Preparation method of activated carbon supported titanium-pillared montmorillonite composite material

A technology of titanium pillared montmorillonite and composite materials, which is applied in the field of preparation of composite materials, can solve the problems of easy secondary pollution and poor treatment effect, and achieve the effect of good ion exchange performance and good molecular adsorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

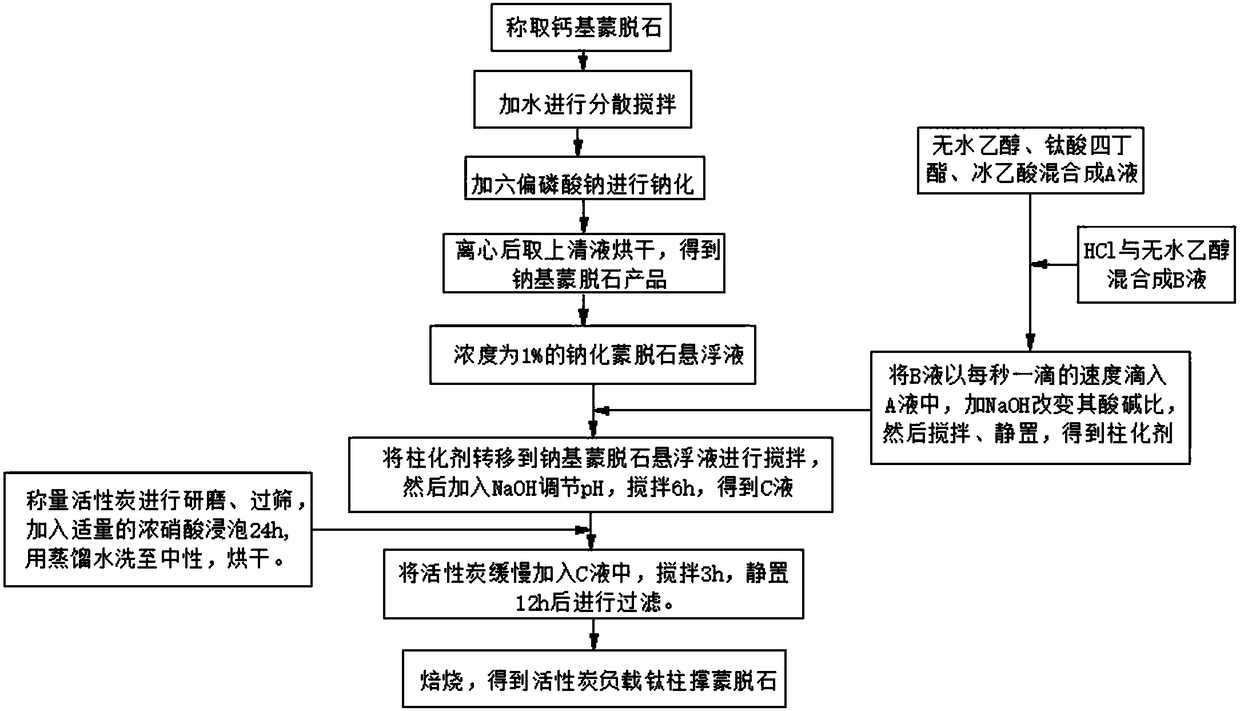

[0026] Refer to attached figure 1 , the present embodiment provides a preparation method of activated carbon-supported titanium pillared montmorillonite composite material, specifically as follows:

[0027] Weigh 20g of calcium-based montmorillonite, immerse in 500ml of distilled water, stir and disperse with a magnetic stirrer, add 2.5g of sodium hexametaphosphate and stir for 3 hours, let it stand for 30 minutes, and use a centrifuge (3600r / min) to get the supernatant The solution was dried at a constant temperature at 80°C, and ground through a 200-mesh sieve to obtain the sodium-based montmorillonite product.

[0028] Weigh 4g of sodium montmorillonite, add 400ml of distilled water, stir and disperse to form a suspension with a concentration of 1%, mix 10ml of absolute ethanol, 10ml of tetrabutyl titanate and 2ml of glacial acetic acid to prepare A solution, 24ml 0.1mol Mix / L of HCl and 5ml of absolute ethanol to form B solution. Under magnetic stirring, slowly drop B so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com