Solid-state battery

A solid-state battery, solid electrolyte technology, applied in the direction of lithium battery, secondary battery, solid electrolyte, etc., can solve the problem of no solid-state battery work report, and achieve the effect of high utilization rate, high specific capacity and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

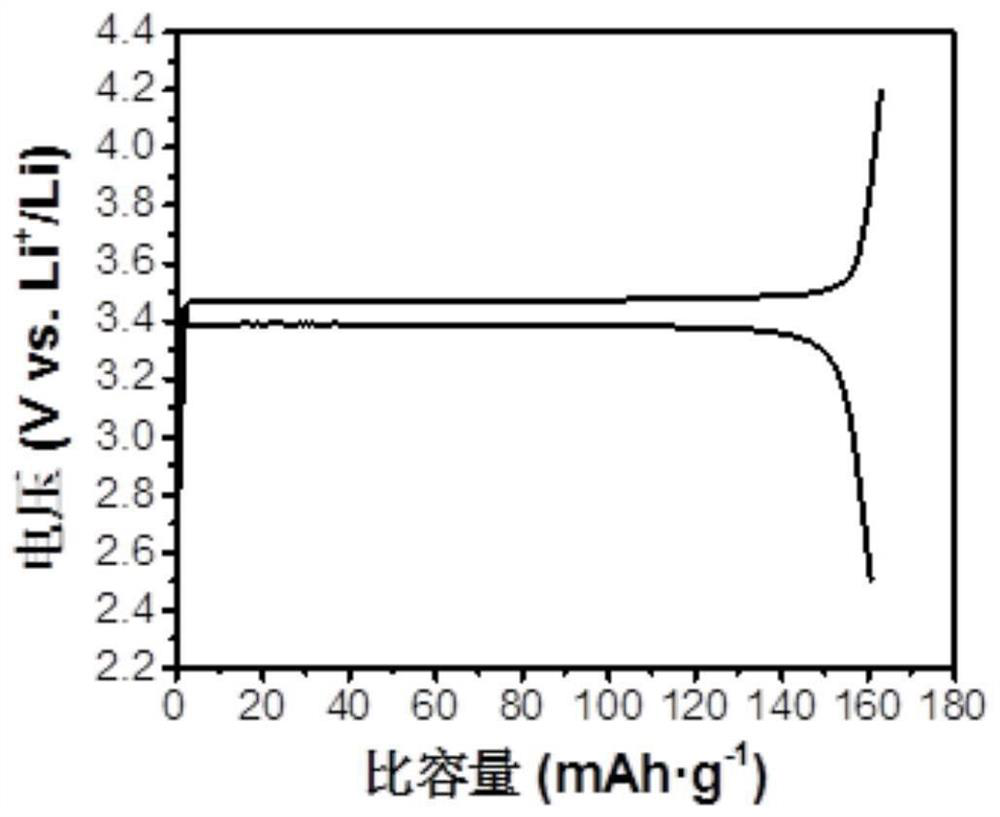

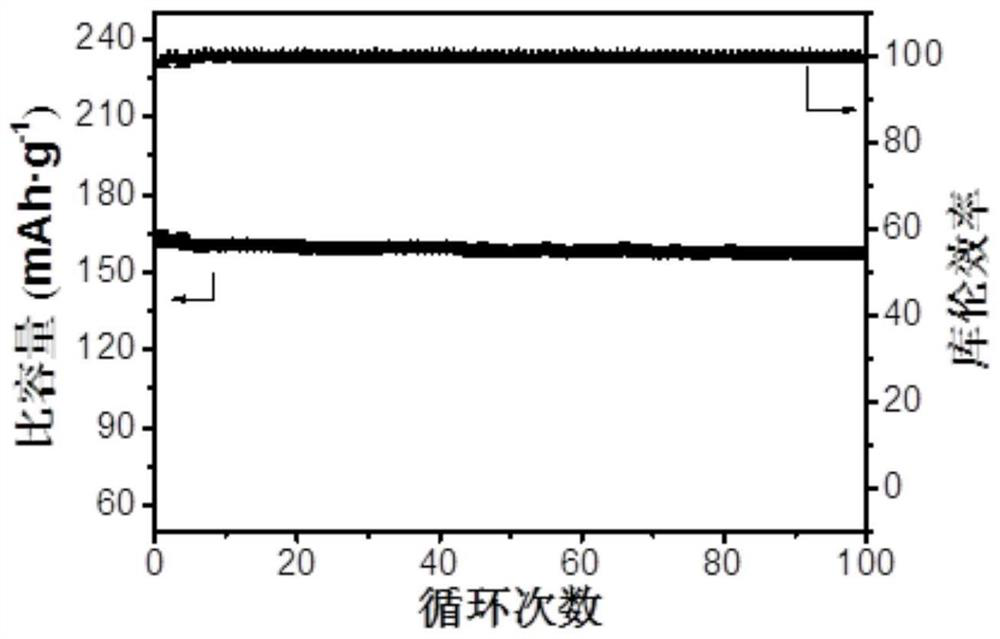

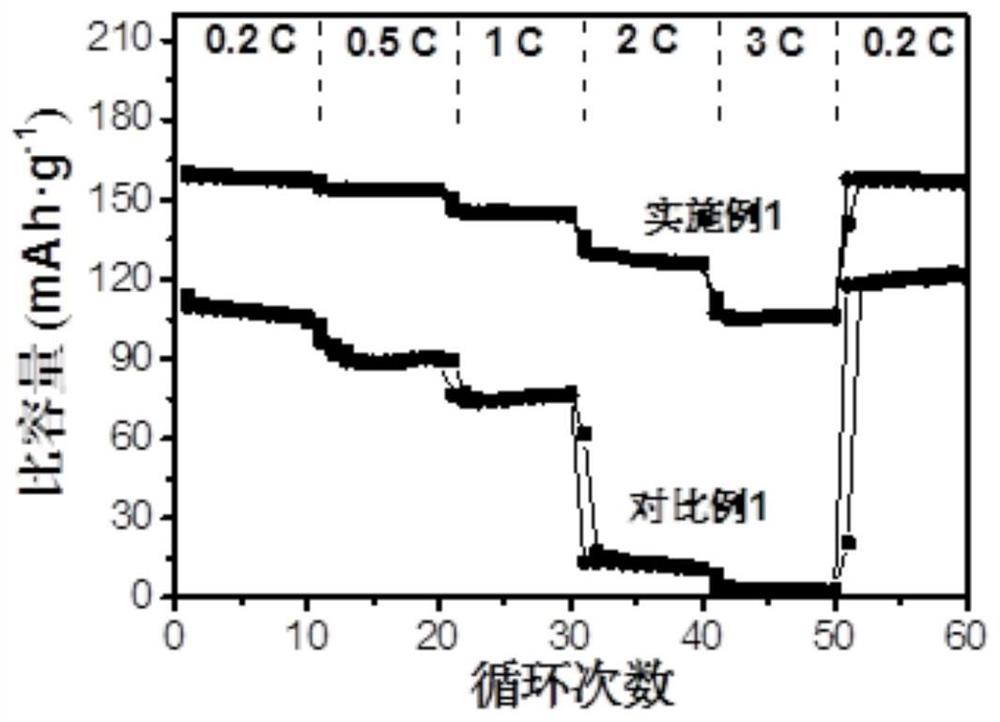

Embodiment 1

[0067] (1) Preparation of positive electrode: 80wt.% positive electrode active material LiFePO 4 , 10wt.% conductive agent acetylene black, 10wt.% polymer electrolyte polyethylene carbonate-LiFSI (mass ratio 10:1) and solvent NMP are mixed and mixed by stirring or ball milling to make a slurry. The solid content is 20%, and then the slurry is coated on one side of the aluminum foil current collector by coating, and then placed in a vacuum oven at 80°C for 24 hours, and then the positive electrode is compacted under 10MPa by cold pressing ;

[0068] (2) Preparation of organic-inorganic composite solid electrolyte separator: Li 7 La 3 Zr 2 o 12 Preparation of Inorganic Ceramic Oxide Fibers: LiNO 3 , La(NO 3 ) 3 6H 2 O, ZrO(NO 3 ) 2 Added to deionized water at a molar ratio of 7.7:3:2, in which LiNO 3 The concentration is 0.1mol / L, and 15wt.% PVP (molecular weight 1300,000) is added after dissolving. Then electrospinning to form a film: 15kV, 0.12mL / h. Li 7 La 3 Zr...

Embodiment 2

[0071] (1) Preparation of positive electrode: 75wt.% positive electrode active material LiNi 0.8 co 0.15 Al 0.05 o 2 , 10wt.% conductive agent Super-P, 15wt.% polymer electrolyte PVDF-LiTFSI (mass ratio 5:2) and solvent NMP are mixed and mixed by stirring or ball milling to make a slurry. The solid content of the slurry Then, the slurry was coated on one side of the aluminum foil current collector by coating, and then dried in a vacuum oven at 80°C for 24 hours, and then the positive electrode was compacted under 15MPa by cold pressing;

[0072] (2) Preparation of organic-inorganic composite solid electrolyte separator: 2,5-diamino-1,4-benzenedithiol dihydrochloride, bis(3-sodium sulfonate-4-carboxyphenyl)sulfone and 2, Sulfonated polybenzothiazole was prepared by direct polycondensation of 5-dicarboxyphenyl sulfone in polyphosphoric acid, and lithium polybenzothiazole sulfonate was prepared by ion exchange with LiOH. Prepare 7wt.% PVP (molecular weight 1300,000) aqueous s...

Embodiment 3

[0076] (1) Preparation of positive electrode: 50wt.% positive active material elemental sulfur, 10wt.% conductive agent Super-P and 10wt.% graphene, 30wt.% polymer electrolyte PEO-LiBF 4 (mass ratio 20:1) mixed with solvent ethanol and deionized water (volume ratio 1:1) and mixed by stirring or ball milling to make a slurry, the solid content of the slurry is 30%, and then coated with The slurry was coated on one side of the carbon-coated aluminum foil current collector, and then dried in a vacuum oven at 55°C for 24 hours, and then the positive electrode was cold-pressed at 1MPa;

[0077] (2) Preparation of organic-inorganic composite solid electrolyte diaphragm: preparation of polybenzimidazole sulfonamide lithium containing carboxyl lithium: 3,3'-diaminobiphenyl, diphenyl isophthalate, p-carboxybenzenesulfonamide Condensation at 180°C, H 2 SO 4 After sulfonation, LiOH aqueous solution replaced. Li 6 P.S. 5 Preparation of Cl ceramic particles: the Li 2 S:LiCl:P 2 S 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com