Lithium metal battery with high specific energy

A lithium metal battery, high ratio technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of increasing cost and safety hazards, hindering the practical application of lithium metal batteries, reducing battery energy density, etc., to achieve cost reduction and safety Hidden dangers, low manufacturing cost, and the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

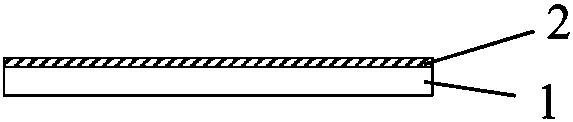

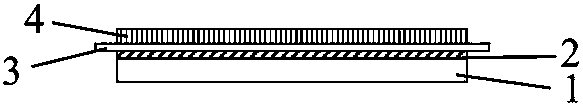

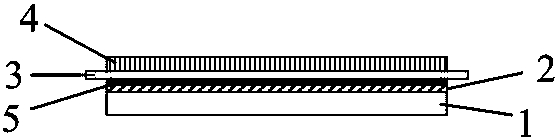

[0027] A layer of indium metal layer with a thickness of 100nm was evaporated on the surface of the copper foil by thermal evaporation as the negative electrode ( figure 1 ), and Li-rich material Li 1.2 mn 0.6 Ni 0.2 o 2 Positive electrode, carbonate-based electrolyte (solute is 1M LiPF 6 , the solvent is EC:DMC:DEC with a volume ratio of 1:1:1) and the polypropylene separator is assembled in an argon-filled glove box (water, oxygen content ≤ 1ppm) to assemble the battery ( figure 2 ), and test the battery performance after 12 hours of storage. The test temperature is 20°C, the charge and discharge voltage range is 2.0-4.8V, the battery is activated at 0.1C (1C=300 mAh / g) for 3 times and then cycled at 1C. After one cycle, a thin layer of uniform and dense metal lithium ( image 3 ). After 500 cycles, the capacity retention rate of the battery is 90.2%, and the average Coulombic efficiency is 97.1%. For pouch batteries, the thickness of the copper foil is 10 μm, the t...

Embodiment 2

[0029] A layer of zinc metal layer with a thickness of 50nm was evaporated on the surface of the nickel foil by thermal evaporation as the negative electrode ( figure 1 ), and Li-rich material Li 1.2 mn 0.54 Ni 0.16 co 0.10 o 2 Positive electrode, carbonate-based electrolyte (solute is 1M LiPF 6 , the solvent is EC:DMC:DEC with a volume ratio of 1:1:1) and the polypropylene separator is assembled in an argon-filled glove box (water, oxygen content ≤ 1ppm) to assemble the battery ( figure 2 ), and test the battery performance after 12 hours of storage. The test temperature is 20°C, the charge and discharge voltage range is 2.0-4.8V, 0.1C (1C=300mAh / g) is activated for 3 times and then cycled at 1C. After one cycle, a thin layer of uniform and dense metal lithium ( image 3 ). After 500 cycles, the capacity retention rate of the battery is 91.6%, and the average Coulombic efficiency is 96.9%. For pouch batteries, the thickness of the nickel foil is 10 μm, the thickness...

Embodiment 3

[0031] A tin metal layer with a thickness of 100 nm is evaporated on the surface of foamed copper by thermal evaporation as a negative electrode ( figure 1 ), and Li-rich material Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 Positive electrode, carbonate-based electrolyte (solute is 1M LiPF 6 , the solvent is EC:DMC:DEC with a volume ratio of 1:1:1) and the polypropylene separator is assembled in an argon-filled glove box (water, oxygen content ≤ 1ppm) to assemble the battery ( figure 2 ), and test the battery performance after 12 hours of storage. The test temperature is 20°C, the charge and discharge voltage range is 2.0-4.8V, 0.1C (1C=300mAh / g) is activated for 3 times and then cycled at 1C. After one cycle, a thin layer of uniform and dense metal lithium ( image 3 ). After 500 cycles, the capacity retention rate of the battery is 93.8%, and the average Coulombic efficiency is 97.4%. For pouch batteries, the thickness of foamed copper is 20μm, the thickness of the separato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com