Molybdenum disulfide/metal oxide composite material for energy storage device electrode and preparation thereof

A technology of molybdenum disulfide and composite materials, which is used in the manufacture of hybrid capacitor electrodes, battery electrodes, and secondary batteries to achieve the effects of alleviating volume changes, tight bonding, and long cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

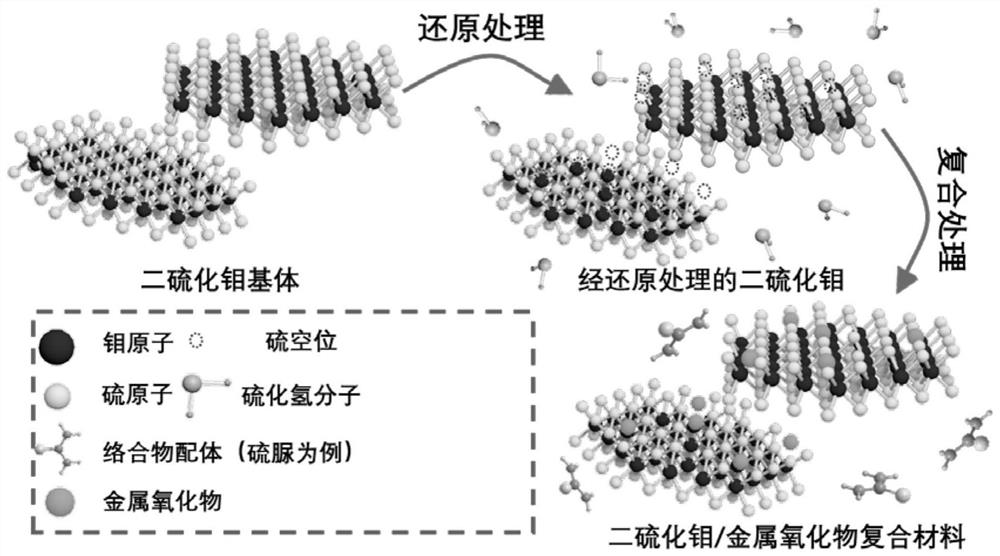

[0029] A preparation method of molybdenum disulfide / metal oxide composite material for electrodes of energy storage devices, the principle is as follows figure 1 As shown, the following steps are taken:

[0030] The first step: prepare molybdenum disulfide matrix by hydrothermal method by ammonium molybdate tetrahydrate, 1,6-hexanediamine and L-cysteine;

[0031] The second step: calcining the prepared molybdenum disulfide substrate at 900°C for 2 hours under an argon atmosphere;

[0032] The third step: the calcined molybdenum disulfide in 5% H 2 / Ar atmosphere and temperature of 750 ° C for 2 hours, and then cooled with the furnace;

[0033] Step 4: Mix 0.1mol / L tin tetrachloride pentahydrate solution with thiourea with a coordination number stoichiometric ratio of 0.83 times to form a stable metal ion complex solution;

[0034] Step 5: Mix the reduced molybdenum disulfide with the stable metal ion complex solution at a molar ratio of 1:1 and hydrothermally treat it at 17...

Embodiment 2

[0037] A method for preparing a molybdenum disulfide / metal oxide composite material for an electrode of an energy storage device. The method is as follows: using molybdenum disulfide as a matrix, firstly performing inert atmosphere calcination and in-situ reduction treatment on the matrix to generate microscopic defects in the matrix, Then compound with metal oxide to get molybdenum disulfide / metal oxide composite material.

[0038] Specifically include the following steps:

[0039] 1) Using molybdenum disulfide as a substrate, the substrate is calcined under an inert atmosphere;

[0040] 2) reducing the calcined matrix in a hydrogen atmosphere to generate microscopic defects in the matrix;

[0041] 3) Mix the reduced matrix with the metal ion complex solution, and then conduct a hydrothermal reaction to obtain a molybdenum disulfide / metal oxide composite material.

[0042] In step 1), molybdenum trioxide or molybdate is used as raw material, and the molybdenum disulfide mat...

Embodiment 3

[0047] A method for preparing a molybdenum disulfide / metal oxide composite material for an electrode of an energy storage device. The method is as follows: using molybdenum disulfide as a matrix, firstly performing inert atmosphere calcination and in-situ reduction treatment on the matrix to generate microscopic defects in the matrix, Then compound with metal oxide to get molybdenum disulfide / metal oxide composite material.

[0048] Specifically include the following steps:

[0049] 1) Using molybdenum disulfide as a substrate, the substrate is calcined under an inert atmosphere;

[0050] 2) reducing the calcined matrix in a hydrogen atmosphere to generate microscopic defects in the matrix;

[0051] 3) Mix the reduced matrix with the metal ion complex solution, and then conduct a hydrothermal reaction to obtain a molybdenum disulfide / metal oxide composite material.

[0052] In step 1), molybdenum trioxide or molybdate is used as raw material, and the molybdenum disulfide mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com