Silicone adhesive composition and adhesive tape

A technology of silicone adhesives and compositions, applied in the direction of film/sheet adhesives, non-polymer adhesive additives, adhesives, etc. To solve problems such as poor capacitance and insufficient curing, achieve the effects of favorable process and price, excellent adhesion, and excellent antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0401] [Embodiment 1: the first scheme]

[0402] Embodiment 1 is about the embodiments and comparative examples of the first scheme. Each component used in the following Examples and Comparative Examples is as follows. In the following, the viscosity is a value at 25° C. measured using a Brookfield rotational viscometer (BM type viscometer).

[0403] (A) Addition curing silicone

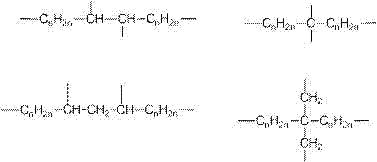

[0404] ・Polysiloxane (a1): Both ends of the molecular chain are covered with dimethylvinylsilyl (SiMe 2 Vi group) end-capped vinyl-containing polydimethylsiloxane has a viscosity of 27000mPa·s in 30% toluene solution, and has a vinyl content of 0.075 mol%.

[0405] ・Polysiloxane (a2): Both ends of the molecular chain are covered with dimethylvinylsilyl (SiMe 2 Vi group) end-capped vinyl-containing polydimethylsiloxane has a viscosity of 27000mPa·s in 30% toluene solution, and has a vinyl content of 0.15 mol%.

[0406] ・Silicone (b): by Me 3 SiO 0.5 Cell and SiO 2 Units of polysiloxane (Me 3 ...

Embodiment 1

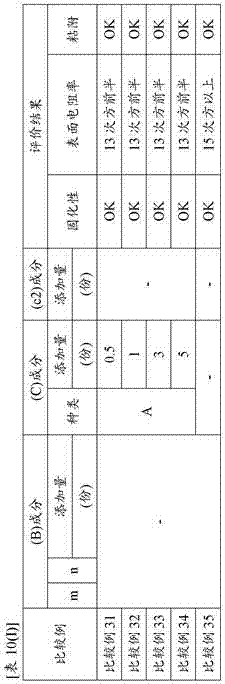

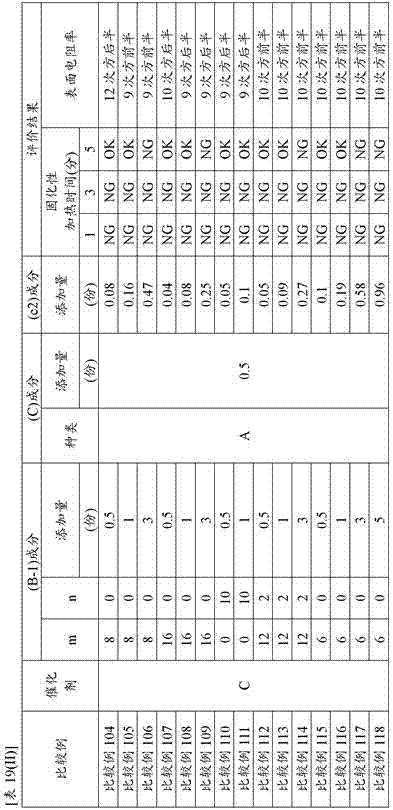

[0462] Use polyoxyalkylene compound (m=2, n=0) and ionic liquid A in embodiment 1 (I)~4 (I) and comparative example 1 (I) and 2 (I), changed polyoxyalkylene Amount of alkyl compound added. The results are shown in the following Table 1 (I) (the symbol (I) is omitted in the following table).

[0463]

Embodiment 5

[0465] Use polyoxyalkylene compound (m=8, n=0) and ionic liquid A in embodiment 5 (I)~8 (I) and comparative example 3 (I) and 4 (I), changed polyoxyalkylene Amount of alkyl compound added. The results are shown in the following Table 2 (I) (the symbol (I) is omitted in the following table).

[0466]

[0467] Silicone Adhesive Composition I-α

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com