Cerium-containing silver-based hydrotalcite oxygen reduction catalyst as well as preparation method and application thereof

A hydrotalcite and catalyst technology, applied in the field of cerium-containing silver-based hydrotalcite oxygen reduction catalyst and its preparation, can solve the problems of weakening the catalytic activity and poor catalytic activity of the oxygen reduction electrocatalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

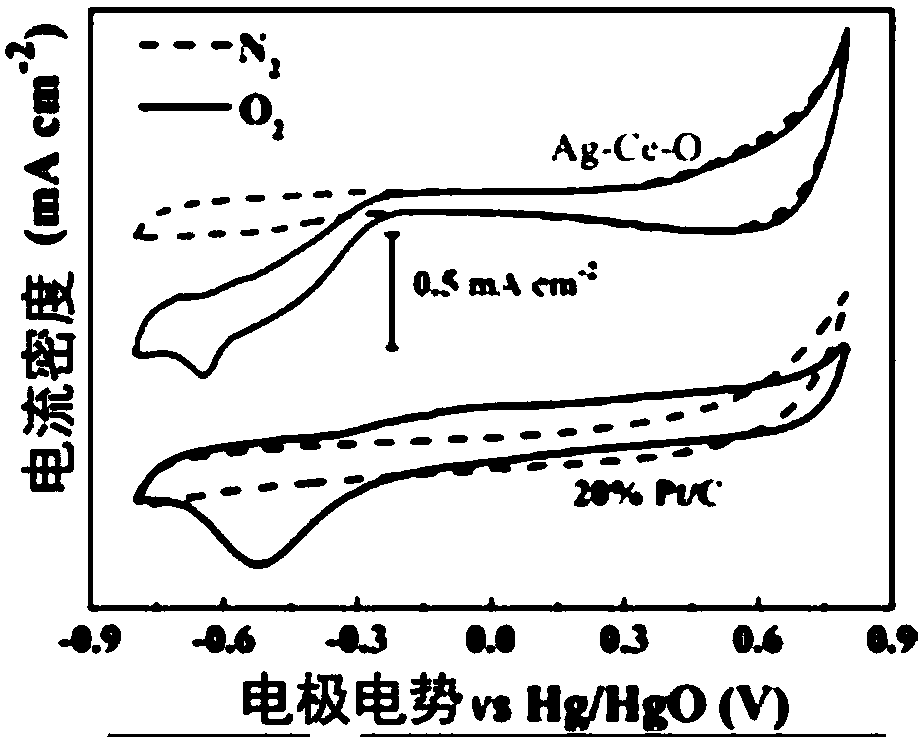

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

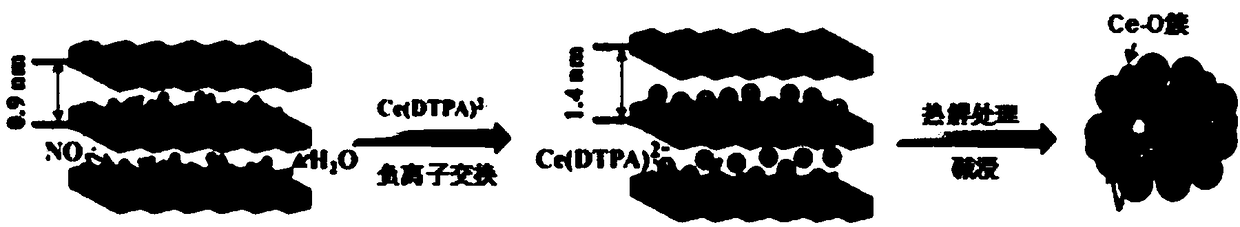

[0031] The invention provides a preparation method of a cerium-containing silver-based hydrotalcite oxygen reduction catalyst, comprising the following steps:

[0032] 1) mixing water-soluble silver salt, water-soluble zinc salt, water-soluble aluminum salt with alkaline solution and heating to obtain silver-zinc-aluminum hydrotalcite suspension;

[0033] 2) performing solid-liquid separation on the suspension obtained in step 1) to obtain a precipitate;

[0034] 3) mixing the precipitate obtained in step 2) with water, and hydrothermally reacting to obtain silver-zinc-aluminum hydrotalcite nanosheets;

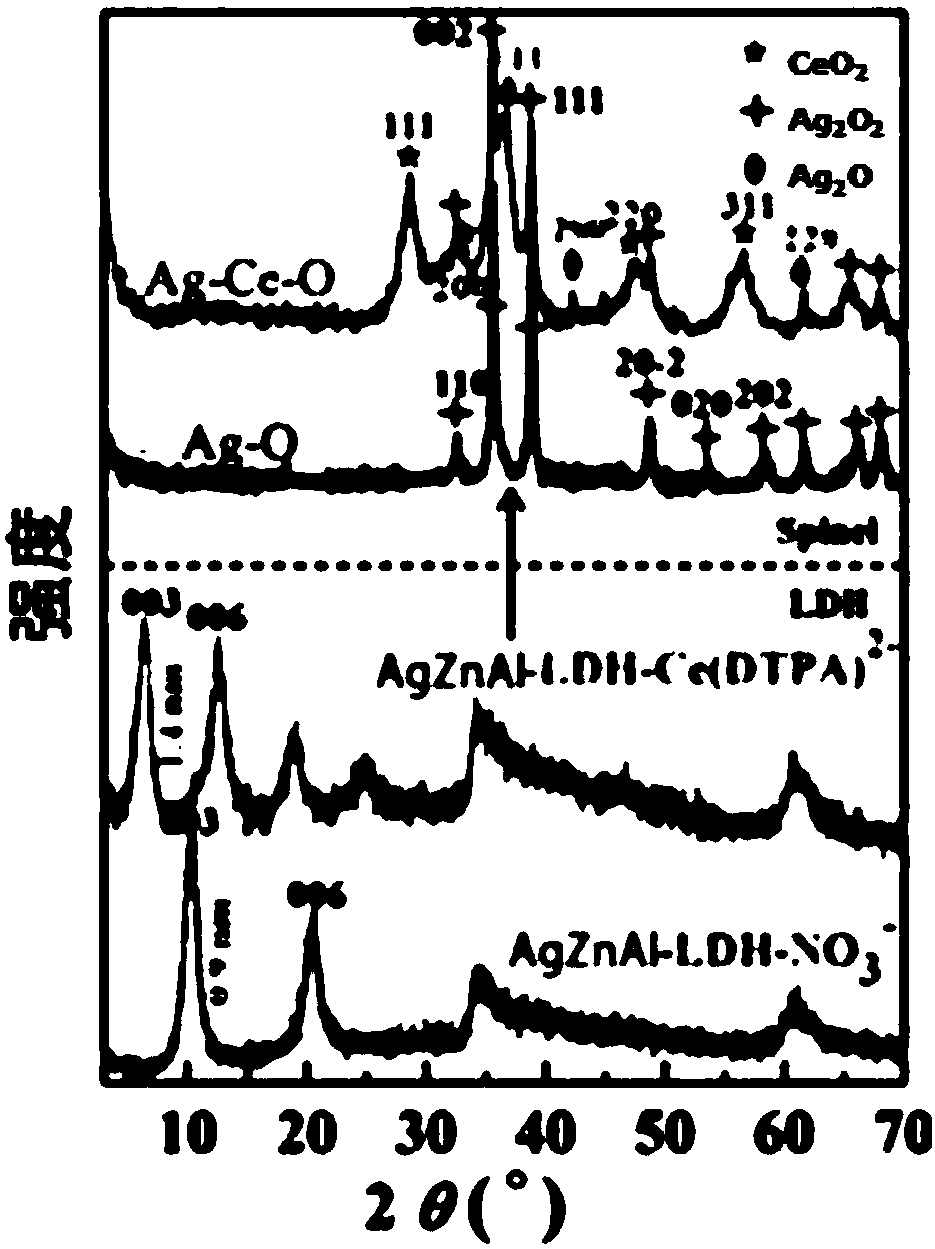

[0035] 4) the silver-zinc-aluminum hydrotalcite nanoplate that described step 3) obtains and Ce(DTPA) 2- The anion exchange solution is anion exchanged to obtain Ce(DTPA) 2- Intercalated silver zinc aluminum hydrotalcite;

[0036] The Ce(DTPA) 2- The anion exchange liquid is obtained by mixing cerium salt solution, DTPA solution and sodium hydroxide solution;

[0037] 5) ...

Embodiment 1

[0065] 1) Add silver nitrate, zinc nitrate and aluminum nitrate to 100ml of water in a molar ratio of 1:1:1 to fully dissolve, add sodium hydroxide and sodium carbonate to 100ml of water in a molar ratio of 1:3 to fully dissolve; The two obtained solutions were mixed, and heated in a water bath at 70° C. for 30 minutes under a stirring condition to obtain a suspension of silver-zinc-aluminum hydrotalcite.

[0066] 2) The silver-zinc-aluminum hydrotalcite suspension is centrifuged to obtain the bottom sediment, and the centrifugal speed is 2000r / min;

[0067] 3) Redisperse the bottom sediment obtained after centrifugation in ultrapure water, transfer it to a 200mL hydrothermal reaction kettle, conduct a hydrothermal reaction at 140°C and 480kPa for 24 hours, filter through a filter membrane, wash, and vacuum dry to obtain particles Uniform white powdery silver-zinc-aluminum hydrotalcite nanosheets (AgZnAl-LDHs);

[0068] 4) Obtain 0.2M by adding NaOH dropwise, 50ml of DTPA (di...

Embodiment 2

[0073] Silver nitrate, zinc nitrate and aluminum nitrate are added to 100ml of water in a molar ratio of 1:1:1 and fully dissolved, and sodium hydroxide and sodium carbonate are added to 100ml of water in a molar ratio of 1:1 to fully dissolve; The two solutions were mixed, and heated in a water bath at 80° C. for 10 minutes with stirring to obtain a suspension of silver-zinc-aluminum hydrotalcite.

[0074] 2) The silver-zinc-aluminum hydrotalcite suspension is centrifuged to obtain the bottom sediment, and the centrifugal speed is 2000r / min;

[0075] 3) Redisperse the bottom sediment obtained after centrifugation in ultrapure water, transfer it to a 200mL hydrothermal reaction kettle, conduct a hydrothermal reaction at 150°C and 400kPa for 10 hours, filter through a filter membrane, wash, and vacuum dry to obtain particles Uniform white powdery silver-zinc-aluminum hydrotalcite nanosheets (AgZnAl-LDHs);

[0076] 4) Obtain 0.2M by adding NaOH dropwise, 50ml of DTPA (diethyltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com