Pre-embedding method of lithium ion super capacitor cathode

A supercapacitor, lithium ion technology, applied in capacitors, electrolytic capacitors, electrode manufacturing, etc., can solve the problems of difficult control of external short-circuit process, complex electrode group manufacturing process, harsh assembly environment requirements, etc., to improve capacitor safety performance, assembly The effect of process simplification and improvement of mass specific capacity and volume specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

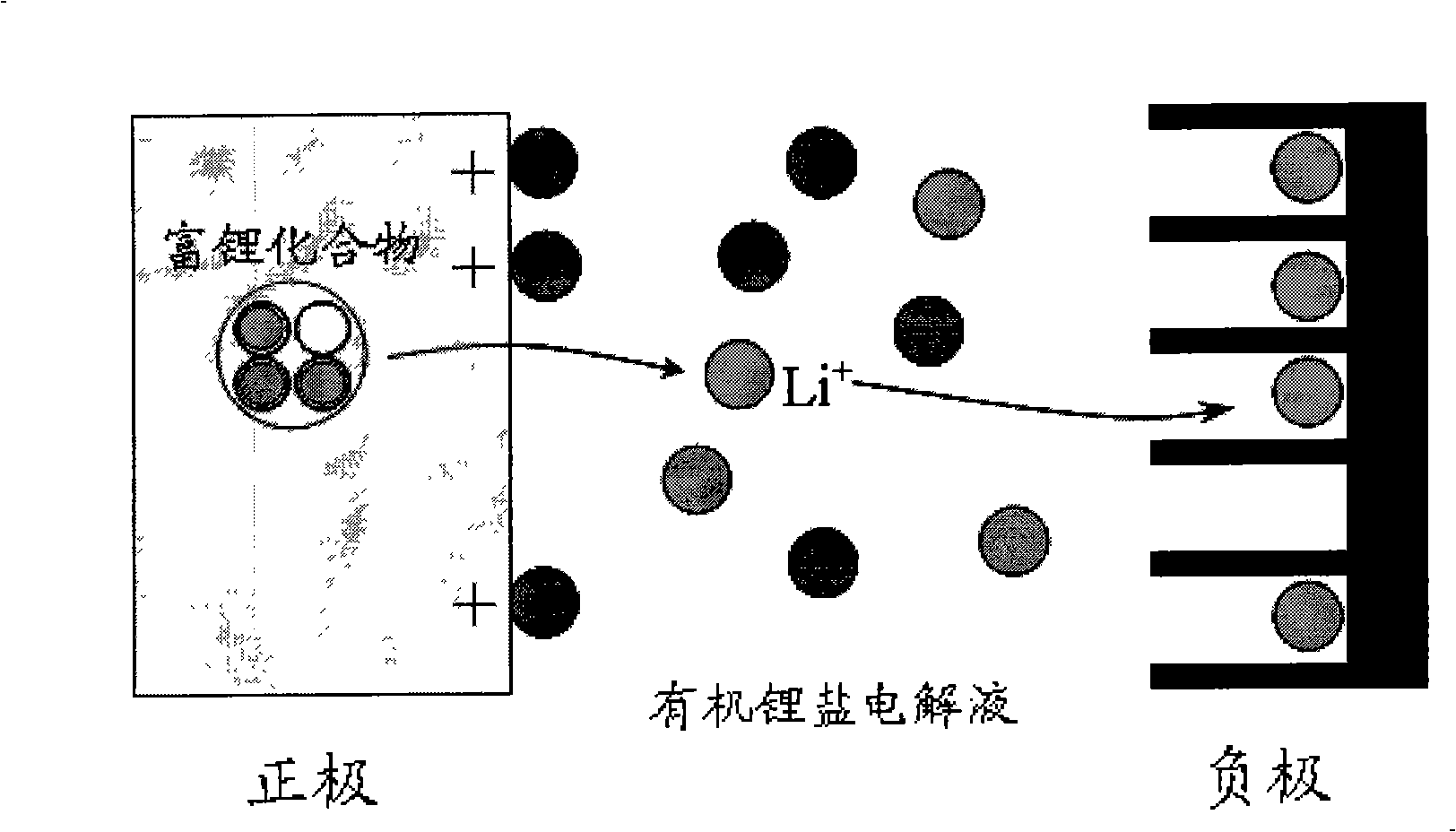

[0018] specific implementation plan

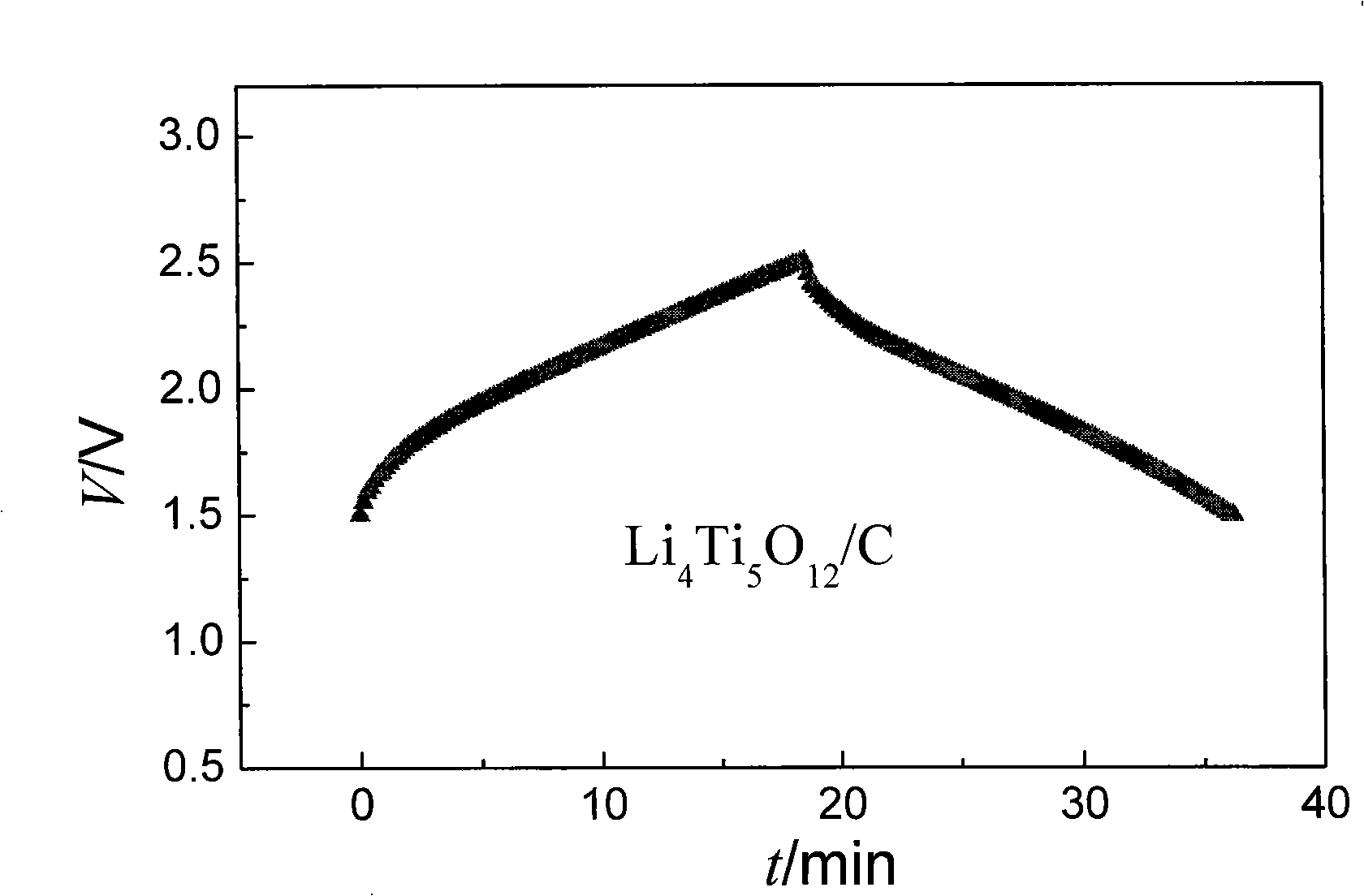

[0019] 1. Doping 10% lithium cobalt oxide, LiBF in the positive electrode of activated carbon powder 4 Acetonitrile solution as electrolyte, lithium titanium oxide Li4Ti 5 o 12 As the negative electrode, it is assembled into a lithium-ion supercapacitor. After 5 weeks of activation, the negative electrode is pre-intercalated with lithium at a depth of 5%. The operating voltage range of the capacitor is 1.0-2.8V. The symmetry of the charge-discharge curve is good, and the charge-discharge efficiency is close to 100%, the capacity loss of 5000 cycles of charge and discharge cycle is only 5%, the discharge capacity at 30C discharge rate can be maintained at more than 85% of the 1C discharge capacity, and the specific energy is higher than that of activated carbon / activated carbon electric double layer capacitance using the same electrolyte More than 4 times.

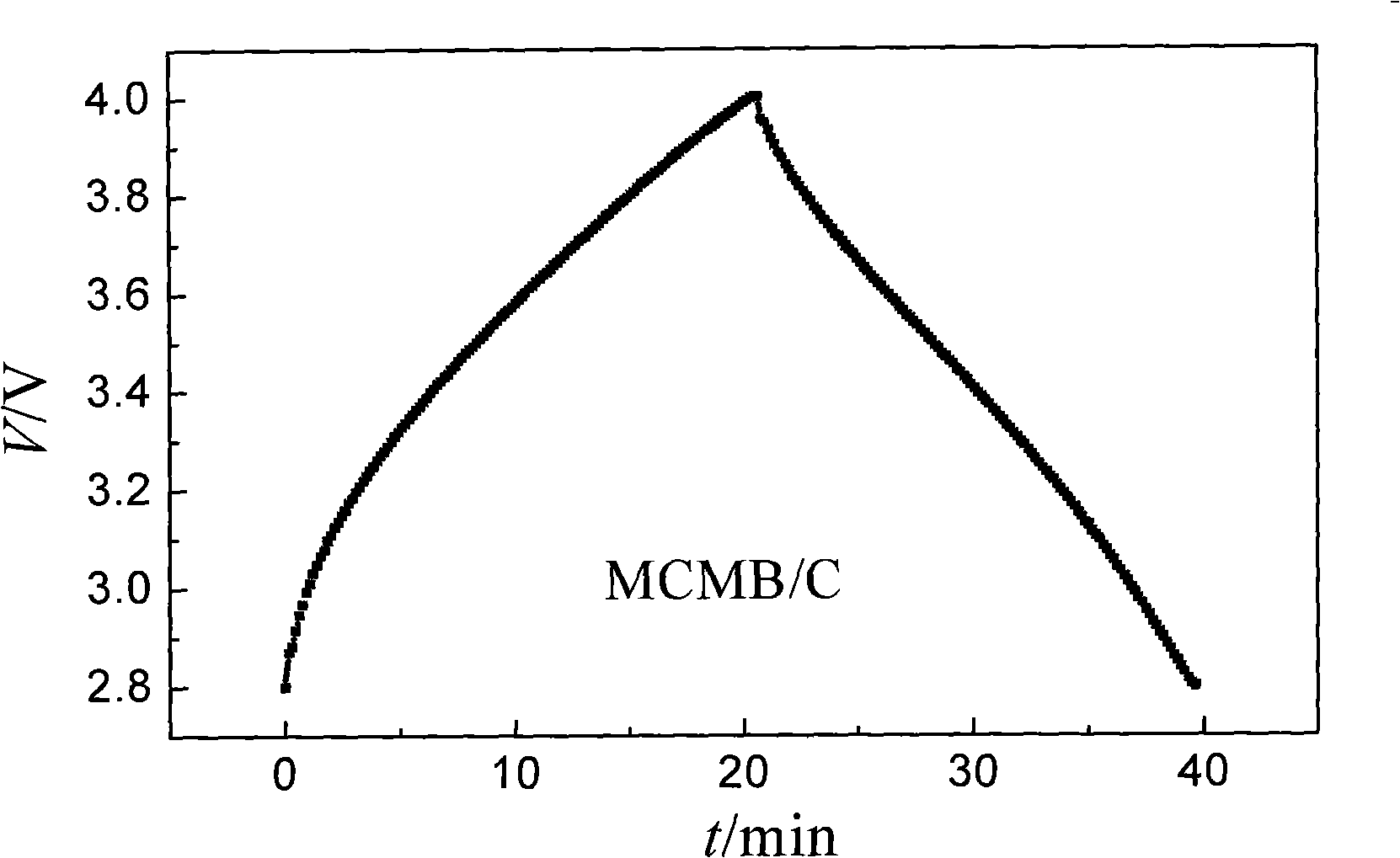

[0020] 2. Add 15% nickel-cobalt lithium manganese oxide and 1mol / L LiPF to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com