Patents

Literature

50results about How to "Increase interplanar spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

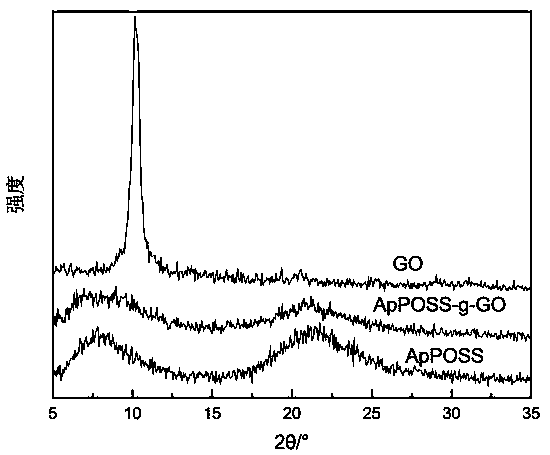

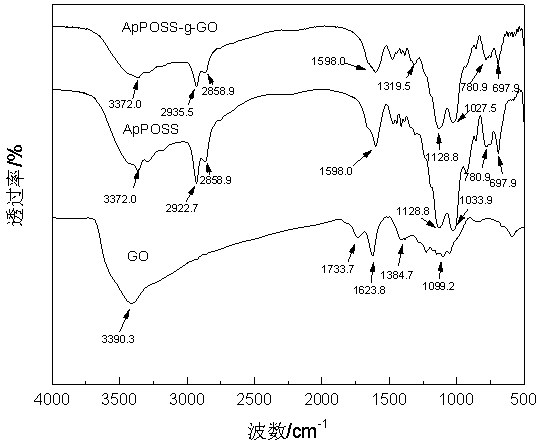

Method for preparing flame retardant epoxy resin from modified graphene

The invention discloses a method for preparing flame retardant epoxy resin from modified graphene, and relates to a method for preparing epoxy resin. The method comprises preparation of graphene oxide; preparation of octa-aminopropyl cage-like silsesquioxane; and modifying of epoxy resin with functionalized graphene, to be more specific, heating and melting the epoxy resin, mixing and curing the epoxy resin and the functionalized graphene to obtain modified epoxy resin. According to the method, the graphene oxide (GO) is prepared by modifying, silane coupling agent KH-550 is used as a raw material for preparation of the octa-aminopropyl cage-like silsesquioxane (ApPOSS), the modified graphene is prepared by grafting reaction of the GO and the ApPOSS, the modified graphene and EP are mixedand cured to improve the compatibility of the modified graphene with the epoxy resin, the modified graphene and the epoxy resin are compounded for preparation of an epoxy resin nanocomposite, and thecomprehensive effect is obvious.

Owner:盘锦职业技术学院

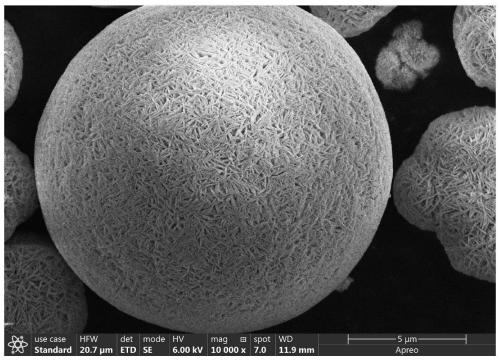

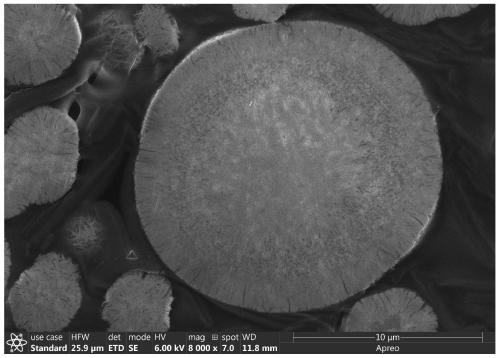

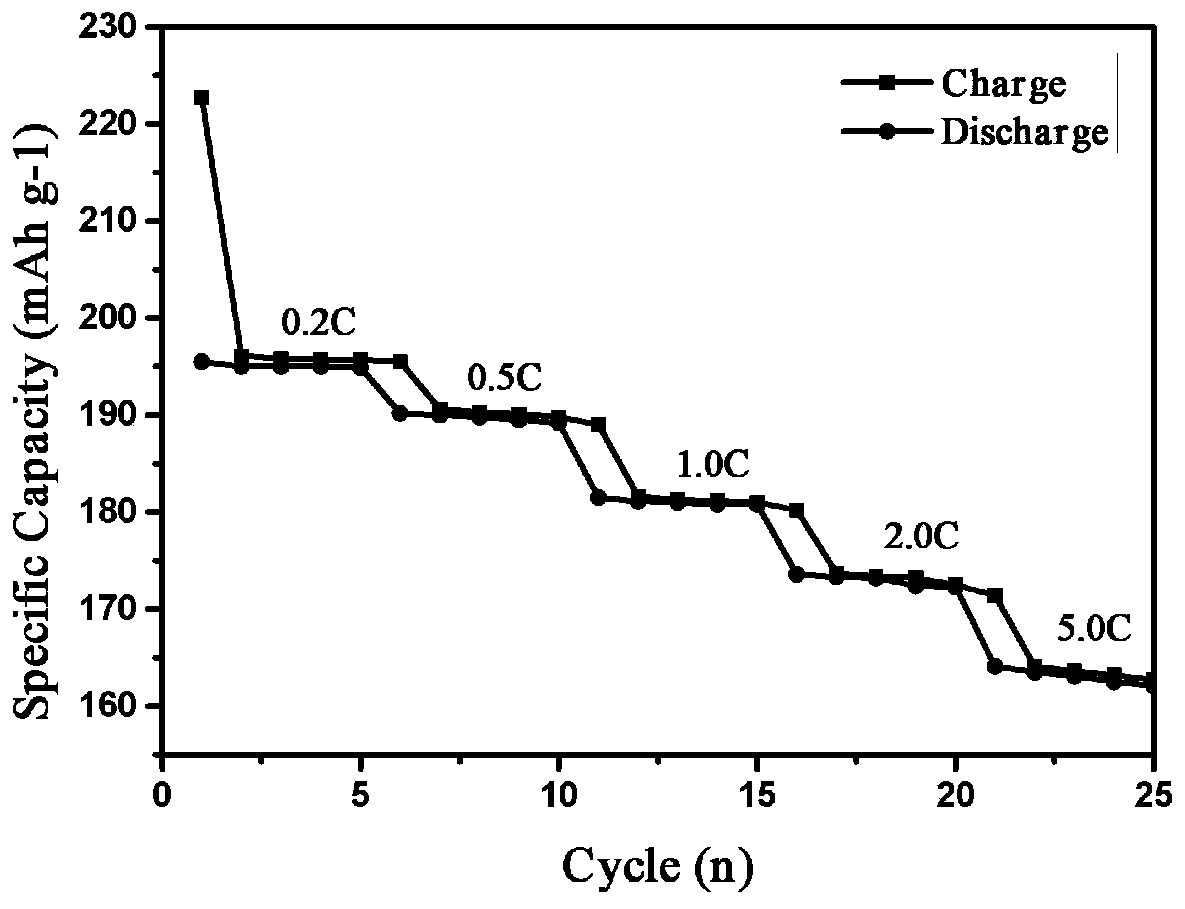

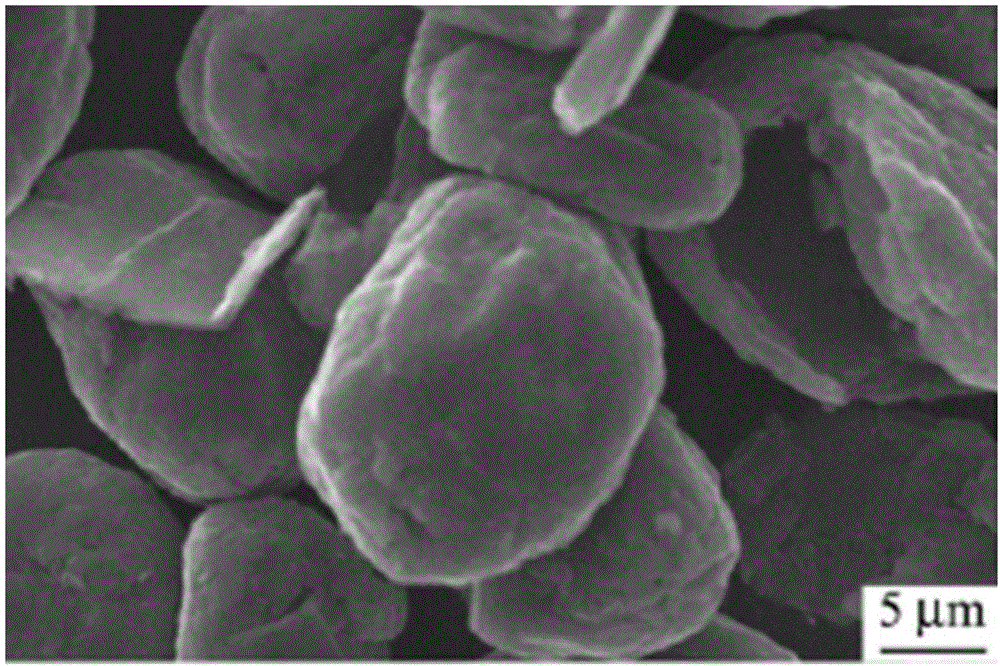

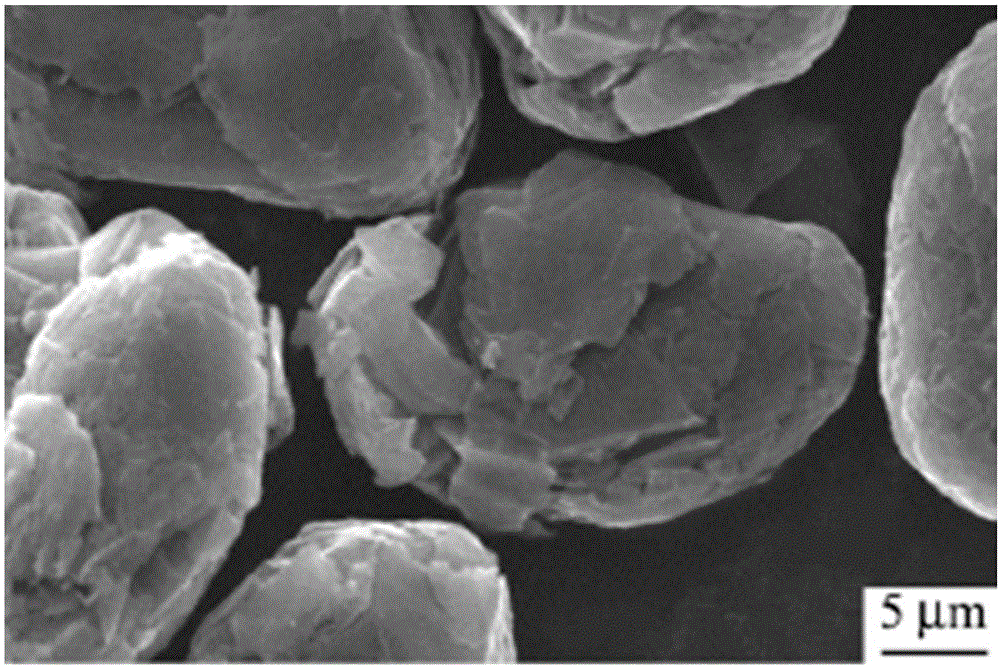

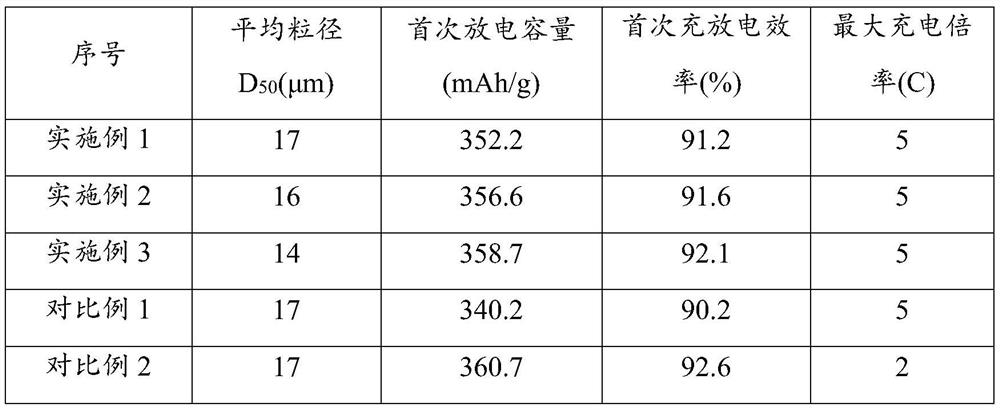

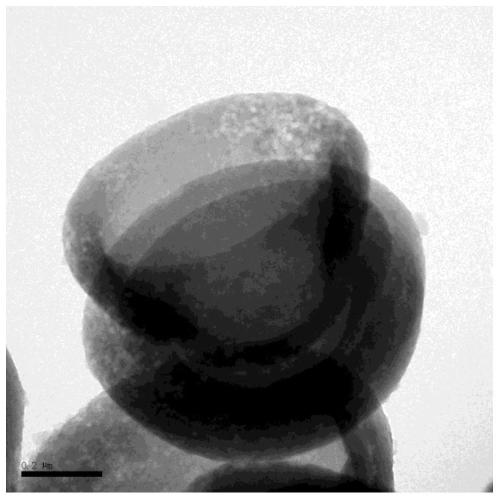

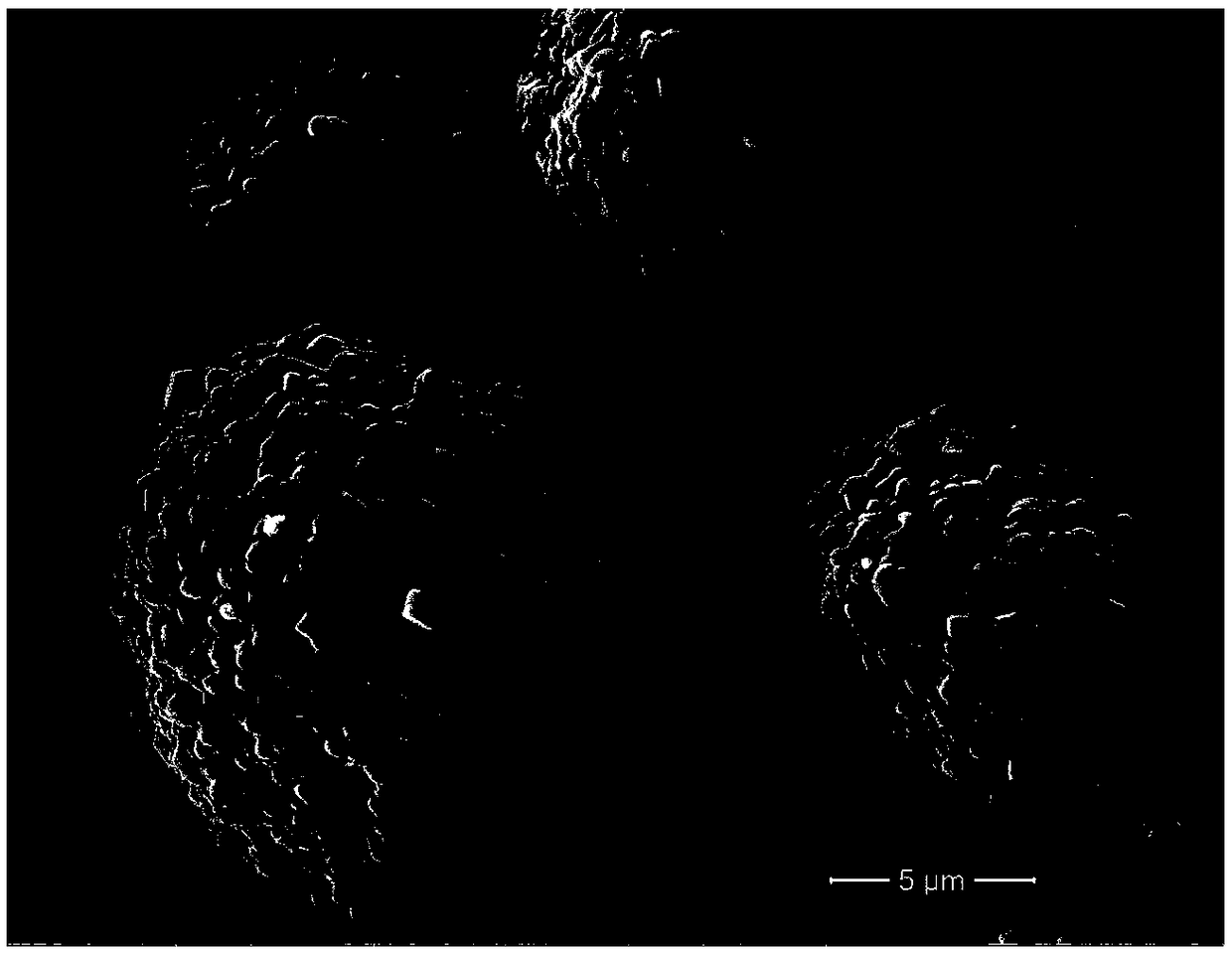

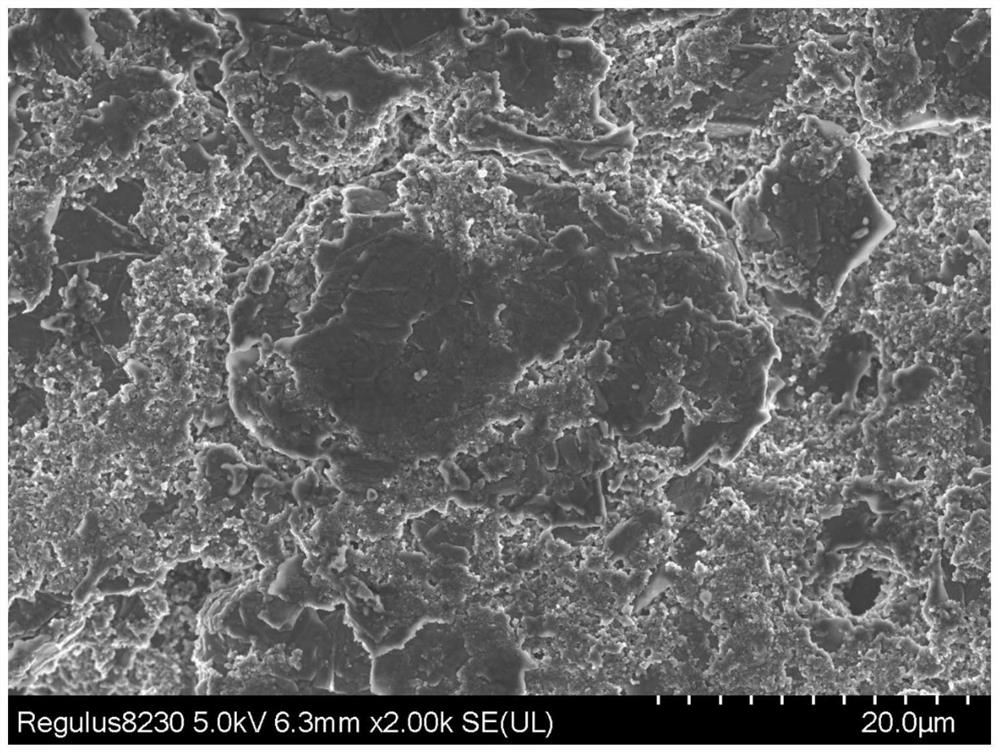

Al/La co-doped high-nickel ternary precursor with core-shell structure and preparation method thereof, and positive electrode material

ActiveCN111422926AImprove cycle performanceSmall sizeCell electrodesSecondary cellsManganeseLithium-ion battery

The invention relates to the field of lithium ion battery materials, and provides an Al / La co-doped high-nickel ternary precursor with a core-shell structure and a preparation method thereof, and a positive electrode material prepared from the precursor. The preparation method mainly comprises the following three steps: step 1, synthesizing an Al-doped high-nickel ternary precursor with rod-like primary particles under the condition of a low pH value; 2, increasing the pH value on the basis of the step 1, growing a La-doped high-nickel ternary precursor shell with needle-shaped primary particles by taking the Al-doped high-nickel ternary precursor as an inner core so as to synthesize an Al / La co-doped high-nickel ternary precursor with a core-shell structure; and 3, mixing the Al / La co-doped high-nickel ternary precursor with the core-shell structure and a lithium salt, and carrying out high-temperature calcination in an oxygen atmosphere to obtain the Al / La co-doped ternary positive electrode material with the core-shell structure. Due to the unique co-doped core-shell structure, the stability of an internal structure is effectively enhanced, the generation of mixed phases such ascation mixing and rock salt structures is inhibited, the breakage of grain boundaries is reduced, the average oxidation state of manganese ions is improved, the Jahn-Teller effect is effectively inhibited, the rapid attenuation of the capacity in a cycle process is reduced, the cycle stability of the material is remarkably improved, and the cycle life of the material is remarkably prolonged. Theproduct synthesized by adopting a coprecipitation method is uniform in component, good in sphericity, good in reproducibility, easy in condition control, low in preparation cost, high in economic value and wide in application prospect.

Owner:ZHUJI PAWA NEW ENERGY

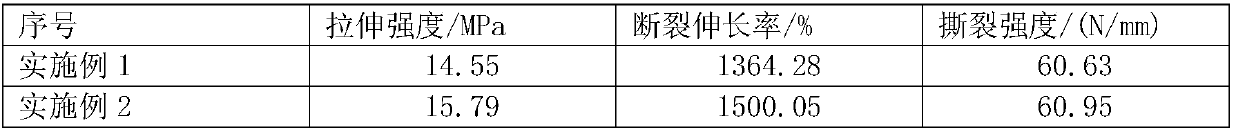

Preparation method of stratified-structure mineral reinforced rubber composite material

The invention relates to a preparation method of a stratified-structure mineral reinforced rubber composite material. The preparation method comprises the following steps: (1) carrying out nano-organic modification on a stratified-structure mineral; (2) preparing an organic modified nano-stratified-structure mineral inserted rubber master batch; (3) preparing the raw materials of an organic modified nano-stratified-structure mineral reinforced rubber composite material; and (4) preparing the organic modified nano-stratified-structure mineral reinforced rubber composite material, wherein the stratified-structure mineral is one or mixture of two of black talc, montmorillonite, kaolin and illite in the same mass ratio. According to the preparation method, the functional rubber composite material with excellent mechanical property, stable weather resistance and good warping strength and humidity resistance is prepared.

Owner:HEBEI UNIV OF TECH

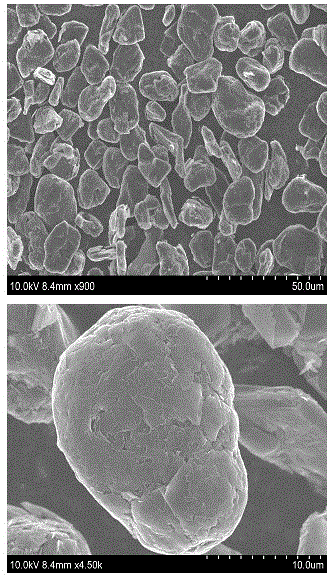

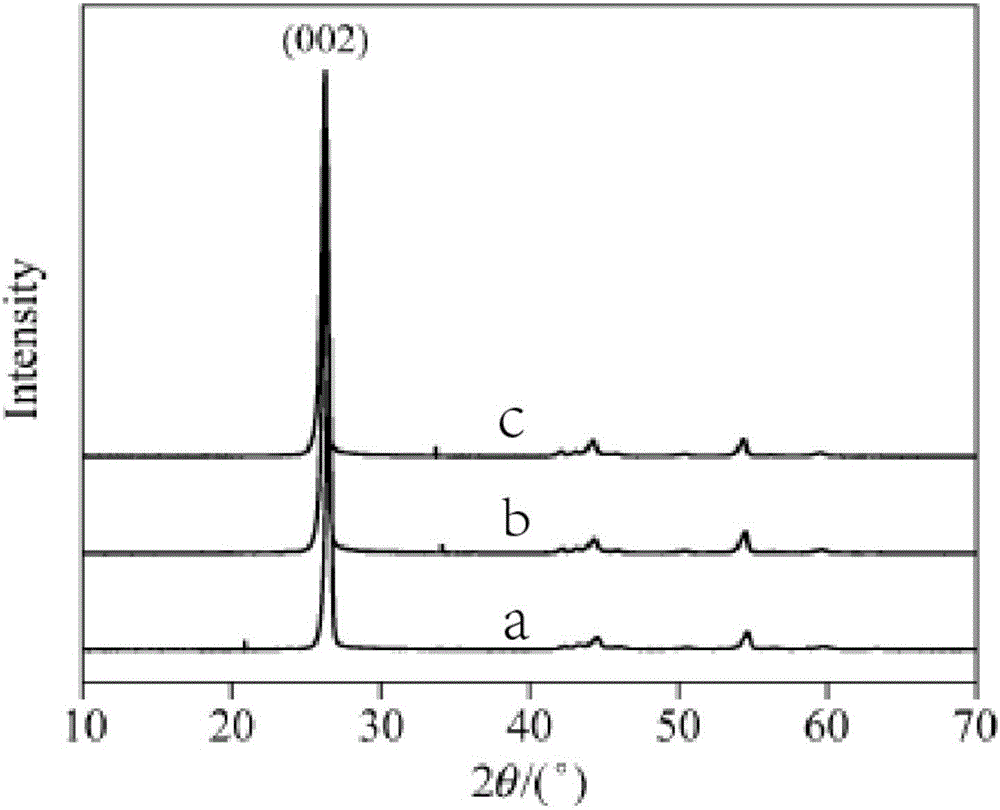

Modified natural graphite and preparation method and application thereof

InactiveCN105633370ASimple processEasy to controlCell electrodesSecondary cellsCruciblePhysical chemistry

The invention discloses modified natural graphite and a preparation method and an application thereof. The method comprises the following specific steps: firstly, mixing a graphite material with an intercalator evenly at the ratio, carrying out constant-temperature treatment on the mixed slurry at 90-200 DEG C for 1-16 hours to obtain an intercalated graphite material; adding an organic amine liquid to the intercalated graphite material, and stirring and mixing the organic amine liquid and the intercalated graphite material evenly; enclosing the obtained sample into a crucible, carrying out high-temperature thermal treatment in an inert gas atmosphere at 500-1500 DEG C for 0.5-14h, naturally cooling the sample and then taking out the sample to obtain the modified natural graphite material. The method is simple in process, mild in reaction condition, easy to control, relatively low in cost and beneficial to industrial implementation; and the obtained modified natural graphite is good in rate capability and cycle performance.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

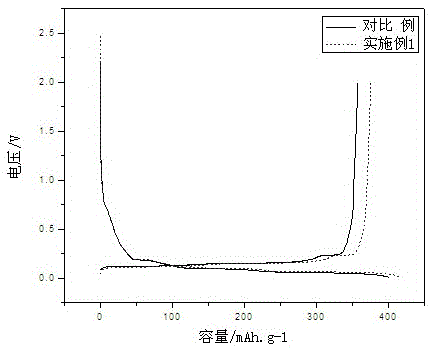

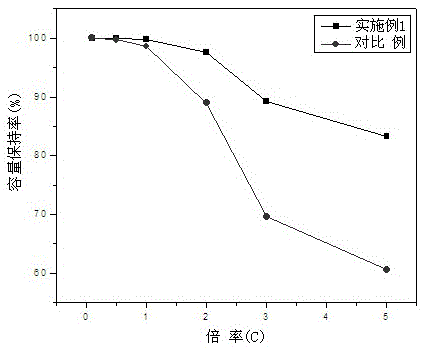

Preparation method of composite modified graphite cathode material, composite modified graphite cathode material and application

InactiveCN107528058AImproved magnification performanceImprove efficiencyCell electrodesSecondary cellsCarbon coatingCycle efficiency

The invention provides a preparation method of a composite modified graphite cathode material, the composite modified graphite cathode material and an application and relates to the technical field of graphite cathode materials. According to the method, a graphite intercalation compound is subjected to coating modification through a phenolic resin mixed solution, wherein the phenolic resin mixed solution is mainly prepared from phenolic resin, a phosphorus compound and water. Different from graphite, the graphite intercalation compound can enlarge the interplanar spacing of graphite and increase the Lithium storage capacity, so that the reversible capacity is increased; besides, a phosphorus-doped carbon coating layer can increase the compactness of the composite modified graphite cathode material and further improve the rate capability of the material; besides, the phosphorus-doped carbon coating layer can uniformly and completely coat the surface of the graphite intercalation compound, the irreversible capacity is reduced, and accordingly, the circulation efficiency is improved. The invention also provides the composite modified graphite cathode material prepared with the preparation method of the composite modified graphite cathode material.

Owner:NORTHERN ALTAIR NANOTECH CO LTD +1

High-voltage lithium nickel-cobalt manganate cathode material and preparation method thereof

ActiveCN109786697AImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsPhosphateManganate

The invention discloses a high-voltage lithium nickel-cobalt manganate cathode material and a preparation method thereof. The lithium nickel-cobalt manganate cathode material is lithium nickel-cobaltmanganate doping material coated with the phosphate, the lithium nickel-cobalt manganate doping material means that the lithium nickel-cobalt manganate doping material is doped with a lanthanum element and a fluorine element; the phosphate is prepared by mixing the aluminum phosphate and diammonium phosphate aqueous solution. The doping of the lanthanum element and the fluorine element can increase the interplanar spacing so as to promote the lithium ion migration and improving the structure stability; the material surface has good lithium ion conductivity feature and a certain electronic conductivity feature by coating the phosphate on the surface, so that the material has higher lithium-removing state stability under high voltage; the residual lithium quantity of the material surface isreduced, the surface side reaction is inhibited, and the structure stability and the cycle performance of the material under high voltage are obviously improved.

Owner:HEFEI RONGJIE ENERGY MATERIALS CO LTD

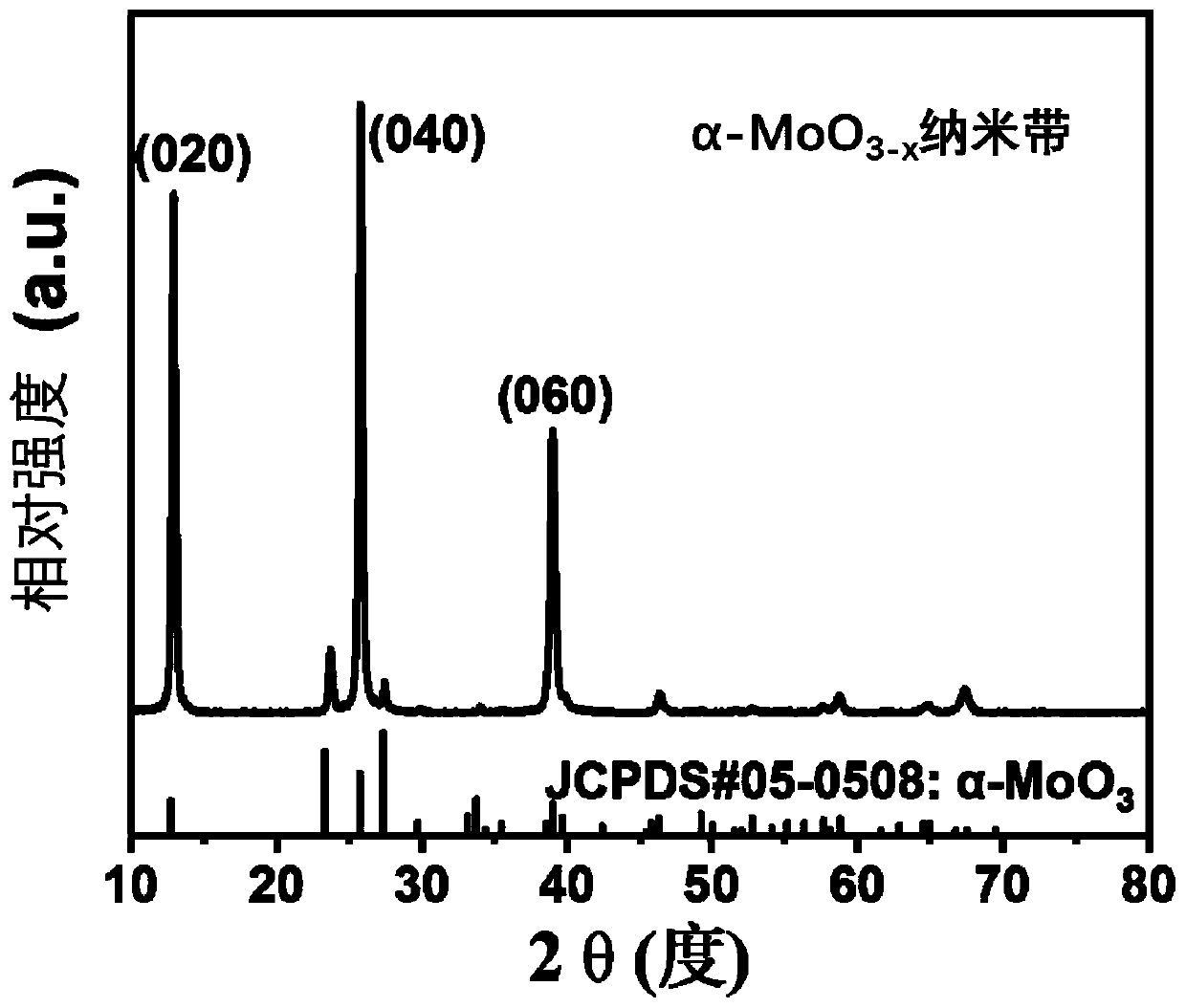

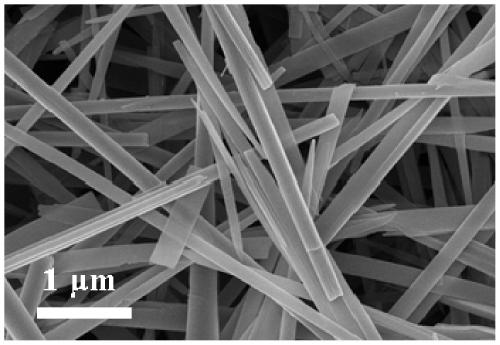

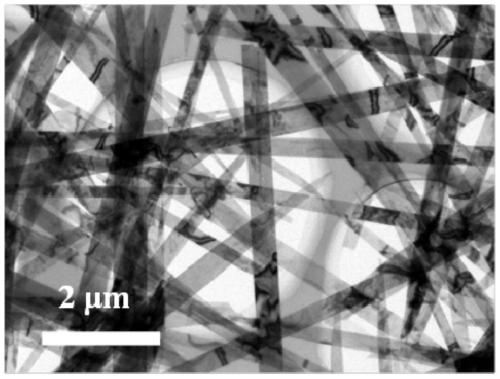

Alpha-MoO3-x nanobelt and preparation method thereof as well as electrode material and energy storage device

ActiveCN109879320AImprove conductivitySimple processHybrid capacitor electrodesCell electrodesOxygen vacancyEnergy storage

The invention discloses an alpha-MoO3-x nanobelt and a preparation method thereof as well as an electrode material and an energy storage device. The preparation method of the alpha-MoO3-x nanobelt comprises the following steps: taking molybdenum powder and dissolving the molybdenum powder in a hydrogen peroxide solution, adding a reducing agent, sufficiently mixing, transferring the obtained mixture into a reaction kettle for reacting to prepare the alpha-MoO3-x nanobelt. The prepared alpha-MoO3-x nanobelt has abundant and uniformly-distributed oxygen vacancies, and is extremely excellent in morphology and excellent in conductivity; and the alpha-MoO3-x nanobelt can be prepared into the electrode material with extremely excellent electrochemical properties such as capacity, rate performance and cycling performance, so that the electrochemical properties of the energy storage device can be improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

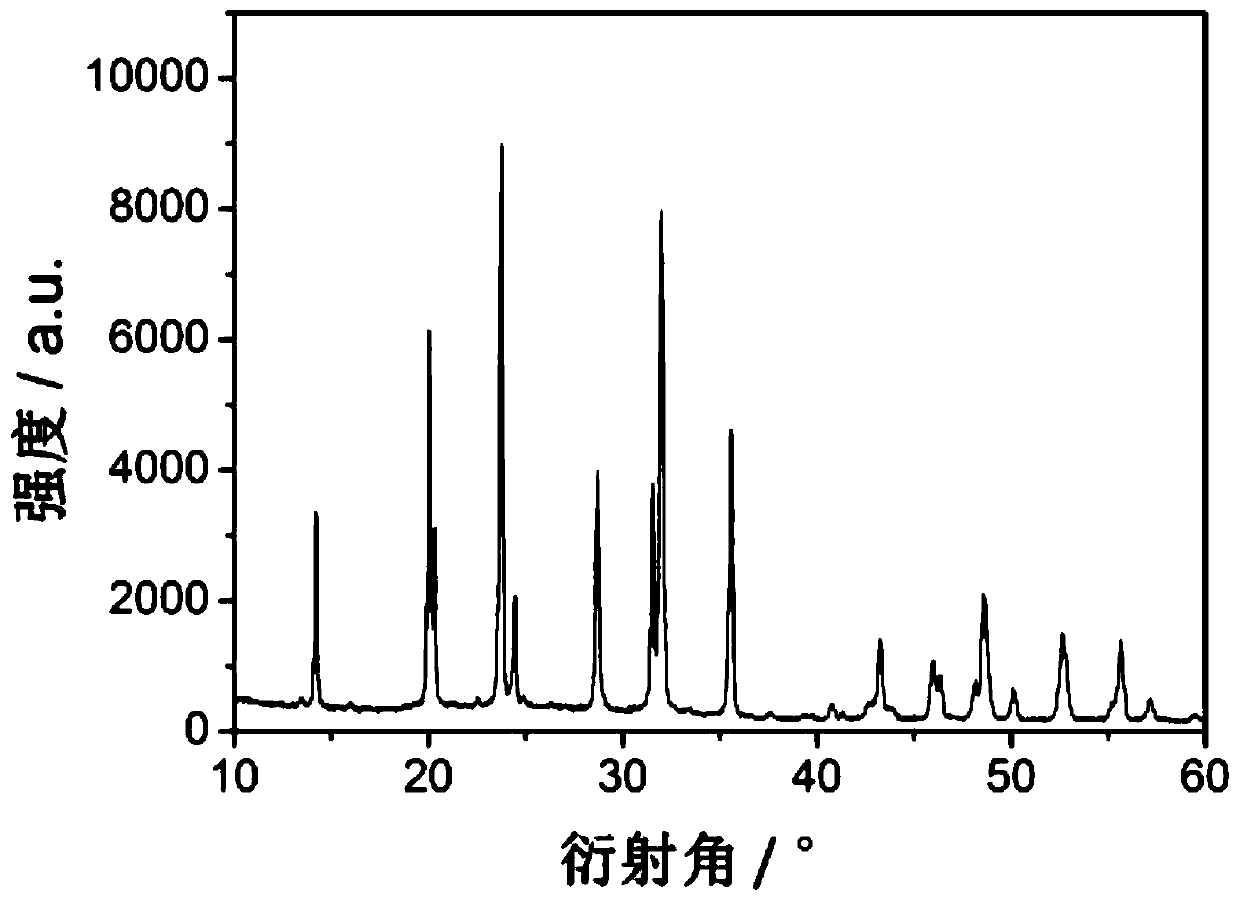

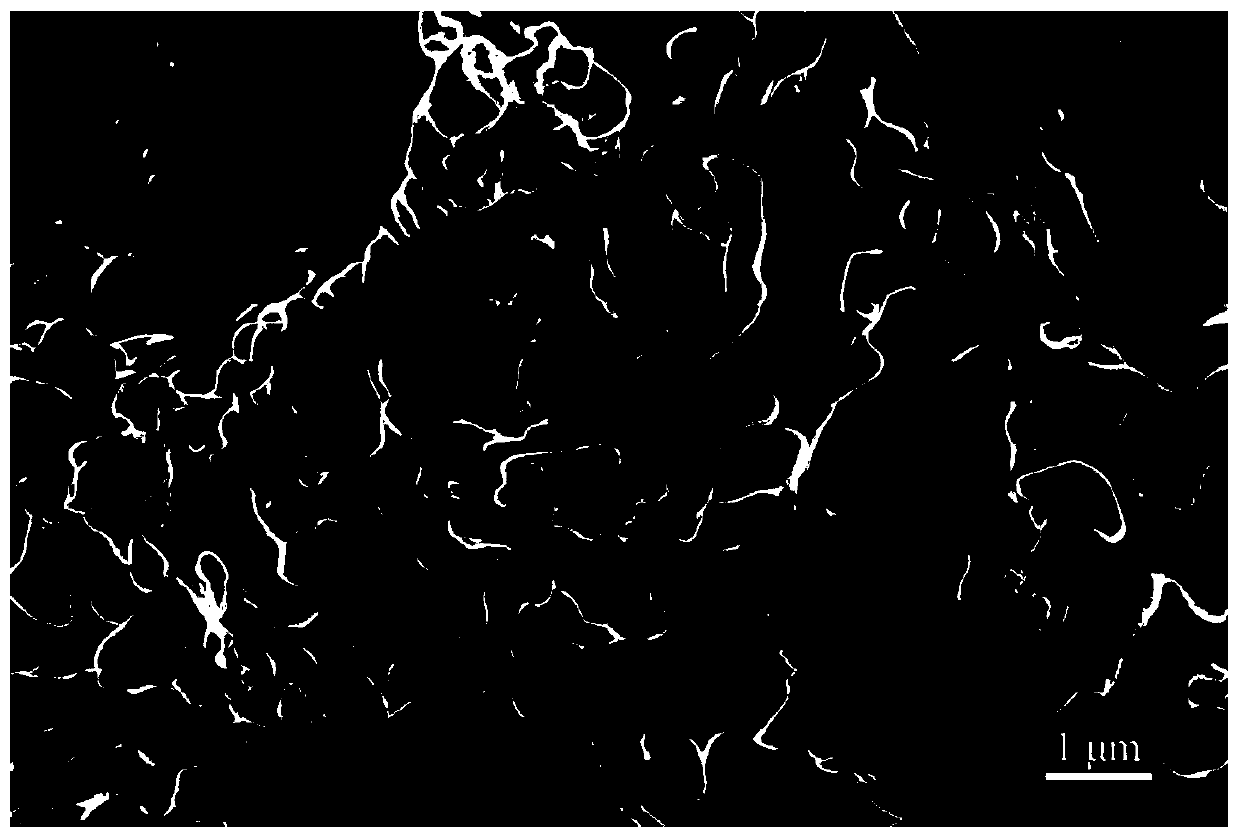

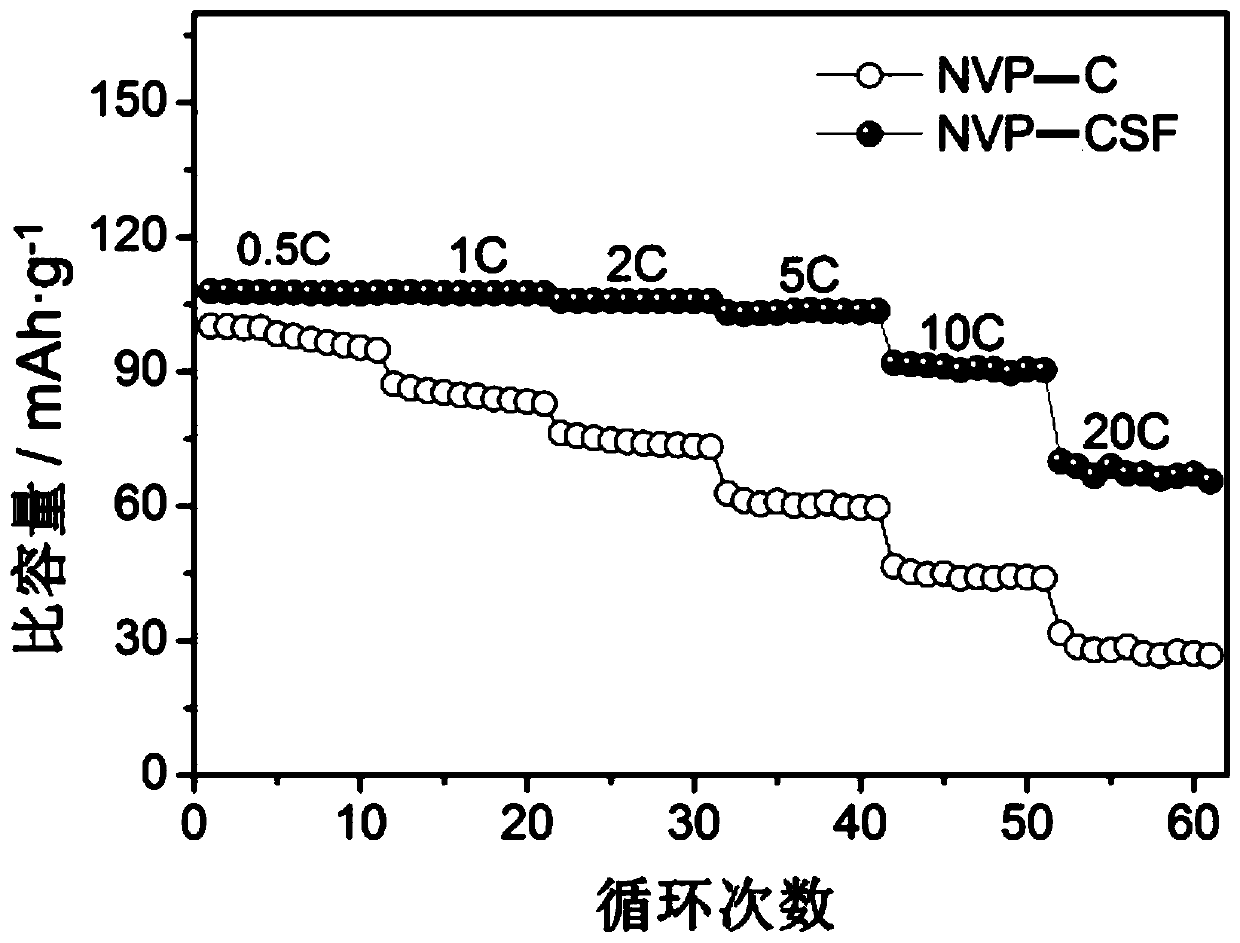

Preparation method of sodium vanadium phosphate sodium ion battery composite material

ActiveCN110165183AHigh reactivityImprove conductivitySecondary cellsPositive electrodesWater bathsSodium-ion battery

The invention relates to the technical field of sodium ion battery materials, and in particular to a preparation method of a sodium vanadium phosphate sodium ion battery composite material. The preparation method provided by the invention comprises the following steps of 1: mixing, ball milling and drying a sodium source, a vanadium source and a phosphorus source to obtain sodium vanadium phosphate precursor powders; 2: pre-sintering and sintering the sodium vanadium phosphate precursor powders is a non-oxidizing atmosphere to obtain sodium ion battery cathode material sodium vanadium phosphate; 3: dissolving a organic carbon source in a dispersant, adding the sodium vanadium phosphate and stirring the mixture in a water bath, evaporating the mixture until a gel is formed, and drying and milling the gel to obtain mixed powders; and 4, mixing and grinding a compound containing the Y element and the mixed powders obtained in the step 3, sintering the mixture at 300 to 500 degrees centigrade for 0.5 to 3 hours to obtain the sodium vanadium phosphate sodium ion battery composite material. The method can solve the technical problem that the existing sodium vanadium phosphate has low electronic conductivity and thus seriously limits its rate performance and cycle performance.

Owner:GUANGDONG POWER GRID CO LTD +1

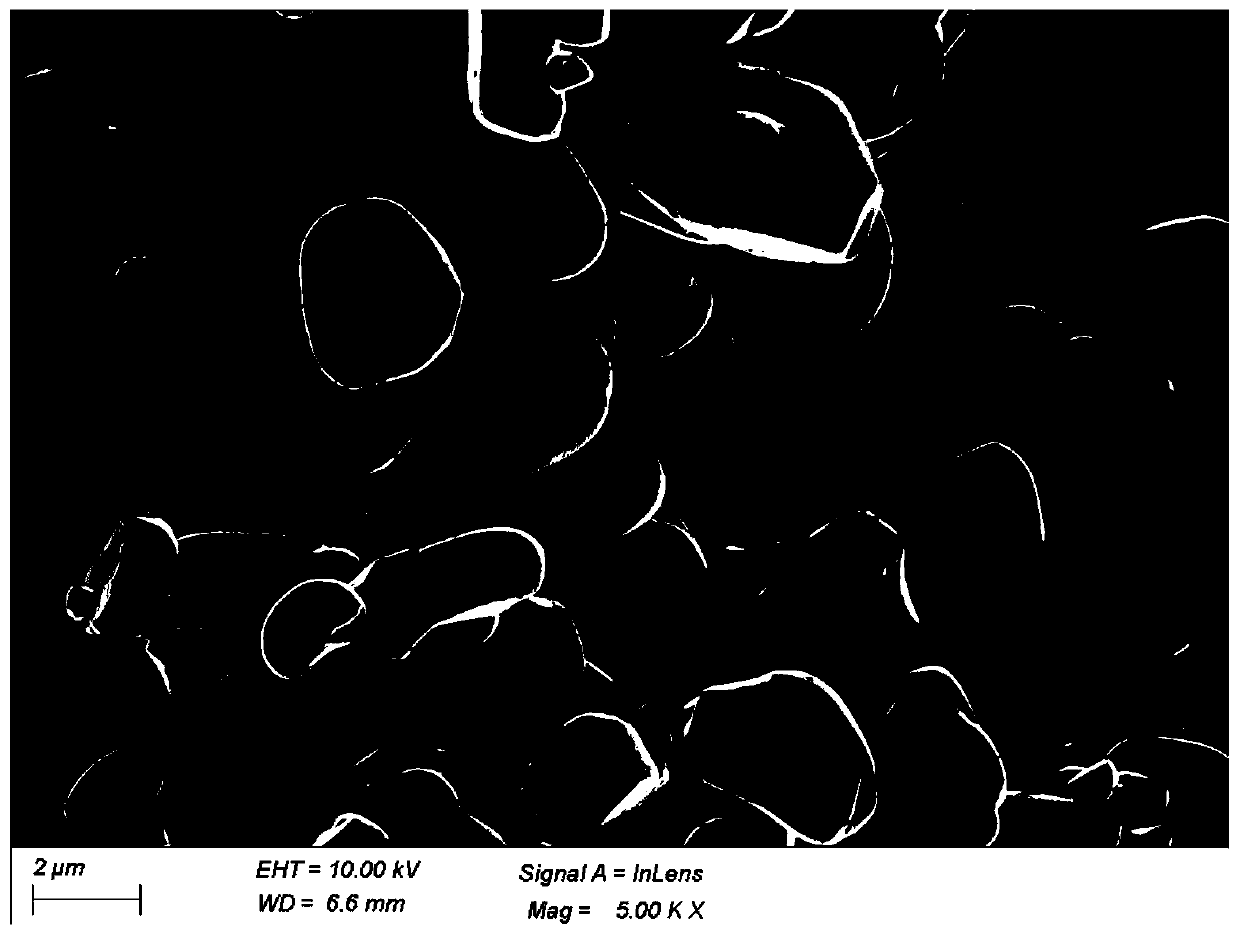

Artificial graphite composite negative electrode material for lithium ion battery as well as preparation method and application of artificial graphite composite negative electrode material

PendingCN114597361AGood compatibilityGood magnification performanceGraphiteSecondary cellsCarbon coatingLithium electrode

The invention provides an artificial graphite composite negative electrode material and a preparation method and application thereof. The preparation method comprises the following steps: (1) calcining green coke at a high temperature of 800-1200 DEG C, and cooling to obtain shallow calcined coke; (2) crushing and shaping the shallow calcined coke obtained in the step (1) to obtain coke powder; (3) mixing the coke powder obtained in the step (2) with asphalt, and granulating to obtain secondary particles; (4) carrying out graphitization treatment on the secondary particles obtained in the step (3), and then scattering and screening to obtain screened materials; and (5) carrying out carbon coating treatment on the screened material obtained in the step (4) to obtain the artificial graphite composite negative electrode material. The graphite negative electrode material prepared by the method is used for the lithium ion battery, has high capacity and high magnification at the same time, and is simple in preparation process and relatively high in practicability.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

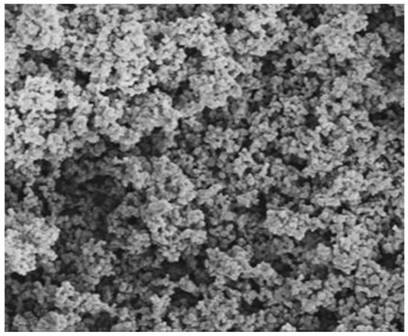

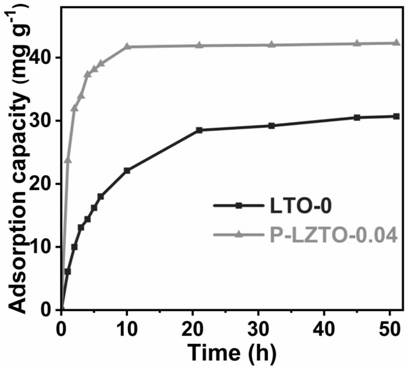

Porous doped titanium-based lithium adsorbent and preparation method thereof

The invention discloses a porous doped titanium-based lithium adsorbent and a preparation method thereof, and relates to the technical field of preparation of lithium adsorbents. According to the porous doped titanium-based lithium adsorbent, a rapid and efficient lithium adsorption effect is achieved by regulating and controlling the types and the amount of substances of a lithium source, a nitrogen-containing surfactant and doped elements. According to the invention, through the modification method, raw materials can be fully and uniformly mixed, an adsorption effect is enhanced, a titanium-based lithium adsorbent precursor can be obtained through high-temperature sintering, and the lithium ions in the titanium-based lithium adsorbent precursor are removed through acid pickling so as to obtain the porous doped titanium-based lithium adsorbent; and the macropores of the porous doped titanium-based lithium adsorbent can effectively improve the wettability of the material, N doping provides rich nitrogen functional groups for the adsorbent, the adsorption effect of the adsorbent is improved, metal ion doping facilitates expansion of an internal lithium ion diffusion channel, the internal and external diffusion rate of the adsorbent is increased, and the adsorption capacity of the adsorbent is improved, so that the adsorption capacity and dynamic characteristics of the adsorbent are enhanced.

Owner:SICHUAN UNIV

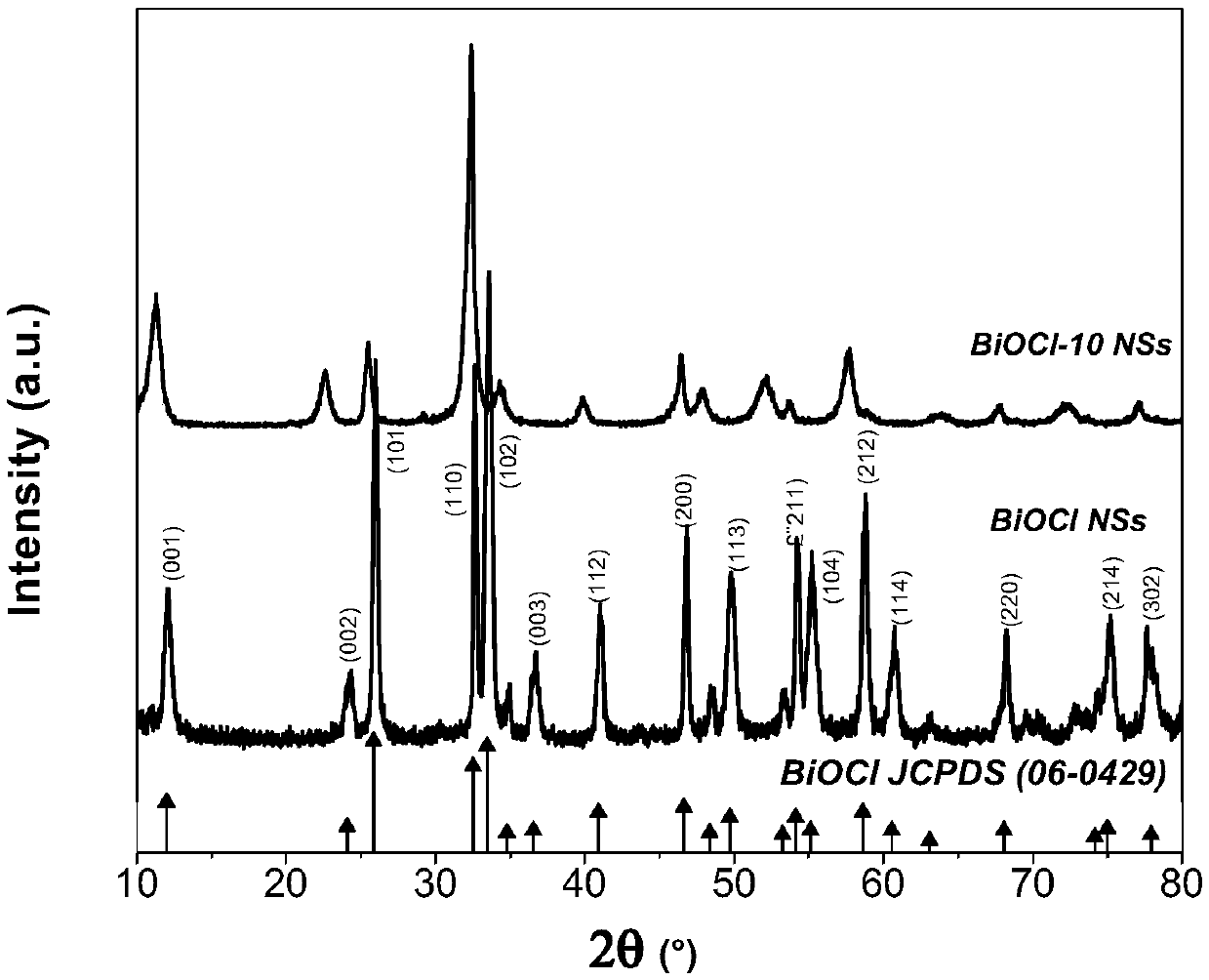

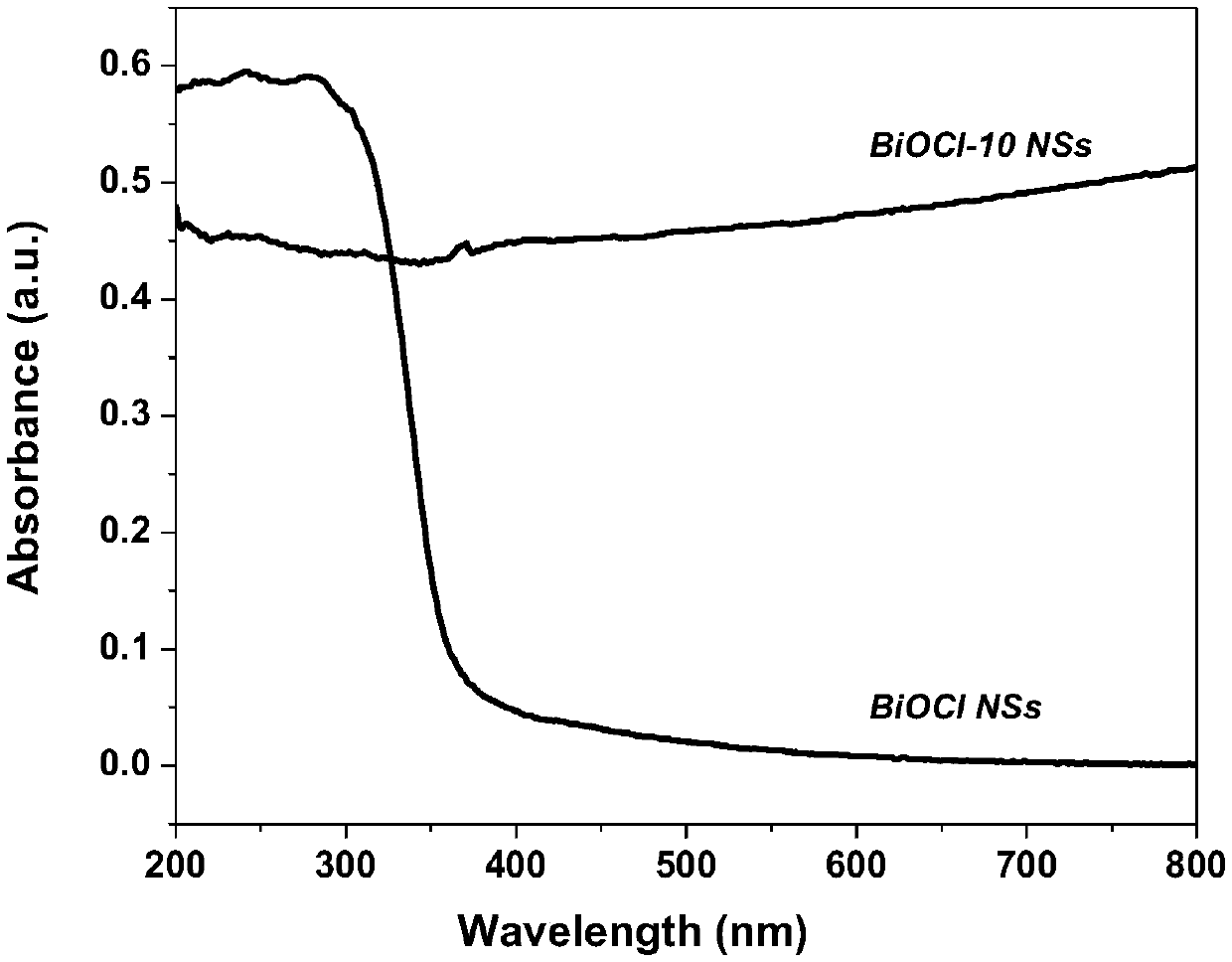

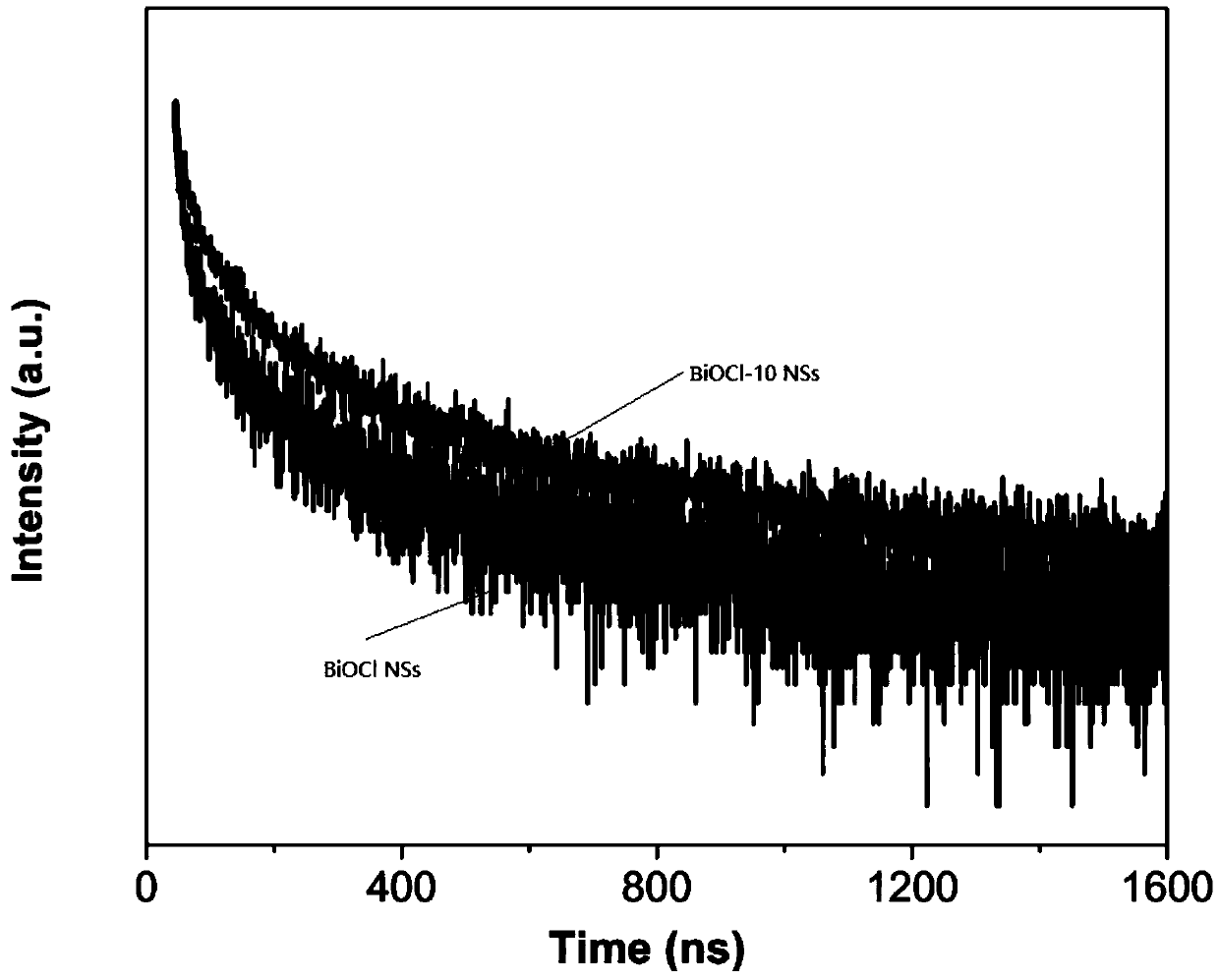

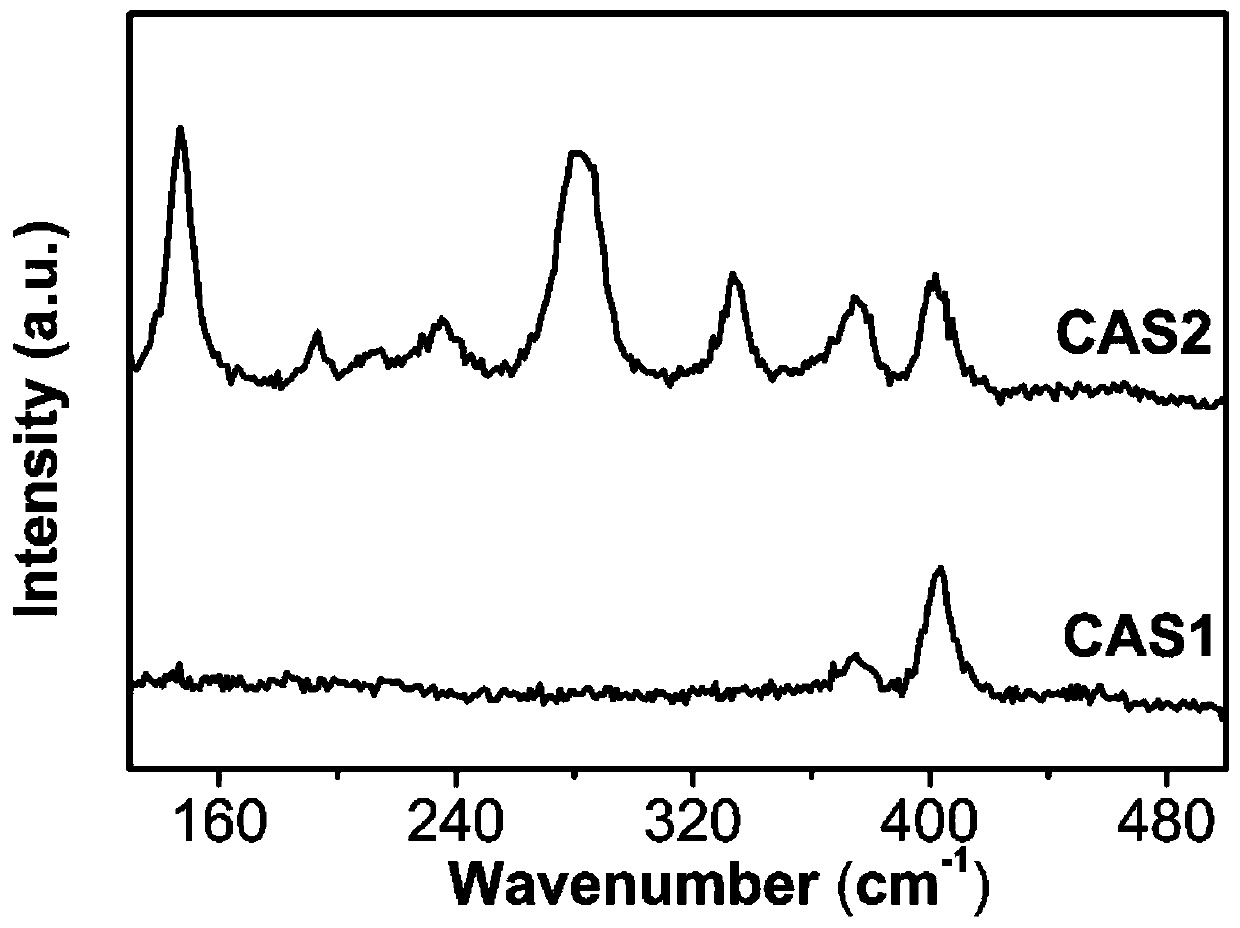

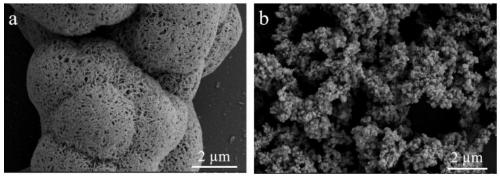

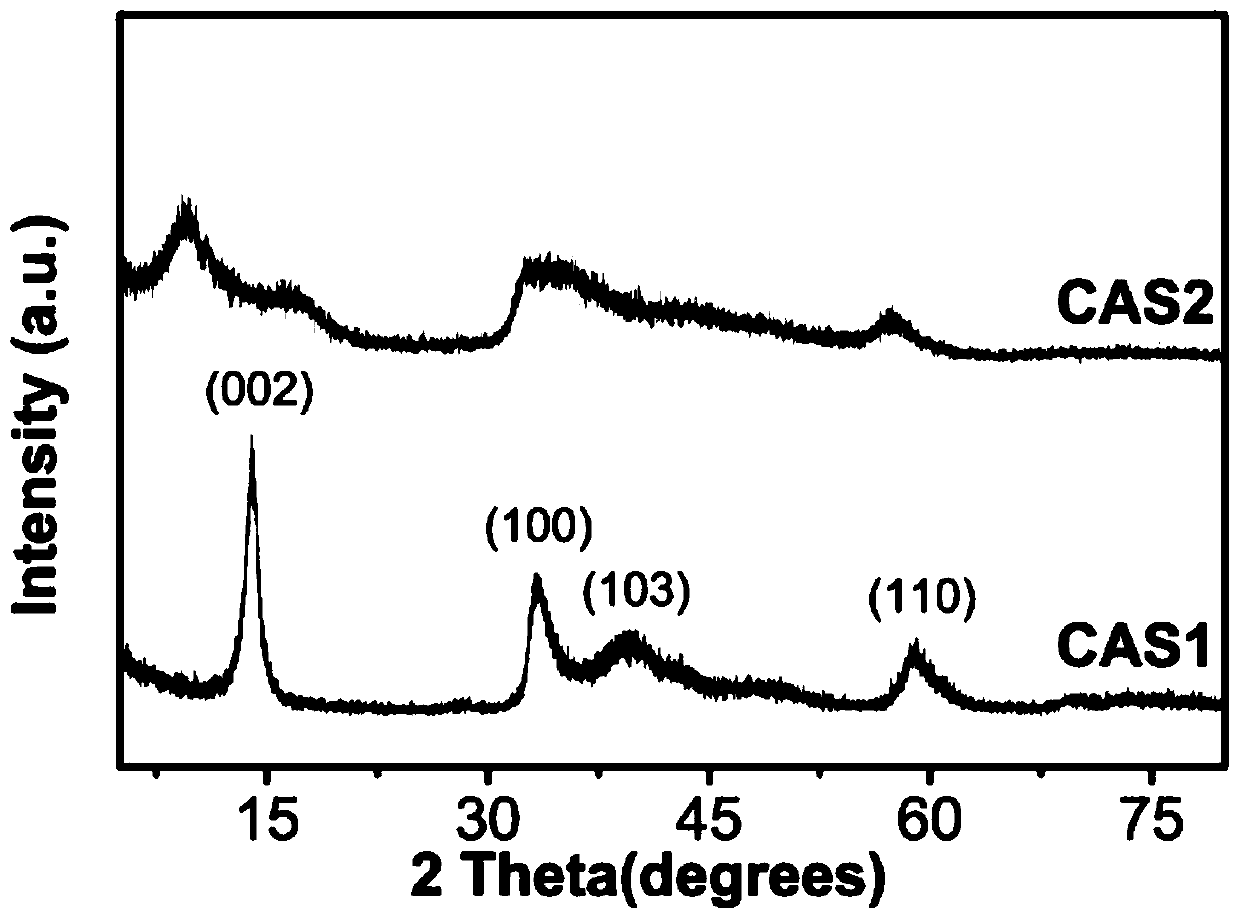

Carbon and nitrogen-doped full spectrum absorbing BiOCl and preparation and application methods thereof

ActiveCN109665560AExtend your lifeReduce pollutionPhysical/chemical process catalystsNanotechnologySolventMuffle furnace

The invention relates to a carbon and nitrogen-doped full spectrum absorbing BiOCl and preparation and application methods thereof. The preparation method of the carbon and nitrogen-doped full spectrum absorbing BiOCl comprises the following steps of dissolving and mixing a chlorine ion source, polyethyleneimine, polyvinyl pyrrolidone and urea in solvent to obtain a solution A; dissolving bismuthsalt into solvent to obtain a solution B; pouring the solution A into the solution B to obtain a precursor solution, uniformly stirring and then pouring the precursor solution into a reactor for thermal reaction; cooling the reactor down to room temperature to obtain precipitates, and washing and drying the precipitates to obtain solid powder; pouring the solid powder into a crucible, placing thecrucible into a muffle furnace, increasing the temperature to 350 DEG C at a heating speed of 3-5 DEG C / min, keeping the temperature and then cooling the muffle furnace down to room temperature to obtain gray powder, namely, the carbon and nitrogen-doped full spectrum absorbing BiOCl. By means of a hydrothermal method, the urea can produce gas during reaction to expand crystal lattices and meanwhile can enter into the BiOCl crystal lattices, and then by calcination, the carbon and nitrogen-doped full spectrum absorbing BiOCl can be obtained.

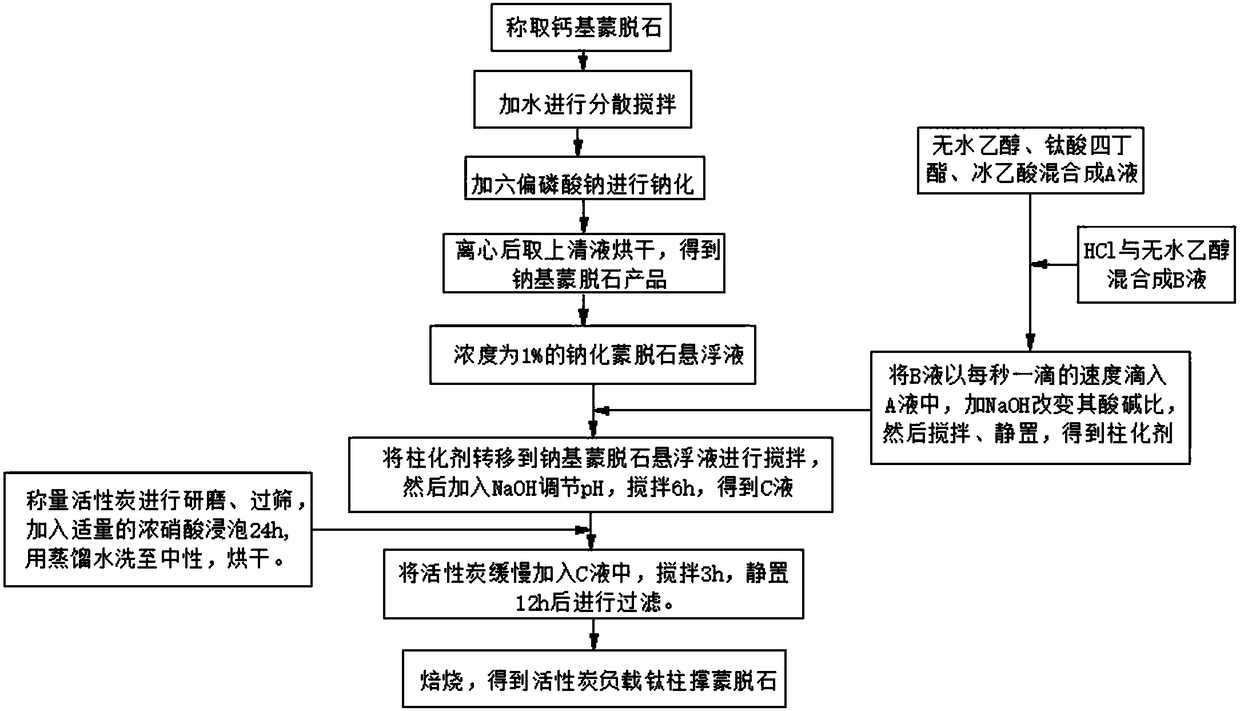

Preparation method of activated carbon supported titanium-pillared montmorillonite composite material

InactiveCN108554377ADistributeGood molecular adsorption characteristicsOther chemical processesWater contaminantsRecovery methodTreatment effect

The invention provides a preparation method of an activated carbon supported titanium-pillared montmorillonite composite material. The method comprises the following steps: firstly, performing sodiumtreatment on calcium-based montmorillonite to obtain sodium-based montmorillonite, and then, uniformly dispersing the sodium-based montmorillonite in distilled water to prepare suspension; uniformly mixing absolute ethanol, tetrabutyl titanate and glacial acetic acid according to a certain proportion to prepare a solution A; mixing HCL and absolute ethanol to prepare a solution B; preparing a pillared agent by utilizing the solution A and the solution B; transferring the pillared agent into the sodium-based montmorillonite suspension, and performing intense stirring; adding a proper amount ofNaOH solution to adjust the pH of the mixed solution, and performing stirring at room temperature; and adding activated carbon powder without lime to finally obtain activated carbon supported titanium-pillared montmorillonite. The method provided by the invention solves the problems that an existing heavy metal recovery method has a poor treatment effect, easily causes secondary pollution and thelike. The invention belongs to the field of preparation of composite materials.

Owner:GUIZHOU UNIV

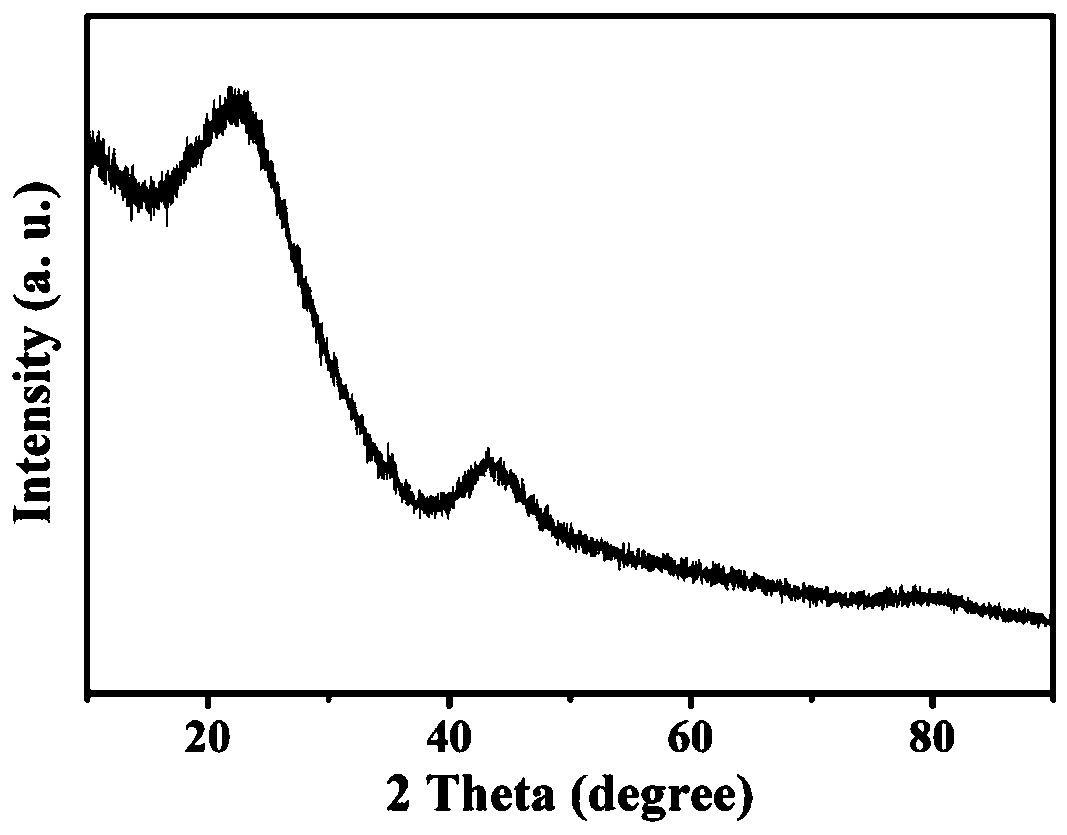

Method for preparing 1T-phase molybdenum disulfide induced by carbon dot doping and application thereof to energy storage material

InactiveCN110228821AImprove electrochemical performanceExcellent catalytic absorbing performanceHybrid capacitor electrodesNano-carbonSulfurHybrid material

The invention discloses a method for preparing 1T-phase molybdenum disulfide induced by carbon dot doping and application thereof to an energy storage material. The preparation method comprises the following steps: fully mixing a molybdenum source, a sulfur source, a carbon source and water according to a certain molar ratio and stirring to obtain a uniform solution, namely a precursor solution; transferring the precursor solution into an autoclave, reacting at a high temperature and under high pressure, filtering a reaction solution after the reaction and washing, and drying to obtain the carbon dot-doped 1T molybdenum disulfide powder. The 1T-phase molybdenum disulfide hybrid material prepared in the invention shows good electrochemical performance and catalytic absorbing property, and has broad potential for industrial application.

Owner:ANHUI UNIVERSITY

Nitrogen-oxygen double-doped porous hollow bowl-shaped carbon material and preparation method thereof

ActiveCN110255999AIncrease interplanar spacingStable structureCell electrodesCarbon preparation/purificationDispersitySodium-ion battery

The invention belongs to the technical field of inorganic material preparation and battery materials, and relates to a carbon-oxygen double-doped porous hollow bowl-shaped carbon material and a preparation method thereof. The material is carbon bowl-shaped structure particles, which are high in dispersity, narrow in particle size distribution and controllable in particle size; a hollow structure exists in the particles, the appearance is in a concave bowl shape, and the wall thickness is controllable; a plurality of holes are formed in the bowl wall and comprise micropores and mesopores, so that the specific surface area is high. The material has the characteristic of double doping of nitrogen and oxygen elements, and can be used for a potassium ion battery negative electrode with high volume specific capacity and cycling stability. Due to the characteristics of rich potassium global reserve and low oxidation-reduction voltage value, the potassium ion battery is considered to be one of traditional high-price lithium ion battery candidates; however, the size of potassium ions is large, so that the potassium ion battery electrode material with high specific capacity and good cycling stability and rate capability is lacked in the prior art. The material is used for potassium ion battery electrodes, and the purposes of enhancing the stability of the potassium ion battery, improving the rate capability and improving the volume specific capacity of the battery are achieved.

Owner:UNIV OF SCI & TECH BEIJING

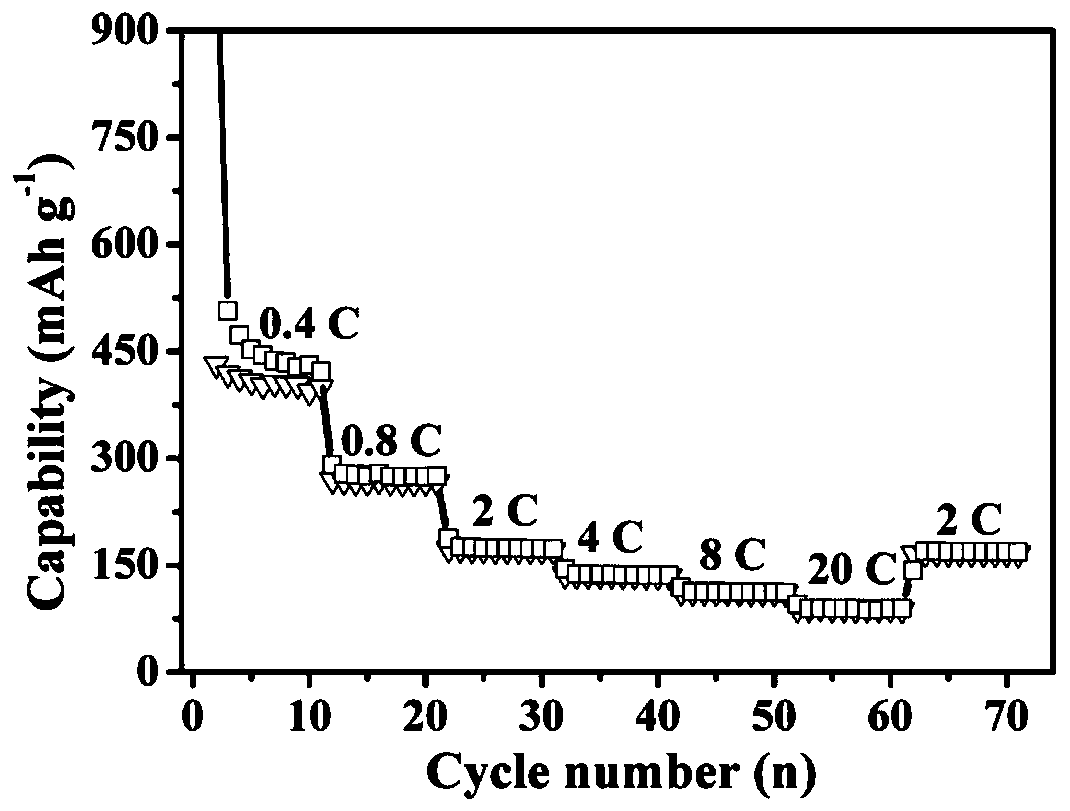

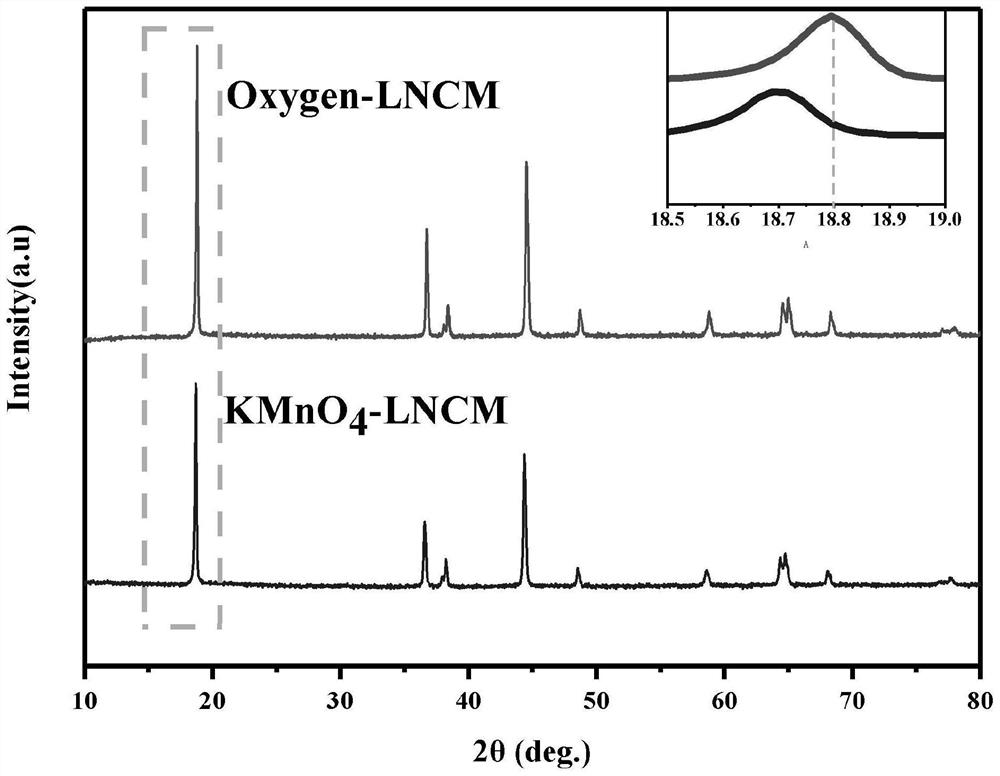

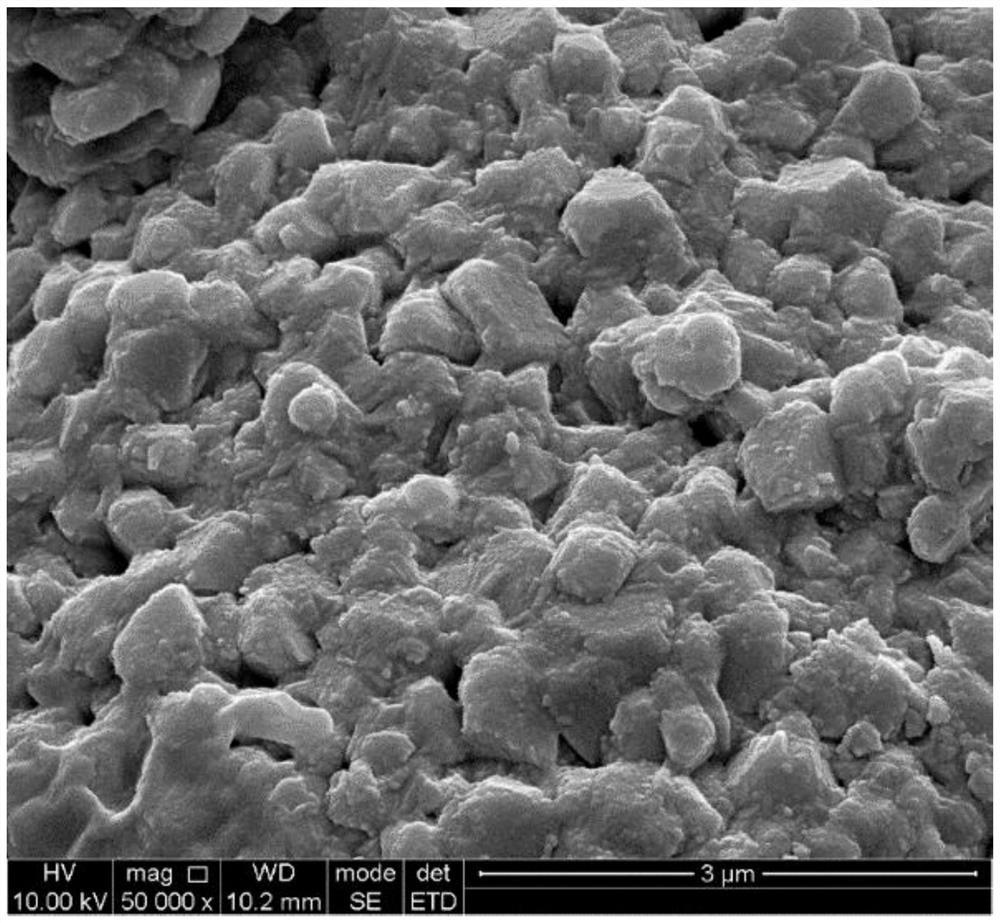

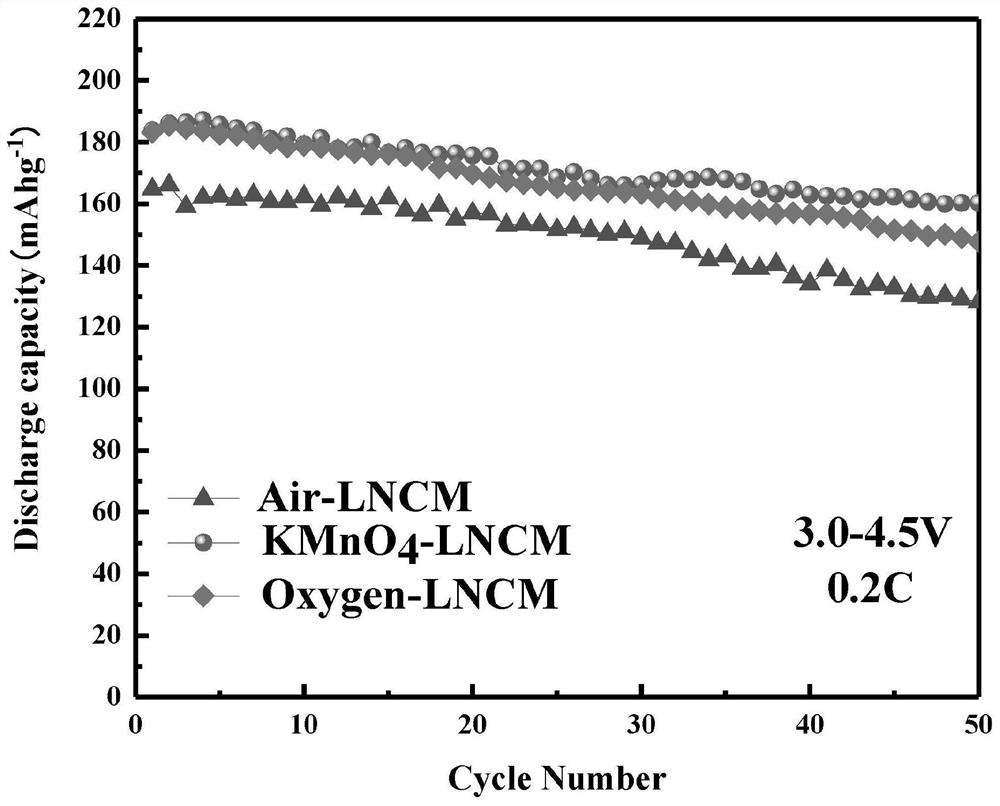

Modification method for realizing doping and coating of a high-nickel ternary positive electrode material by using pretreatment precursor

PendingCN112038613AGuaranteed doping ratioAdulteration protectionSecondary cellsPositive electrodesAir atmospherePotassium manganate

The invention discloses a modification method for realizing doping and coating of a high-nickel ternary positive electrode material by using a pretreatment precursor. The modification method comprisesthe following steps of: (1) dispersing a high-nickel ternary precursor into deionized water to obtain a precursor solution; (2) dissolving potassium permanganate in deionized water to obtain a potassium permanganate solution; (3) adding the potassium permanganate solution into the precursor solution, stirring the mixed solution, carrying out suction filtration, and carrying out vacuum drying on the mixed solution to obtain a potassium permanganate pretreatment precursor; and (4) grinding and uniformly mixing the potassium permanganate pretreatment precursor and LiOH.H2O, and calcining the mixture in air to obtain a high-nickel ternary positive electrode modified material. According to the modification method, the potassium permanganate is used as a strong oxidant and a pretreatment precursor, so that the preparation conditions of the product are simplified, the current oxygen atmosphere is replaced, MnO2 coating and Mn <4+> doping can be realized through high-temperature calcination in the air atmosphere, and the prepared product has the advantages of good structural stability, good cycle performance, high rate capability, capability of inhibiting surface side reaction, good electrochemical performance and the like.

Owner:GUIZHOU UNIV

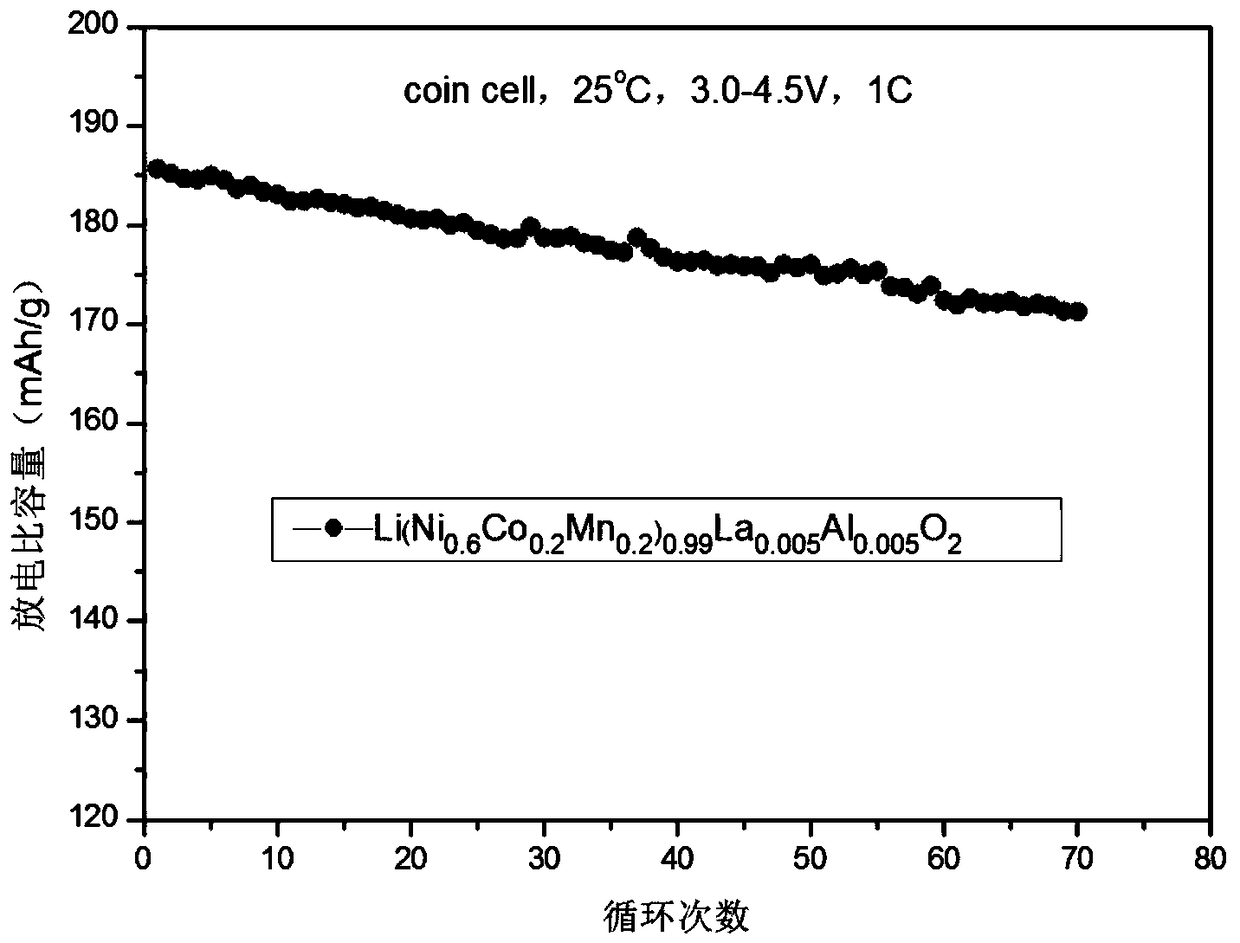

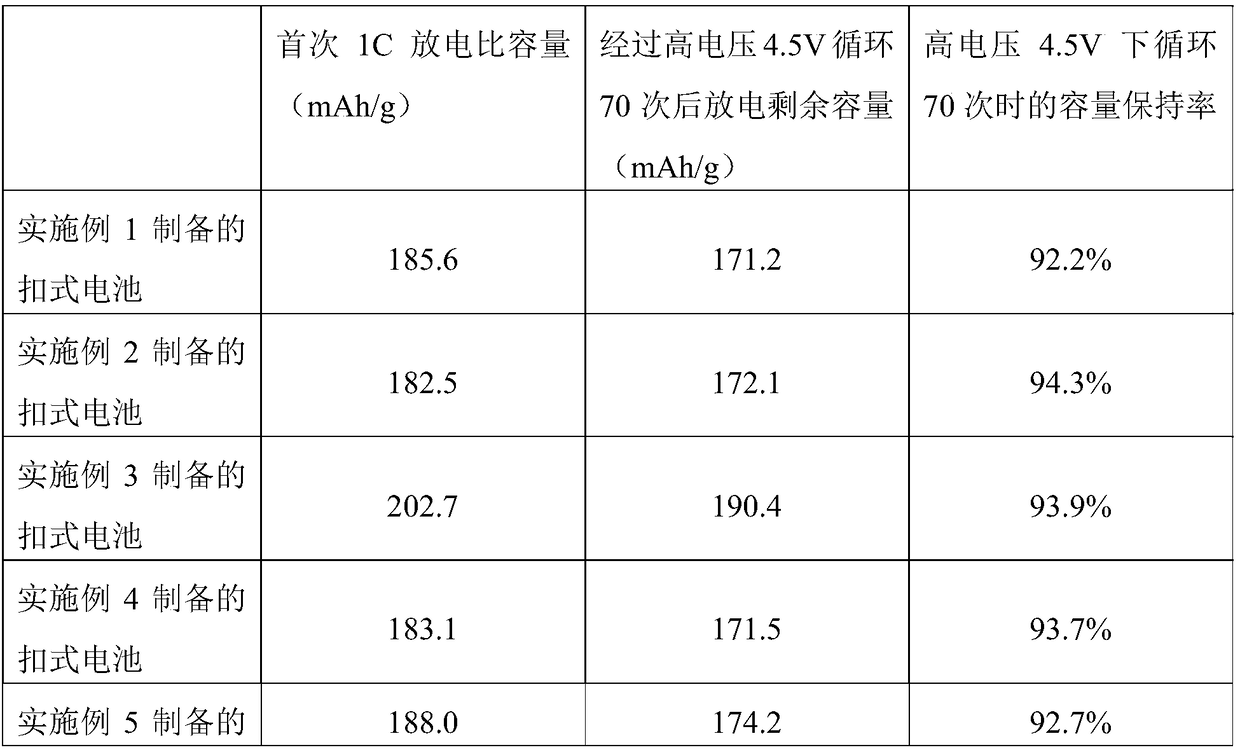

Nickel-cobalt lithium manganate positive electrode material applied to high-voltage lithium ion batteries and preparation method thereof

InactiveCN108807975ASolve the problem of rapid capacity decayPromote migrationCell electrodesSecondary cellsManganateLanthanum

The invention discloses a nickel-cobalt lithium manganate positive electrode material applied to high-voltage lithium ion batteries. The chemical formula of nickel-cobalt lithium manganate is Li(NixCoyMn1-x-y)1-a-bLaaAlbO2, wherein a is greater than or equal to 0 and is less than or equal to 0.05, b is greater than or equal to 0 and is less than or equal to 0.1, x is greater than or equal to 0.3 and is less than or equal to 0.8, and y is greater than or equal to 0.05 and is less than or equal to 0.4. A preparation method of the nickel-cobalt lithium manganate positive electrode material comprises the following steps: carrying out ball milling and mixing a nickel-cobalt-manganese precursor, a lanthanum source, an aluminum source and lithium salt in a horizontal ball mill, then pre-sinteringthe obtained mixture in a muffle furnace, then carrying out secondary ball milling and mixing the obtained mixture in the horizontal ball mill, and finally sintering the obtained mixture in a high-temperature tubular furnace to obtain a final product which is nickel-cobalt lithium manganate used as a positive electrode material. According to the nickel-cobalt lithium manganate positive electrodematerial, La and Al are co-doped in the nickel-cobalt lithium manganate positive electrode material; the interplanar crystal spacing can be increased, so that the migration of lithium ions can be accelerated; the stability of the lithium-free state of the crystal structure under high voltage can be improved; meanwhile, the crystal lattice volume and the stress expansion can be effectively reduced;the nickel-cobalt lithium manganate positive electrode material has the characteristics of high capacity and excellent cycle performance under high voltage; the disordered-ordered phase change underhigh voltage of the nickel-cobalt lithium manganate positive electrode material can be effectively inhibited; the problem of rapid capacity attenuation of the material in cycle under high voltage is solved, so that the service life of the lithium ion batteries can be prolonged.

Owner:ETRUST POWER ETP GRP LTD

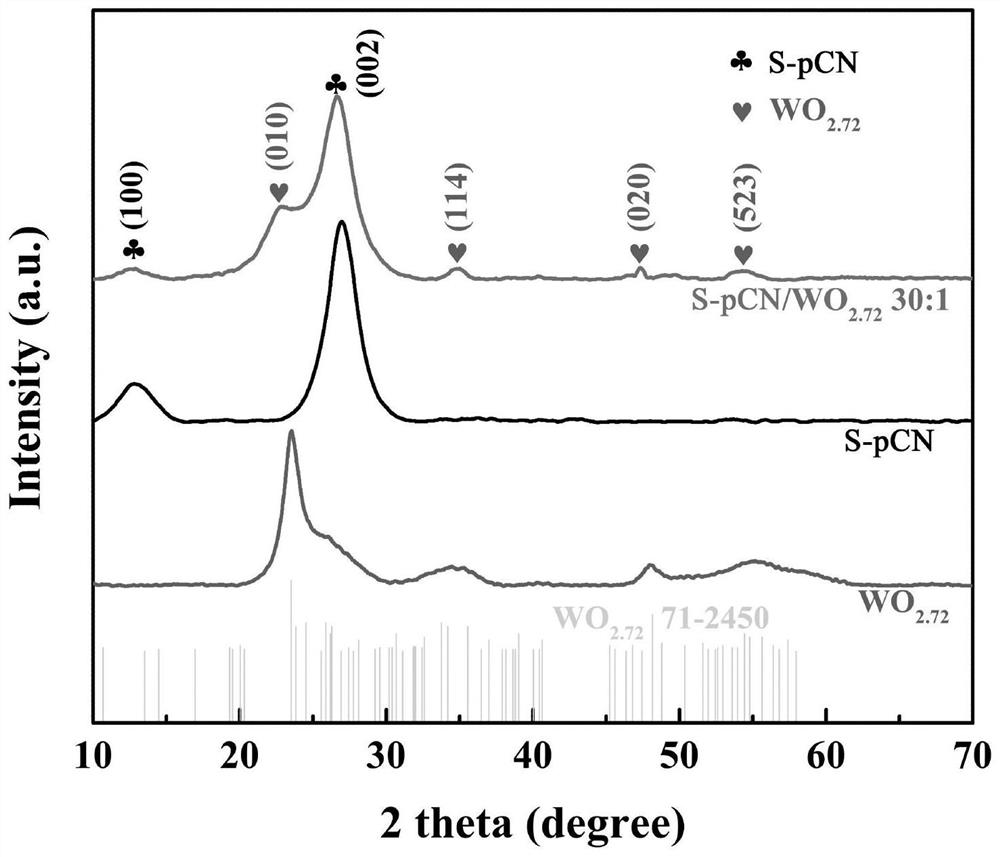

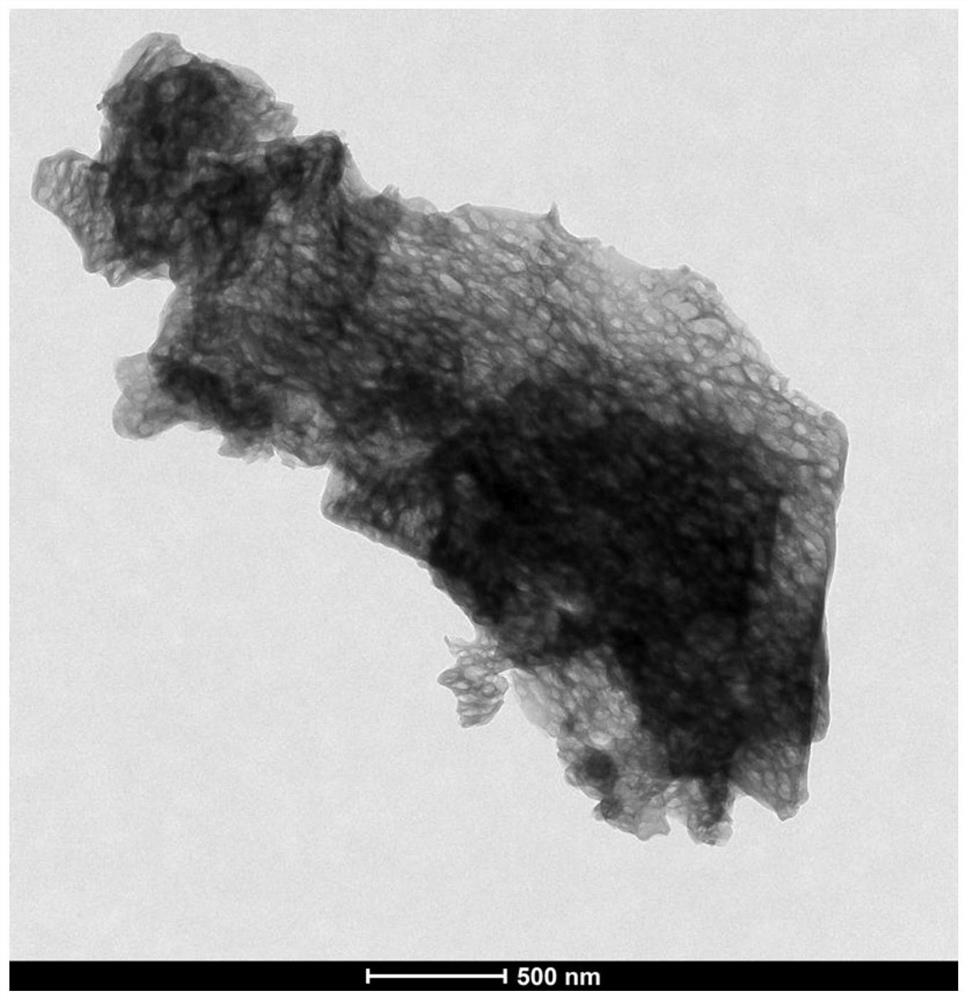

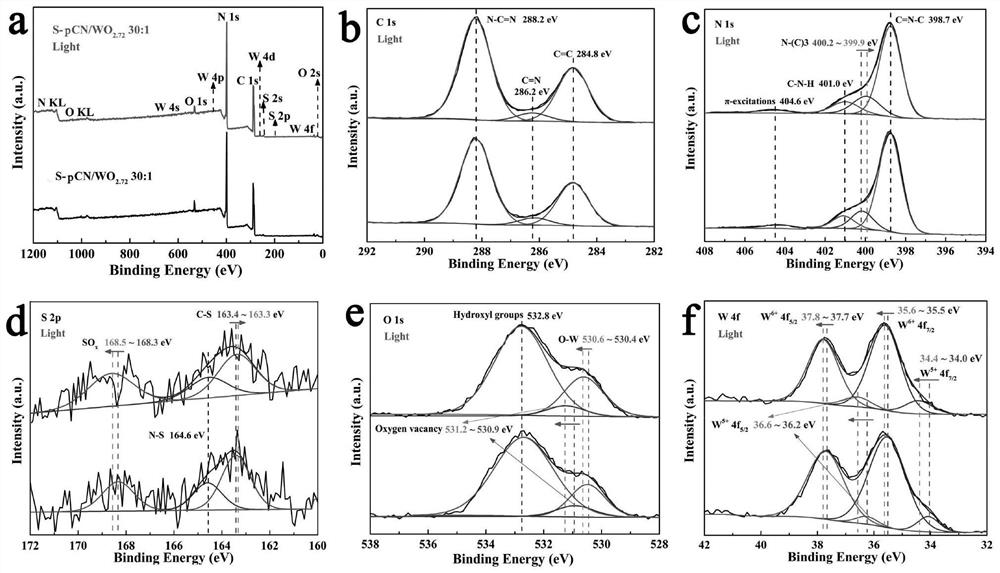

Preparation method of two-dimensional S-type heterojunction composite photocatalyst sulfur-doped porous carbon nitride/defective tungsten oxide

ActiveCN111659452AEasy transferPromote formationPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionPtru catalyst

The invention discloses a preparation method of a two-dimensional S-type heterojunction composite photocatalyst sulfur-doped porous carbon nitride / defective tungsten oxide. The sulfur-doped porous carbon nitride / defective tungsten oxide (S-pCN / WO2.72) is a two-dimensional S-type heterojunction composite photocatalyst which is constructed by compounding sulfur-doped porous carbon nitride (S-pCN) and defective tungsten oxide (WO2.72). The preparation method comprises the following steps of: taking urea and thioacetamide as raw materials, and preparing S-pCN through a simple calcining method; preparing WO2.72 by taking tungsten chloride as a raw material and ethanol as a solvent and adopting a solvothermal method; letting S-pCN and WO2.72 be subjected to a solvent evaporation induced self-assembly method in an ethanol solvent to prepare the S-pCN / WO2.72. The method has the advantages that the process is simple, the cost is low, the sunlight utilization range is wider, surface oxygen vacancies are introduced to improve the separation capacity of electron hole pairs, a built-in electric field is constructed on a heterojunction interface to promote separation of photo-induced charges andimprove the oxidation-reduction capacity of the composite catalyst, and efficient photocatalytic degradation of sewage and wastewater is expected to be achieved.

Owner:NANCHANG HANGKONG UNIVERSITY

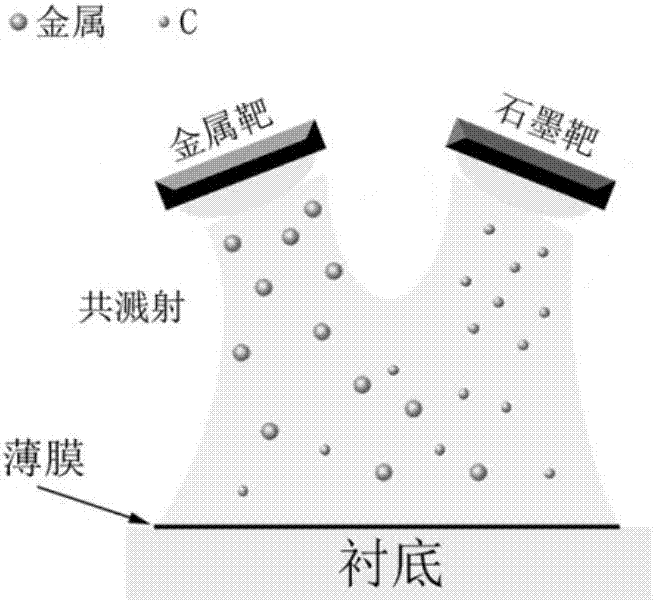

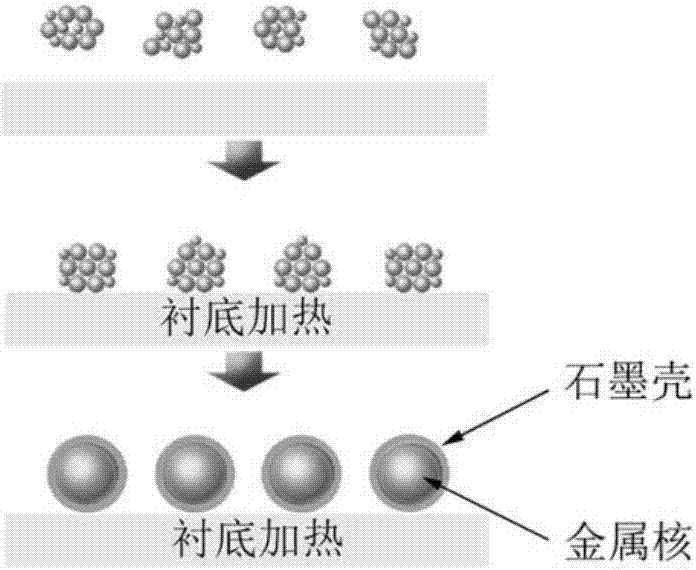

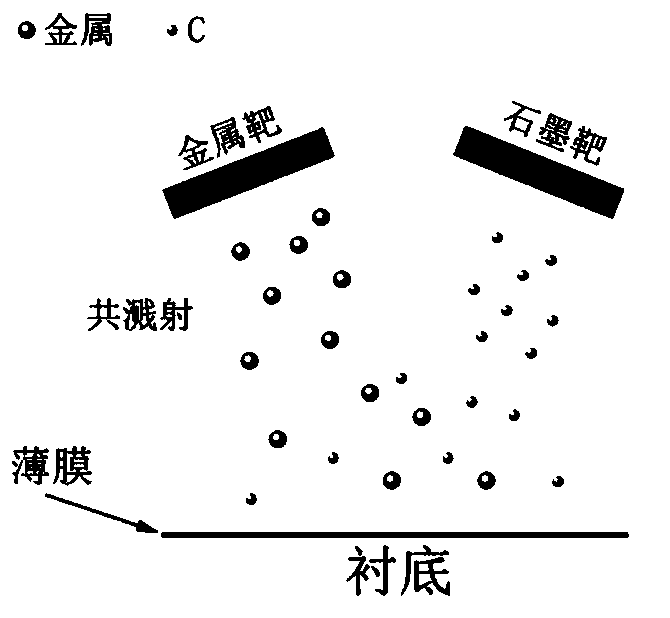

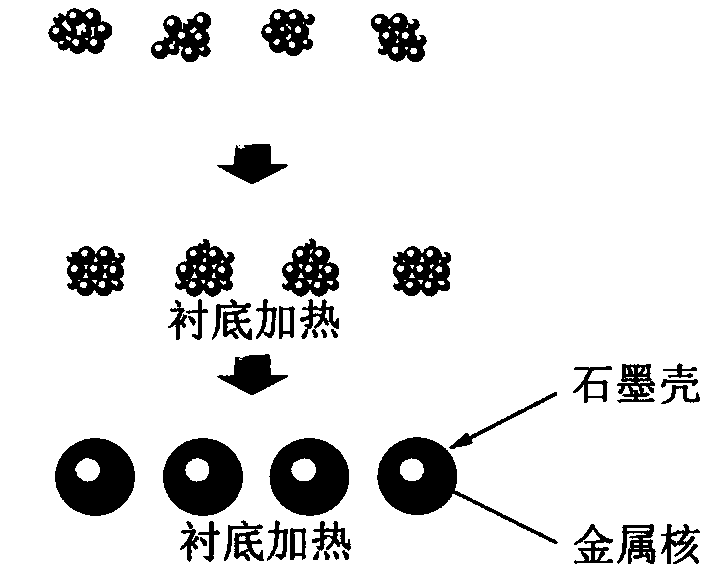

Electrocatalyst for transition metal core-shell structure film and preparation method thereof

ActiveCN107579257AIncrease surface areaGood repeatabilityCell electrodesFinal product manufactureNitrogen gasMethane gas

The invention relates to an electrocatalyst for a transition metal core-shell structure film and preparation method thereof, and belongs to the field of the preparation of catalyst materials. The filmtakes a metal nanometer particle as a core, and nitrogen-doped onion-shaped graphite as a shell, and the thickness of the film formed by the nanometer particle adopting a core-shell structure on a substrate is 200 to 1200nm. According to the method, a magnetron sputtering small angle deposition technology is adopted, a metal target is taken as a metal nanometer particle source, a graphite targetor methane gas is taken as a carbon source, nitrogen is taken as nitrogen source gas, and meanwhile argon is led, so as be taken as sputtering gas, so that the fact that metal catalyzes the graphitization growth and in-situ self-assembly of carbon to form a nitrogen-doped onion-shaped graphite packed metal nanometer particle film is realized. The electrocatalyst has the advantages of simple technology, low cost, high repeatability, high yield and capability of realizing mass industrial production; no by-products exist during the preparation, and a formed sample presents stability and methanoltolerant property superior to that of commercial Pt / C catalysts.

Owner:JILIN UNIV

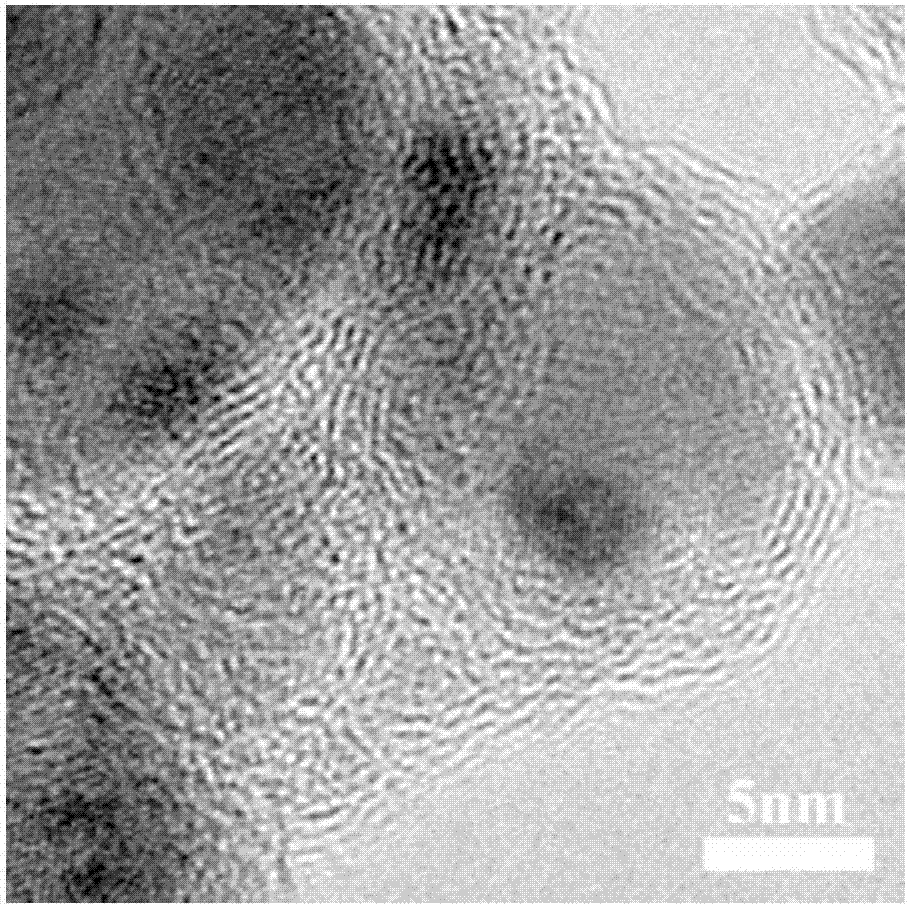

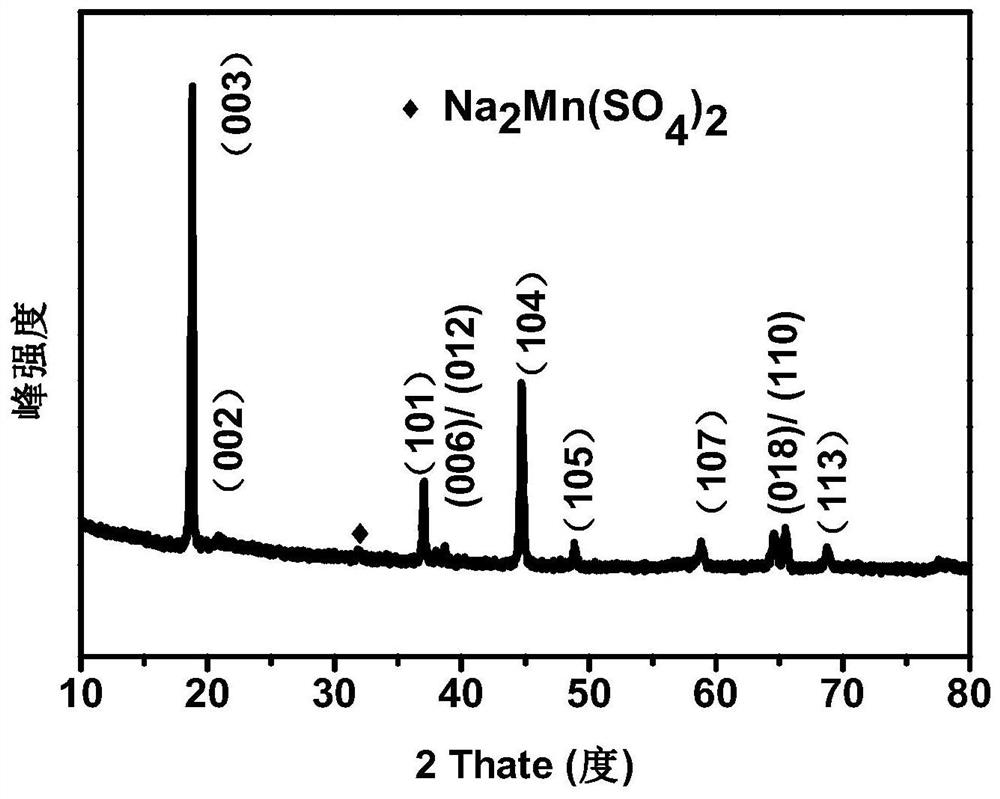

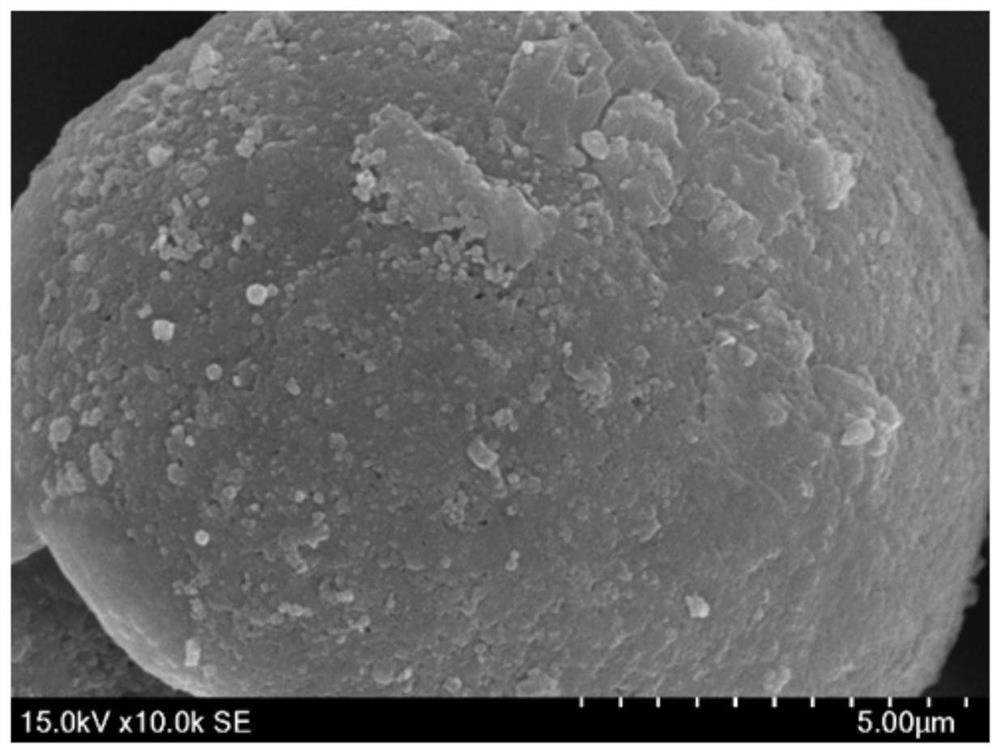

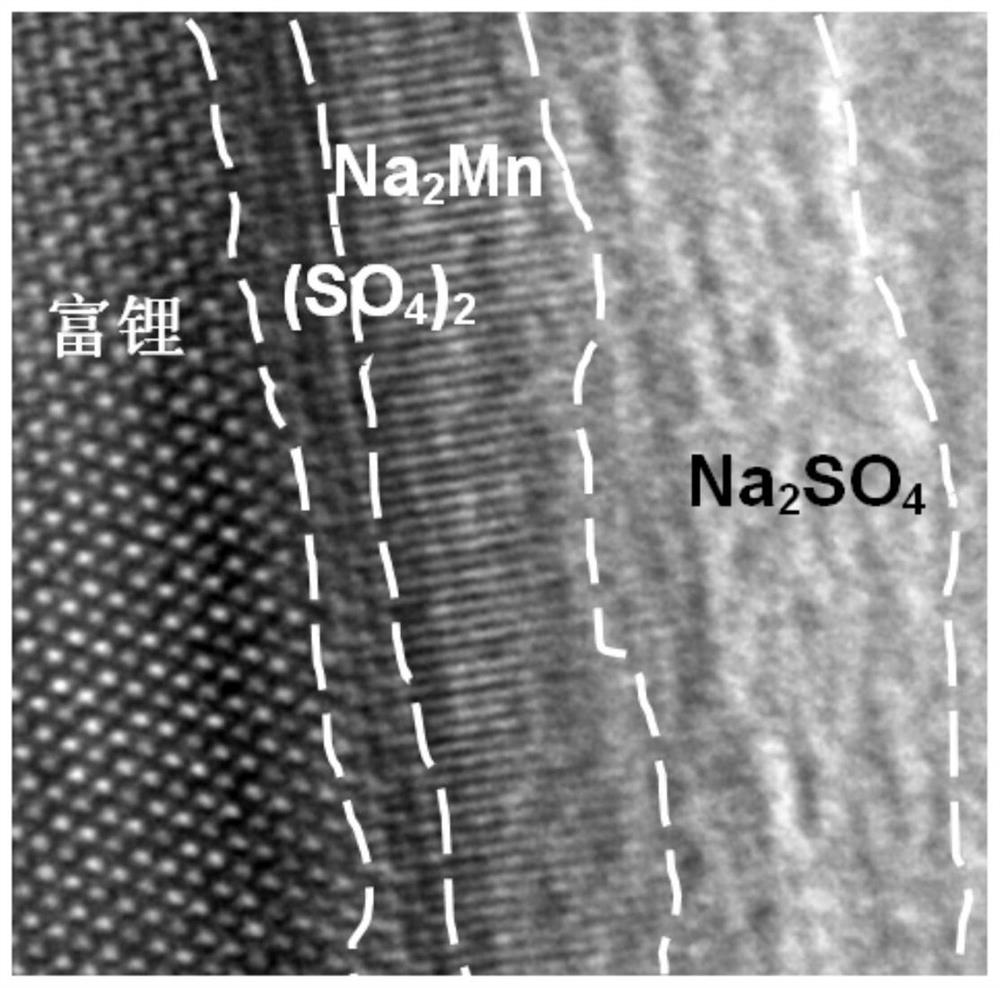

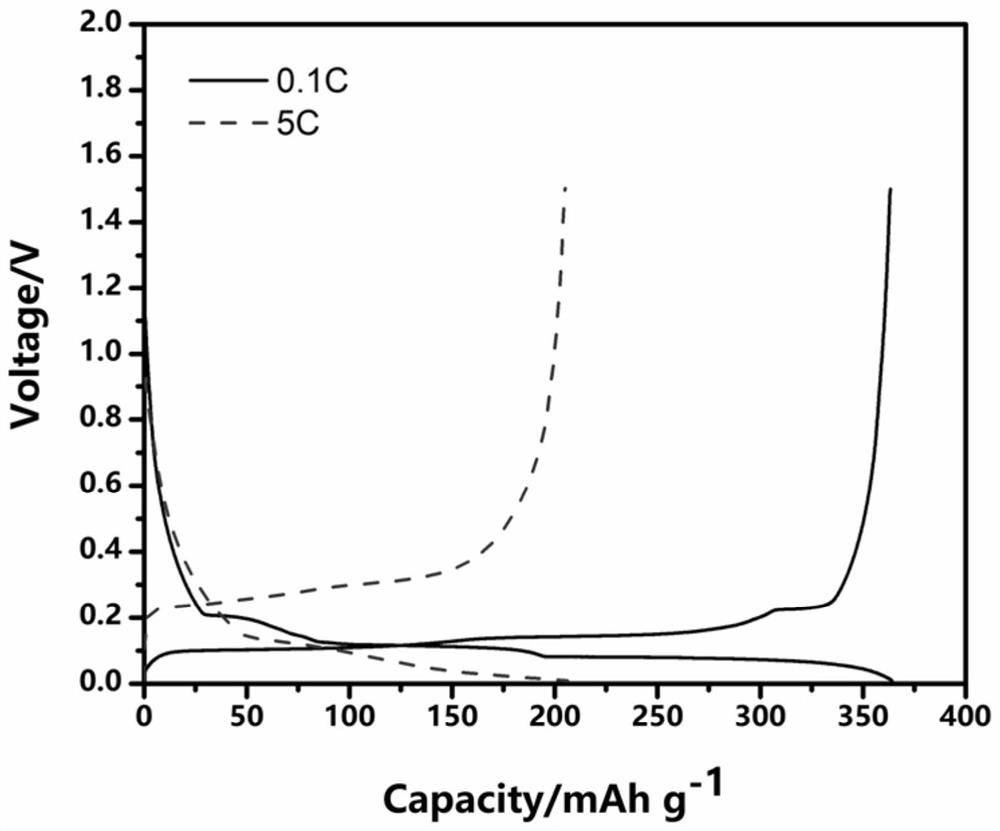

Preparation method and application of epitaxial growth layer and sulfur-sodium lattice modified lithium-rich manganese-based positive electrode material

InactiveCN112242510AImprove cycle lifeIncrease interplanar spacingCell electrodesSecondary cellsElectrical batteryManganese

The invention discloses a preparation method and application of an epitaxial growth layer and sodium sulfide lattice modified lithium-rich manganese-based positive electrode material. The epitaxial growth layer and the sulfur-sodium lattice modified lithium-rich manganese-based positive electrode material provided by the invention are simple in preparation method, easy in post-treatment and low incost; the particle size distribution of the prepared positive electrode material is uniform, the discharge specific capacity of the 0.1 C first circle is 304.69 mAh g < -1 >, the discharge specific capacity of the 5C is 129.43 mAh g < -1 >, and the capacity retention rate is 93.31%. Not only are the specific discharge capacity, the rate capability and the cycle performance of the first circle remarkably improved, but also the attenuation of the voltage is effectively relieved; therefore, the epitaxial growth layer and the sulfur-sodium lattice modified lithium-rich manganese-based positive electrode material prepared by the method have wide application prospects in preparation of lithium ion batteries.

Owner:乳源东阳光新能源材料有限公司 +1

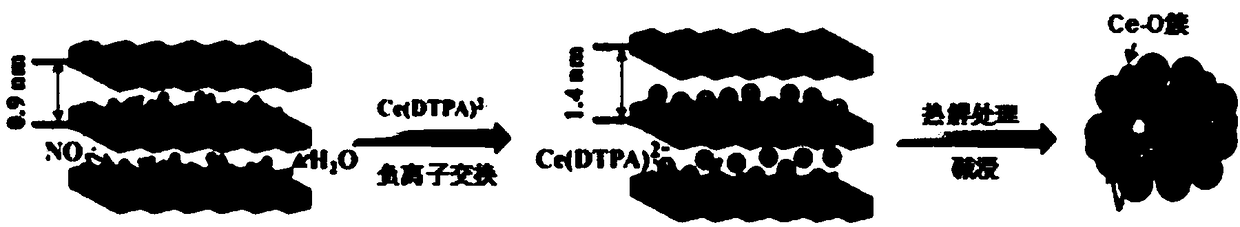

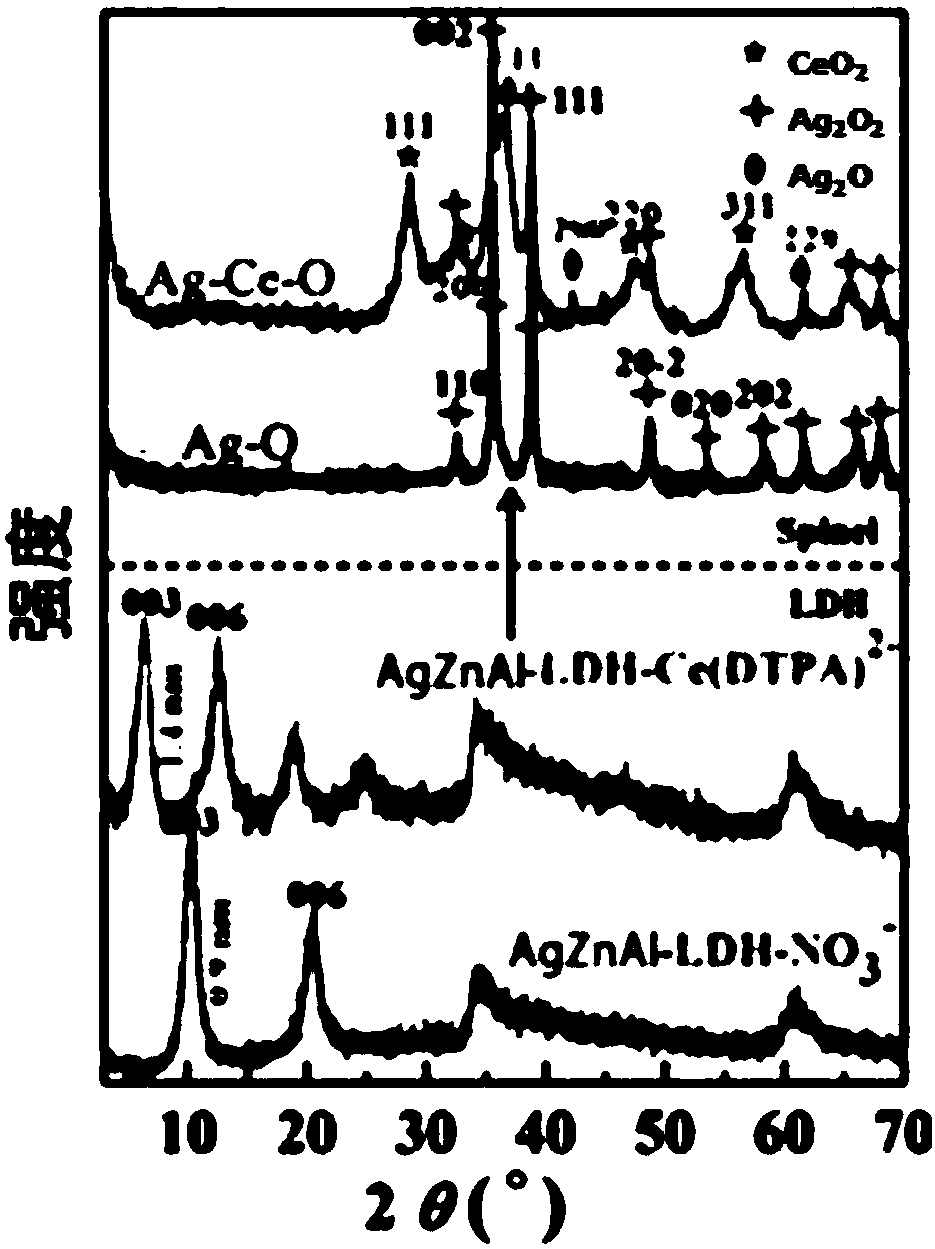

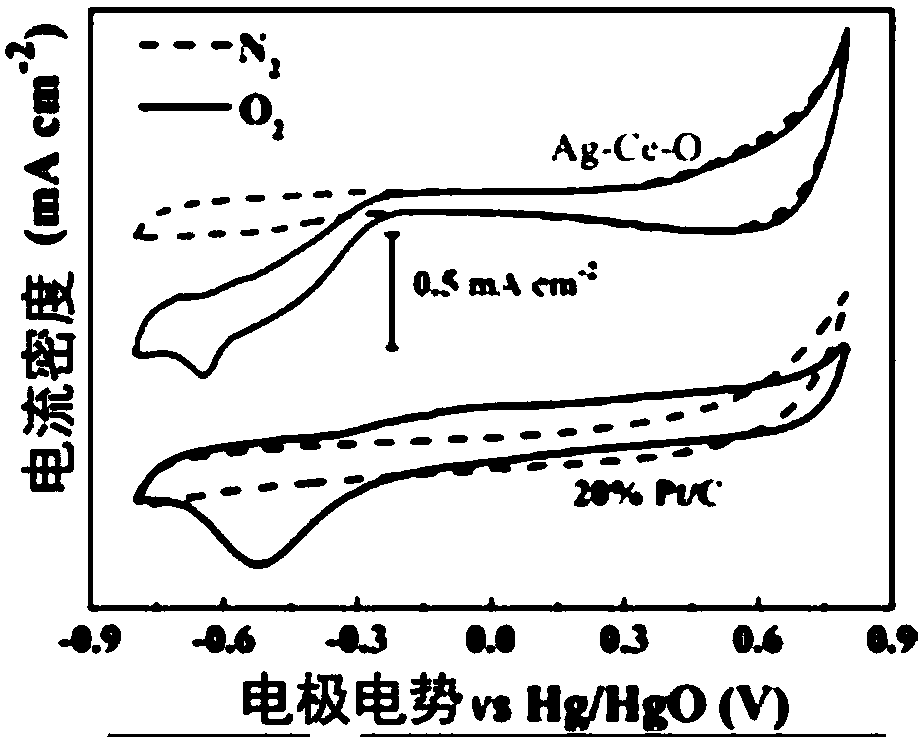

Cerium-containing silver-based hydrotalcite oxygen reduction catalyst as well as preparation method and application thereof

ActiveCN108428904ALarge specific surface areaImprove electrocatalytic activityFuel and primary cellsCell electrodesCeriumIon exchange

The invention relates to the technical field of electrocatalysts and provides a cerium-containing silver-based hydrotalcite oxygen reduction catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing a water-soluble silver salt, a water-soluble zinc salt, a water-soluble aluminum salt and an alkaline solution, heating to obtain silver-zinc-aluminum hydrotalcite suspension, performing solid-liquid separation to obtain a precipitate, and carrying out a hydrothermal reaction on the precipitate and water so as to obtain silver-zinc-aluminum hydrotalcite nanosheets; performing anion exchange with a Ce(DTPA)2-anion exchange solution so as to obtain Ce(DTPA)2-intercalated silver-zinc-aluminum hydrotalcite; finally performing pyrolysis and alkaline leaching, thereby obtaining the cerium-containing silver-based hydrotalcite oxygen reduction catalyst. The preparation method provided by the invention is low in cost and simple inprocess, and the prepared cerium-containing silver-based hydrotalcite oxygen reduction catalyst has excellent electrocatalytic activity.

Owner:BEIHANG UNIV

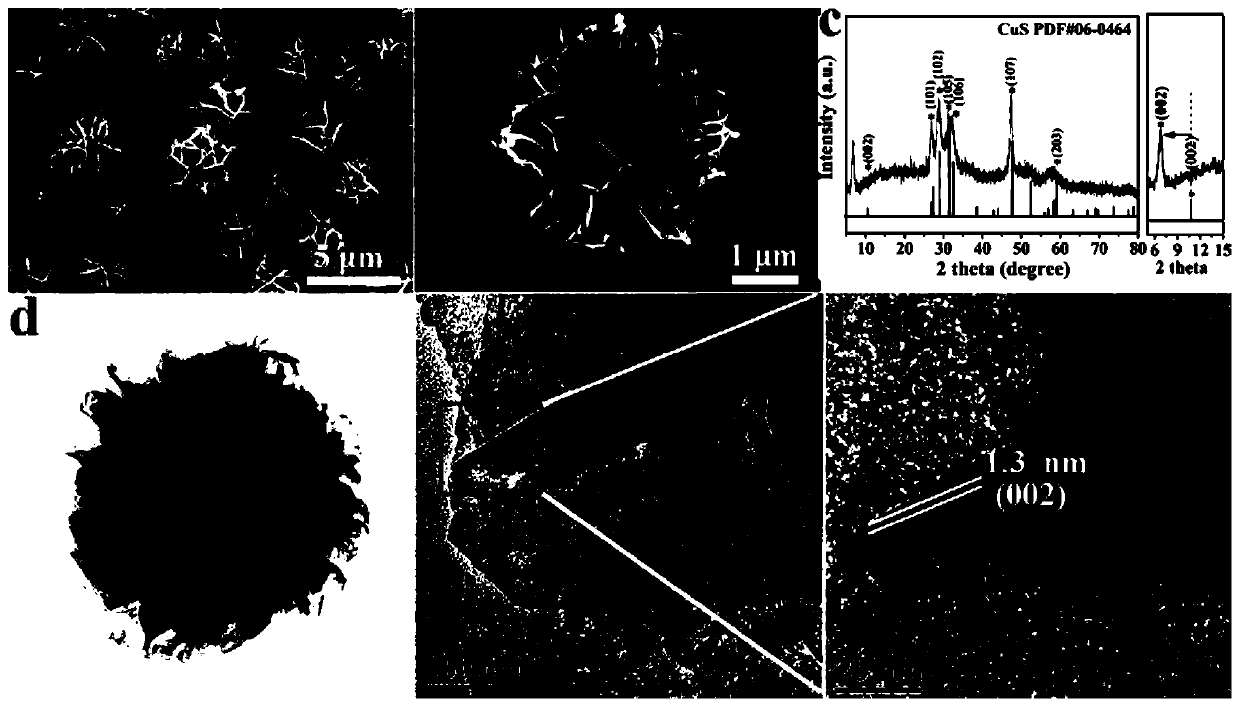

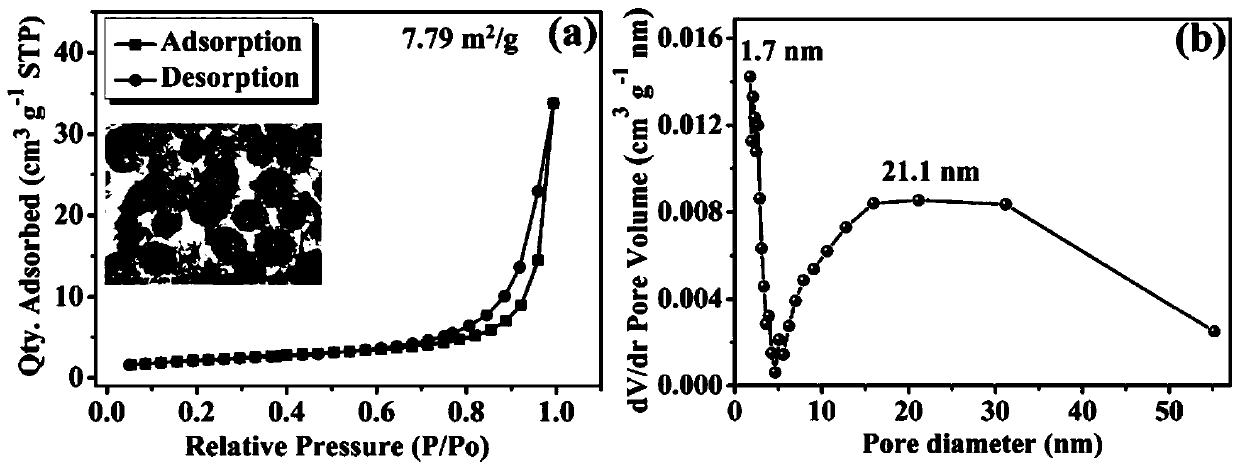

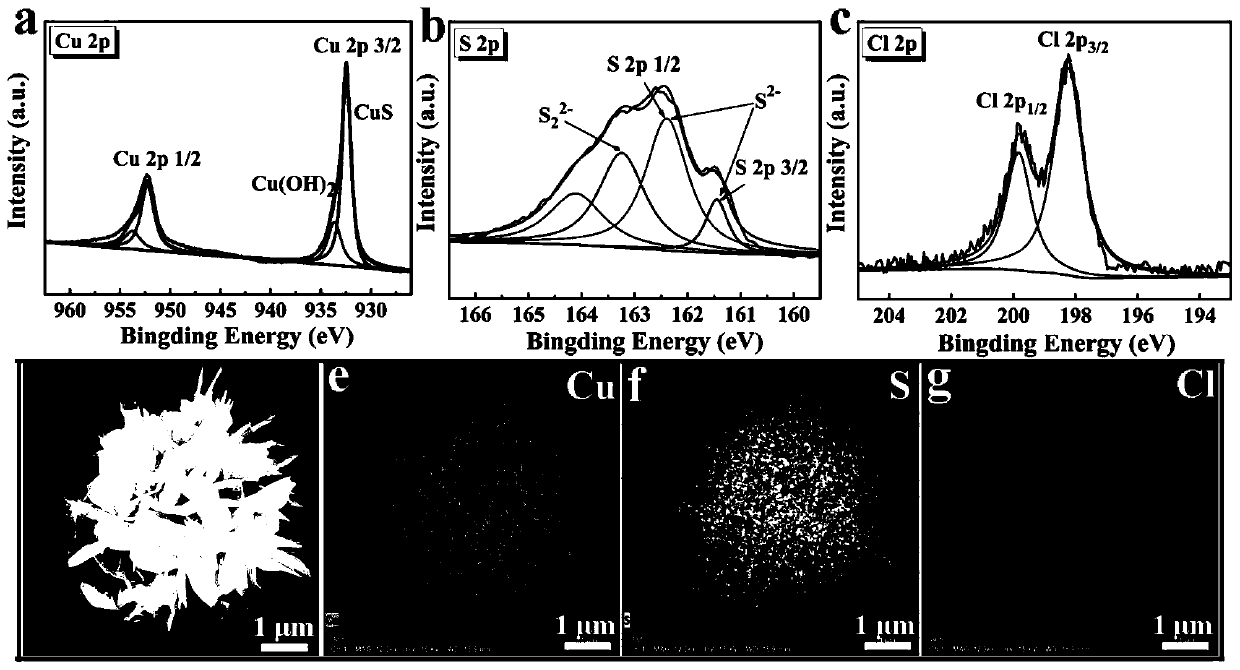

Halide ion assisted copper sulfide micron flower-structure material as well as preparation method and application thereof

InactiveCN109921016AHigh purityGood dispersionHybrid capacitor electrodesCell electrodesThioureaCharge discharge

The invention discloses a halide ion assisted copper sulfide micron flower-structure material as well as a preparation method and an application thereof. A copper source and thiourea are dissolved ina mixed solution of redistilled water and absolute ethyl alcohol and mixed uniformly, sodium halide is added, after sodium halide is completely dissolved, the sodium halide is transferred into a high-pressure reactor for a hydrothermal reaction, natural cooling is performed after a reaction ends, centrifugation, washing and drying are performed, and the material can be obtained. The interlayer spacing of copper sulfide is increased through halide ions, meanwhile, the structure of copper sulfide is adjusted by use of a coordination effect, and the specific surface area and the active edge are increased. The halide ion assisted copper sulfide micron flower-structure material is taken as a lithium / sodium ion battery negative electrode material, has a large specific surface area and is favorable for infiltrating an electrode material by an electrolyte, so that more lithium / sodium ions are disembedded from an active substance, and the capacity of a lithium / sodium ion battery is increased; the material has larger interlayer spacing, rapid movement of lithium / sodium ions in the charge-discharge process is guaranteed, and the cycle stability of the lithium / sodium ion battery is improved.

Owner:ANHUI NORMAL UNIV

High-quality PVC (polyvinyl chloride) heat-shrinkable sleeve

InactiveCN109082043ACorrosion resistanceHas good corrosion resistanceHeat-shrinkable sleevePolyester

The invention discloses a high-quality PVC (polyvinyl chloride) heat-shrinkable sleeve. The high-quality PVC heat-shrinkable sleeve comprises, by weight, 56-66 parts of PVC resin, 25-35 parts of acrylonitrile-butadiene-styrene copolymers, 2-5 parts of diatomaceous earth composite urea, 3-7 parts of diphenylethanedione oxide, 3-6 parts of graphite-modified polyurethane elastomers, 3-6 parts of nanometer aluminum oxide, 2-4 parts of nanometer carbon fibers, 2-4 parts of polyester fibers, 2-5 parts of toughening agents, 2-6 parts of stabilizers, 3-8 parts of poly-silicon borane, 0.2-0.8 part of lithium oxide, 2-3 parts of compatilizer, 2-4 parts of flame retardants, 2-4 parts of antioxidants and 2-5 parts of dispersing agents. The high-quality PVC heat-shrinkable sleeve has the advantages that the PVC resin is used as a main material and is matched with the acrylonitrile-butadiene-styrene copolymers and diversified additives, and accordingly the high-quality PVC heat-shrinkable sleeve isexcellent in heat resistance, heat-shrinkable performance, impact resistance, corrosion resistance and aging resistance.

Owner:安徽同利塑胶彩印有限公司

A kind of thin film electrocatalyst with transition metal core-shell structure and preparation method thereof

ActiveCN107579257BIncrease surface areaGood repeatabilityCell electrodesFinal product manufacturePtru catalystMethane gas

The invention relates to an electrocatalyst for a transition metal core-shell structure film and preparation method thereof, and belongs to the field of the preparation of catalyst materials. The filmtakes a metal nanometer particle as a core, and nitrogen-doped onion-shaped graphite as a shell, and the thickness of the film formed by the nanometer particle adopting a core-shell structure on a substrate is 200 to 1200nm. According to the method, a magnetron sputtering small angle deposition technology is adopted, a metal target is taken as a metal nanometer particle source, a graphite targetor methane gas is taken as a carbon source, nitrogen is taken as nitrogen source gas, and meanwhile argon is led, so as be taken as sputtering gas, so that the fact that metal catalyzes the graphitization growth and in-situ self-assembly of carbon to form a nitrogen-doped onion-shaped graphite packed metal nanometer particle film is realized. The electrocatalyst has the advantages of simple technology, low cost, high repeatability, high yield and capability of realizing mass industrial production; no by-products exist during the preparation, and a formed sample presents stability and methanoltolerant property superior to that of commercial Pt / C catalysts.

Owner:JILIN UNIV

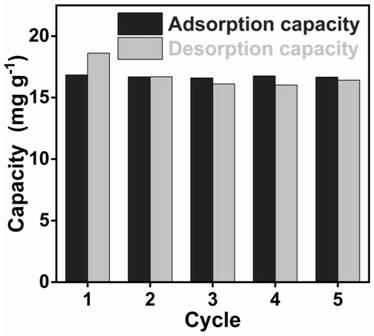

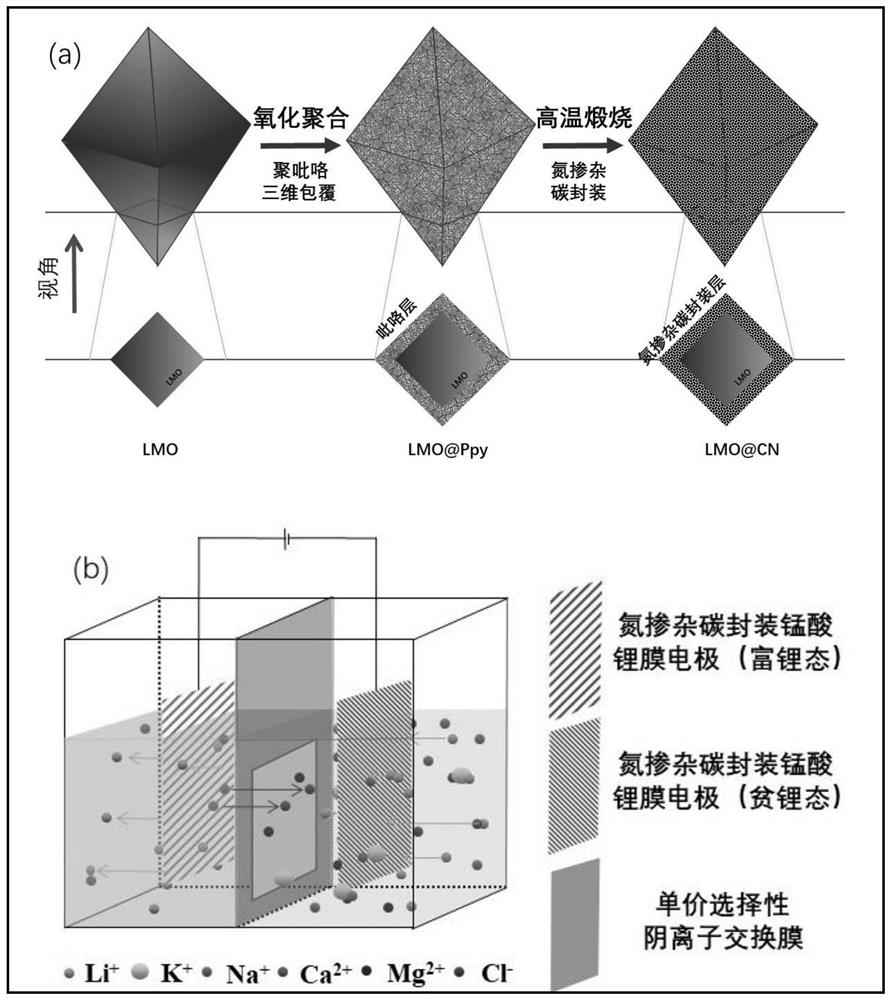

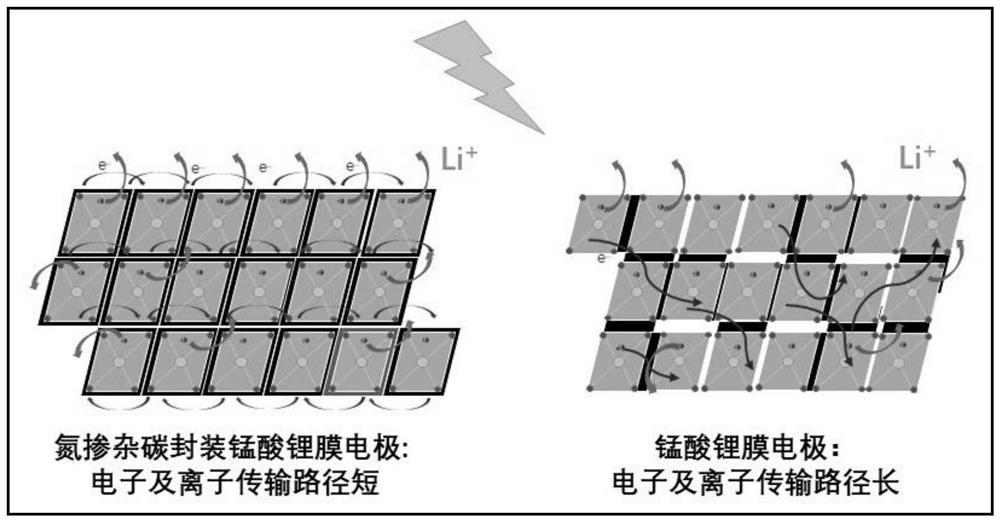

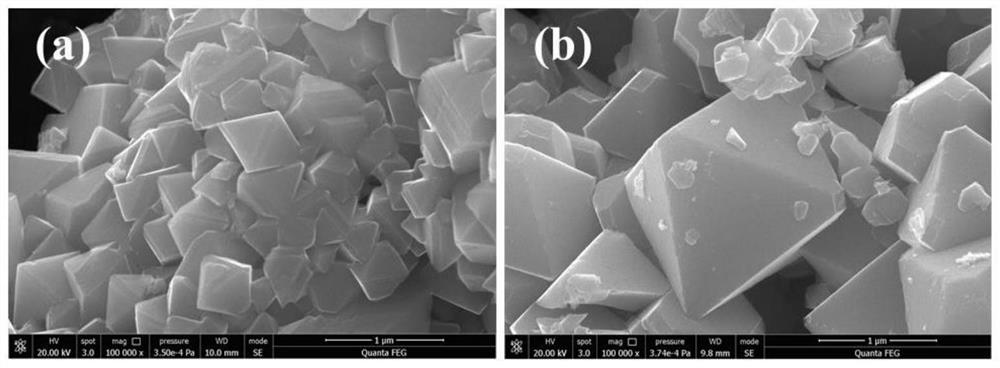

Nitrogen-doped carbon-packaged lithium ion sieve membrane electrode for electrochemical extraction of dissolved lithium resources

ActiveCN113337735AHigh selectivityEfficient enrichmentProcess efficiency improvementAcrylonitrileAniline

The invention relates to a nitrogen-doped carbon-packaged lithium ion sieve membrane electrode for electrochemical extraction of dissolved lithium resources. An electrode material of the membrane electrode comprises a lithium ion sieve and a packaging layer derived from a nitrogen-containing polymer, and nitrogen-containing polymer monomers are specifically pyrrole, aniline, acrylonitrile, amide, ethyleneimine, dopamine and urethane. In the preparation process, a two-stage polymerization mode, namely low-temperature prepolymerization and room-temperature polymerization, is adopted, different feeding ratios with the interval of 1: 0.1-1: 10 are adjusted, and calcination is carried out at the high temperature of 200-700 DEG C in an N2 environment, so that a uniform and complete carbon-packaged lithium ion sieve electrode material is obtained, and the carbon-packaged lithium ion sieve membrane electrode is prepared for enrichment of the dissolved lithium resources. The novel lithium ion sieve membrane electrode has the relatively high lithium extraction rate, the lithium ion selectivity and the stable circulation capability in a low-grade lithium raw material solution with complex coexisting ions.

Owner:HEBEI UNIV OF TECH

Ink anti-settling agent for identifying and code spraying before steel pipe delivery

ActiveCN107955457AIncrease interplanar spacingImprove blend compatibilityInksWater basedAcrylic resin

The invention discloses an ink anti-settling agent for identifying and code spraying before steel pipe delivery, and relates to the technical field of steel pipe identification. A specific preparationmethod comprises the following steps: (1) preparation of hydrogenated castor oil intercalated zeolite powder; (2) preparation of polyglutamic acid grafted acrylic resin; (3) preparation of anti-settling agent. The anti-settling agent disclosed by the invention is used for preparing water-based ink for identifying and code spraying of a steel pipe, and the ink is endowed with excellent storage stability while the safety problem in use of solvent type ink is avoided; moreover, the phenomenon of pigment settling occurring after pigment particles are stored for a long time is prevented, and thusthe normal code spraying and identifying function of the ink is guaranteed.

Owner:HEFEI ZIKING PIPE INC

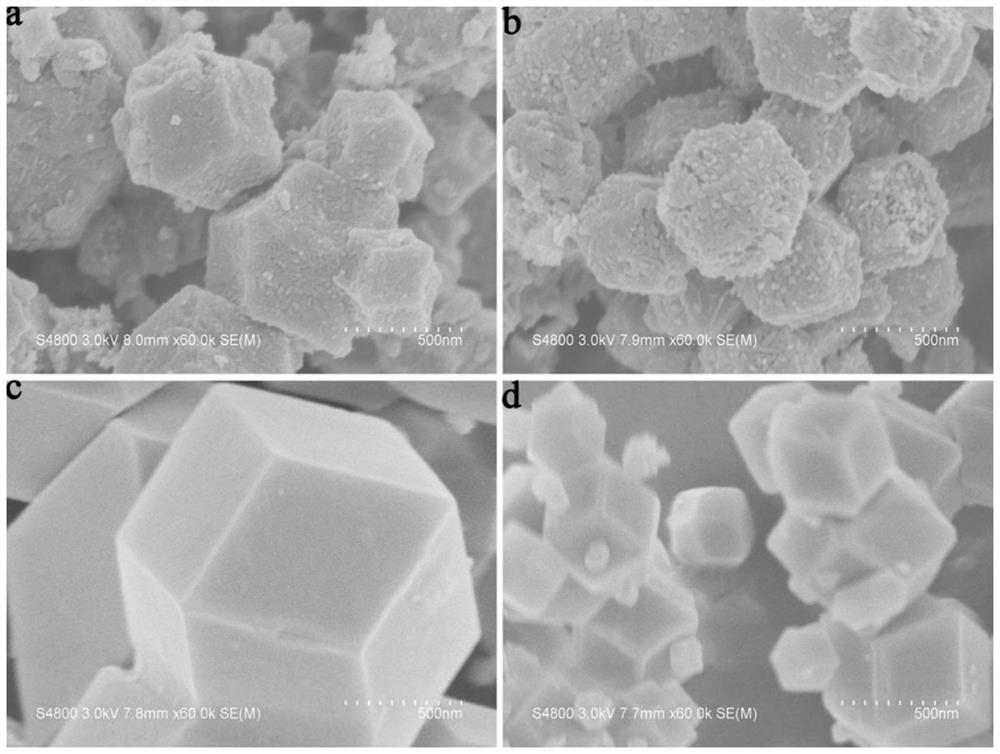

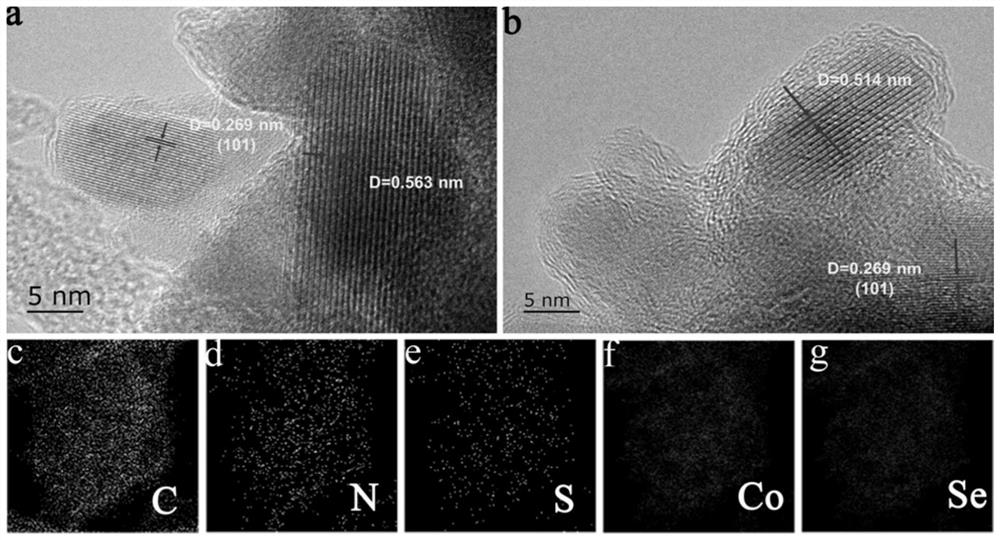

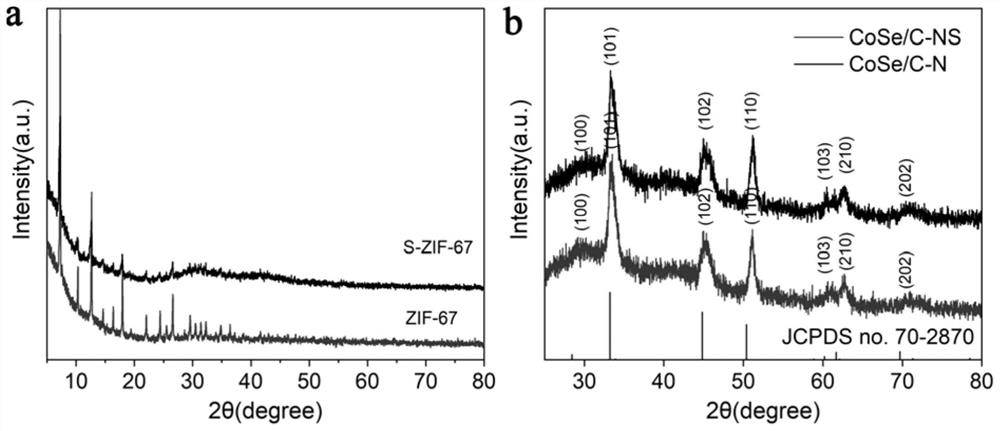

Preparation method of high-performance CoSe/C-NS composite material, material and application

PendingCN113346065AGood hollow structureHollow structure is stableSecondary cellsNegative electrodesElectrical batteryThiourea

The invention discloses a preparation method of a high-performance CoSe / C-NS composite material. The preparation method comprises the following steps of: adding thiourea as an S source in the process of preparing ZIF-67 to prepare an S-doped S-ZIF-67 precursor; and fully mixing the S-ZIF-67 precursor with selenium powder, and carrying out annealing treatment under the protection of nitrogen to obtain the CoSe / C-NS composite material. The invention also discloses a high-performance CoSe / C-NS composite material and application of the high-performance CoSe / C-NS composite material in a lithium ion battery. The S-doped S-ZIF-67 precursor is synthesized in one step, a hydrothermal reaction is not needed, energy and time are saved; the S element is uniformly distributed on the surface of the outer layer of the composite material after selenylation annealing treatment; and the interplanar spacing of the outer layer carbon skeleton of the material is widened through more defects introduced by S, so that the overall structure of the composite material is more stable, and the conductivity of the material is enhanced, and therefore, the CoSe / C-NS composite material has higher energy density, better rate capability and higher cycling stability when being used as a negative electrode.

Owner:广东格林赛福能源科技有限公司 +2

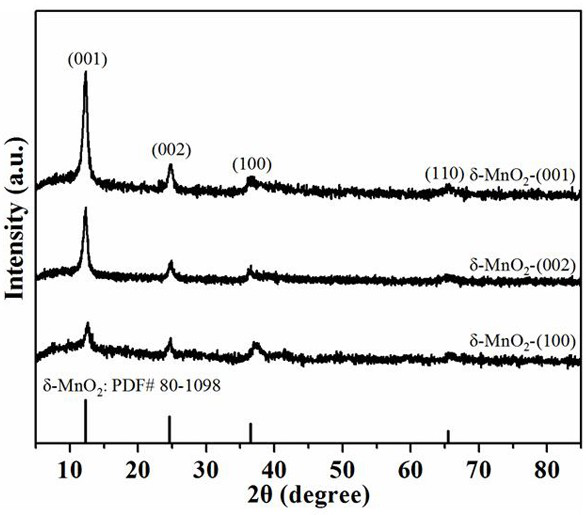

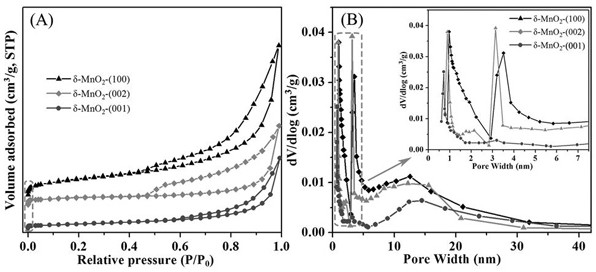

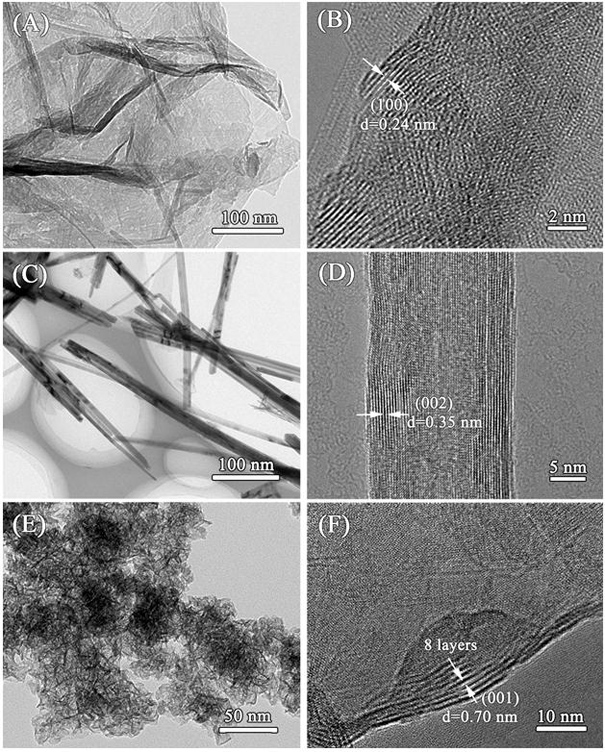

Crystal face regulation and control preparation method and application of porous manganese dioxide

InactiveCN112794366AReduce inhibitionFacilitation is weakManganese oxides/hydroxidesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOxygen vacancy

The invention discloses a crystal face regulation and control preparation method and application of porous manganese dioxide, and belongs to the technical field of catalyst preparation. Potassium permanganate is used as a raw material, ammonium oxalate is used as a reducing agent, hexadecyl trimethyl ammonium bromide, urea or hydrochloric acid is used as an additive, and after hydrothermal treatment is performed in a high-pressure reaction kettle, washing, drying and roasting are performed to obtain the manganese dioxide which has a hierarchical pore structure and exposes different crystal faces. The synthesis method is simple in process and high in repeatability; the number of oxygen vacancies and the oxidation-reduction capacity of manganese dioxide can be regulated and controlled through crystal face control, so that the catalytic activity is improved; and the hierarchical pore structure promotes diffusion of reactants, so that the catalyst shows higher H2S conversion rate, elemental sulfur selectivity and stability in selective catalytic oxidation of H2S.

Owner:FUZHOU UNIV

Modification method of natural graphite negative electrode material

ActiveCN113644264AExcellent rate performanceImprove low temperature performanceNegative electrodesSecondary cellsElectrolytic agentAlkaline earth metal

The invention relates to a modification method of a natural graphite negative electrode material, and belongs to the technical field of lithium ion batteries. Natural graphite and alkaline earth metal with a large ion radius are subjected to thermal doping so that the alkaline earth metal elementary substance reaches a molten state and is diffused in the graphite, and the bulk phase doping of the graphite is completed. Or according to the method, large-size alkali metal ions are introduced into the positive electrode material or electrolyte of the battery system in advance, and the large-size ions are pre-embedded into the natural graphite bulk phase in the working process of the battery. According to the method disclosed by the invention, the distance between graphite sheet layers is increased, and the rate capability and the low-temperature performance of natural graphite are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

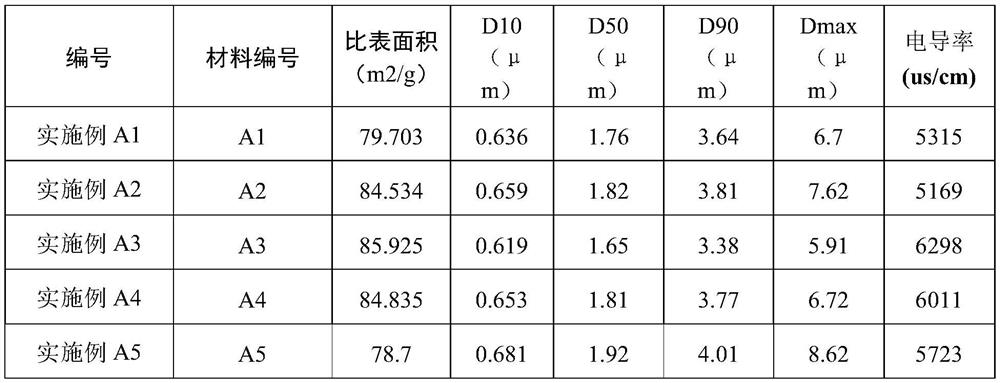

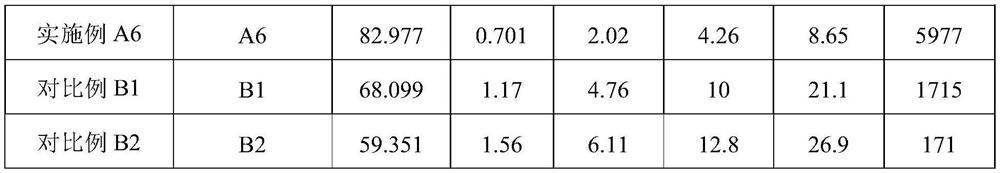

Multi-ion doped battery-grade iron phosphate material and preparation method thereof

PendingCN114751390AImprove electrochemical performanceFacilitate de-intercalationPhosphorus compoundsLithium iron phosphateElectrical battery

The invention provides a multi-ion doped battery grade iron phosphate material and a preparation method thereof, the iron phosphate material is prepared by a one-step synthesis method, drying and dehydration, the mass ratio of doped V ions is 0.2%-0.5%, and the mass ratio of doped Ti ions is 0.2%-0.5%. According to the present invention, the iron phosphate preparation process is simple, the operability is strong, the doped particles of the prepared multi-ion doped battery grade iron phosphate material are reduced, the specific surface area is increased, the chemical activity is improved, the grinding efficiency during the lithium iron phosphate preparation process is improved, and the co-doping of V and Ti does not change the crystal form structure of the iron phosphate, optimizes the crystal structure, and further improves the lithium iron phosphate preparation efficiency. The diffusion impedance of lithium ions is reduced, the exchange current density is increased, and the conductivity of a material body is improved. And multiple ions are doped into iron phosphate crystal lattices, so that the interplanar spacing is increased, Li < + > de-intercalation is facilitated, the transfer rate of lithium ions among particles is increased, the impedance among the particles is reduced, the exchange current density is increased, and the electrochemical performance of lithium iron phosphate is improved.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

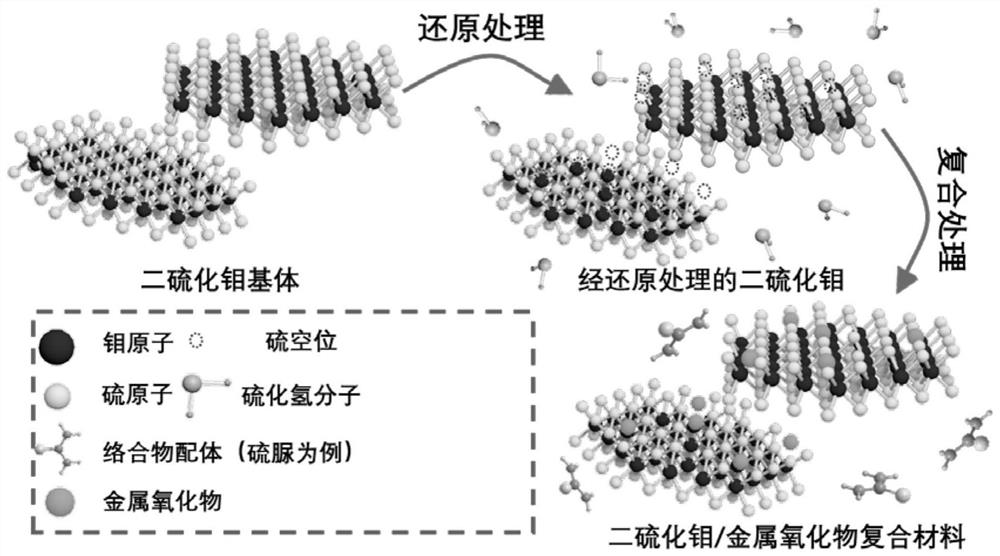

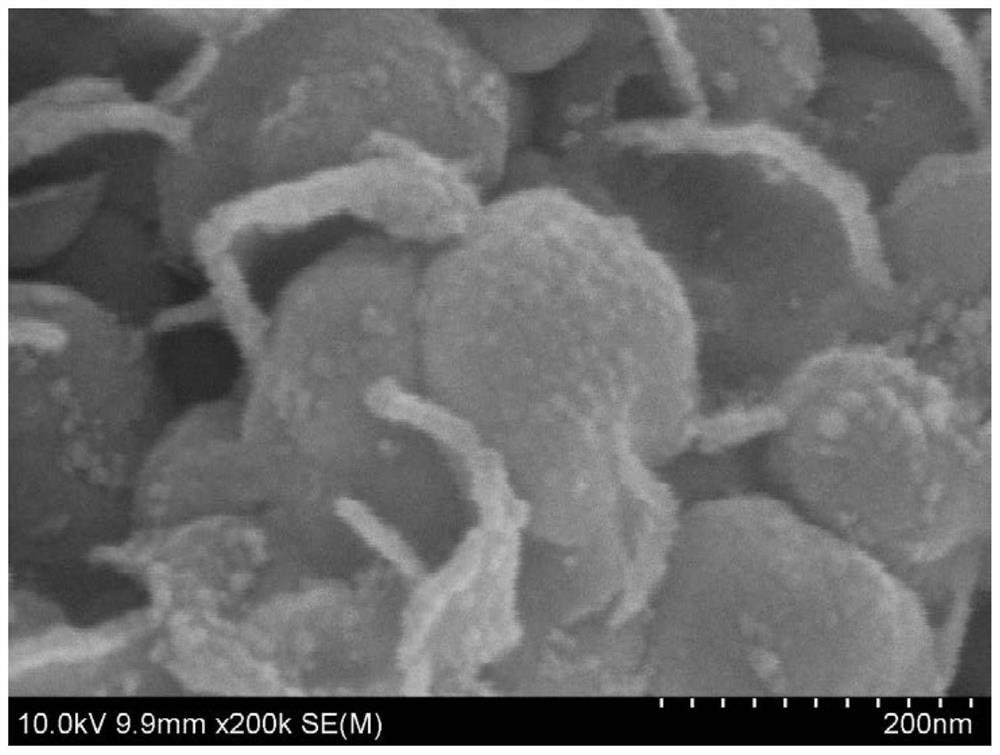

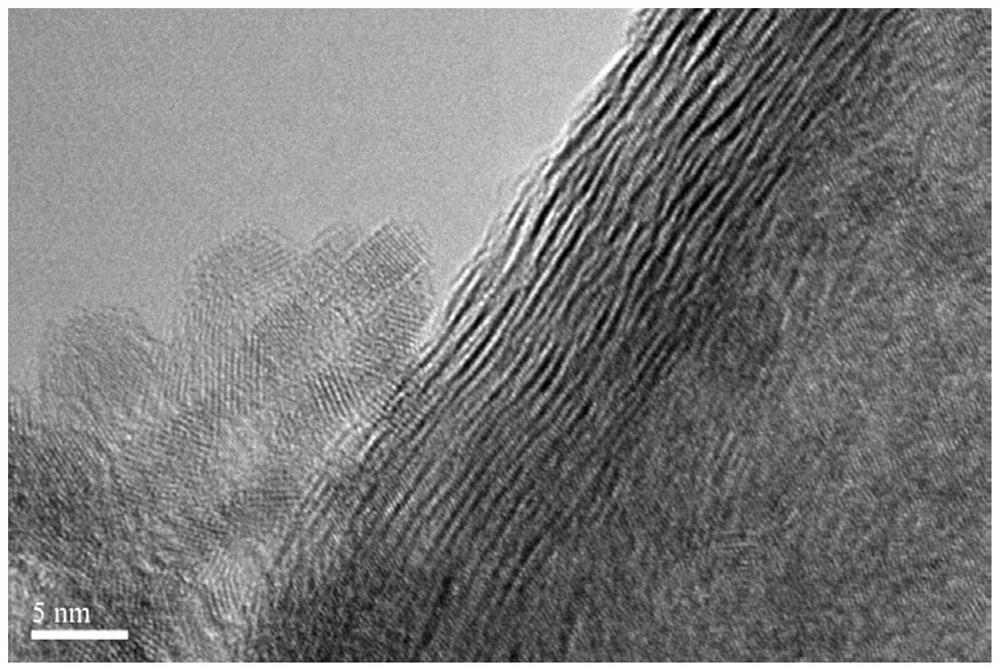

Molybdenum disulfide/metal oxide composite material for energy storage device electrode and preparation thereof

InactiveCN112310366AHigh specific capacityPromote circulationHybrid capacitor electrodesCell electrodesLithium sulfurOxide composite

The invention relates to a molybdenum disulfide / metal oxide composite material for an energy storage device electrode and a preparation method thereof. The preparation method comprises the steps thatmolybdenum disulfide serves as a matrix, inert atmosphere calcination and in-situ reduction treatment are conducted on the matrix in sequence to generate microdefects in the matrix, and then the matrix is compounded with metal oxide to obtain the molybdenum disulfide / metal oxide composite material. During application, the composite material is applied to a lithium ion battery, a sodium ion battery, a lithium-sulfur battery, a supercapacitor or a hybrid capacitor. Compared with the prior art, the molybdenum disulfide / metal oxide composite material prepared by the invention has the characteristics of uniform dispersion, tight combination and controllable components, and can effectively relieve the problems of volume change and rapid capacity decline of the metal oxide in an electrode reaction.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com