Positive active material and preparation method thereof

A positive electrode active material and a technology of positive electrode materials, applied in the field of positive electrode active materials and their preparation, can solve the problems of poor cycle performance and low initial discharge efficiency, and achieve improved cycle performance, simple and easy preparation method, and improved charge and discharge efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

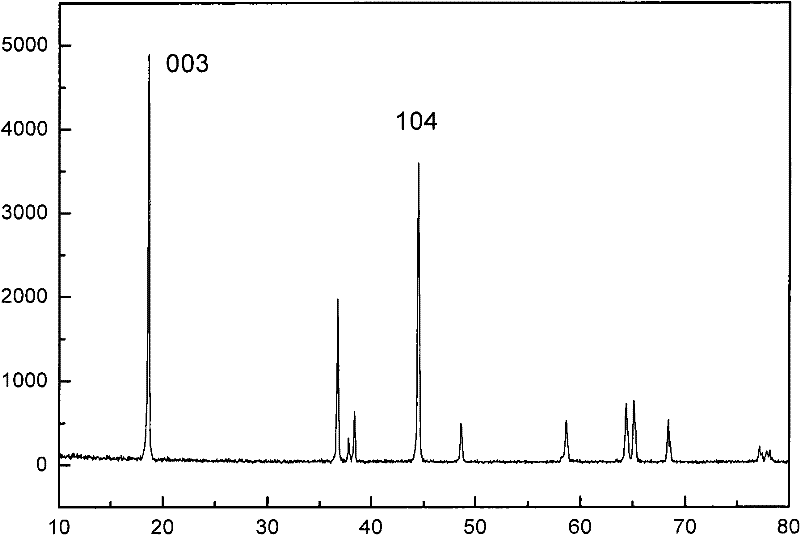

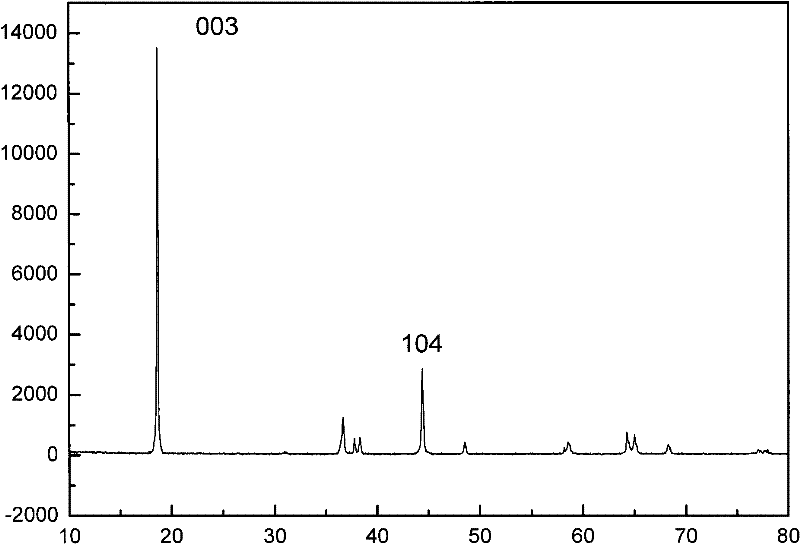

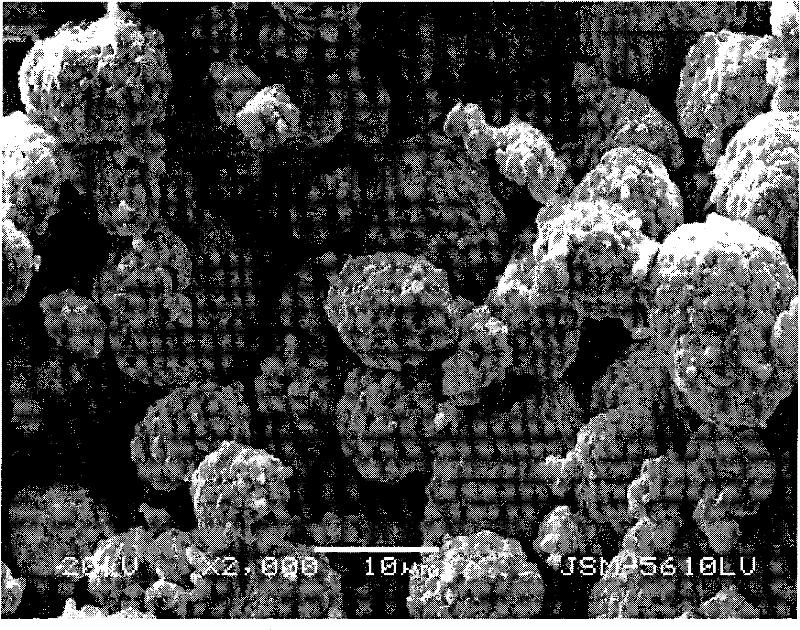

Image

Examples

preparation example Construction

[0024] A method for preparing the above-mentioned cathode material, comprising the steps of:

[0025] (1) Carry out step S: Add solution A and solution C to the bottom liquid to precipitate, and wait for the nickel ion in the bottom liquid to be lower than 2000ppm; then add solution B and solution C to the bottom liquid to precipitate, and wait for the bottom liquid to Nickel ions below 2000ppm;

[0026] Repeat step S, and the number of repetitions is not less than 5 times; during the precipitation process, control the pH of the bottom solution to 10.5-12.0;

[0027] Solution A is a solution containing nickel ions, cobalt ions, and manganese ions, and solution B is a solution of nickel ions, cobalt ions, and doping ions; the concentration ratio of nickel ions and cobalt ions in the solution A and solution B is the same;

[0028] Solution C is an alkali solution, and the bottom liquid is a complexing agent solution;

[0029] (2) After the precipitation is completed, age to ob...

Embodiment 1

[0059] Embodiment 1 Best Embodiment

[0060] Solution A: Dissolve nickel sulfate, cobalt sulfate and manganese sulfate in water to make a solution, in which Ni 2+ 、Co 2+ , Mn 2+ The concentration is 2 / 3mol / L

[0061] Solution B: Dissolve nickel sulfate, cobalt sulfate and magnesium sulfate in water to make a solution, in which Ni 2+ 、Co 2+ , Mg 2+ The concentration is 2 / 15mol / L

[0062] Solution C: 5.6mol / L NaOH, 4.8mol / L NH 3 ·H 2 Mixed solution of O

[0063] Bottom solution: 2.0mol / L NH 3 ·H 2 o

[0064] Pour 20L of the bottom liquid into a 100L reactor, and pass nitrogen gas to exhaust the reactor and the oxygen in the bottom liquid. And continue feeding nitrogen to ensure the inert atmosphere in the reactor.

[0065] Add 2.8L of solution A and solution C to the reaction kettle in parallel, and detect Ni in the bottom solution 2+ , until less than 2000ppm. Then 1.1L of solution B and solution C were added to the reaction kettle in parallel, and the Ni in the ...

Embodiment 2

[0071] The difference from Example 1 is that solution B is made by dissolving nickel sulfate, cobalt sulfate and aluminum manganate in water, wherein Ni 2+ 、Co 2+ 、Al 3+ The concentration is 2 / 15mol / L.

[0072] Other parts are with embodiment 1.

[0073] The obtained positive electrode material is denoted as S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com