Three-dimensional graded porous current collector and preparation method thereof

A hierarchical porous and current collector technology, which is applied in the field of lithium-ion batteries, can solve the problems of small preparation scale, increased battery internal resistance, etc., and achieve the effect of increasing affinity and dispersing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

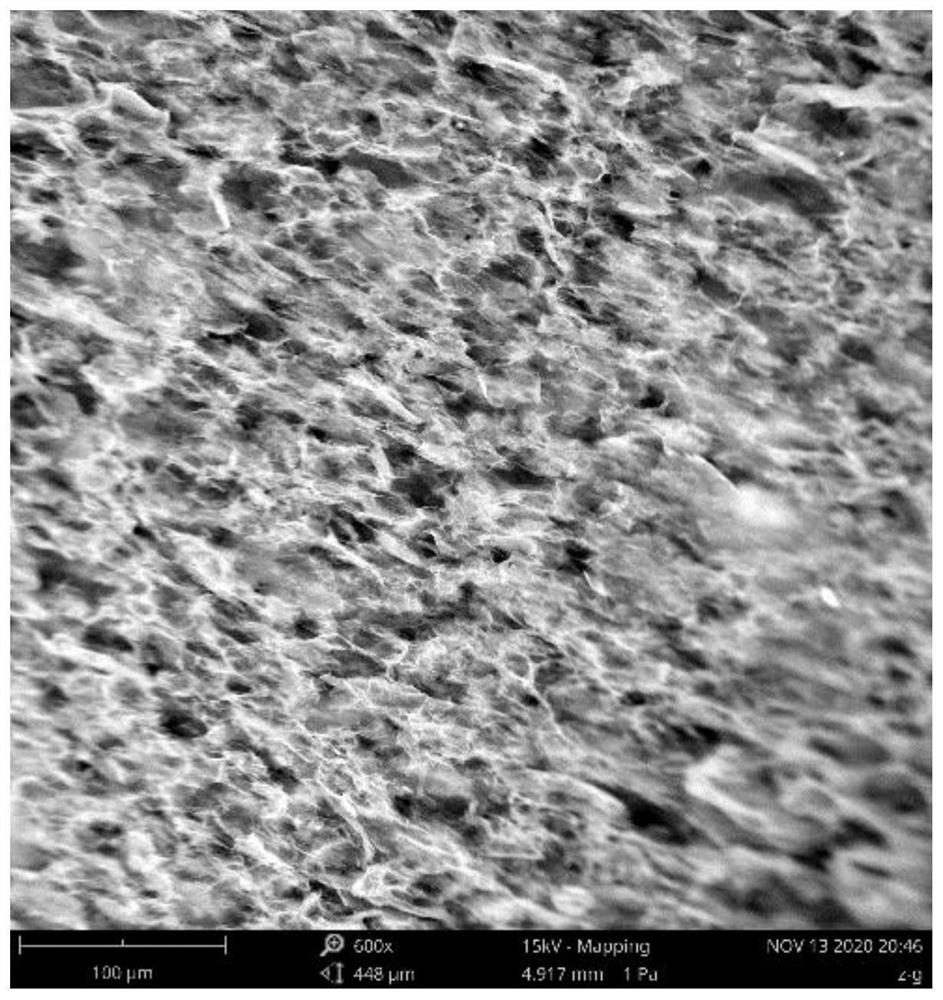

[0027] The invention provides a method for preparing a three-dimensional hierarchical porous current collector, comprising: S1) mixing a conductive agent, an adhesive, a pore-forming agent modified by a conductive polymer material, and a solvent to obtain a slurry; S2) coating the slurry On the surface of the current collector, after drying, the pore-forming agent is removed to obtain a three-dimensional hierarchical porous current collector; the decomposition temperature of the conductive polymer material is higher than that of the pore-forming agent.

[0028] The present invention adopts the existing lithium battery slurry technology, adds a pore-forming agent that can be volatilized at low temperature, and the volatilization of the pore-forming agent leaves holes to realize the construction of a three-dimensional current collector on a flat copper foil, which can not only realize the traditional three-dimensional current collector to achieve It can also be coated on a large ...

Embodiment 1

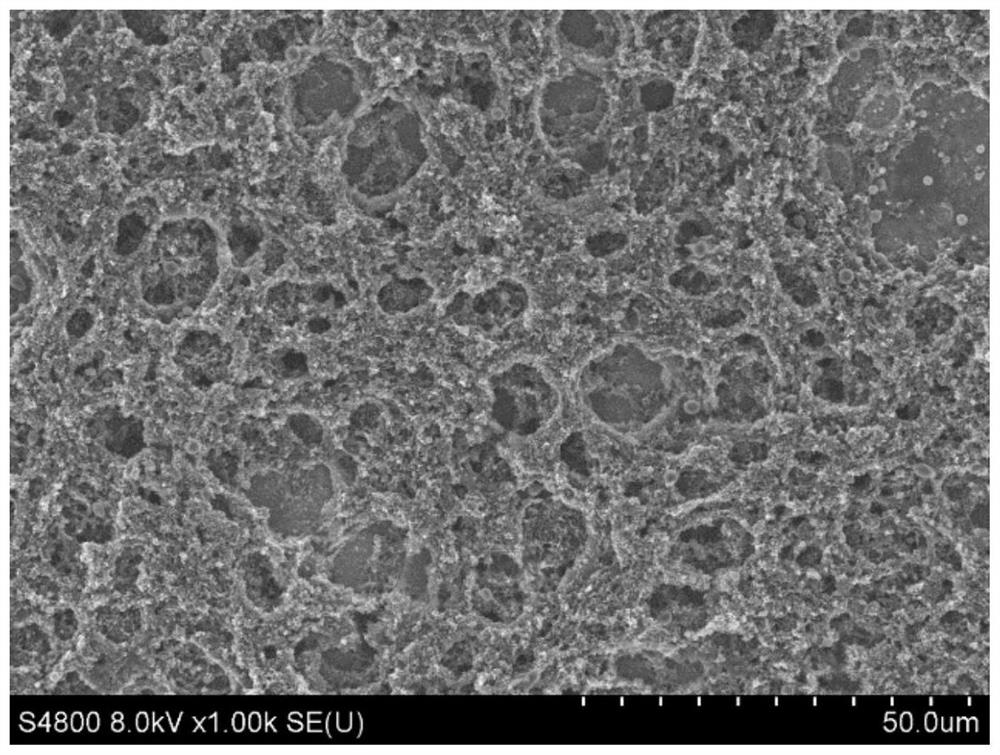

[0043] Step 1, pore-forming agent PMMA pre-polymerized conductive polymer polypyrrole

[0044] The pore-forming agent selects PMMA powder, wherein 0.1g of pore-forming agent PMMA spherical powder (average particle size 10μm) is dispersed in deionized water to form a 1mg / ml solution, then 0.1g of pyrrole monomer is added, stirred evenly, and the stirring temperature Controlled at 5°C. After mixing well, add ammonium persulfate equimolar to pyrrole, stir fully for 24 hours to realize in-situ oxidative polymerization of pyrrole on the surface of the pore-forming agent PMMA material to form polypyrrole, and collect the polypyrrole-modified pore-forming agent material PMMA by vacuum filtration.

[0045] Step 2, slurry configuration

[0046] The PMMA powder modified by the polypyrrole that step 1 obtains: the two-dimensional conductive material graphene: the mass ratio of high temperature resistant adhesive PAN: PMMA powder (6:2:2), solvent selects NMP (the quality of high temperat...

Embodiment 2

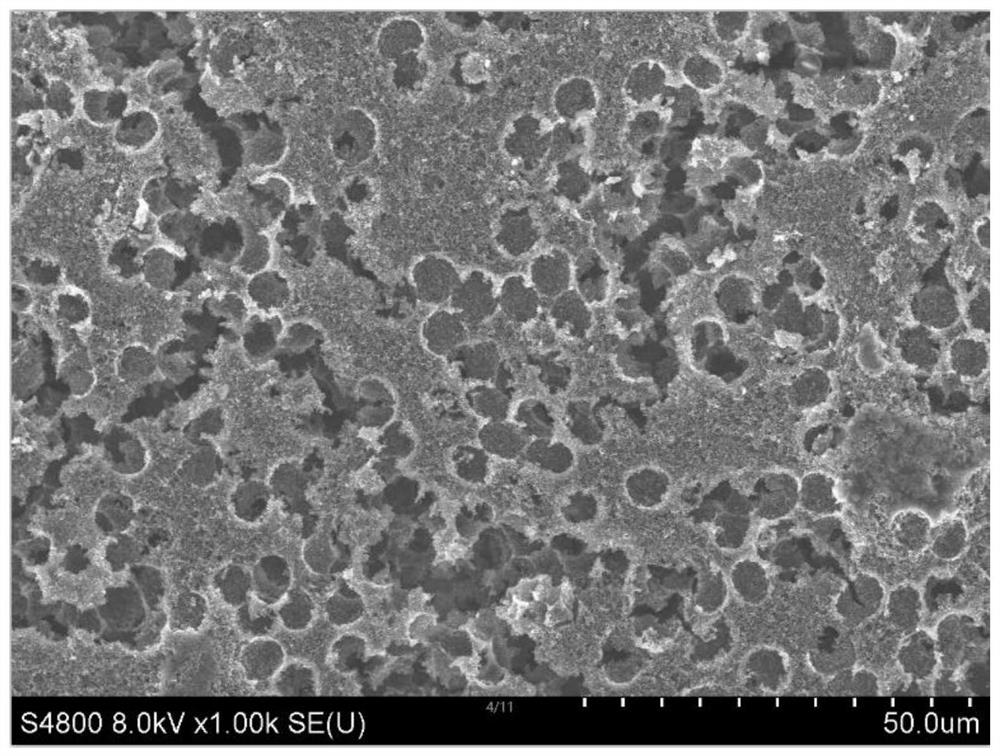

[0054] Step 1, pore-forming agent PMMA powder modified polyaniline

[0055] The pore-forming agent is PMMA powder, in which 0.1g pore-forming agent PMMA (average particle size 10μm) is dispersed in deionized water to form a 1mg / ml solution, then hydrochloric acid is added to make the concentration of hydrochloric acid 1M, and then 0.1g aniline is added Monomer, stirred evenly, and the stirring temperature was controlled at 5°C. After mixing well, add ammonium persulfate which is equimolar to aniline, stir fully for 24 hours to realize in-situ oxidative polymerization of aniline on the surface of the pore-forming agent PMMA material to form polyaniline, and collect the polyaniline-modified pore-forming agent material PMMA by suction filtration.

[0056] Step 2, slurry configuration

[0057] Select PAN as binding agent in implementing 2, the PMMA powder of polyaniline modification is pore-forming agent, and conductive phase selects two-dimensional graphene for use, with binding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com