Eutectic solvent electrolyte, preparation method and lithium metal battery

A low eutectic solvent and electrolyte technology, applied in non-aqueous electrolyte batteries, lithium batteries, secondary batteries, etc., can solve problems such as lithium dendrite growth and electrolyte flammability, and achieve a large electrochemical window and low cost. , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Stir lithium bistrifluorosulfonylimide and N-methylacetamide at 60°C in a molar ratio of 1:4 until clear and transparent, then add 10%wt fluoroethylene carbonate to prepare a deep eutectic solvent electrolysis liquid.

[0051] The anti-oxidation potential of the deep eutectic solvent electrolyte prepared in this example can reach 4.9V.

[0052] The prepared deep eutectic solvent electrolyte is used as the electrolyte of the lithium metal battery, the lithium metal is used as the negative electrode of the lithium metal battery, and the lithium iron phosphate is used as the positive electrode of the lithium metal battery to build the lithium metal battery.

[0053] A full battery test was carried out on the built lithium metal battery. After testing, it was found that the Coulombic efficiency of the lithium metal battery can reach 99.9%, and the cycle life can reach 2000 cycles.

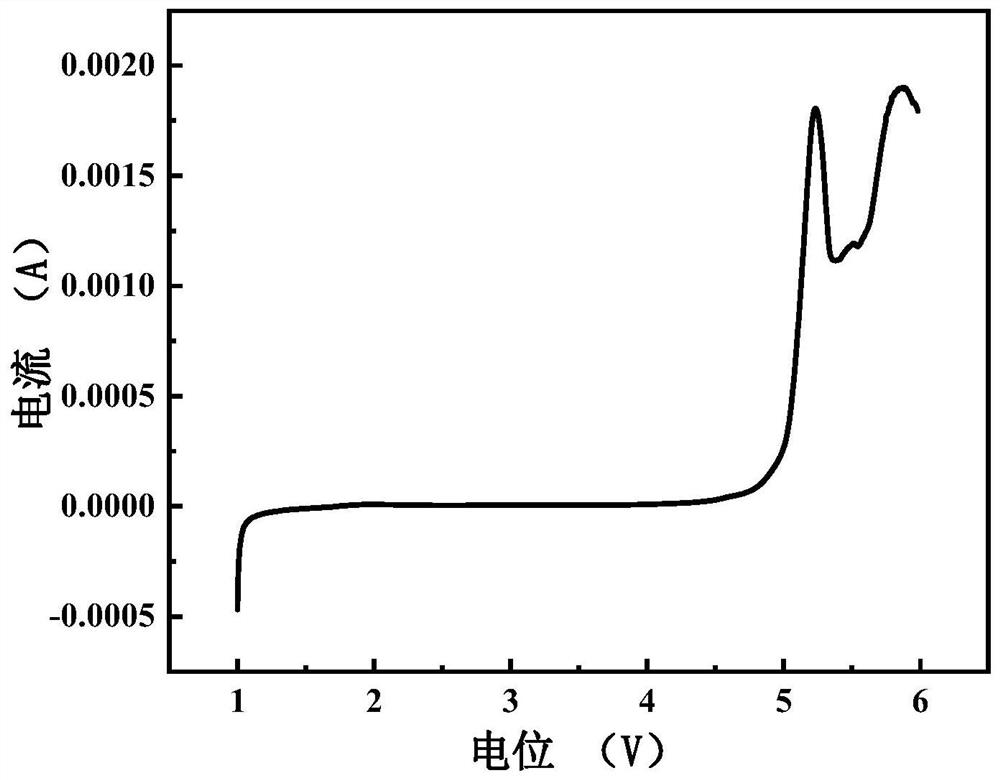

[0054] figure 1 It is the linear sweep voltammogram of the electrolyte solution of this em...

Embodiment 2

[0056] Stir lithium bistrifluorosulfonyl imide and butyrolactam at a molar ratio of 1:3 at 60°C until clear and transparent, and then add 5%wt fluoroethylene carbonate to prepare a deep eutectic solvent electrolyte.

[0057] The anti-oxidation potential of the deep eutectic solvent electrolyte prepared in this example can reach 4.8V.

[0058] The prepared deep eutectic solvent electrolyte is used as the electrolyte of the lithium metal battery, the metal lithium is used as the negative electrode, and the lithium manganate is used as the positive electrode of the lithium metal battery to construct the lithium metal battery.

[0059] A full-battery test was carried out on the built lithium metal battery. After testing, it was found that the Coulombic efficiency of the lithium metal battery can reach 99%, and the cycle life can reach 400 cycles.

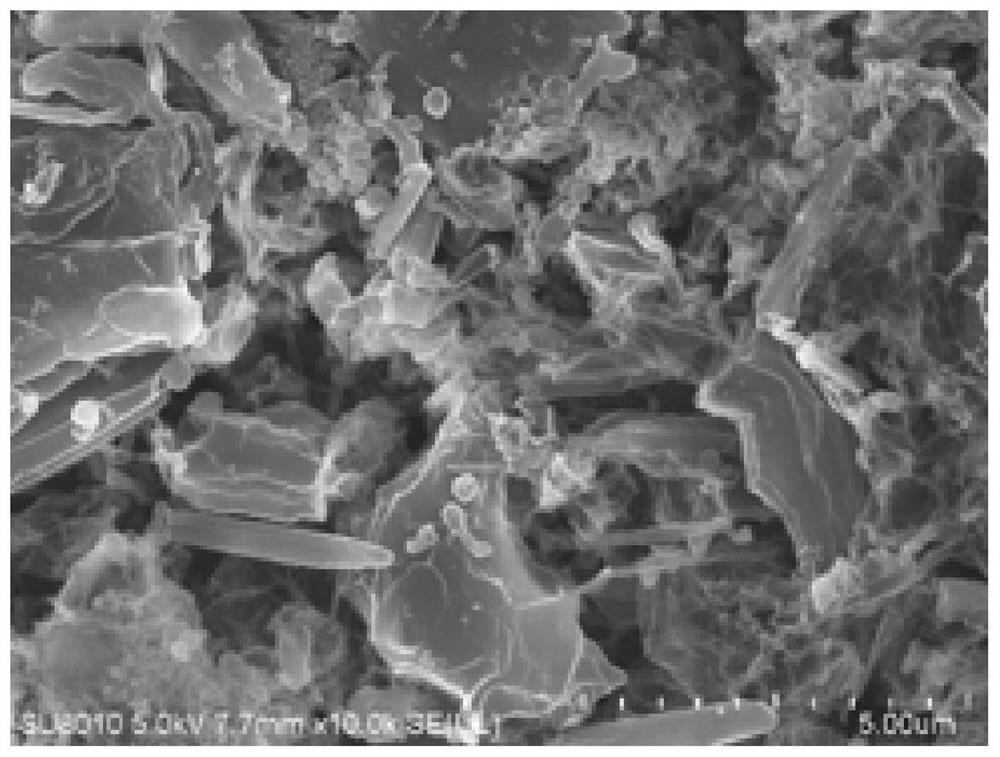

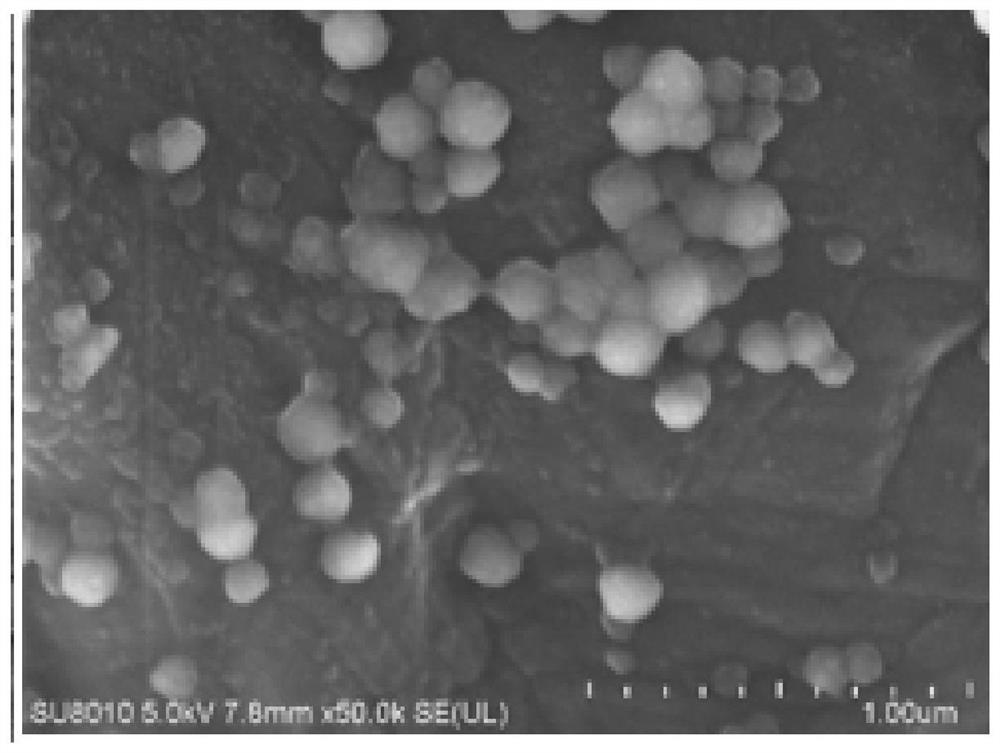

[0060] Figure 5 It is the linear sweep voltammogram of the electrolyte solution of this embodiment. Image 6 It is the lithium depo...

Embodiment 3

[0062] Lithium bisfluorosulfonyl imide and acetamide were stirred at 60°C at a molar ratio of 1:5 until clear and transparent, and then 5%wt fluoroethylene carbonate was added to prepare a deep eutectic solvent electrolyte.

[0063] The anti-oxidation potential of the deep eutectic solvent electrolyte prepared in this example can reach 4.9V.

[0064] The prepared deep eutectic solvent electrolyte is used as the electrolyte of the lithium metal battery, the lithium metal is used as the negative electrode of the lithium metal battery, and the lithium nickel manganese oxide is used as the positive electrode of the lithium metal battery to build the lithium metal battery.

[0065] A full-battery test was carried out on the built lithium metal battery. After testing, it was found that the Coulombic efficiency of the lithium metal battery can reach 99%, and the cycle life can reach 300 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com