Preparation method and application of epitaxial growth layer and sulfur-sodium lattice modified lithium-rich manganese-based positive electrode material

A cathode material, epitaxial growth technology, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of poor positive cycle performance, rapid voltage decay, low rate performance, etc. The effect of suppressing the release of oxygen, expanding the interplanar spacing, and improving the rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

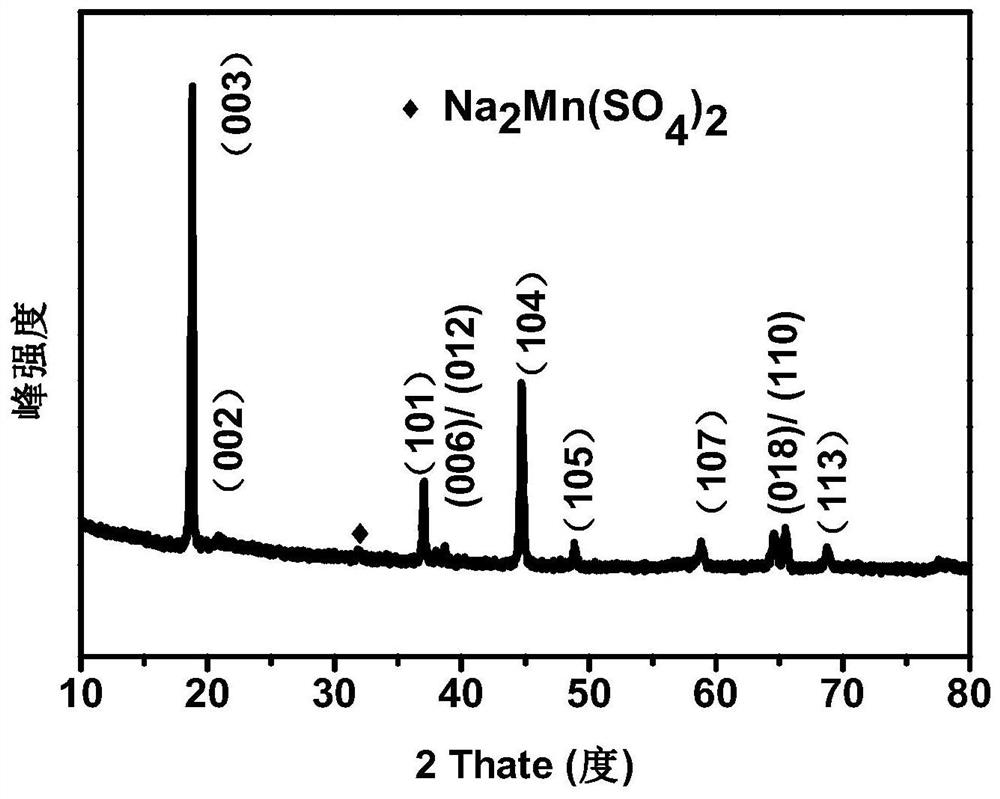

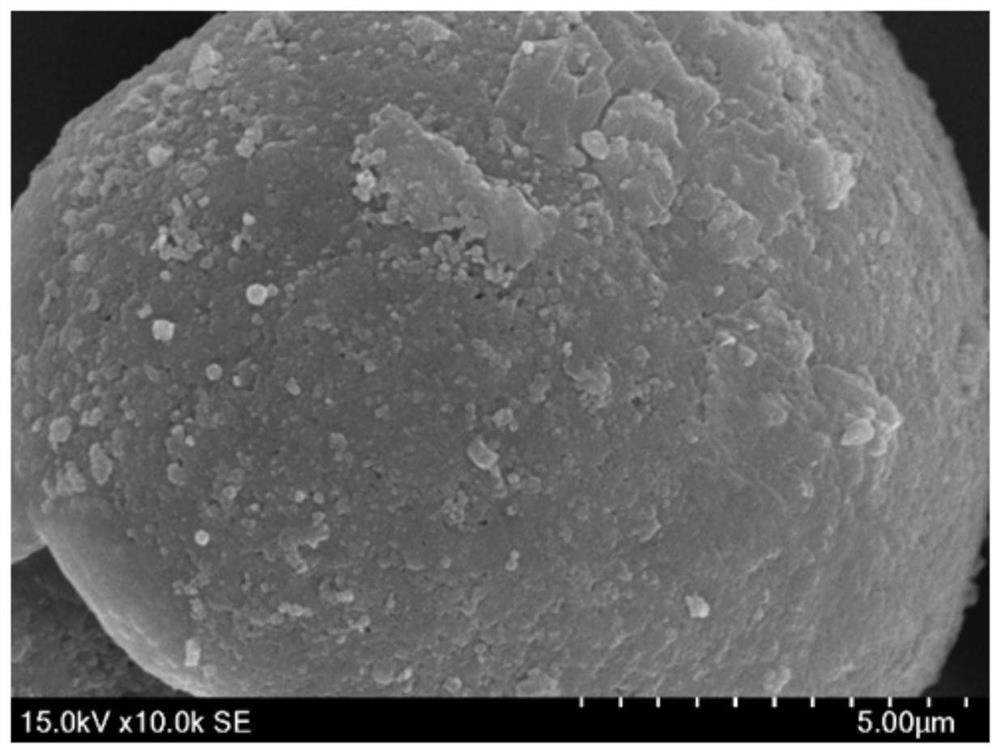

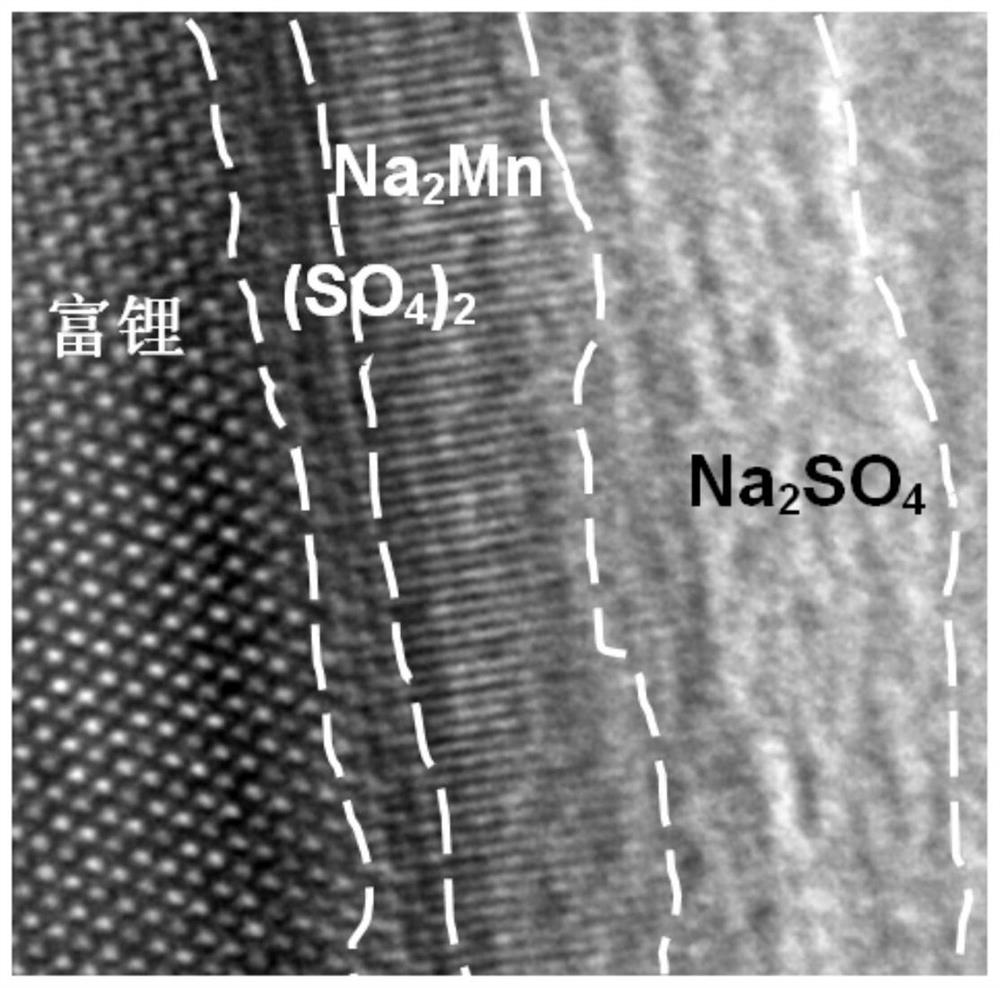

[0049] Example 1 Preparation of epitaxial growth layer and sulfur-sodium lattice modified lithium-rich manganese-based positive electrode material

[0050] A method for preparing an epitaxial growth layer and a sulfur-sodium lattice modified lithium-rich manganese-based positive electrode material, comprising the following steps:

[0051] S1. Manganese acetate, nickel acetate and cobalt acetate are fully dissolved in deionized water to obtain a mixed metal salt solution (the concentration of the metal in the mixed metal salt solution is 2mol / L);

[0052] S2. After adding ammonia solution (the mol ratio of the metal in the mixed metal salt solution and ammonia solution is 5: 1, the concentration of ammonia solution is 1.2mol / L) in step S1 gained mixed metal salt solution, use Na 2 CO 3 (concentration is 2mol / L) adjusting pH is 8, stirs and carries out co-precipitation reaction, filters, washes, and dries, obtains lithium-rich manganese-based layered oxide precursor (the mol ra...

Embodiment 2

[0056] Example 2 Preparation of epitaxial growth layer and sulfur-sodium lattice modified lithium-rich manganese-based positive electrode material

[0057] A method for preparing an epitaxial growth layer and a sulfur-sodium lattice modified lithium-rich manganese-based positive electrode material, comprising the following steps:

[0058] S1. Manganese nitrate, nickel nitrate and cobalt nitrate are fully dissolved in deionized water to obtain a mixed metal salt solution (the concentration of the metal in the mixed metal salt solution is 1.8mol / L);

[0059] S2. After adding ammonia solution (the mol ratio of the metal in the mixed metal salt solution and ammoniacal liquor is 10:3, the concentration of ammonia solution is 1mol / L) in step S1 gained mixed metal salt solution, use Na 2 CO 3 (concentration is 2.2mol / L) adjust pH to be 7, stir and carry out co-precipitation reaction, filter, wash, dry, obtain lithium-rich manganese-based layered oxide precursor (the molar ratio of m...

Embodiment 3

[0063] Example 3 Preparation of epitaxial growth layer and sulfur-sodium lattice modified lithium-rich manganese-based positive electrode material

[0064] A method for preparing an epitaxial growth layer and a sulfur-sodium lattice modified lithium-rich manganese-based positive electrode material, comprising the following steps:

[0065] S1. Manganese sulfate, nickel sulfate and cobalt sulfate are fully dissolved in deionized water to obtain a mixed metal salt solution (the concentration of the metal in the mixed metal salt solution is 2.2mol / L);

[0066] S2. After adding ammonia solution (the mol ratio of the metal in the mixed metal salt solution and ammoniacal liquor is 10: 1, the concentration of ammonia solution is 2mol / L) in step S1 gained mixed metal salt solution, use Na 2 CO 3 (concentration is 1.8mol / L) adjust pH to be 9, stir and carry out co-precipitation reaction, filter, wash, dry, obtain lithium-rich manganese-based layered oxide precursor (the mol ratio of ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com