Lithium battery silicon-carbon nanotube composite cathode material as well as preparation method and application thereof

A technology of nanotube composite and negative electrode material, which is applied in battery electrodes, nanotechnology, nanotechnology and other directions, can solve problems such as complex process, and achieve the effects of simple preparation process, alleviation of volume expansion effect, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

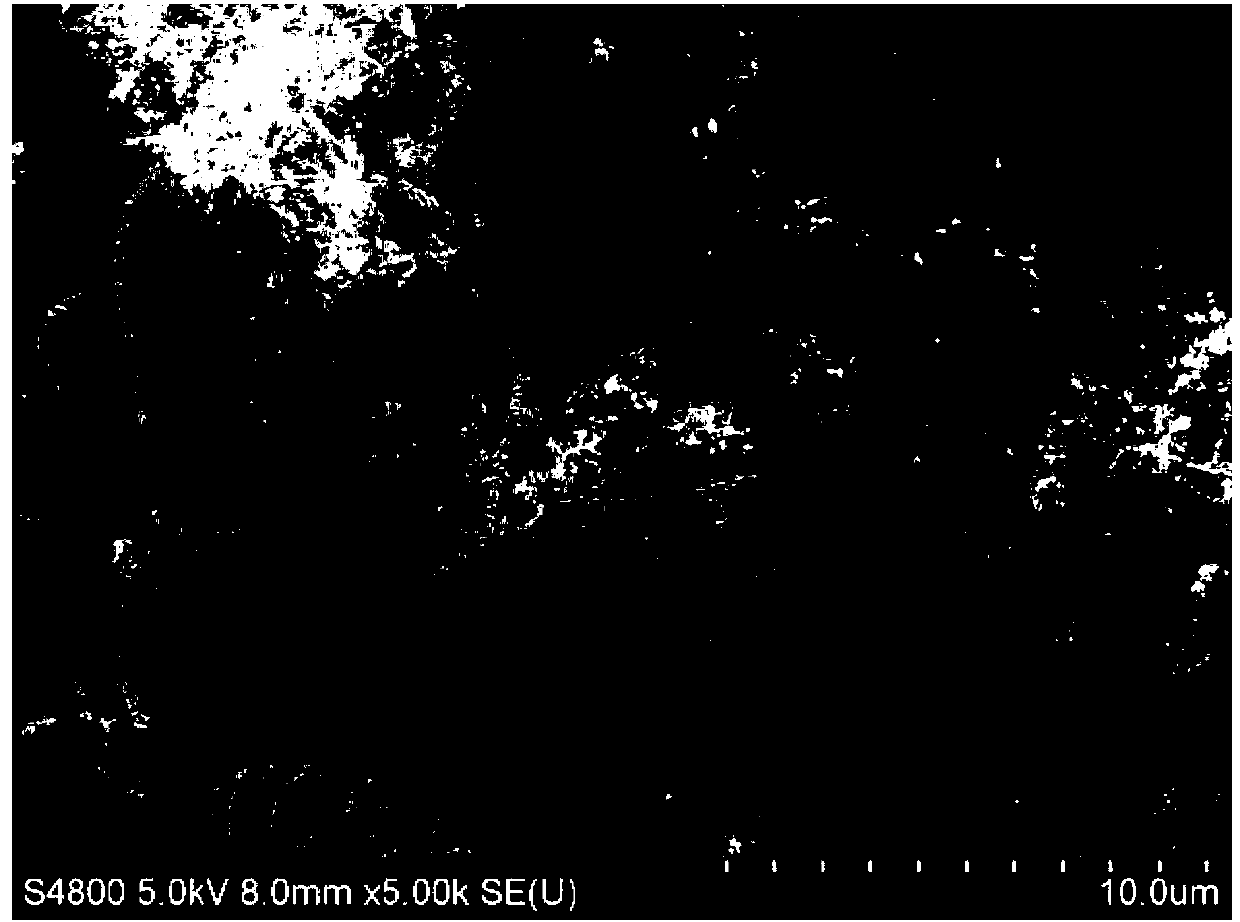

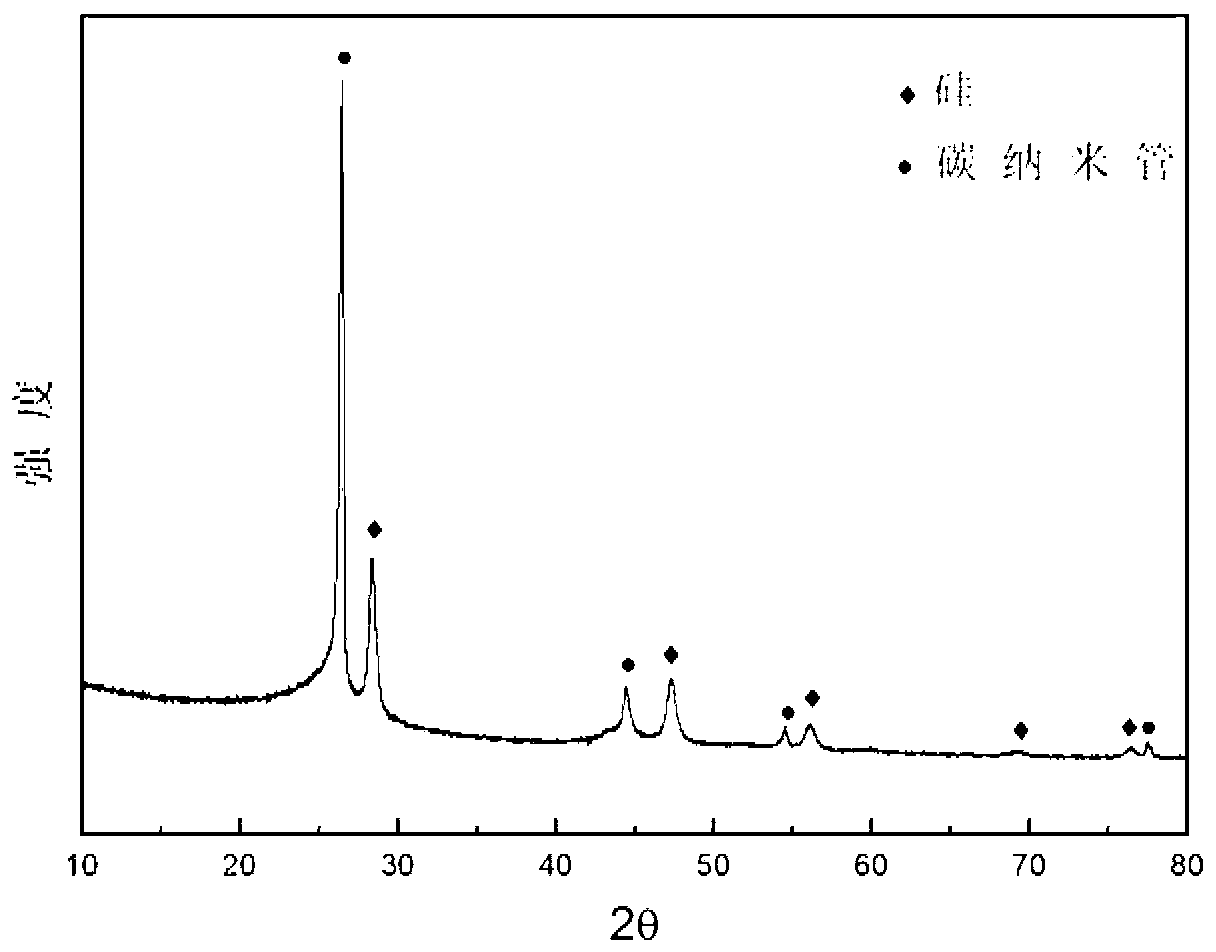

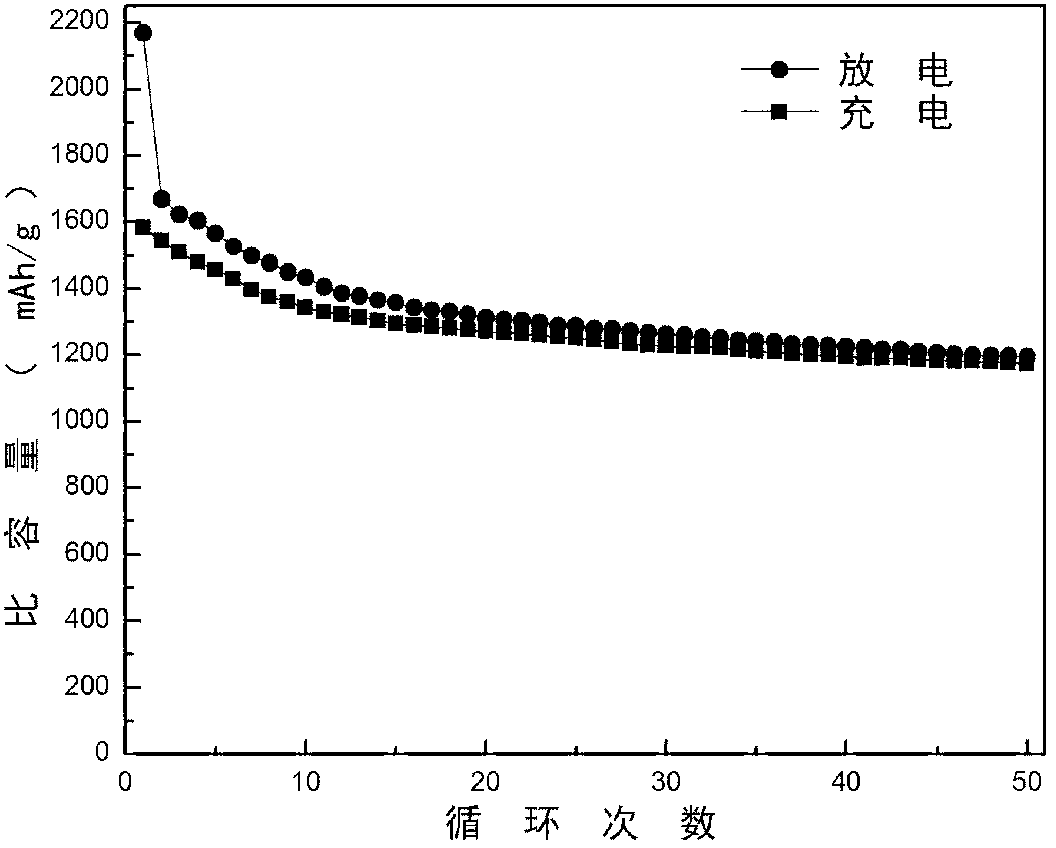

[0046] (1) Preparation of silicon-carbon nanotube composite negative electrode material for lithium battery, the specific steps are as follows:

[0047] (1) Weigh 14.25g of citric acid (C 6 h 8 o 7 ·H 2 O) and 0.05g nickel acetate (C 4 h 6 o 4 Ni·H 2 O) Dissolve in 100mL of absolute ethanol to obtain solution A; weigh 0.02g of dispersant polyvinylpyrrolidone, dissolve it in absolute ethanol, add it to 20g of nano-silicon liquid (silicon content is 2g), and sonicate for 30min to obtain solution B, Pour solution B into solution A to obtain a mixed slurry;

[0048] (2) Stir the mixed slurry obtained in step (1) for 1 hour at a stirring speed of 1000r / min, then add absolute ethanol to adjust the solid content of the mixed slurry to about 15% (mass), and mix The mixed slurry was pumped to the atomizer by a peristaltic pump for centrifugal closed cycle spray drying to obtain precursor A; the feed rate was 15mL / min, the inlet temperature was 105°C, the outlet temperature was ...

Embodiment 2

[0056] (1) Preparation of silicon-carbon nanotube composite negative electrode material for lithium battery, the specific steps are as follows:

[0057] (1) Weigh 2.85g phenolic resin and 0.05g nickel acetate (C 4 h 6 o 4 Ni·H 2 O) Dissolve in 100mL of absolute ethanol to obtain solution A; weigh 0.04g of dispersant polyethyleneimine and dissolve it in absolute ethanol, add it to 40g of nano-silicon liquid (4g of silicon content), and sonicate for 60min to obtain solution B , Pour solution B into solution A to obtain a mixed slurry;

[0058] (2) Stir the mixed slurry obtained in step (1) for 1 hour at a stirring speed of 1200r / min, then add absolute ethanol to adjust the solid content of the mixed slurry to about 20% (mass), and pass the mixed slurry through peristalsis Pumped to the atomizer for centrifugal closed cycle spray drying to obtain precursor A; wherein the feed rate is 15mL / min, the inlet temperature is 110°C, the outlet temperature is 82°C, and the atomizer sp...

Embodiment 3

[0065] (1) Preparation of silicon-carbon nanotube composite negative electrode material for lithium battery, the specific steps are as follows:

[0066] (1) Weigh 2.45g of high-temperature asphalt and 0.05g of iron acetate and dissolve them in tetrahydrofuran and absolute ethanol to obtain solution A; weigh 0.04g of dispersant polyetherimide and dissolve them in absolute ethanol and add them to 40g of nano silicon Liquid (silicon content is 4g), and ultrasonic 1.5h to obtain solution B, solution B is poured into solution A to obtain a mixed slurry;

[0067] (2) Stir the mixed slurry obtained in step (1) for 2 hours at a stirring speed of 800r / min, then add tetrahydrofuran to adjust the solid content of the mixed slurry to about 25% (mass), and pump the mixed slurry through a peristaltic pump To the atomizer for centrifugal closed cycle spray drying to obtain precursor A; wherein the feed rate is 15mL / min, the inlet temperature is 115°C, the outlet temperature is 85°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com