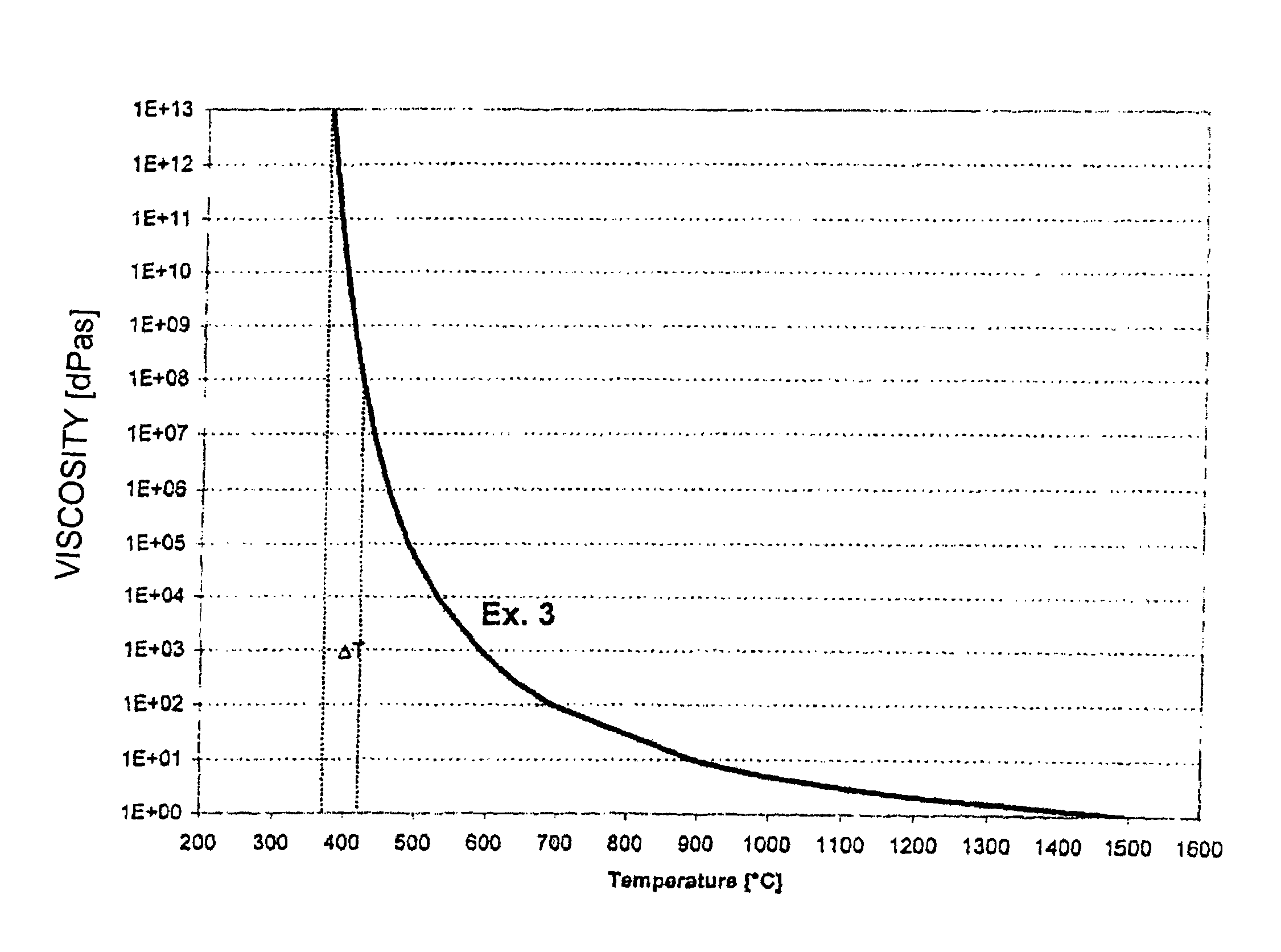

Optical glass and process for making precise-pressed optical elements therefrom as well as said optical elements

InactiveUS20050159291A1Promote meltingGood processing propertyOptical elementsRefractive indexOptical communication

The lead-free, preferably lithium-free, optical glass is useful in imaging, projection, telecommunications, optical communication and / or laser technology, particularly for making precise-pressed optical elements. It has a refractive index nd of 1.50 to 1.57, an Abbé number νd of 61 to 70. It also has a low transformation temperature of about or below 400° C., good production and processing properties and crystallization resistance. It has a composition, in percent by weight, based on oxide content of P2O5, 40 to 60; Al2O3, 1 to 20; B2O3, 0 to <5; Na2O, 0 to 30; K2O, 0 to 30; Li2O, 0 to <1; ΣM2O, >15 to 40; BaO, 1 to 20; ZnO, 1 to 20; SrO, 0 to 5; CaO, 0 to 5; MgO, 0 to 5; and ΣMO, 5 to 25. In addition, it may contain standard refining agents, although it is preferably free of arsenic and fluorine.

Owner:SCHOTT AG

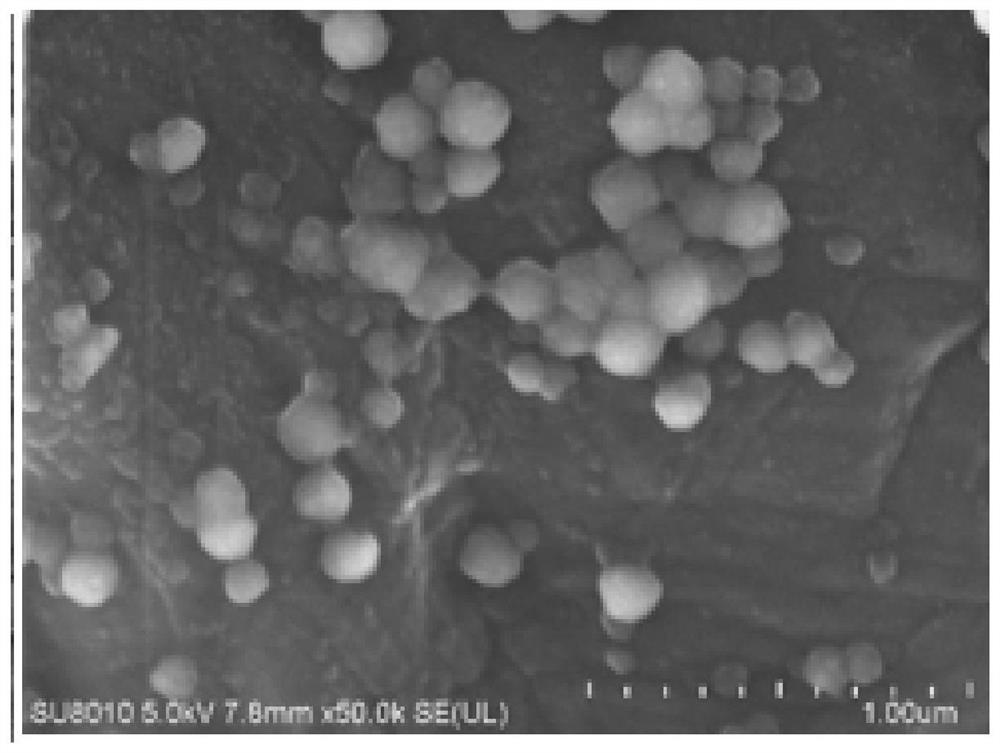

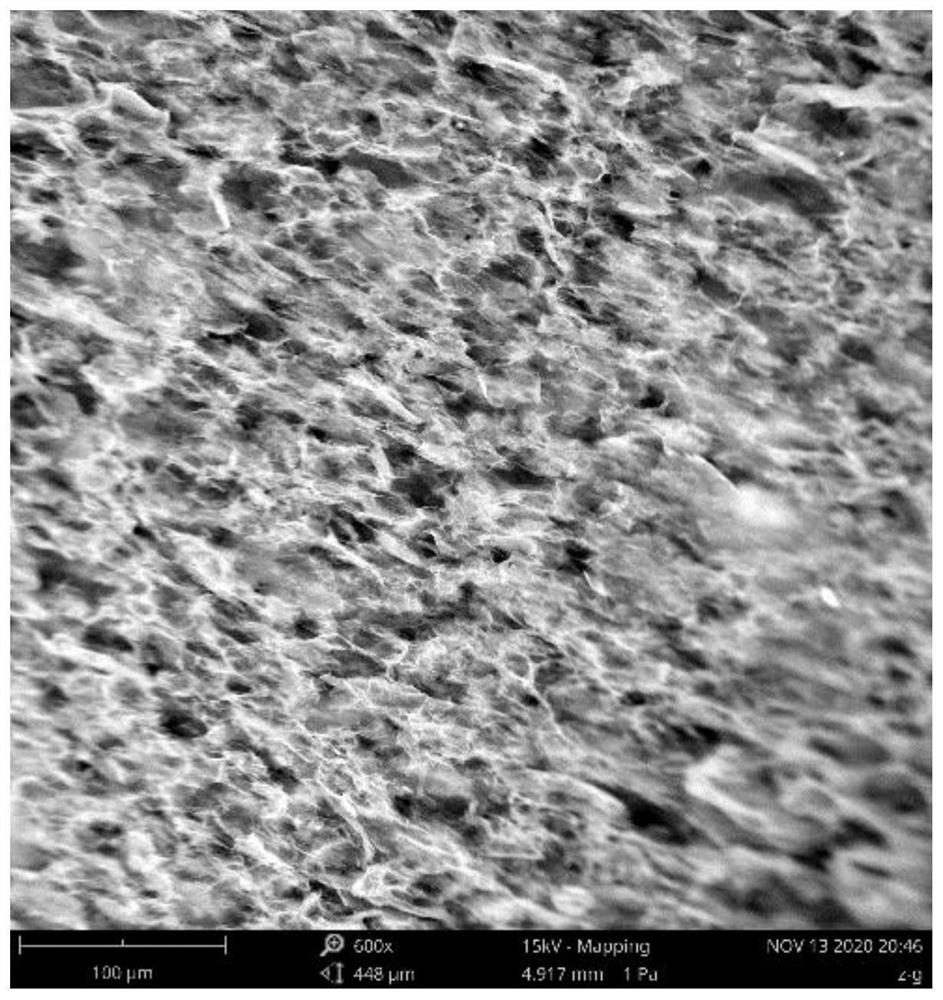

Lithium metal anode material based on tio2 nanotube array/titanium foam and preparation method thereof

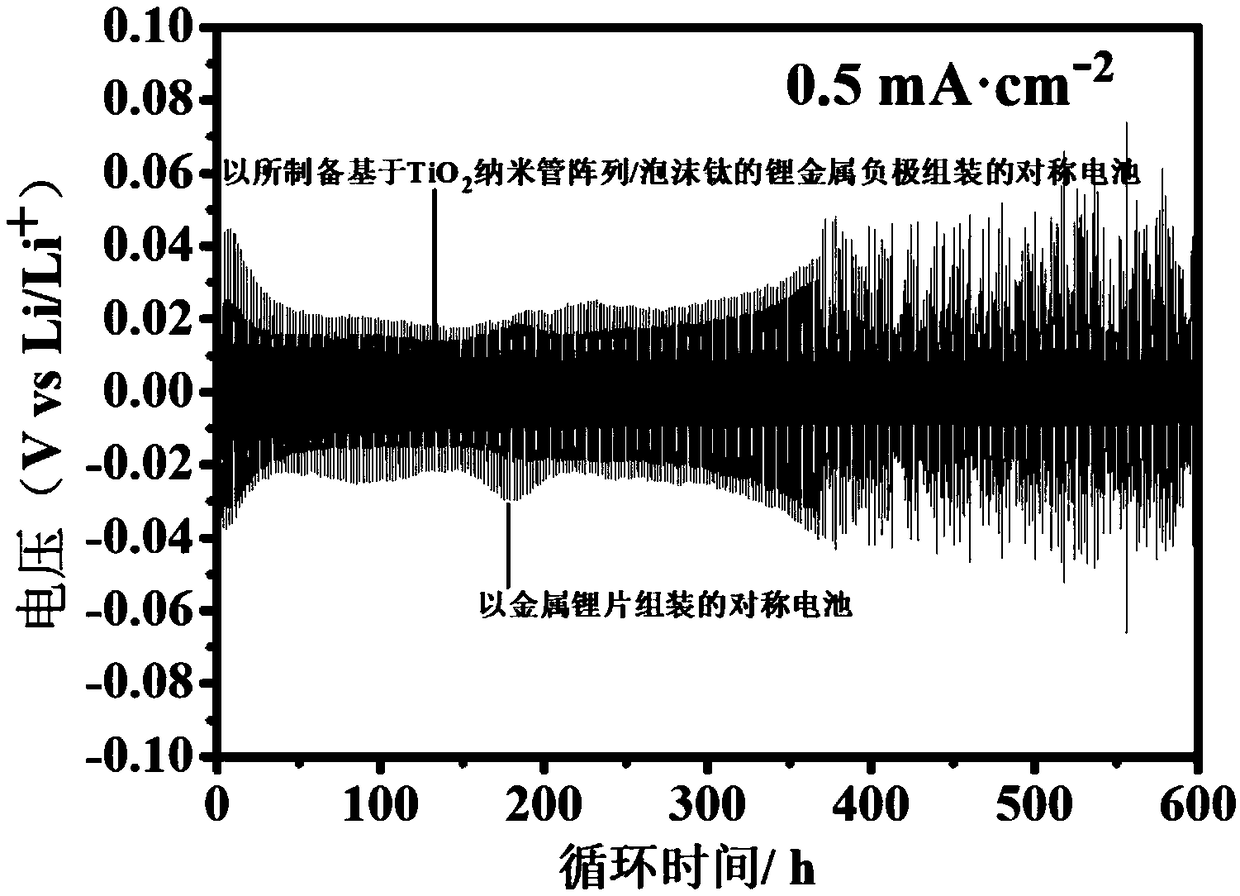

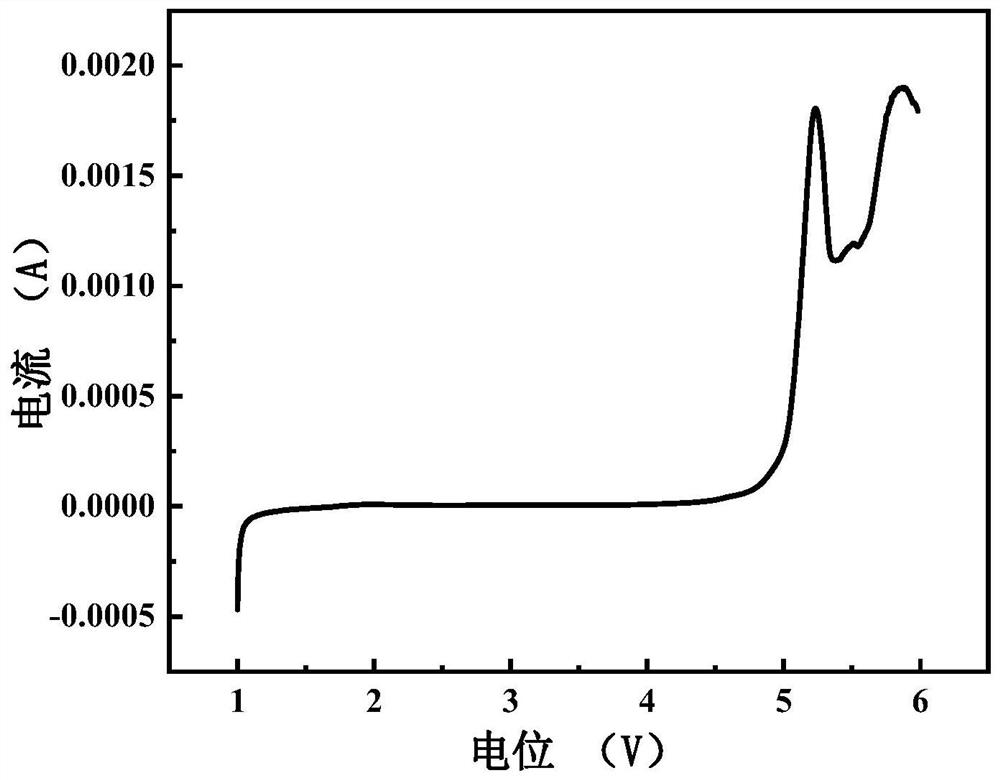

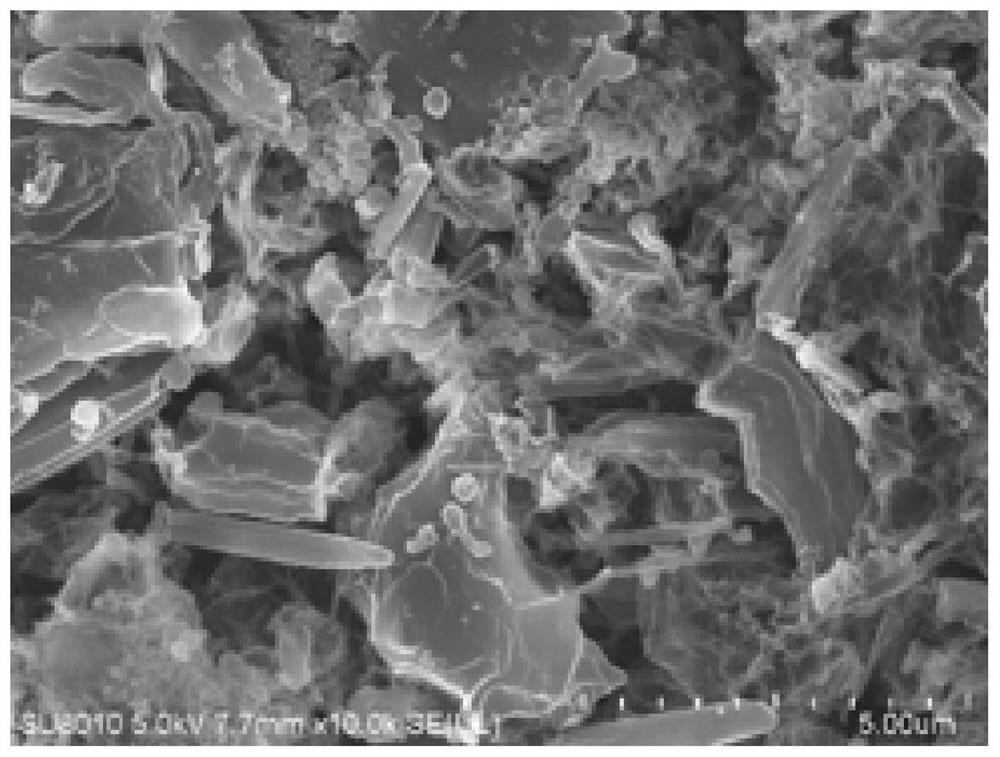

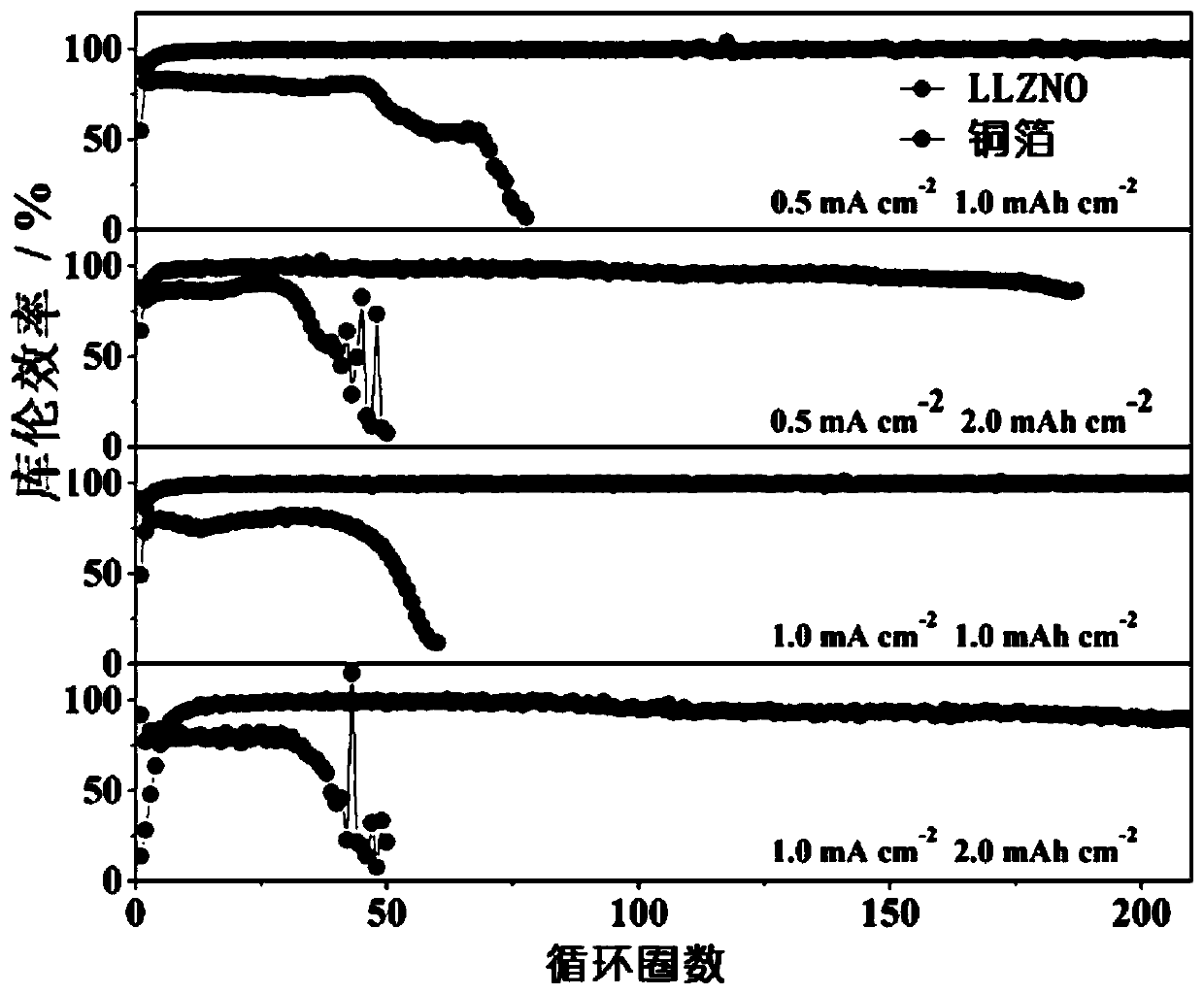

The invention belongs to the technical field of new energy materials and energy storage and conversion materials, in particular to a lithium metal anode electrode material based on TiO2 nanotube array / titanium foam and a preparation method thereof. TiO2 nanotube arrays were prepared on the surface of porous titanium foam by anodic oxidation and annealed, A lithium metal anode material with high loading of lithium metal, which can greatly alleviate the volume expansion effect of lithium metal and restrain the lithium dendrite in the process of cycling charge and discharge, was prepared by melt-perfusion method by compositing lithium metal with TiO2 nanotube array / titanium foam. A surface of that porous titanium foam three-dimensional conductive skeleton in the negative electrode material isuniformly covered with a lay of ordered TiO2 nanotube array, and lithium metal is uniformly filled with the TiO2 nanotube array / titanium foam matrix. A symmetrical cell was fabricate by using that lithium metal anode material. The cell was fabricated at 0.5 mA- cm<2> Cycling 300 cycles (600 hours) at current density, exhibiting lithium-free dendrite and stable cycling.

Owner:HEFEI UNIV OF TECH

All-solid-state battery

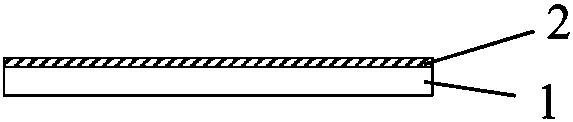

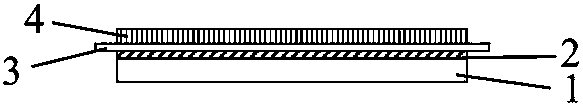

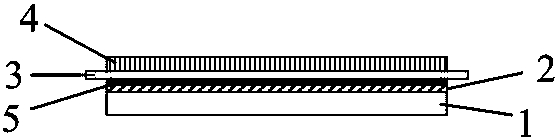

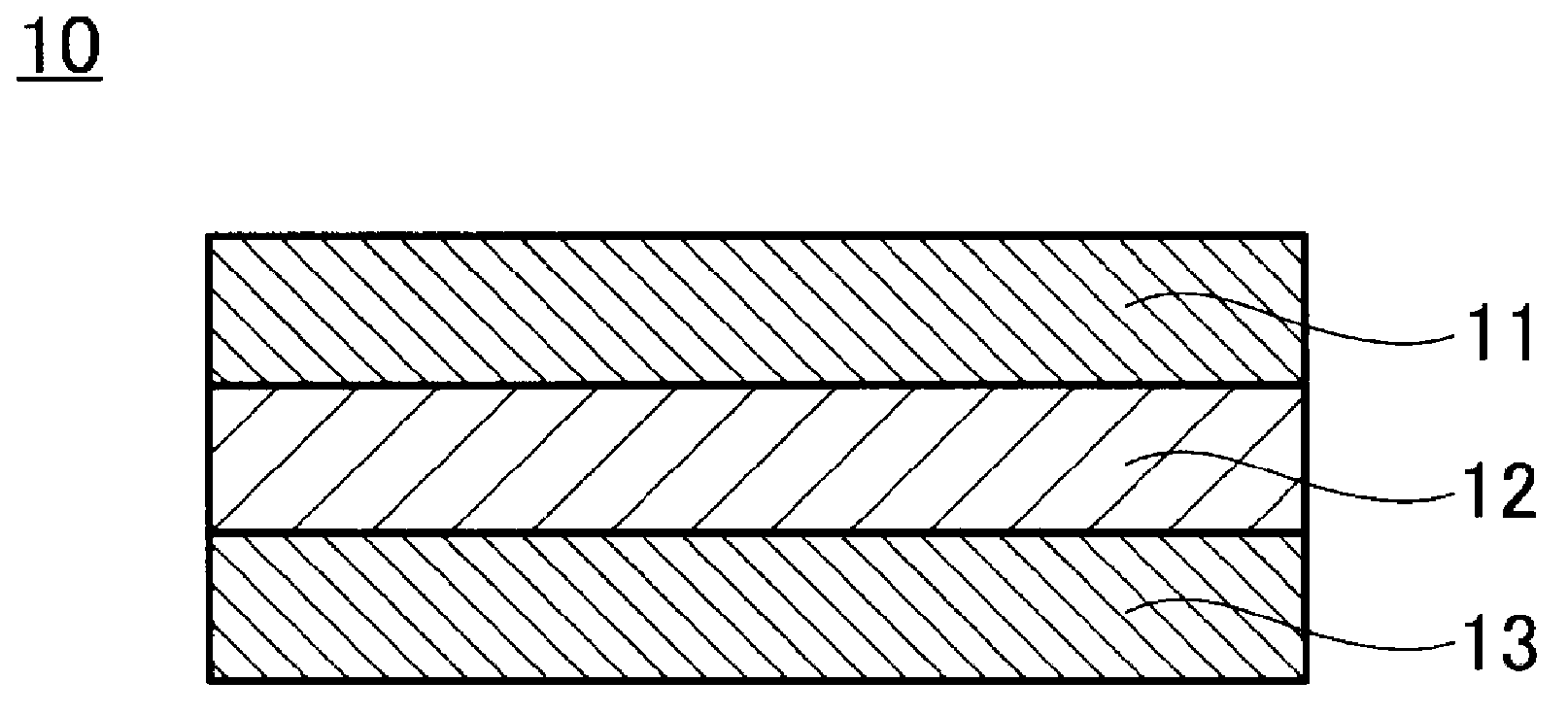

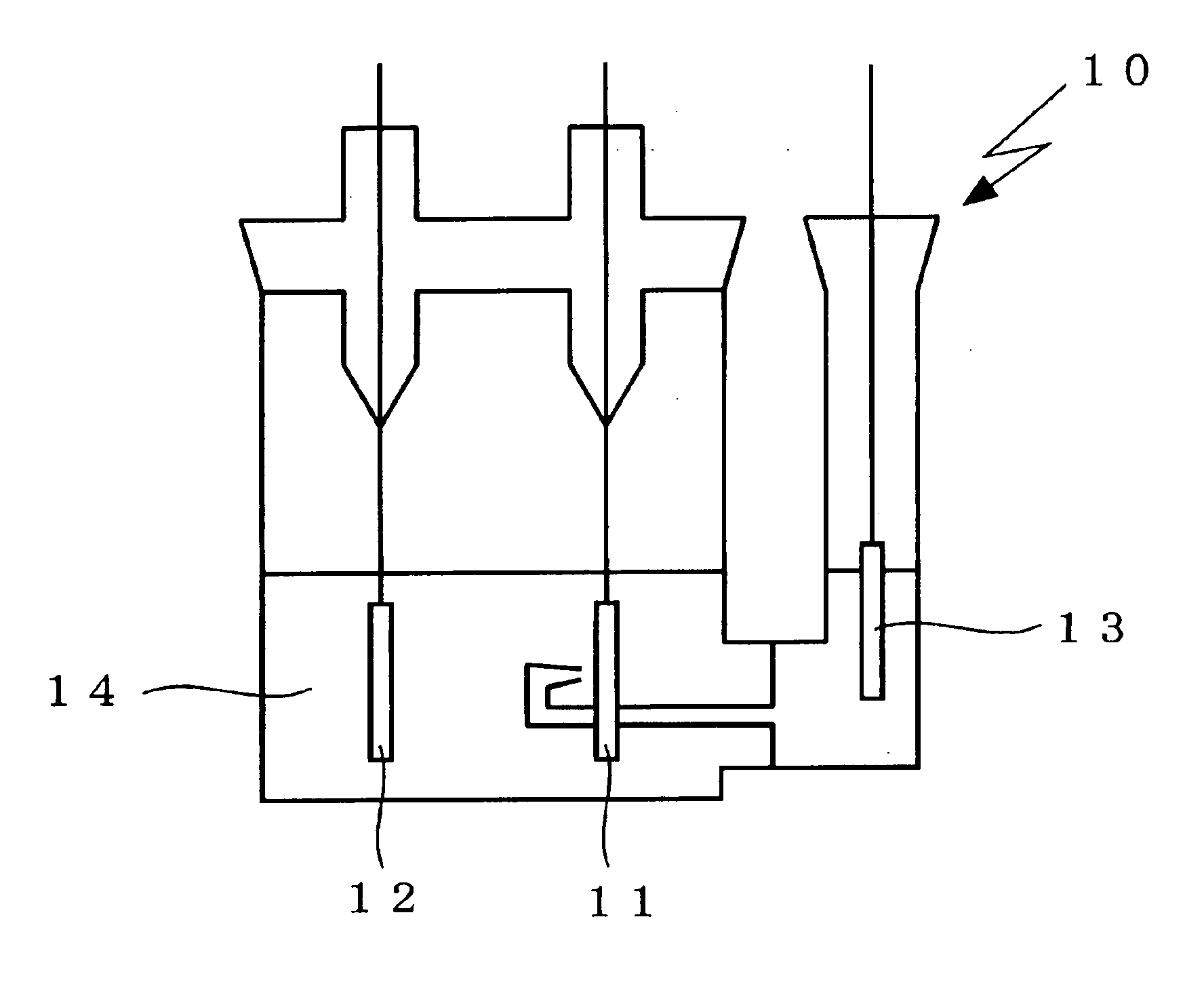

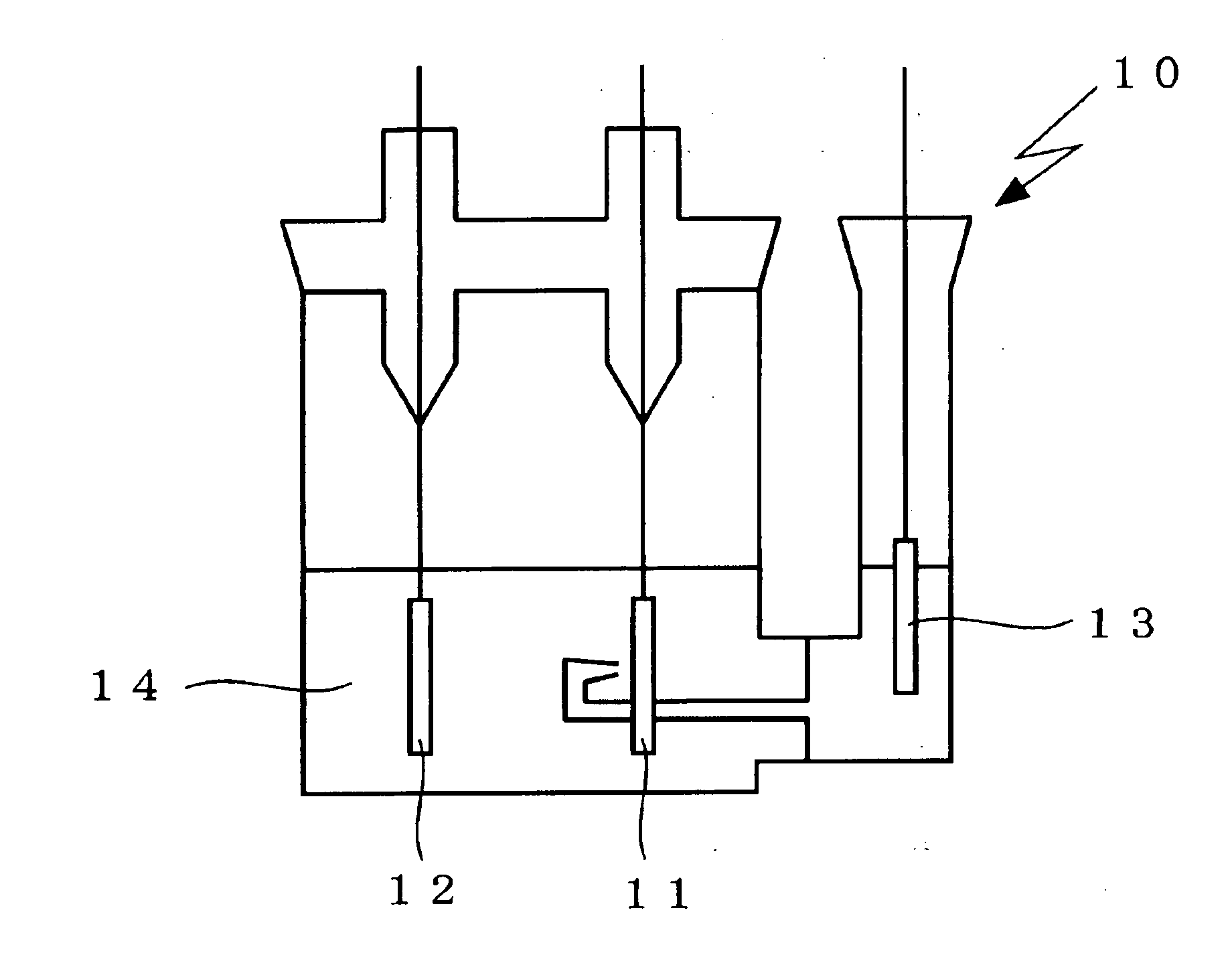

InactiveCN102844929AWith discharge capacityImprove cycle stabilityElectrode thermal treatmentFinal product manufactureAll solid stateTitanium

Provided is an all-solid-state battery which has the same level of discharge capacity as that achieved when an electrolytic solution is used, and which can have improved cycle stability. The all-solid-state battery (10) is provided with a solid electrolyte layer (12) and a positive electrode layer (11) and a negative electrode layer (13) both so arranged as to face to each other through the solid electrolyte layer (12). The positive electrode layer (11) and / or the negative electrode layer (13) is bonded to the solid electrolyte layer (12) by burning. The negative electrode layer (13) comprises an electrode active material composed of a lithium-free metal oxide and a titanium-free solid electrolyte.

Owner:MURATA MFG CO LTD

Eutectic solvent electrolyte, preparation method and lithium metal battery

ActiveCN112242561ALow costImprove conductivityLi-accumulatorsSecondary cells servicing/maintenanceElectrolytic agentPhysical chemistry

The invention discloses a eutectic solvent electrolyte, a preparation method and a lithium metal battery. The eutectic solvent electrolyte comprises a lithium salt, an amide compound and an additive,wherein the molar ratio of the lithium salt to the amide compound is 1: 1-1: 10; and the additive comprises a cyclic carbonate compound. According to the invention, the lithium salt and the amide compound in a predetermined molar ratio are blended to form the eutectic solvent electrolyte. The eutectic solvent electrolyte has the advantages of incombustibility, high conductivity, large electrochemical window and the like; when the electrolyte is applied to the lithium metal battery, rapid migration and spherical deposition of lithium ions in the electrolyte can be realized, lithium dendrites donot grow, the cycle life is long, and meanwhile, the eutectic solvent electrolyte is relatively low in cost and high in safety, and has a good application prospect.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Optical glass and process for making precise-pressed optical elements therefrom as well as said optical elements

The lead-free, preferably lithium-free, optical glass is useful in imaging, projection, telecommunications, optical communication and / or laser technology, particularly for making precise-pressed optical elements. It has a refractive index nd of 1.50 to 1.57, an Abbé number nud of 61 to 70. It also has a low transformation temperature of about or below 400° C., good production and processing properties and crystallization resistance. It has a composition, in percent by weight, based on oxide content of P2O5, 40 to 60; Al2O3, 1 to 20; B2O3, 0 to <5; NA2O, 0 to 30; K2O, 0 to 30; Li2O, 0 to <1; SigmaM2O, >15 to 40; BaO, 1 to 20; ZnO, 1 to 20; SrO, 0 to 5; CaO, 0 to 5; MgO, 0 to 5; and SigmaMO, 5 to 25. In addition, it may contain standard refining agents, although it is preferably free of arsenic and fluorine.

Owner:SCHOTT AG

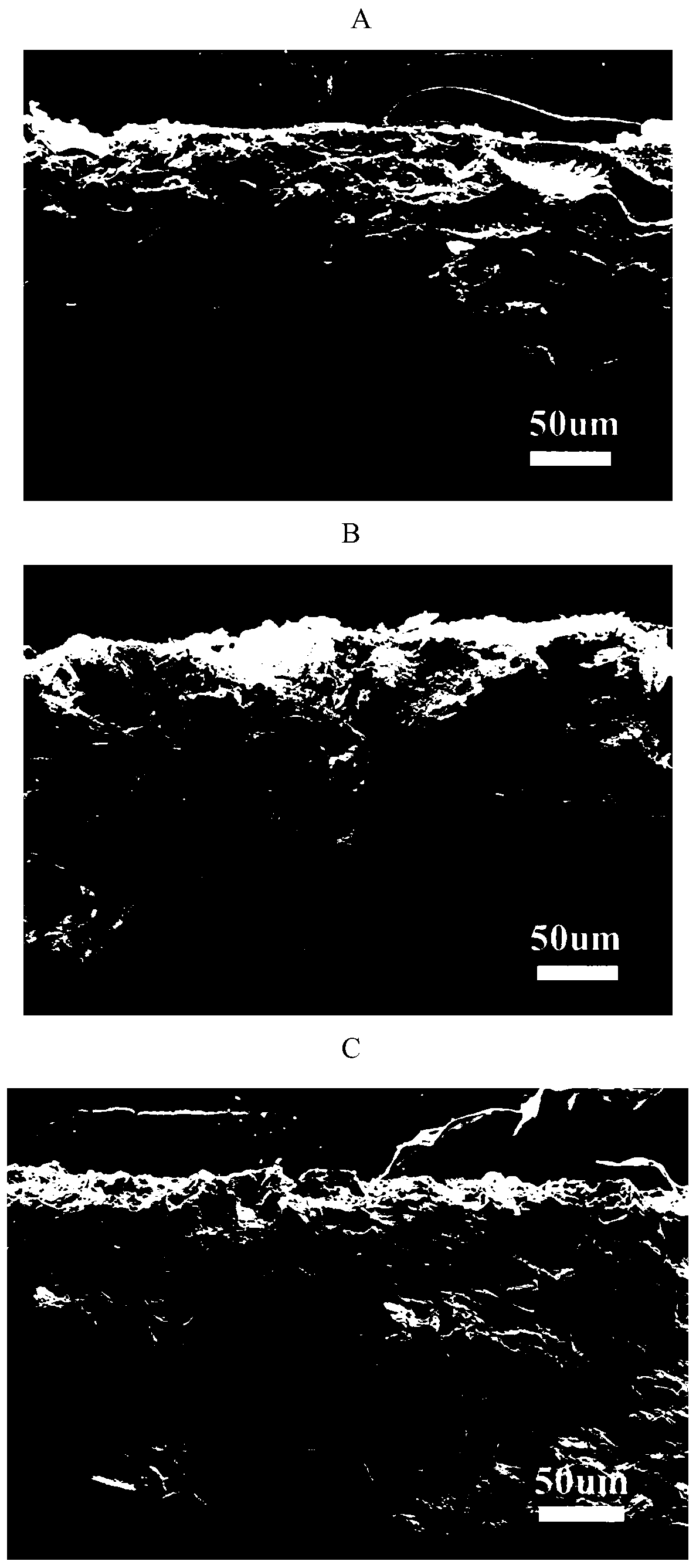

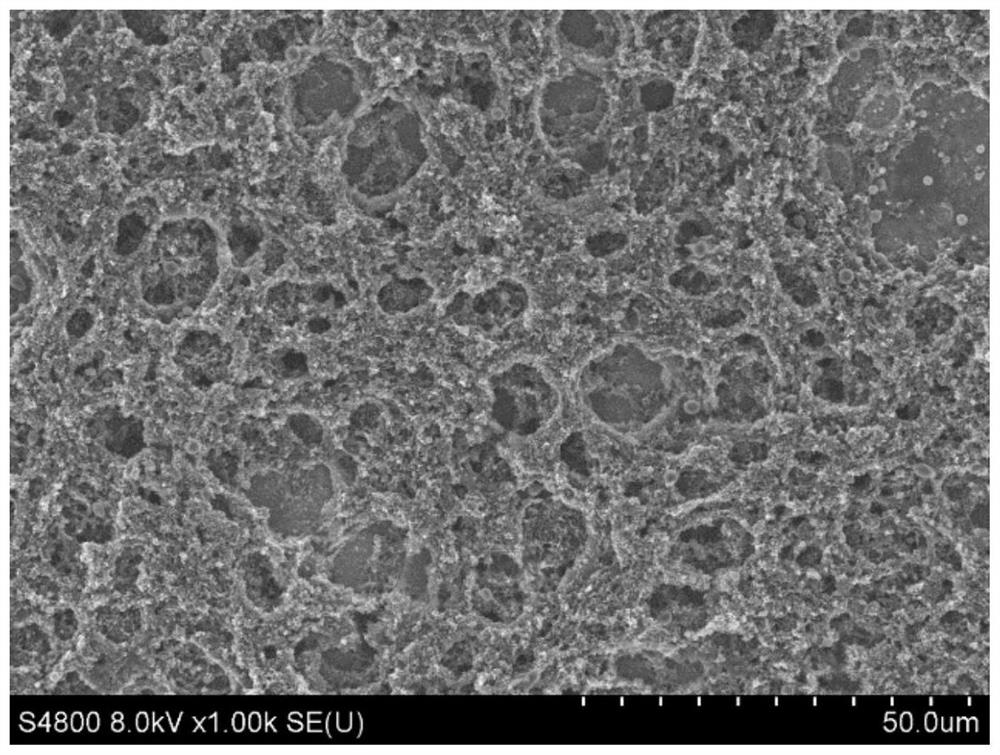

Porous ceramic composite lithium metal negative electrode and preparation method thereof

ActiveCN110957477ASolve insufficient storage spaceEnsure structural stabilityFuel and secondary cellsNegative electrodesAll solid stateLithium–air battery

The invention belongs to the field of high-specific-energy lithium metal batteries, and particularly discloses a porous ceramic composite lithium metal negative electrode and a preparation method thereof. The porous ceramic lithium metal negative electrode is composed of a porous ceramic skeleton, a conductive layer and lithium metal, and compared with a traditional lithium sheet negative electrode, the porous ceramic lithium metal negative electrode disclosed by the invention has the advantages that the porosity of the porous ceramic skeleton can provide sufficient storage space for the lithium metal; the rigidity of the porous ceramic skeleton can maintain the structural stability of the lithium metal negative electrode; the large specific surface area attribute of the porous ceramic skeleton can effectively reduce the local current density of the lithium metal negative electrode and relieve the growth problem of lithium dendrites; the composite negative electrode has the characteristics of high structural strength, high coulombic efficiency, low polarization, no lithium dendrites, good cycling stability and the like, meanwhile, the preparation method is simple, and large-batch manufacturing can be realized. The porous ceramic lithium metal composite negative electrode can be used for preparing a high-specific-energy lithium metal secondary battery, including an organic electrolyte system lithium ion battery, a lithium-air battery, an all-solid-state lithium ion battery, a lithium-air battery and the like.

Owner:SUZHOU UNIV

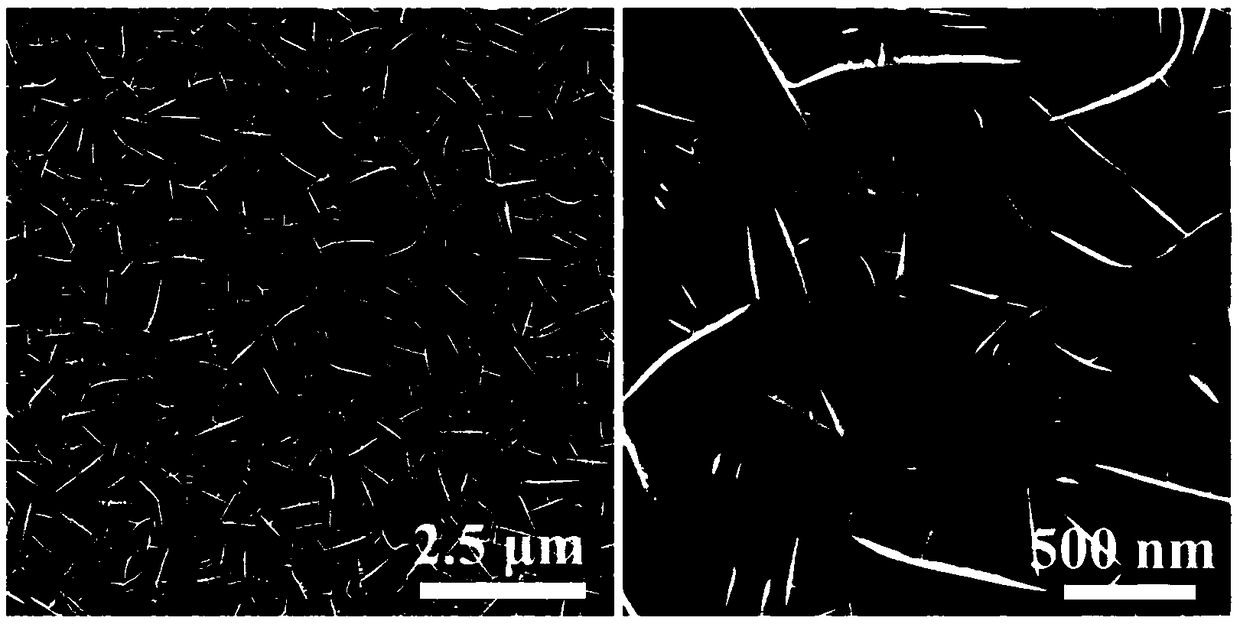

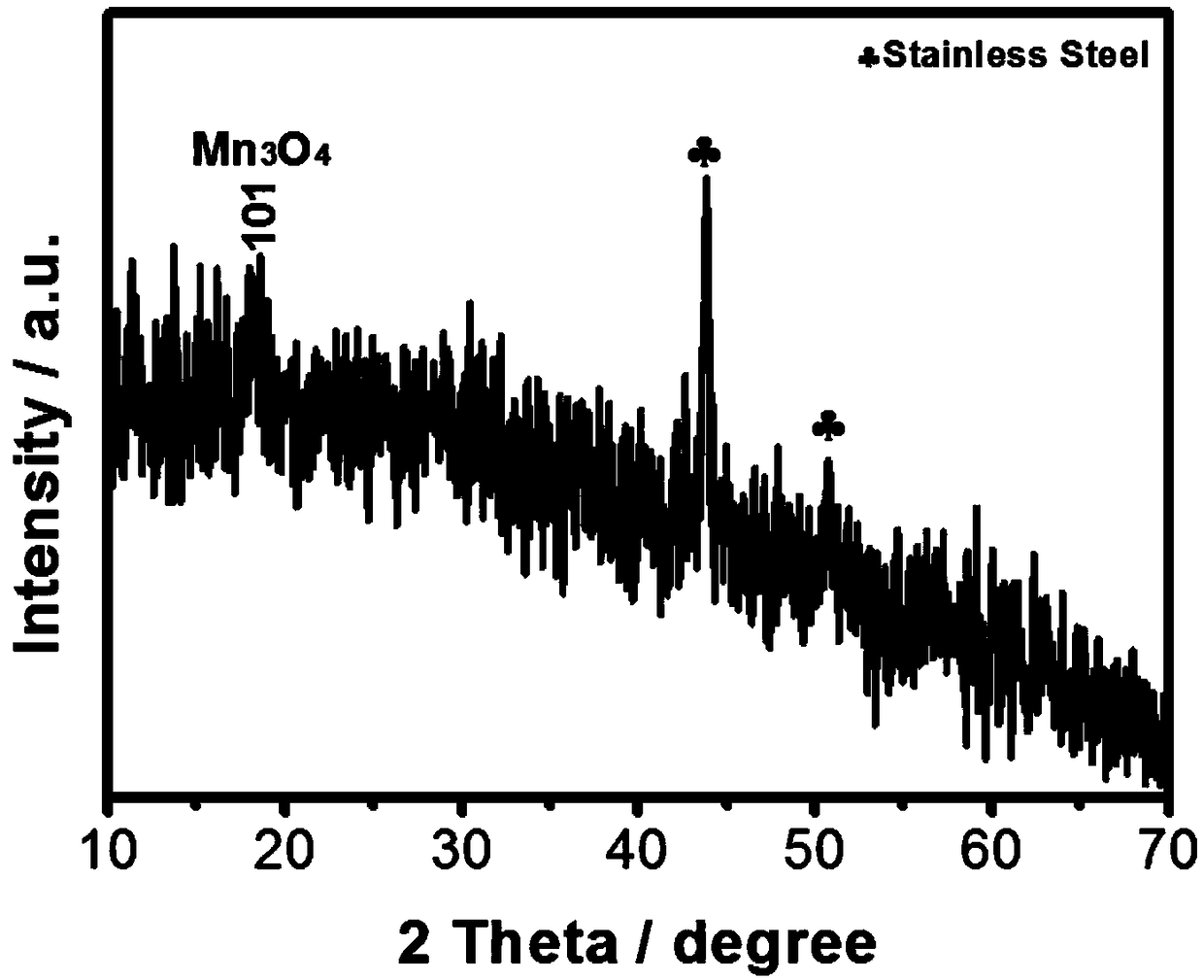

Cathode of lithium ion battery, all-solid-state lithium ion battery, preparation method and electric device thereof

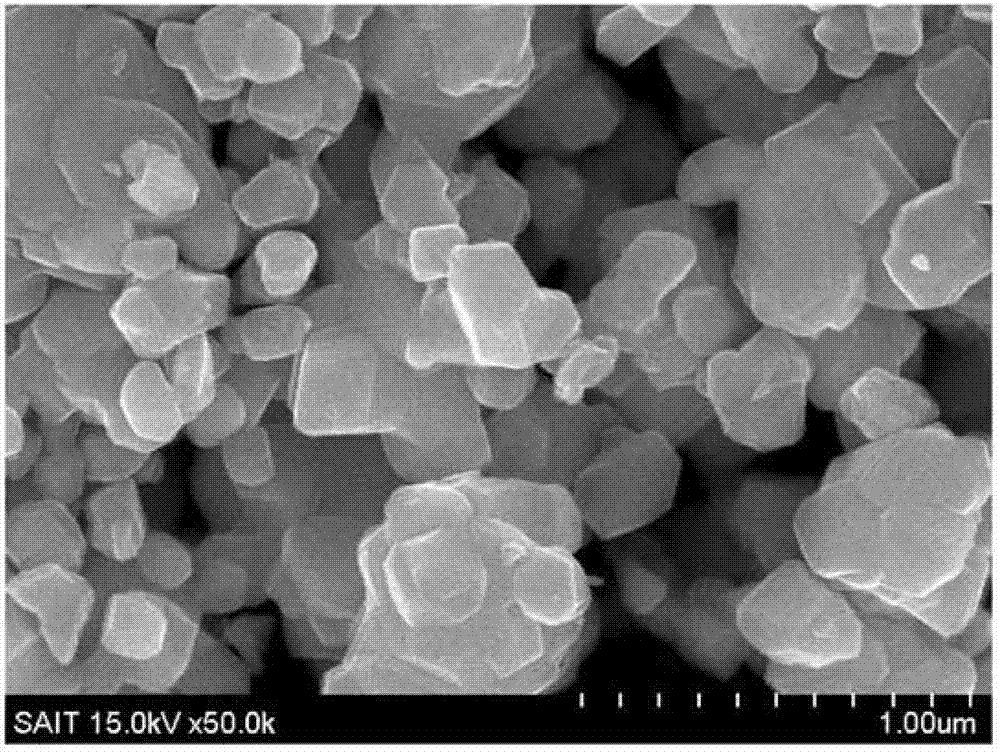

InactiveCN109148894AHigh crystallinityImprove electrochemical performanceSolid electrolytesElectrode carriers/collectorsAll solid stateLithium.free

The invention provides a cathode of a lithium ion battery, an all-solid-state lithium ion battery, a preparation method and an electric device thereof. The lithium ion battery cathode comprise a cathode current collector and a cathode material layer arrange on that surface of the cathode current collector, wherein the cathode active material in the cathode material layer is manganese tetroxide. The lithium-free positive electrode can alleviate cracking under high temperature annealing of the positive electrode suitable for all-solid-state lithium ion batteries, The technical problems of peeling off and difficult to integrate with microcircuits and difficult to combine with the flexible substrate which is not resistant to high temperature can achieve the technical effect of improving the application range of all-solid-state lithium ion batteries, and can reduce the cost of raw materials and preparation at the same time.

Owner:THE NORTHERN RES INST OF NJUST

Additive for electrochemical energy storages and electrochemical energy storage

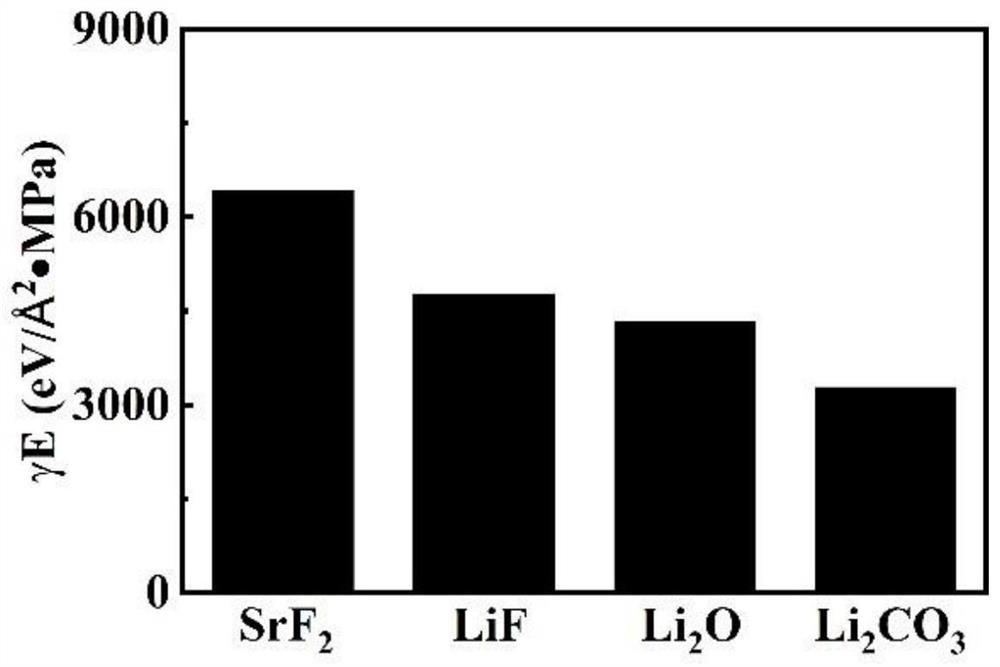

ActiveUS20150207184A1Improve electrochemical energy storage performanceImprove homogeneityCell seperators/membranes/diaphragms/spacersFinal product manufactureStored energyAlkaline earth metal

An additive for electrochemical energy storages is disclosed, wherein the additive contains at least one silicon- and alkaline earth metal-containing compound V1 which in contact with a fluorine-containing compound V2 in the energy storage forms at least one compound V3 selected from the group consisting of silicon- and fluorine-containing, lithium-free compounds V3a, alkaline earth metal- and fluorine-containing, lithium-free compounds V3b, silicon-, alkaline earth metal- and fluorine-containing, lithium-free compounds V3c and combinations thereof. Also disclosed is an electrochemical energy storage containing the additive.

Owner:SCHOTT AG

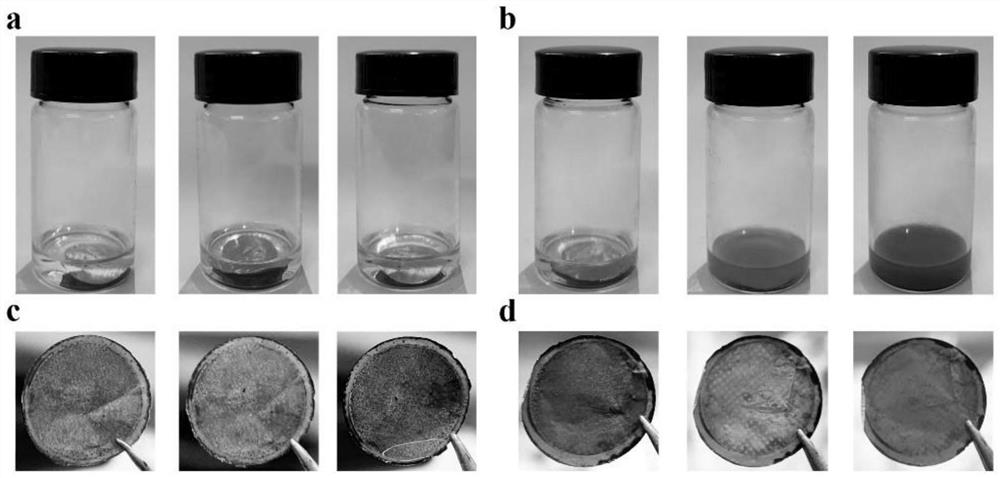

Metal lithium support and preparation method and application thereof

ActiveCN109585855AAffinityEven and stable electrodepositionElectrode carriers/collectorsElectrode melt handlingMetallic lithiumElectrolytic agent

The present invention provides a metal lithium support and a preparation method and application thereof, the support material of the metal lithium support is at least one of metal copper or an alloy thereof, and metallic nickel or an alloy thereof; and the surface of the support has a pro-lithium layer. A support body is placed in the electrochemical cell as a working electrode and an electropolishing liquid is injected into the electrochemical cell, an anode potential or an anode current is applied to the working electrode to change the anode potential or the anode current and time, regulatethe copper anode dissolution kinetics and allow the support body on the working electrode to obtain a relatively flat surface; and an electrolyte containing a crystal face capping agent is injected into the electrochemical cell, a cathodic potential or a cathode current is applied to the working electrode to causes metal deposition reaction, change a cathode potential or a cathode current and timeand adjust the copper deposition process to obtain a metal lithium support. The metal lithium support can be directly used as a lithium-free negative electrode for application in a lithium ion battery, or for application in the preparation of the lithium thin film negative electrode in a secondary battery in an electrodeposition or melting lithium lead mode.

Owner:XIAMEN UNIV

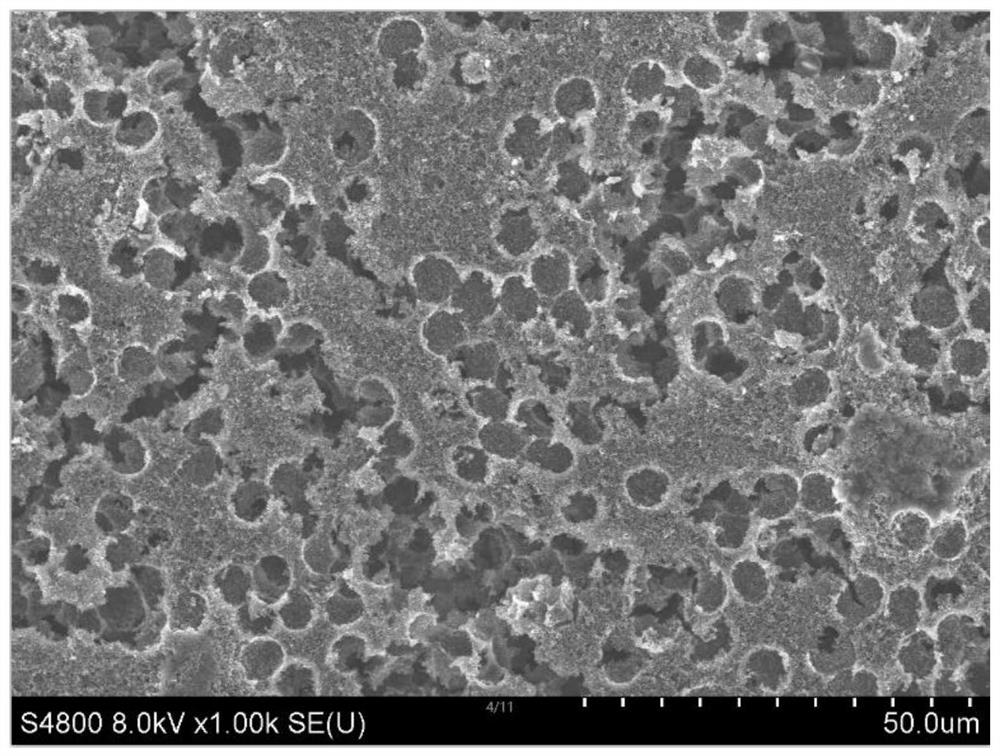

Three-dimensional graded porous current collector and preparation method thereof

ActiveCN113224314AFacilitate depositionUniform dense depositionElectrode carriers/collectorsLi-accumulatorsConductive polymerElectrical battery

The invention provides a preparation method of a three-dimensional graded porous current collector. The preparation method comprises the following steps: S1) mixing a conductive agent, an adhesive, a conductive polymer material modified pore-forming agent and a solvent to obtain slurry; he.and S2) coating the surface of a current collector with the slurry, drying, and removing the pore-forming agent to obtain the three-dimensional graded porous current collector. The decomposition temperature of the conductive polymer material is higher than that of the pore-forming agent. Compared with the prior art, the shape of the three-dimensional structure and the pore size can be regulated and controlled by changing the type of the pore-forming agent, so that lithium electrodeposition in a pore channel cavity is facilitated; by adopting the pore-forming agent modified by the conductive polymer material, electron-rich groups with defect chemical sites, pyridine nitrogen, pyrrole nitrogen and the like can be synthesized in situ in a pore channel in a three-dimensional current collector, and the affinity to lithium ions is increased, so that the lithium ions can be further guided to be deposited in the three-dimensional pore channel, and the pore-forming agent is favorably applied to an actual battery system; and the current collector can be used for lithium metal battery negative electrodes and lithium-free negative electrodes.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

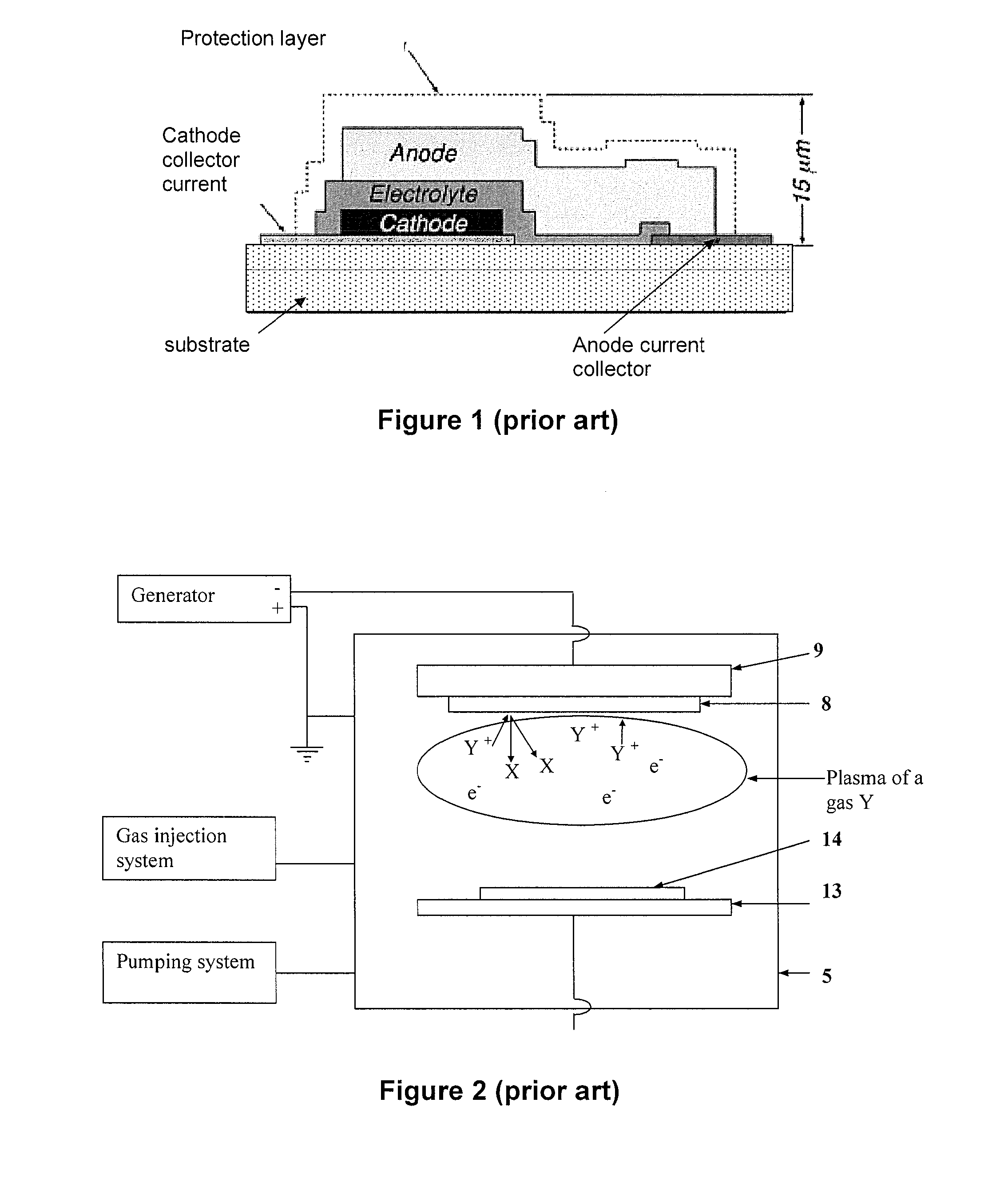

Method For Producing A Lithium-Based Electrolyte For A Solid Microbattery

ActiveUS20150194700A1Improve ionic conductivityAvoid accumulationSolid electrolytesFinal product manufactureLithium.freeElectrolyte

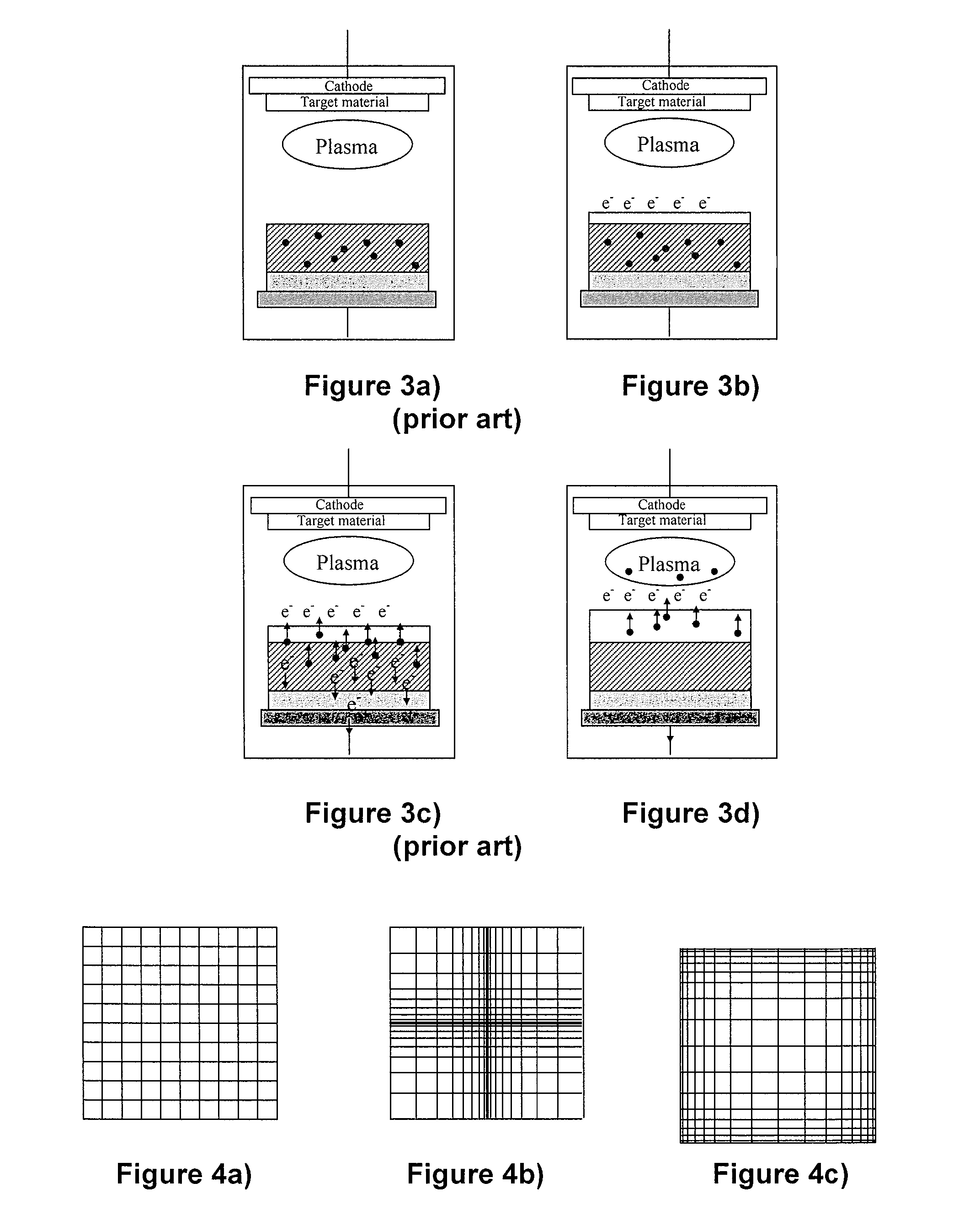

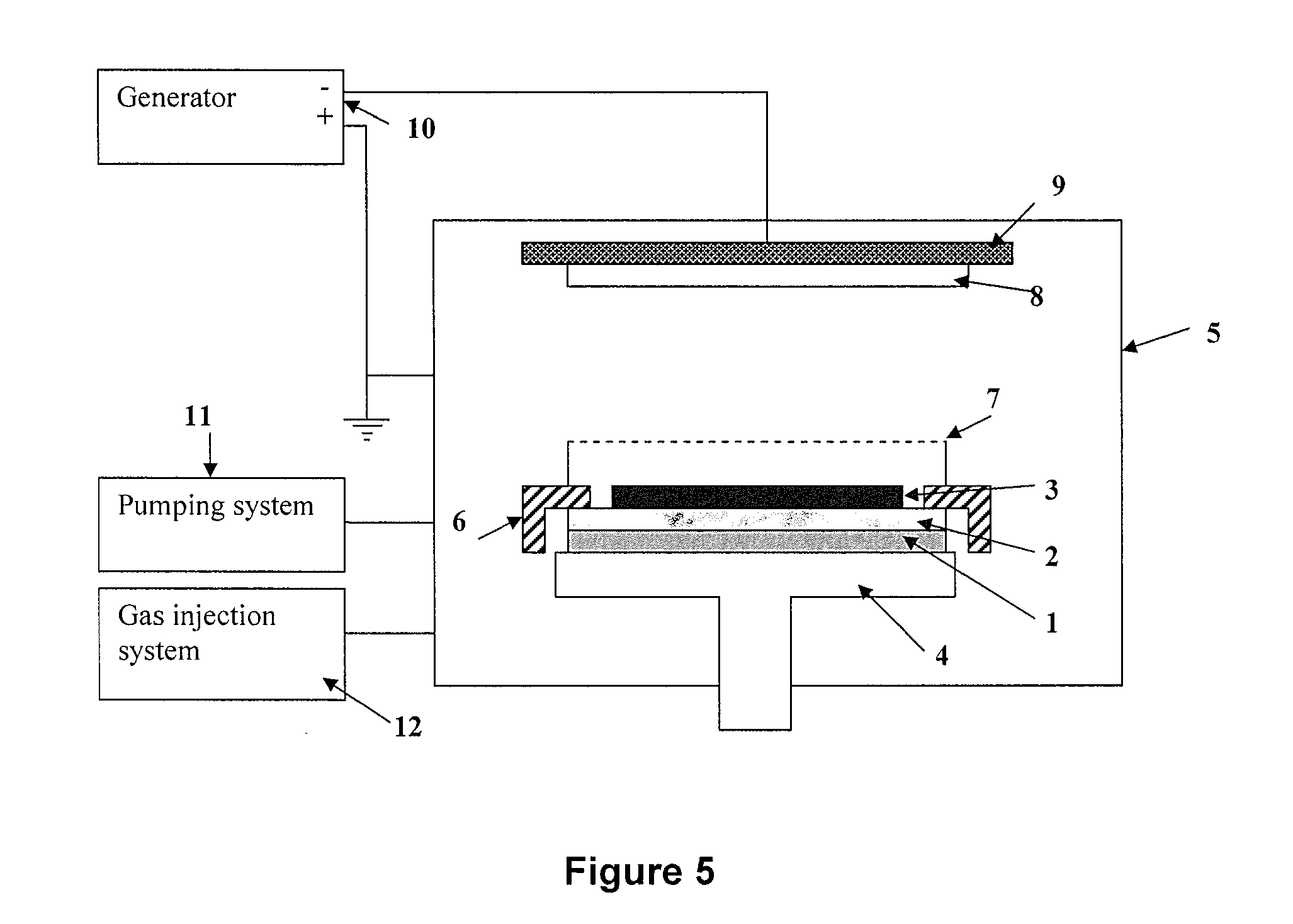

A method for producing a solid lithium-based electrolyte for a solid microbattery implements the cathode sputtering of a lithium-based target material on an object supported by a substrate holder. A grid made of lithium-free electrically conductive material is interposed between the object and the lithium-based target material, the grid being electrically connected to the substrate holder.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

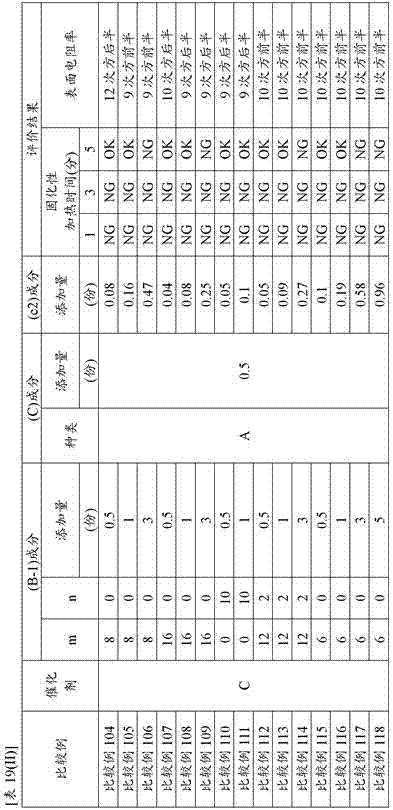

Silicone adhesive composition and adhesive tape

ActiveCN107960100AImprove antistatic performanceImprove adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesUnsaturated hydrocarbonMetal catalyst

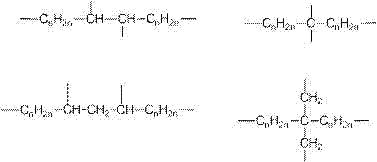

The present invention firstly addresses the problem of providing a silicone adhesive which provides a highly antistatic adhesive layer, exhibits excellent adhesion to a substrate, and reduces the amount of adhesive residue left on an adherend after an adhesive tape or adhesive film having the adhesive layer is peeled off from the adherend. The present invention secondly addresses the problem of providing a silicone adhesive composition which is satisfactorily cured by being heated for a short period of time, particularly, for less than 5 minutes and provides a highly antistatic adhesive layer.The present invention firstly provides an addition reaction-curing silicone adhesive composition, which is characterized by containing (A) an addition reaction-curing silicone, (B) a compound having,in each molecule, at least two unsaturated hydrocarbon groups and two (poly)oxyalkylene residues, and (C) a lithium-free ionic liquid. The present invention secondly provides an addition reaction-curing silicone adhesive composition, which is characterized by containing (A) an addition reaction-curing silicone, (B) a compound having, in each molecule, at least one unsaturated hydrocarbon group and at least one (poly)oxyalkylene residue, (C) a lithium-free ionic liquid, and (e) a non-complex platinum-group metal catalyst of a compound having unsaturated hydrocarbon bonds.

Owner:SHIN ETSU CHEM IND CO LTD

Lithium-free salt modified graphene composite solid electrolyte material, electrolyte membrane and preparation method thereof

InactiveCN108417888AInhibition formationGrowth inhibitionSolid electrolytesFinal product manufactureSolid state electrolyteElectrical conductor

The invention discloses a lithium-free salt modified graphene composite solid electrolyte material, an electrolyte membrane and a preparation method thereof. On the basis of a lithium ion conductor inorganic material and a polymer matrix material, a modified graphene material is added to prepare the composite solid electrolyte material according to an improved preparation method, and the modifiedgraphene composite solid electrolyte material is free of adding of lithium salts. Compared with the prior art, the lithium-free salt modified graphene composite solid electrolyte material, the electrolyte membrane and the preparation method thereof have advantages that a preparation process is simple, low material cost and effectiveness in inhibition of lithium dendrite formation and growth are realized, higher room-temperature ion conductivity, electrochemical work window and mechanical performances are achieved as compared with those of composite solid electrolyte materials with the lithiumsalts and without the modified graphene material, and stability in matching with a positive electrode material of a high-voltage system can be realized, so that solid batteries high in energy densitycan be obtained; in addition, low interface impedance in contact with positive and negative electrodes of all-solid-state lithium ion batteries is realized, and high stability in metal lithium negative electrodes is achieved.

Owner:上海力信能源科技有限责任公司

Non-aqueous electrolyte secondary battery

InactiveUS20070248886A1Easy to operateLittle changePositive electrodesNon-aqueous electrolyte accumulator electrodesPhosphateLithium.free

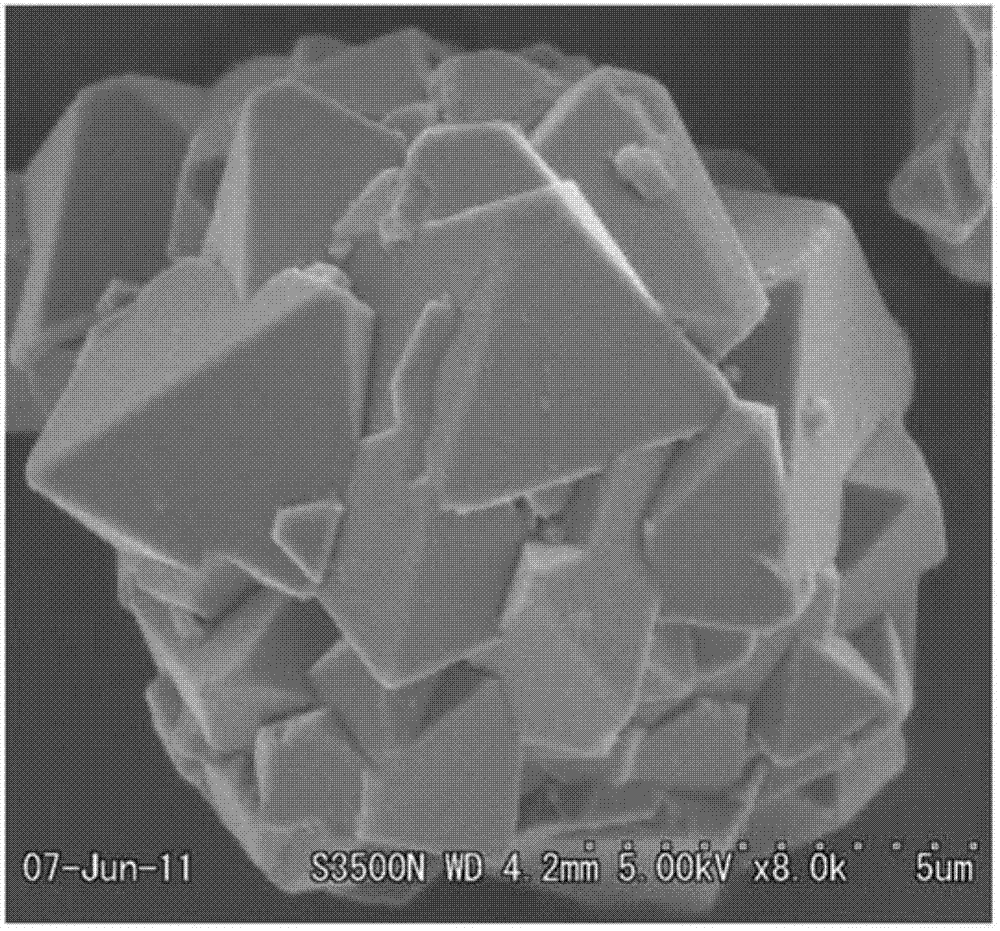

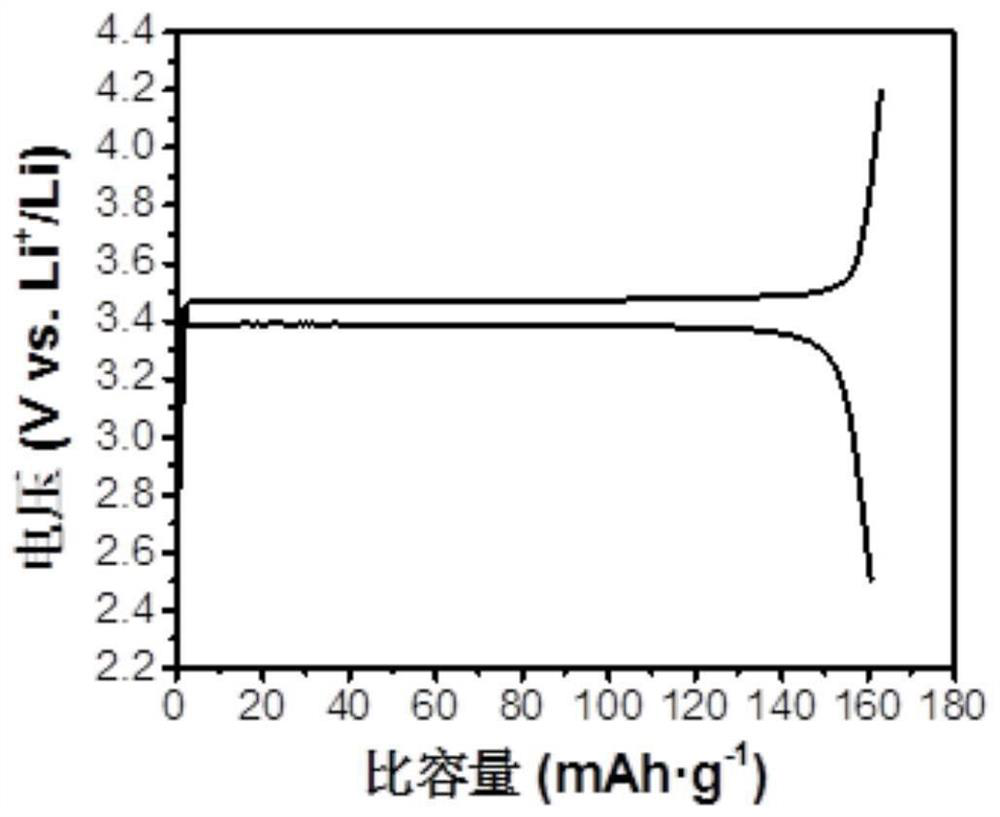

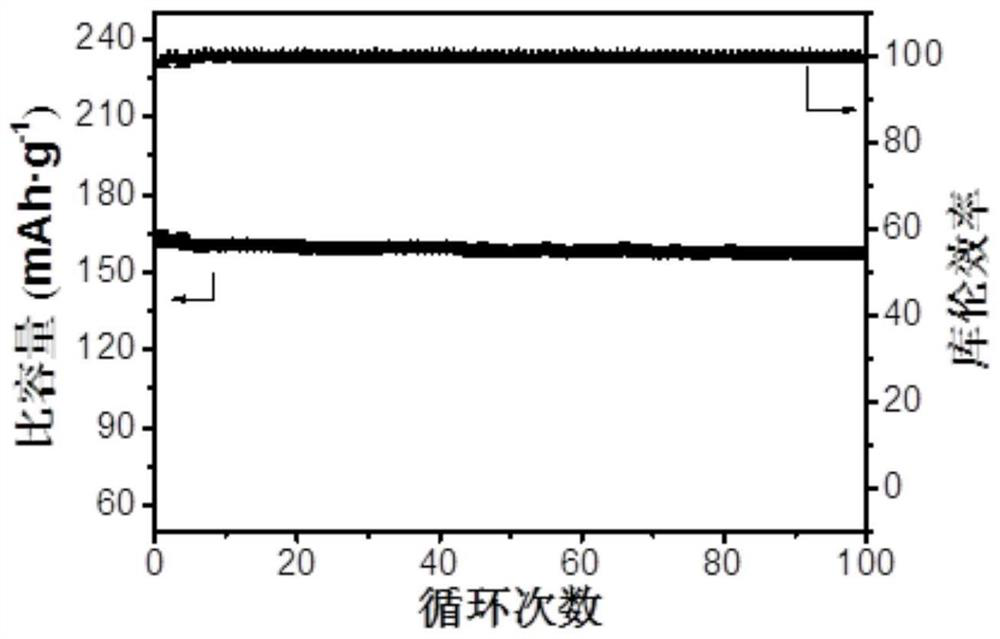

A non-aqueous electrolyte secondary battery includes a positive electrode (11), a negative electrode (12), and a non-aqueous electrolyte (14). The positive electrode contains a lithium-free metal oxide and a positive electrode active material composed of an olivine-type lithium-containing phosphate represented by the general formula LixMPO4, where M is at least one element selected from the group consisting of Co, Ni, Mn, and Fe, and 0<x<1.3.

Owner:SANYO ELECTRIC CO LTD

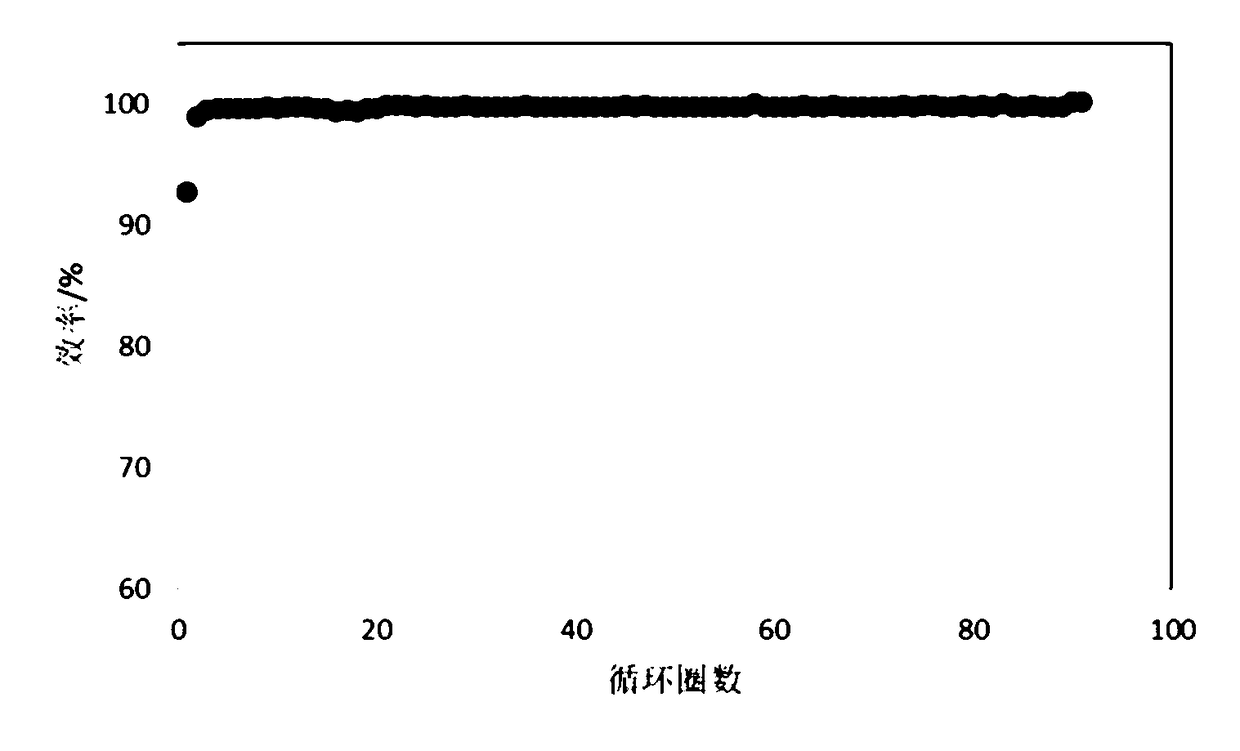

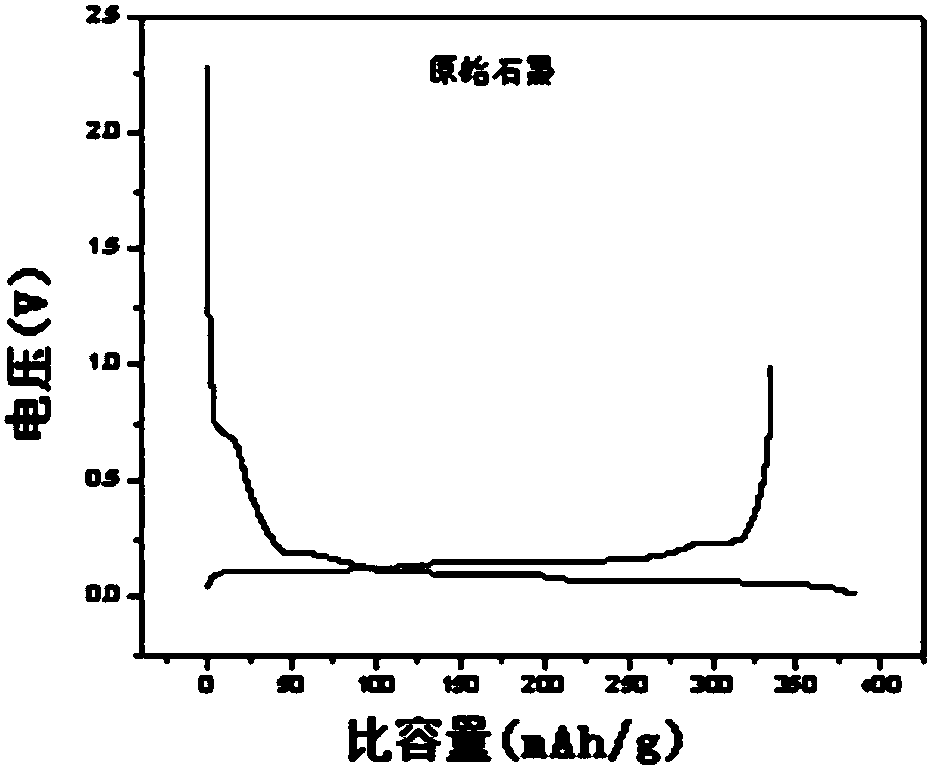

Preparation method for battery based on metal lithium powder and graphite negative electrode

InactiveCN108346794AIncrease energy densitySimple preparation processCell electrodesLithium.freeLithium hexafluorophosphate

The invention provides a preparation method for a battery based on metal lithium powder and a graphite negative electrode. The preparation method comprises the following steps: preparing a metal lithium powder / graphite negative electrode slice and a vanadium pentoxide positive electrode slice; welding the tabs of the positive and negative electrode slices; preparing an organic solvent with a lithium hexafluorophosphate concentration of 1 mol / L as an electrolyte of the battery; cutting a Celgard polymer film used as a battery diaphragm into a rectangular piece with a width of 60 mm and a lengthof 610 mm; winding the electrode slices with a coiler so as to form a lithium battery cell; filling a cylindrical steel shell, with a bottom diameter of 18 mm and a height of 65 mm, with the lithiumbattery cell so as to form a 18650 type lithium battery cell, and transferring the 18650 type lithium battery cell to an argon-protected glove box; injecting the electrolyte; and carrying out sealingso as to obtain the finished soft pack battery. According to the invention, the lithium-free positive electrode material vanadium pentoxide is adopted, and the metal lithium powder is introduced intothe graphite negative electrode slice, so the 18650 type lithium battery cell is formed; and the preparation method has the advantages of simple process, easy enlargement production and large-scale application potential.

Owner:武汉理工力强能源有限公司

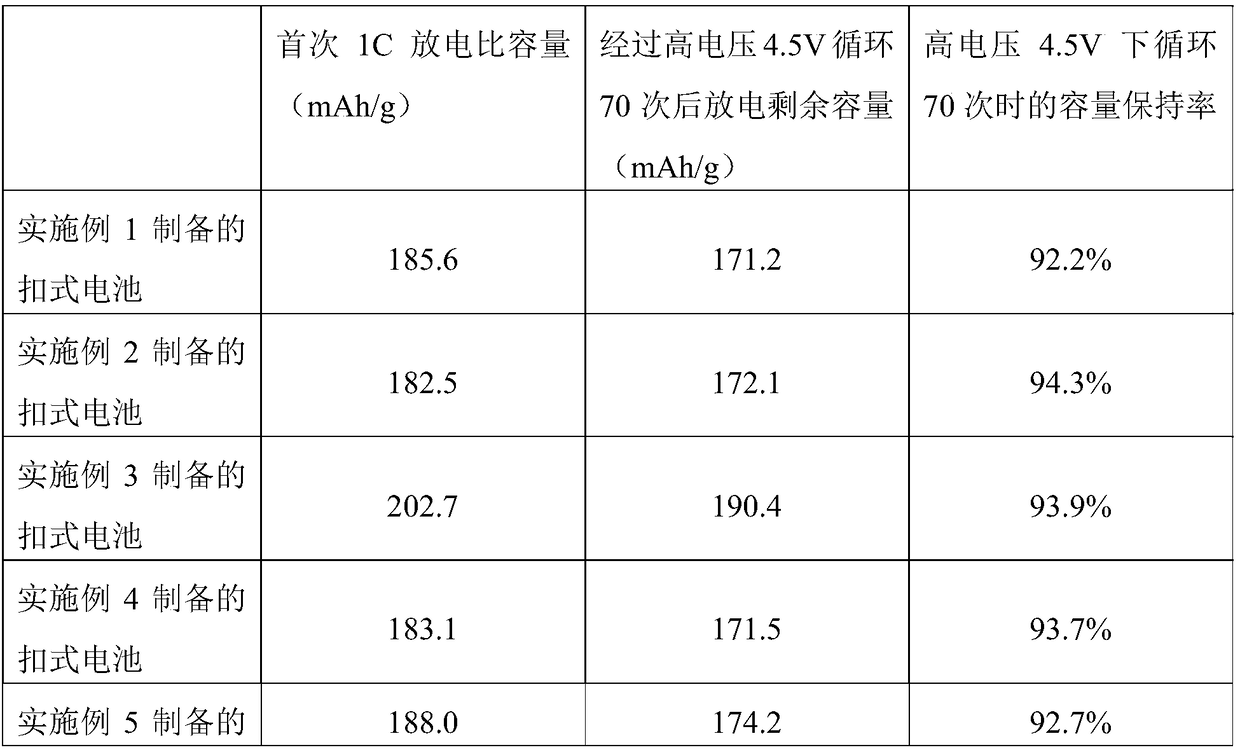

Nickel-cobalt lithium manganate positive electrode material applied to high-voltage lithium ion batteries and preparation method thereof

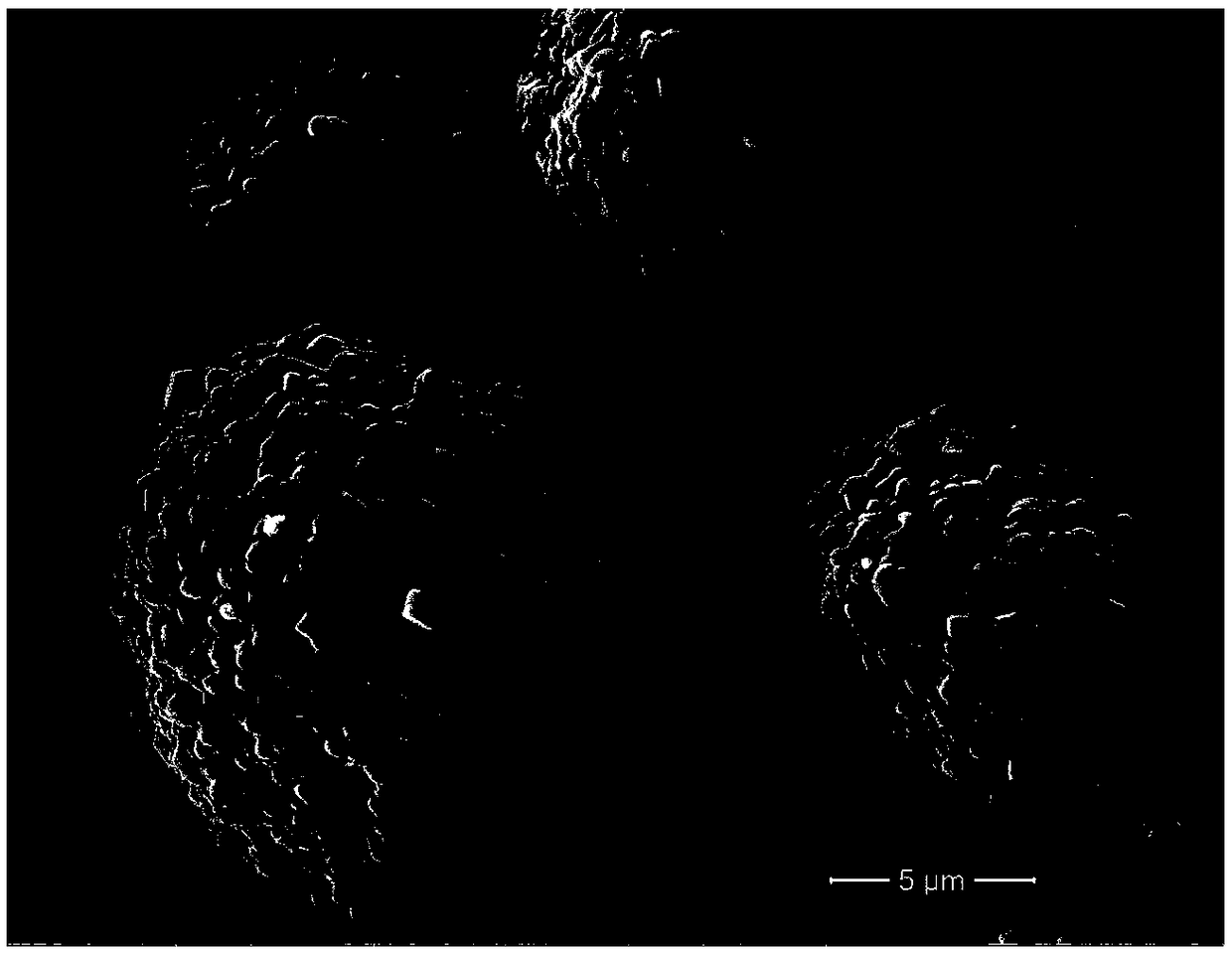

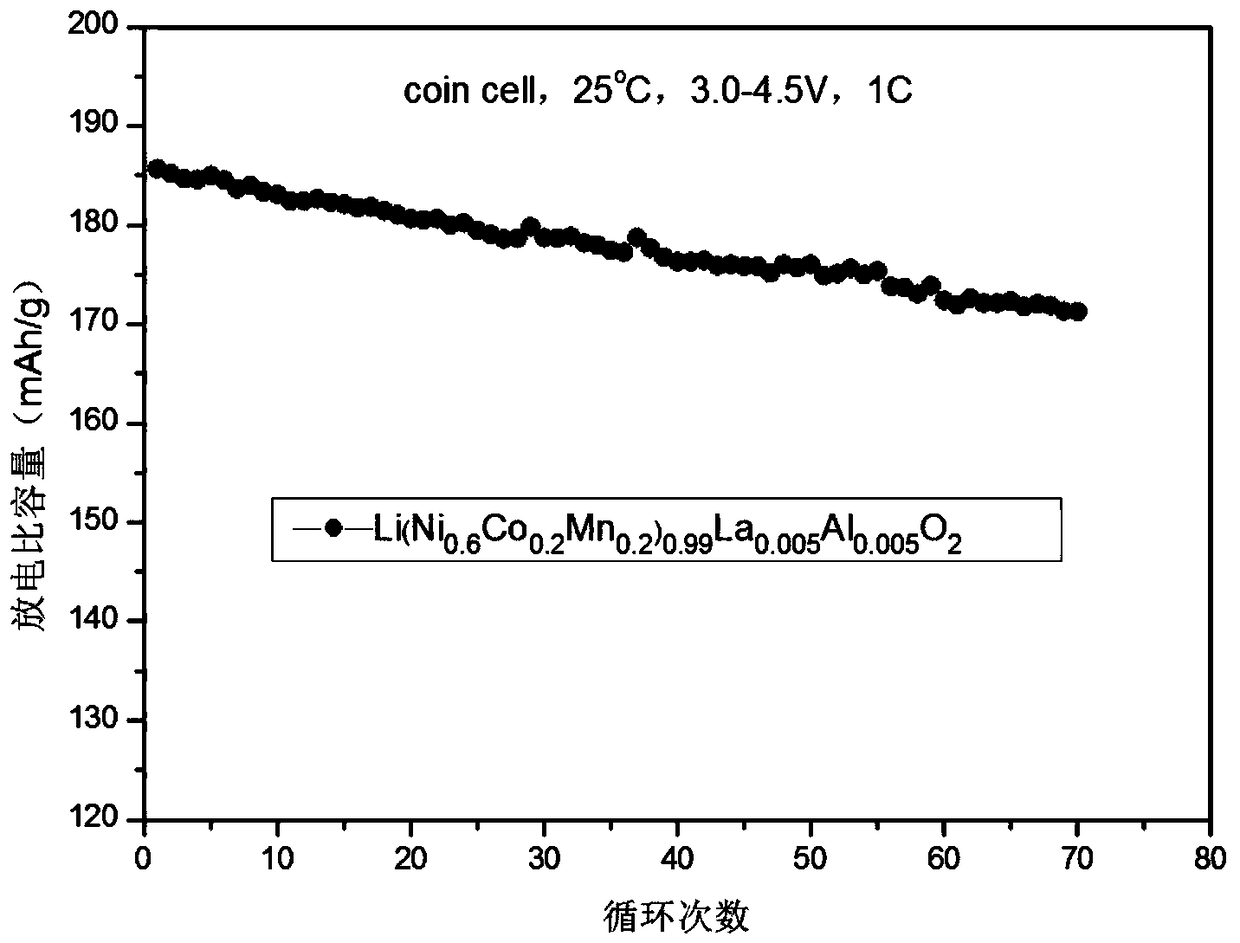

InactiveCN108807975ASolve the problem of rapid capacity decayPromote migrationCell electrodesSecondary cellsManganateLanthanum

The invention discloses a nickel-cobalt lithium manganate positive electrode material applied to high-voltage lithium ion batteries. The chemical formula of nickel-cobalt lithium manganate is Li(NixCoyMn1-x-y)1-a-bLaaAlbO2, wherein a is greater than or equal to 0 and is less than or equal to 0.05, b is greater than or equal to 0 and is less than or equal to 0.1, x is greater than or equal to 0.3 and is less than or equal to 0.8, and y is greater than or equal to 0.05 and is less than or equal to 0.4. A preparation method of the nickel-cobalt lithium manganate positive electrode material comprises the following steps: carrying out ball milling and mixing a nickel-cobalt-manganese precursor, a lanthanum source, an aluminum source and lithium salt in a horizontal ball mill, then pre-sinteringthe obtained mixture in a muffle furnace, then carrying out secondary ball milling and mixing the obtained mixture in the horizontal ball mill, and finally sintering the obtained mixture in a high-temperature tubular furnace to obtain a final product which is nickel-cobalt lithium manganate used as a positive electrode material. According to the nickel-cobalt lithium manganate positive electrodematerial, La and Al are co-doped in the nickel-cobalt lithium manganate positive electrode material; the interplanar crystal spacing can be increased, so that the migration of lithium ions can be accelerated; the stability of the lithium-free state of the crystal structure under high voltage can be improved; meanwhile, the crystal lattice volume and the stress expansion can be effectively reduced;the nickel-cobalt lithium manganate positive electrode material has the characteristics of high capacity and excellent cycle performance under high voltage; the disordered-ordered phase change underhigh voltage of the nickel-cobalt lithium manganate positive electrode material can be effectively inhibited; the problem of rapid capacity attenuation of the material in cycle under high voltage is solved, so that the service life of the lithium ion batteries can be prolonged.

Owner:ETRUST POWER ETP GRP LTD

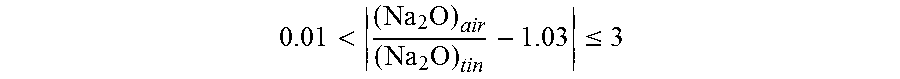

Glass sheet capable of having controlled warping through chemical strengthening

The invention relates to a float glass sheet having a boron- and lithium-free glass composition comprising the following in weight percentage, expressed with respect to the total weight of glass: 65≤SiO2≤78% 5≤Na2O≤20% 0≤K2O<5% 1≤Al2O3<6% 0≤CaO<4.5% 4≤MgO≤12% a (MgO / (MgO+CaO)) ratio≥0.5 characterized in that the glass sheet has: (I). The invention corresponds to an easy chemically-temperable soda-silica type glass composition, which is more suited for mass production than aluminosilicate glass, and therefore is available at low cost, and with a base glass / matrix composition that is close to or very similar to compositions already used in existing mass production, and finally which shows reduced or controlled increased warping effect.

Owner:AGC GLASS EUROPE

Method for preparing metal lithium battery with ultra-high energy density

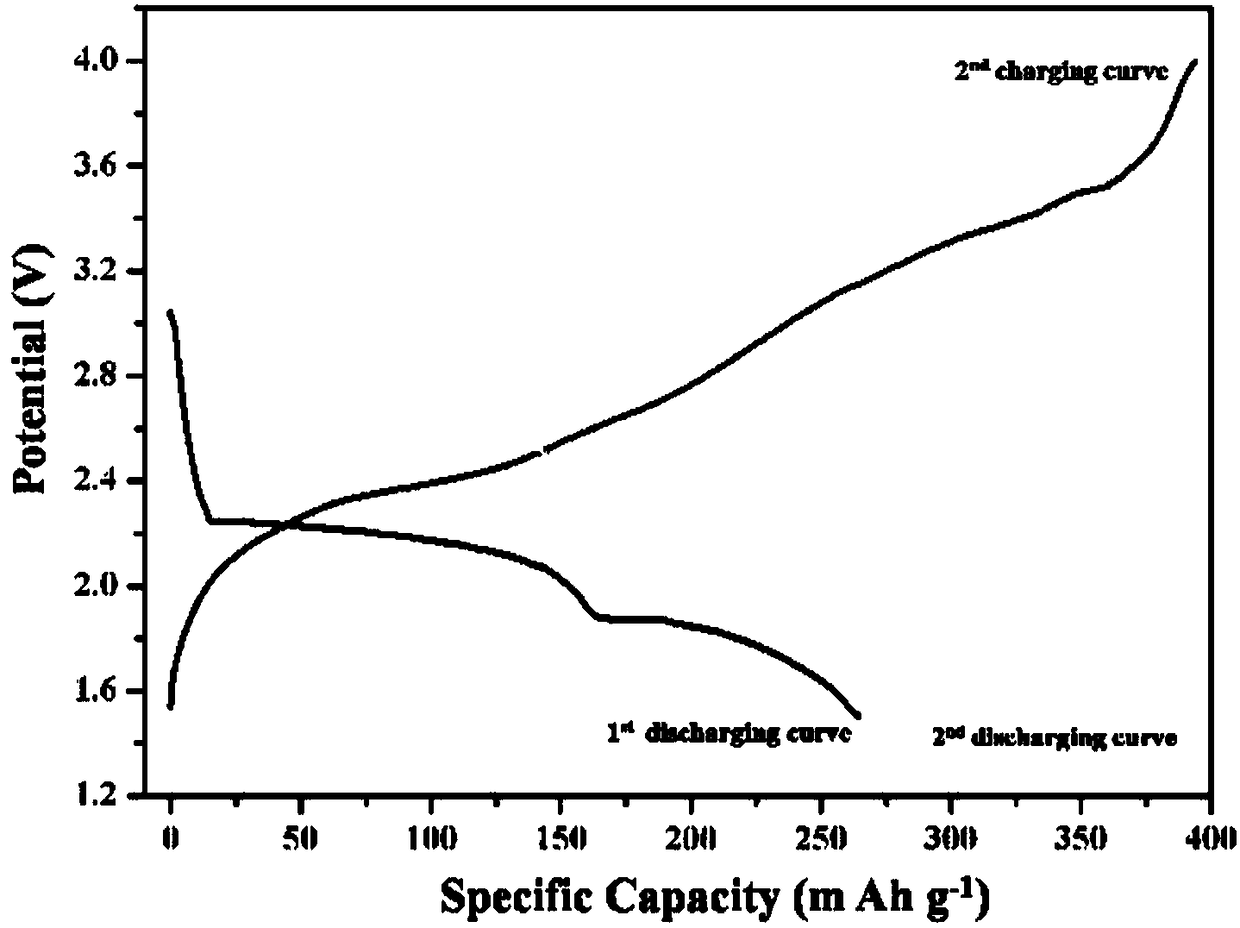

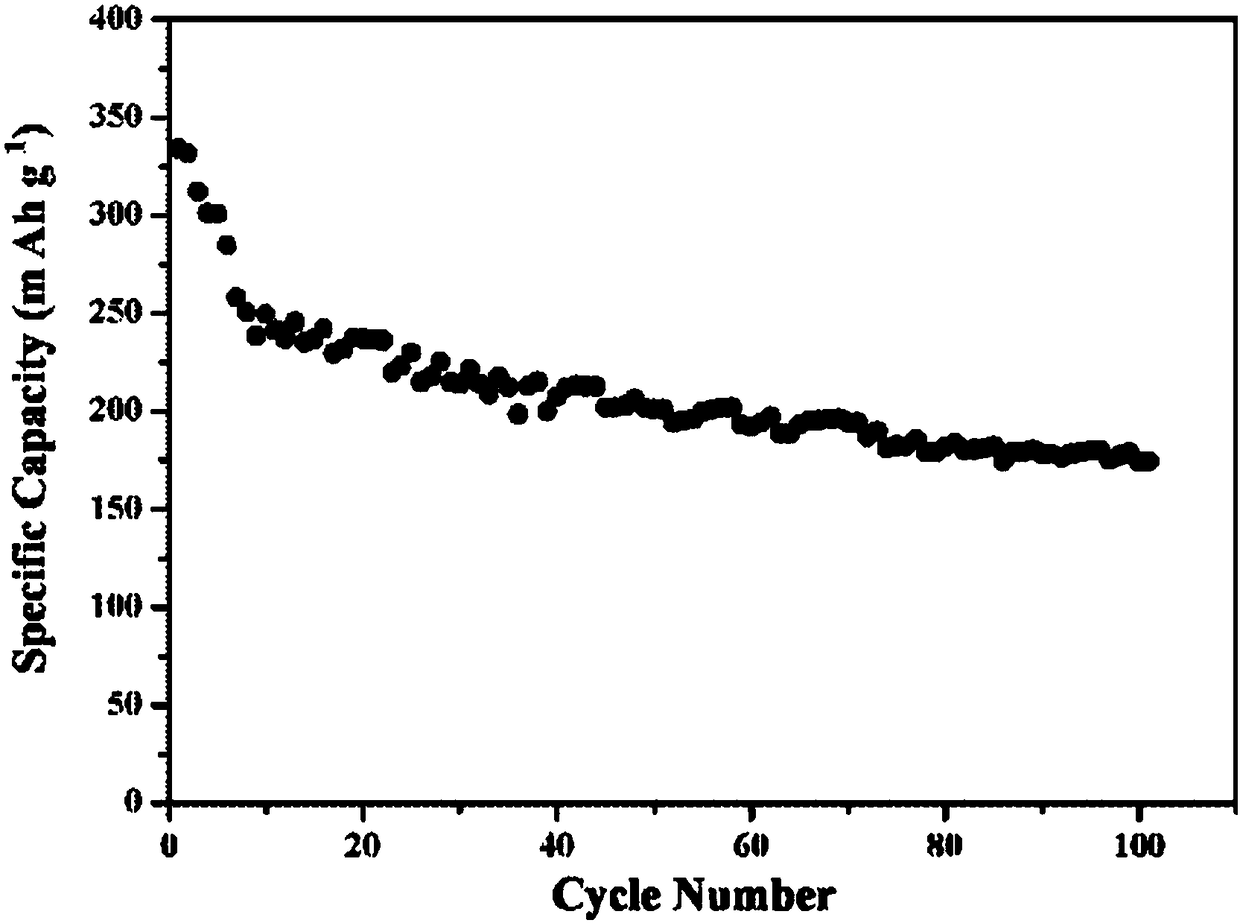

InactiveCN108346779AIncrease energy densityFlexible collocationFinal product manufactureCell electrodesHigh energyNickel–lithium battery

The invention provides a method for preparing a metal lithium battery with ultra-high energy density. The preparation method comprises the following steps: preparing a metal lithium powder / graphite negative electrode slice surface-coated with a metal lithium powder layer and a vanadium pentoxide positive electrode slice; with a Celgard polymer film as a diaphragm material and an organic solvent containing lithium hexafluorophosphate as an electrolyte, assembling the metal lithium powder / graphite negative electrode slice and the vanadium pentoxide positive electrode slice in a glove box with argon protection so as to form a button type lithium battery, and carrying out standing and ageing; subjecting the aged lithium battery to initial discharging to a voltage of 1.5 V, wherein discharge current is 0.05 C; and charging the lithium battery having undergone initial discharging with a current of 0.1 C until the voltage is 4.0 V so as to obtain the metal lithium battery which can work normally. According to the invention, the lithium-free positive electrode material vanadium pentoxide is adopted, and the metal lithium powder is introduced into the graphite negative electrode slice, so the vanadium pentoxide-metal lithium / graphite battery with ultra-high energy density is formed; and the preparation method has the advantages of simple process, easy enlargement production and large-scale application potential.

Owner:武汉理工力强能源有限公司

Composite current collector for lithium battery without lithium negative electrode and preparation method of composite current collector

PendingCN114784288AHigh activityEnhanced inhibitory effectElectrode carriers/collectorsLi-accumulatorsOrganic solventEngineering

The invention discloses a composite current collector for a lithium battery without a lithium negative electrode and a preparation method of the composite current collector, and belongs to the technical field of lithium ion battery material preparation. The problems that dead lithium is easily gathered on the surface of an existing current collector, so that active lithium in a negative-electrode-free lithium battery system is insufficient, battery operation cannot be supported, an SEI film formed on the surface is poor in mechanical performance, and continuous reaction between an electrolyte and a negative electrode cannot be effectively blocked are solved. According to the invention, the carbon paper is taken as the substrate and is soaked in the organic solvent containing the strong reducing compound to form the composite current collector, so that the dead lithium activation and inhibition capability of the current collector is effectively improved, the active lithium resource in a negative-electrode-free lithium battery system is protected, and the cycle performance of the battery is further remarkably improved.

Owner:HARBIN INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com