Atomizer for electronic cigarette and electronic cigarette

An atomizer and electronic cigarette technology, applied in the field of electronic cigarettes, can solve the problems of high cost, many parts, complex assembly process, etc., and achieve the effects of low cost, simple structure and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

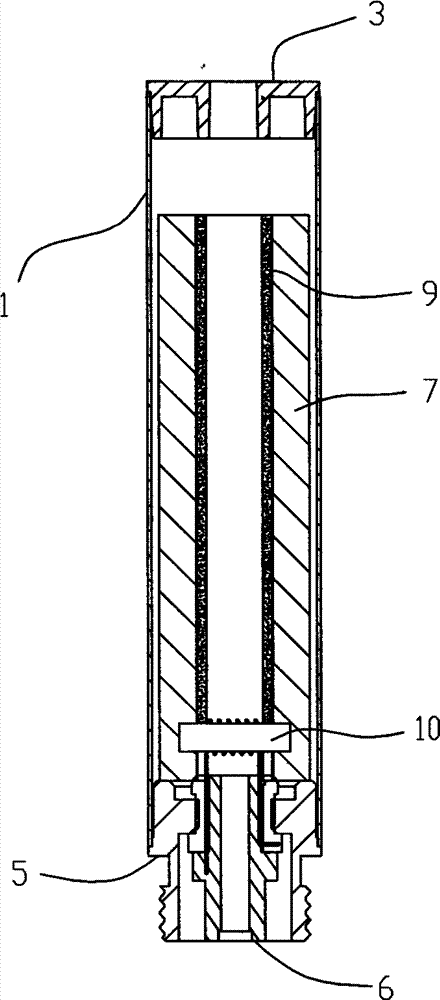

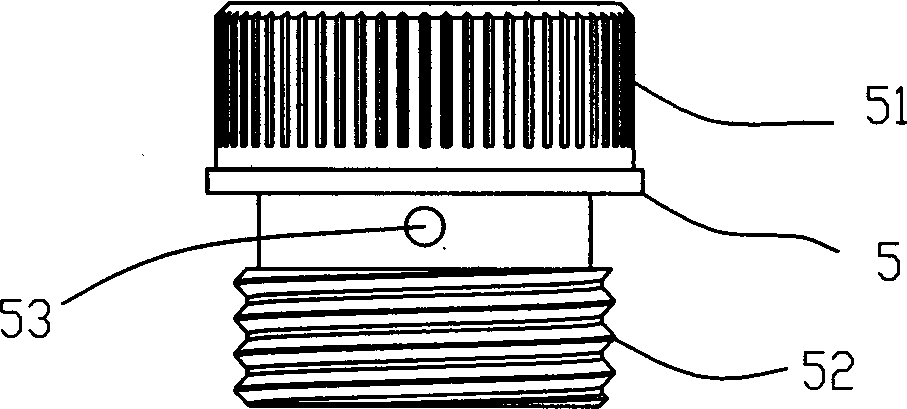

[0040] Such as figure 2As shown, an atomizer for electronic cigarettes includes an atomizing sleeve 1, a nozzle cover 3, a threaded sleeve 5, an electrode ring 6 fixedly arranged in the threaded sleeve 5, and an electrode ring 6 arranged in the atomizing sleeve 1. The oil storage substance and the heating wire assembly 10, an insulating ring 11 is arranged between the threaded sleeve 5 and the electrode ring 6, and the suction nozzle cover 3 and the threaded sleeve 5 are respectively tightly fitted on the two ends of the atomizing sleeve 1 , the two pins of the heating wire assembly 10 are respectively connected to the threaded sleeve 5 and the electrode ring 6; the oil storage substance is composed of at least two layers with different densities; the atomizer does not include glass fiber Tube 2.

[0041] An air flow channel is provided in the oil storage substance, and the heating wire assembly 10 is located in the channel. During operation, the heating wire assembly 10 ab...

specific Embodiment 2

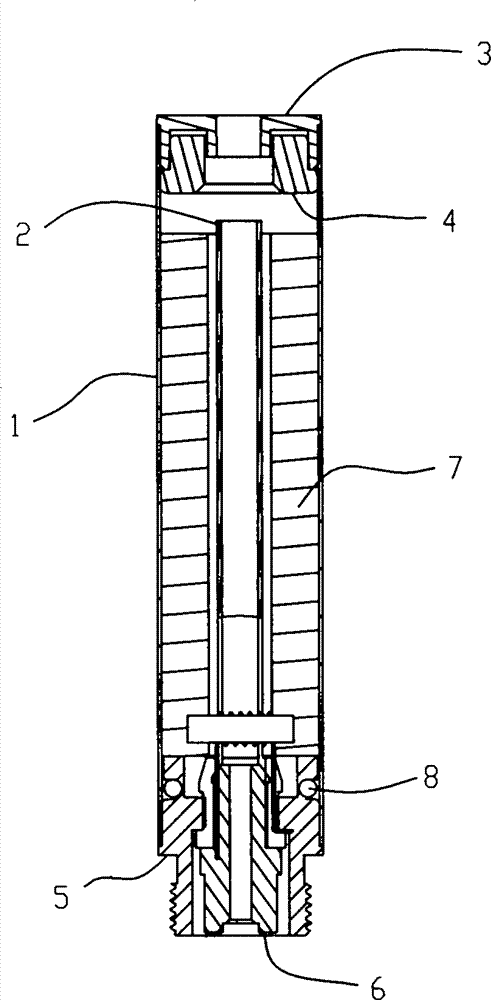

[0047] Such as Figure 5 , Figure 6 As shown, on the basis of including all the technical features in the specific embodiment 1, the main difference between this embodiment and the first embodiment is that it also includes a glass fiber tube 2, and the oil storage substance is wrapped in the glass fiber tube 2, the denser layer is close to the glass fiber tube 2, that is, the cotton cloth layer 9 is wrapped on the outer surface of the glass fiber tube 2.

[0048] Such as Figure 7 As shown, the connecting end of the fiberglass tube 2 and the threaded sleeve 1 is provided with an opening, and the opening divides the fiberglass tube 2 into two connecting pieces 21 and connecting pieces 22 (of course, it can also be divided into three, Four connecting pieces, the purpose of this embodiment being divided into two connecting pieces is to reduce the installation quantity of the wedges, make the assembly easier, and improve the efficiency of the installation process.), the heating...

specific Embodiment 3

[0052] Such as Figure 9 As shown, the main difference between this embodiment and the second embodiment is: the wedge piece 12 is a ring structure, and the wedge piece 12 is also provided with a pressure groove 121 and a pressure groove 122 . The purpose of setting the pressure grooves 121 and 122 is to facilitate the access of the wedge piece 12 during assembly.

[0053] Another example Figure 9 As shown, the ring of the wedge piece 12 is also provided with an opening, and the opening on the wedge piece 12 is provided with a chamfer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com