Windshield wiper structure for vehicles

a technology for windshield wipers and vehicles, applied in vehicle maintenance, vehicle cleaning, domestic applications, etc., can solve the problems of affecting the service life of windshield wipers, and easily falling off unexpectedly, so as to prolong the service life and prolong the service life. the effect of the wiper and the effect of reducing the cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

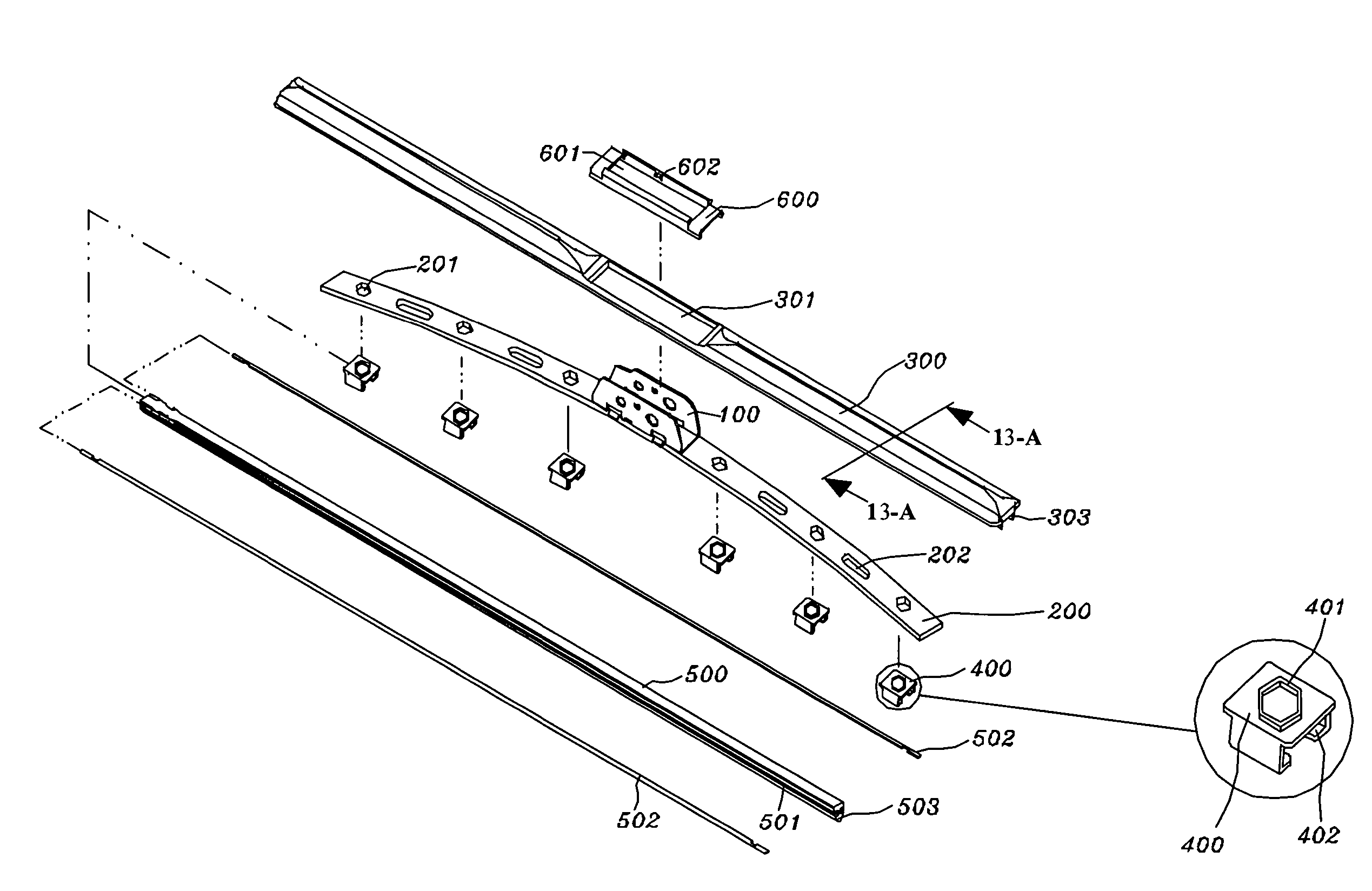

[0047] Referring to FIGS. 13, 14, 15, 16 and 17, a windshield wiper structure for vehicles according to a preferred embodiment of the present invention comprises a truss saddle 100, a bow elastic stripe 200, a cover body 300, a plurality of detachable clamping devices 400, a strip scraper 500 and a frame cover 600; wherein the truss saddle 100 is fixed on one end of the wiper arm (not shown in the figures) by means of wiper connector 700; the bow elastic stripe 200, which being made of metal in stripe of bow-shaped bending downward, and tightly affixed on the bottom side of the truss saddle 100 with a bottom surface of the truss saddle 100 abutting to a central top surface of the bow elastic stripe 200. Referring to FIG. 13, the bow elastic stripe 200 has a plurality of polygon holes 201 by punched on its body with equidistantly, and has a plurality of hollow pressure adjusting vents 202 between in said polygon holes 201 which having a aperture size being determined in coordination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com