Method for preparing metal lithium battery with ultra-high energy density

A technology of energy density and metal lithium, applied in the field of preparation of metal lithium batteries, can solve problems such as restricting the energy density of batteries, and achieve the effects of easy scale-up production, simple process, and ultra-high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

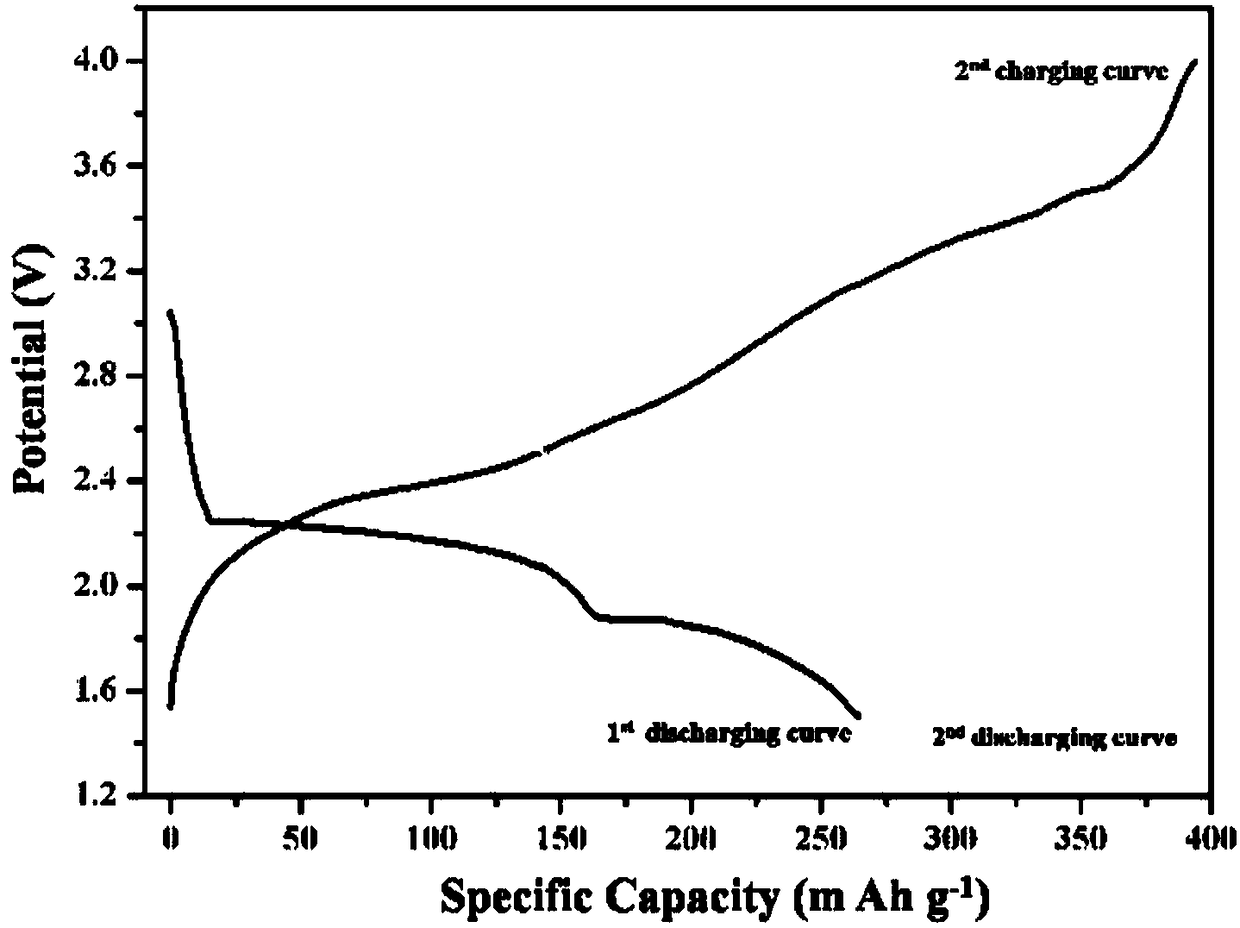

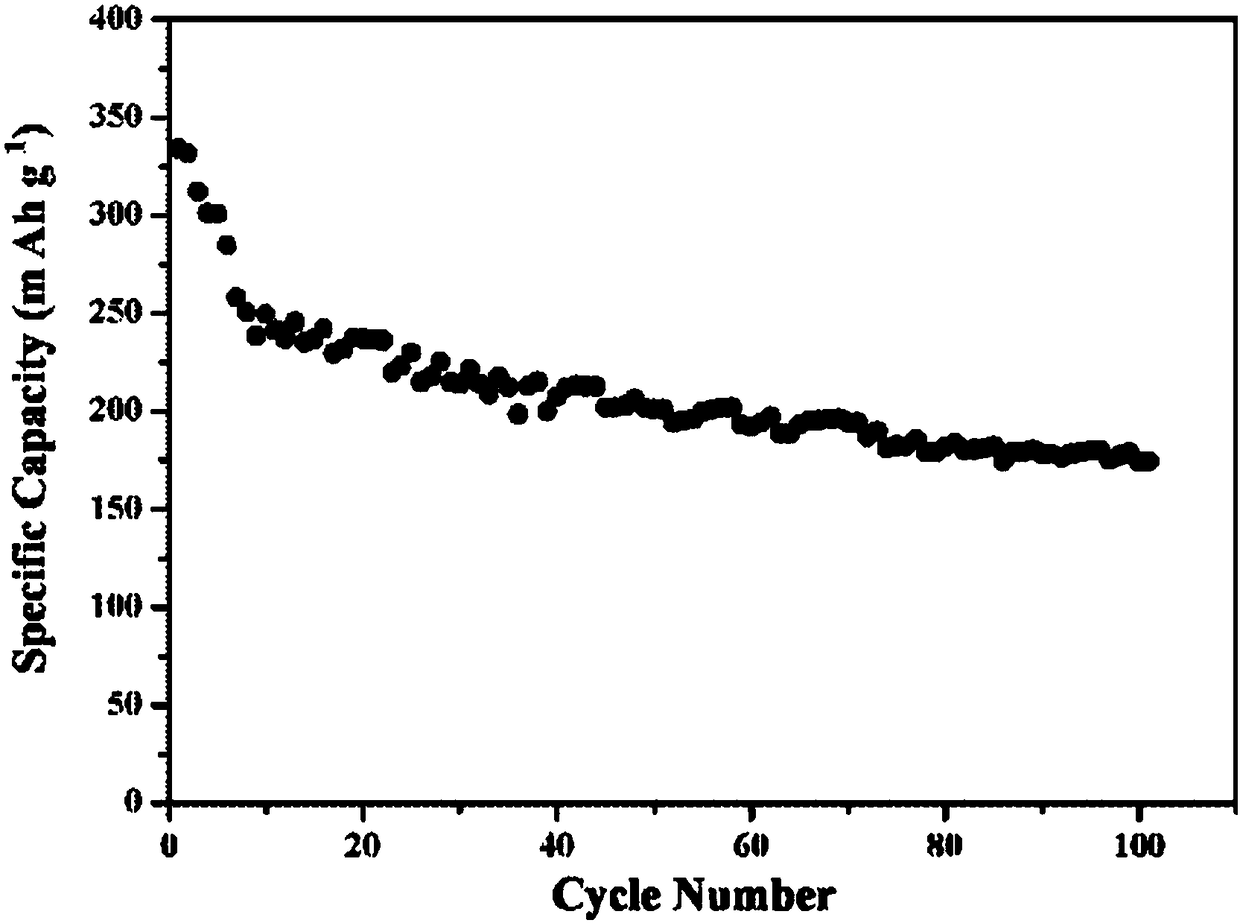

[0024] Example 1, see Figure 1 to Figure 2 :

[0025] The invention provides a method for preparing a metal lithium battery with ultra-high energy density, comprising the following steps:

[0026] 1) The metal lithium powder is coated on the graphite negative electrode sheet by the coating method, and stored in an argon-protected glove box at 60°C for 2 hours, and the metal lithium powder coated with the metal lithium powder layer is coated with a punching machine / The graphite electrode sheet is punched into a disc with a diameter of 14mm; the vanadium pentoxide is ball-milled by ball milling method, and then the slurry containing vanadium pentoxide is evenly coated on the aluminum sheet current collector by a coating machine. Dry for 10 hours, and use a punching machine to punch the vanadium oxide positive electrode sheet into a disc with a diameter of 14 mm;

[0027] 2) Using Celgard polymer film as diaphragm material, organic solvent containing 1mol / L lithium hexafluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com