Scraping structure of spray scraping machine

A technology of nozzles and scrapers, which is applied in the field of scraping structures of nozzle scrapers, can solve problems such as poor scraping effect, inability to fully clean the scraping block 14, and loss of cleaning agent, so as to improve the scraping effect and prolong the cleaning time. Longevity and wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

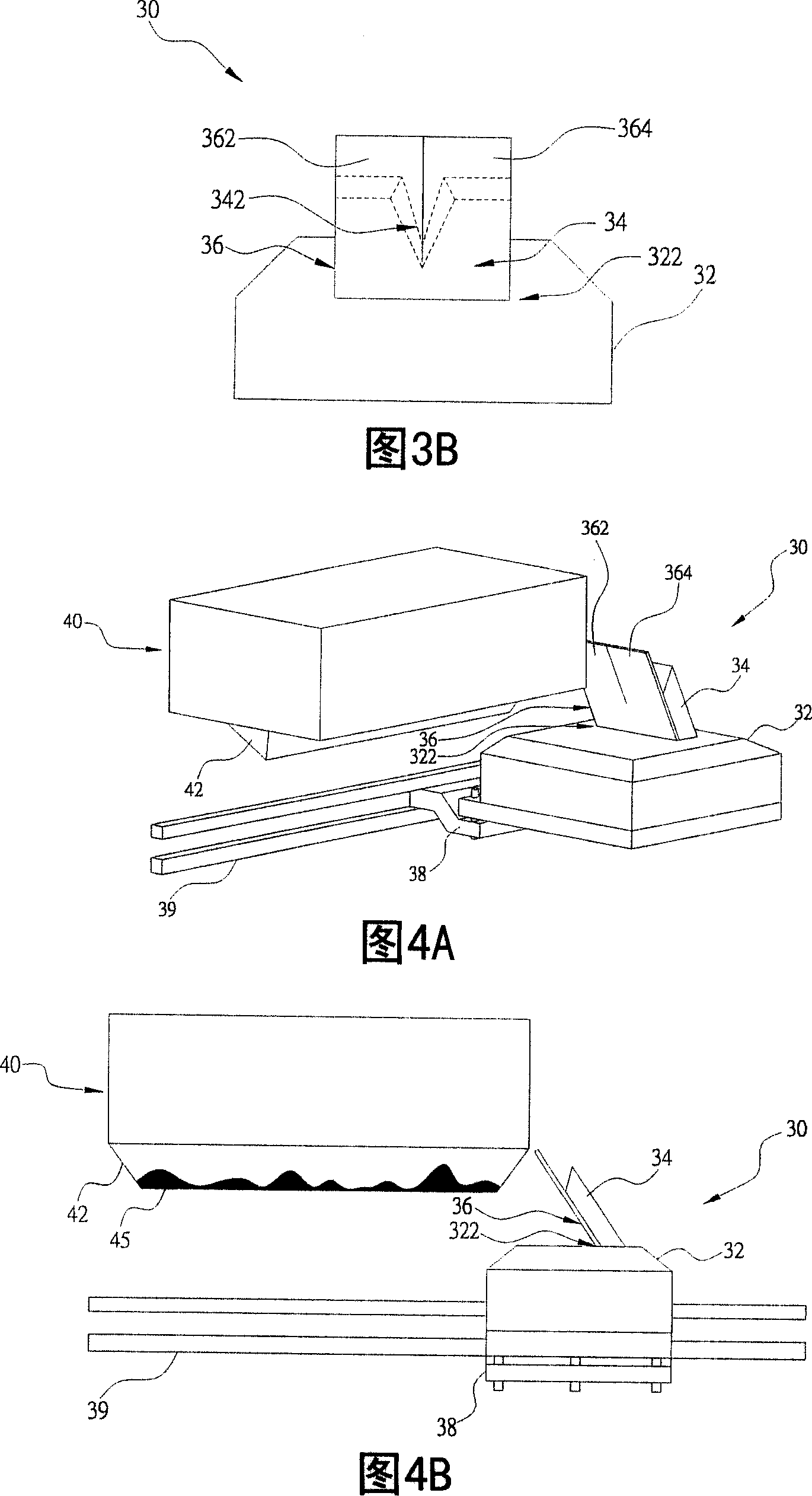

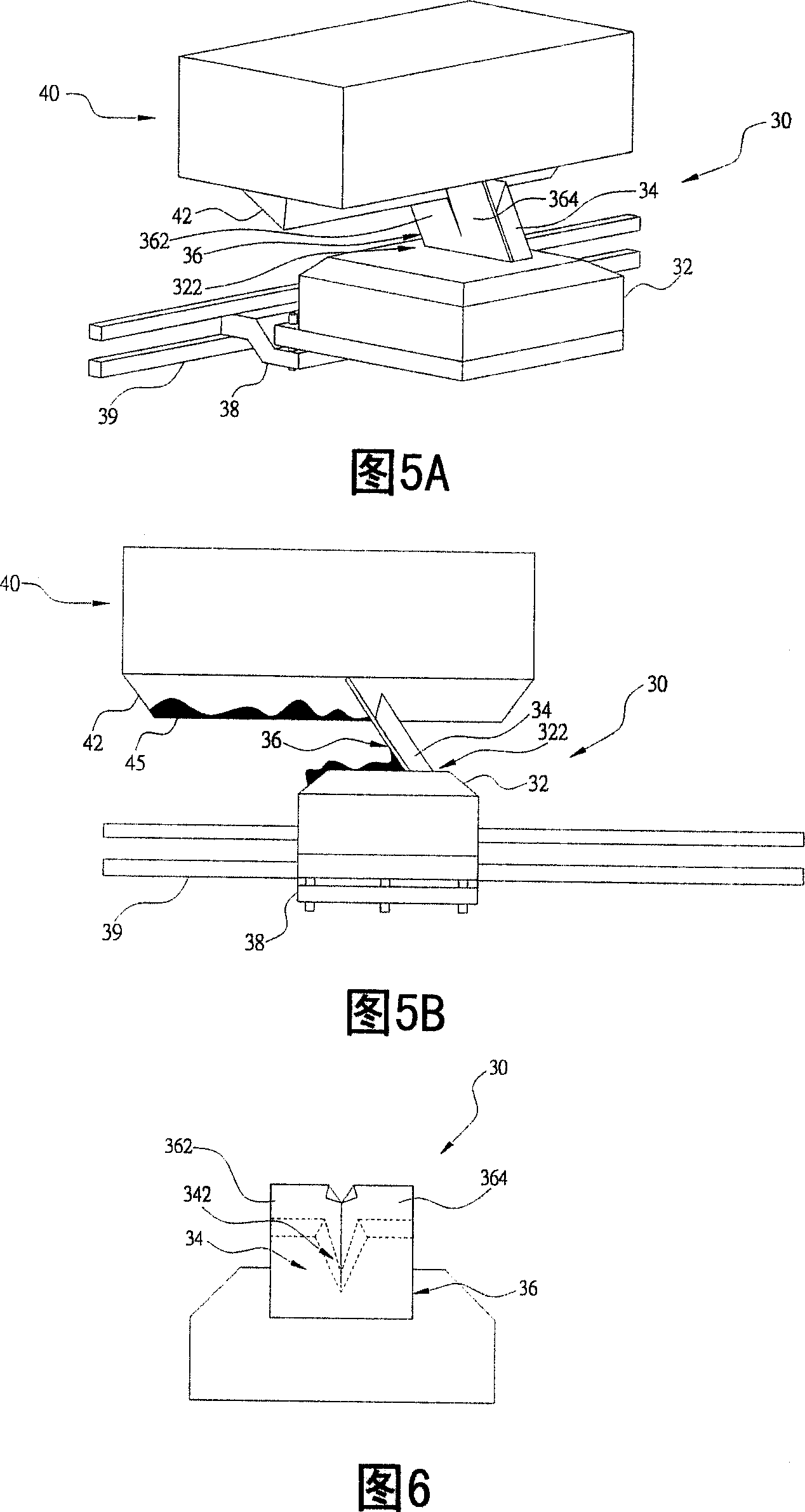

[0033] In order to have a further understanding and understanding of the structural features and the achieved effects of the present invention, a preferred embodiment and accompanying drawings will be described in detail, as follows:

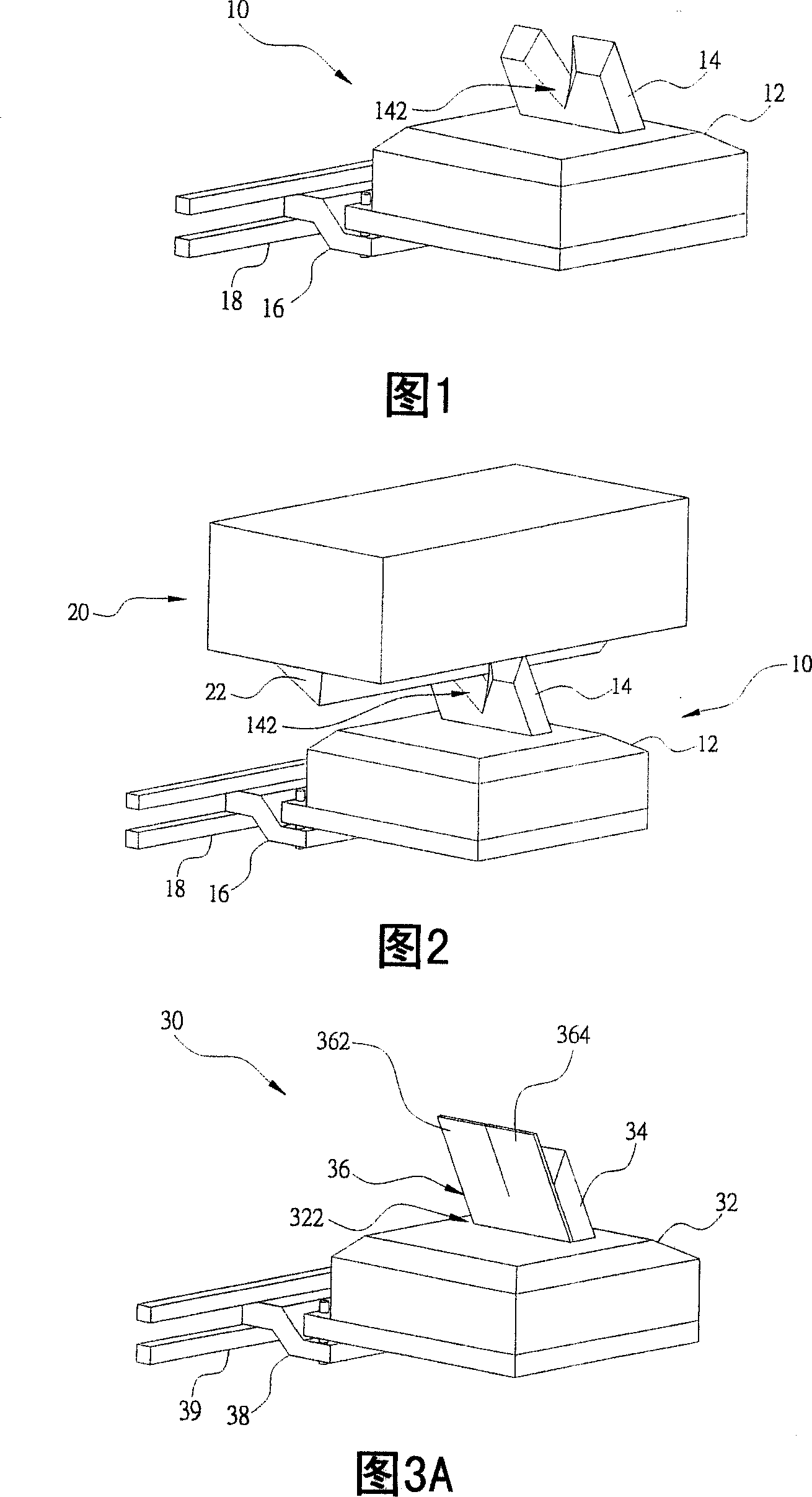

[0034] The invention relates to a scraping structure of a nozzle scraping machine, which improves the scraping effect of scraping coating material and gel remaining on the outside of a nozzle through a scraping piece and a scraping block. Moreover, the invention reduces the abrasion caused by scraping off the gel by the scraper block through the scraper sheet, thereby prolonging the service life of the scraper block.

[0035] Please refer to FIG. 3A and FIG. 3B , which are respectively a perspective view and a front view of a scraping structure of a preferred embodiment of the present invention; as shown in the figure, the scraping structure 30 of the present invention includes a base 32 and a scraping block 34 and a scraper 36. The base 32 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com