Modified lithium-free negative electrode, preparation method thereof and lithium ion battery with modified lithium-free negative electrode

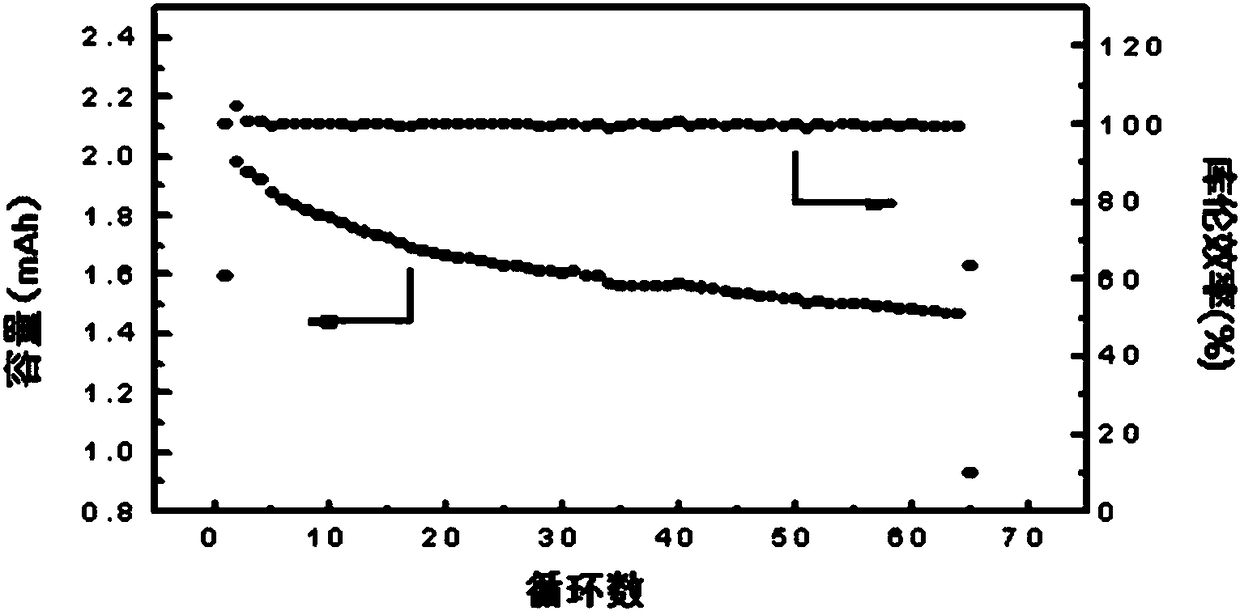

A lithium-ion battery and lithium negative electrode technology, applied in the field of nanomaterials, can solve the problems of high energy consumption, high production equipment requirements, and limited efficiency improvement of graphite negative electrodes, and achieve low energy consumption, low production equipment requirements, and improved circulation. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In some embodiments, the carbon nanotube microspheres can be prepared by dispersing carbon nanotubes in a solvent to form a dispersion, and then spray drying. For example, the preparation method may include the following steps:

[0030] A, the carbon nanotubes are dispersed into a dispersion solvent (without surfactant) by ultrasonic treatment to obtain a dispersion;

[0031] B. The dispersion liquid obtained in step A is sprayed out through the nozzle of the spray dryer, the air inlet temperature and the air outlet temperature are preset, and the solution is kept in a stirring state during the spraying process;

[0032] C. cooling to obtain carbon nanotube microspheres.

[0033] In some embodiments, the solvent is an organic and / or inorganic liquid capable of uniformly dispersing carbon nanotubes / carbon nanofibers and nanocarbon particles, for example, water, ammonia water, hydrochloric acid solution, ethanol, acetone, isopropanol Any one or combination of more.

[...

specific Embodiment approach 1

[0067] Embodiment 1 is a modified lithium-free negative electrode of a lithium-ion battery, wherein the modified lithium-free negative electrode contains metal lithium-skeleton carbon composite material in addition to lithium-free negative electrode material, and the metal lithium-skeleton carbon composite material The content of the material is 2%-20% of the mass of the negative electrode active material in terms of mass percentage.

specific Embodiment approach 2

[0068] Embodiment 2 is the modified lithium-free negative electrode according to Embodiment 1, wherein the metal lithium-skeleton carbon composite material comprises a porous carbon material carrier and a metal present in the pores and on the surface of the porous carbon material carrier lithium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com