Preparation method of sodium vanadium phosphate sodium ion battery composite material

A sodium vanadium phosphate ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of rate performance and cycle performance limitations, low electronic conductivity, etc., to prevent structural collapse and shedding, and simple operation , the effect of enhancing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

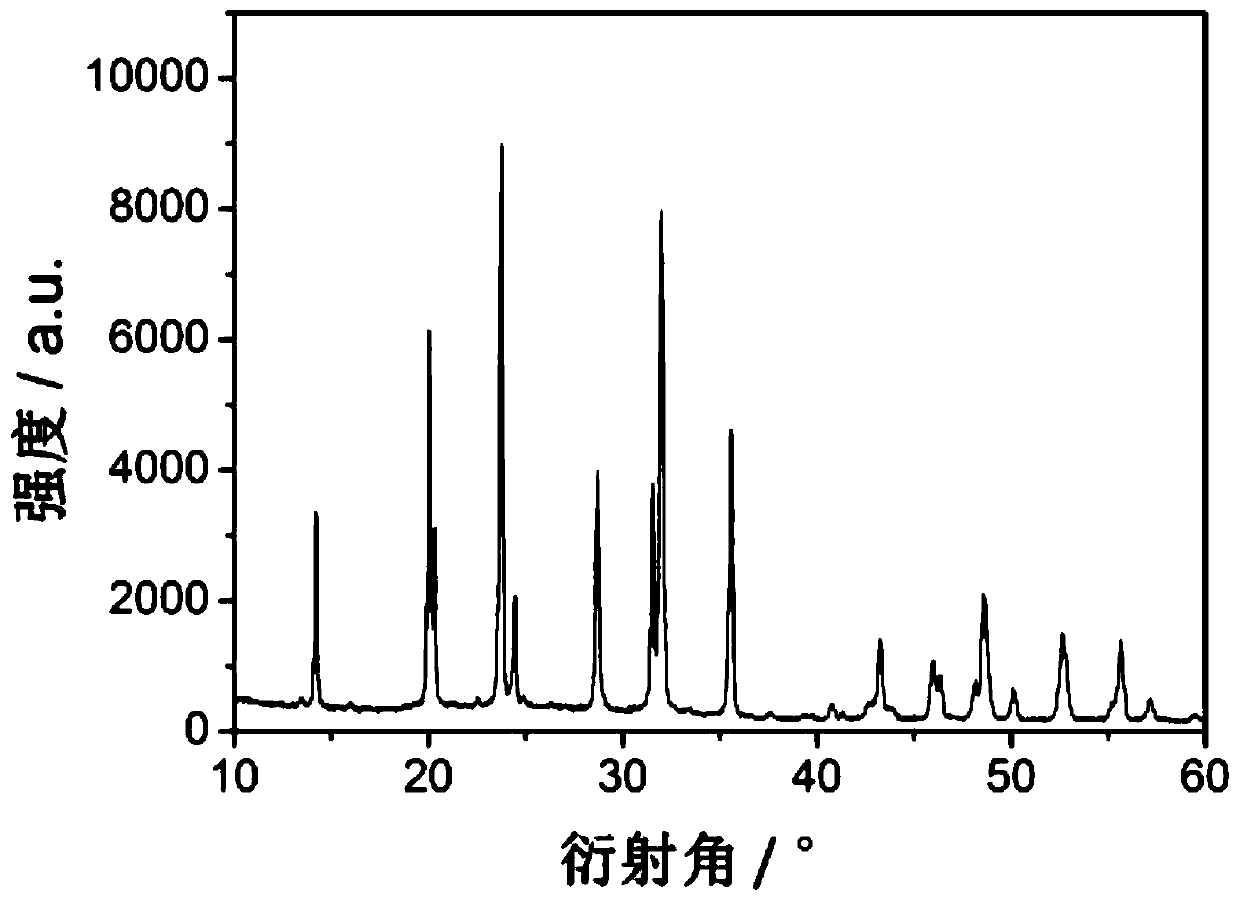

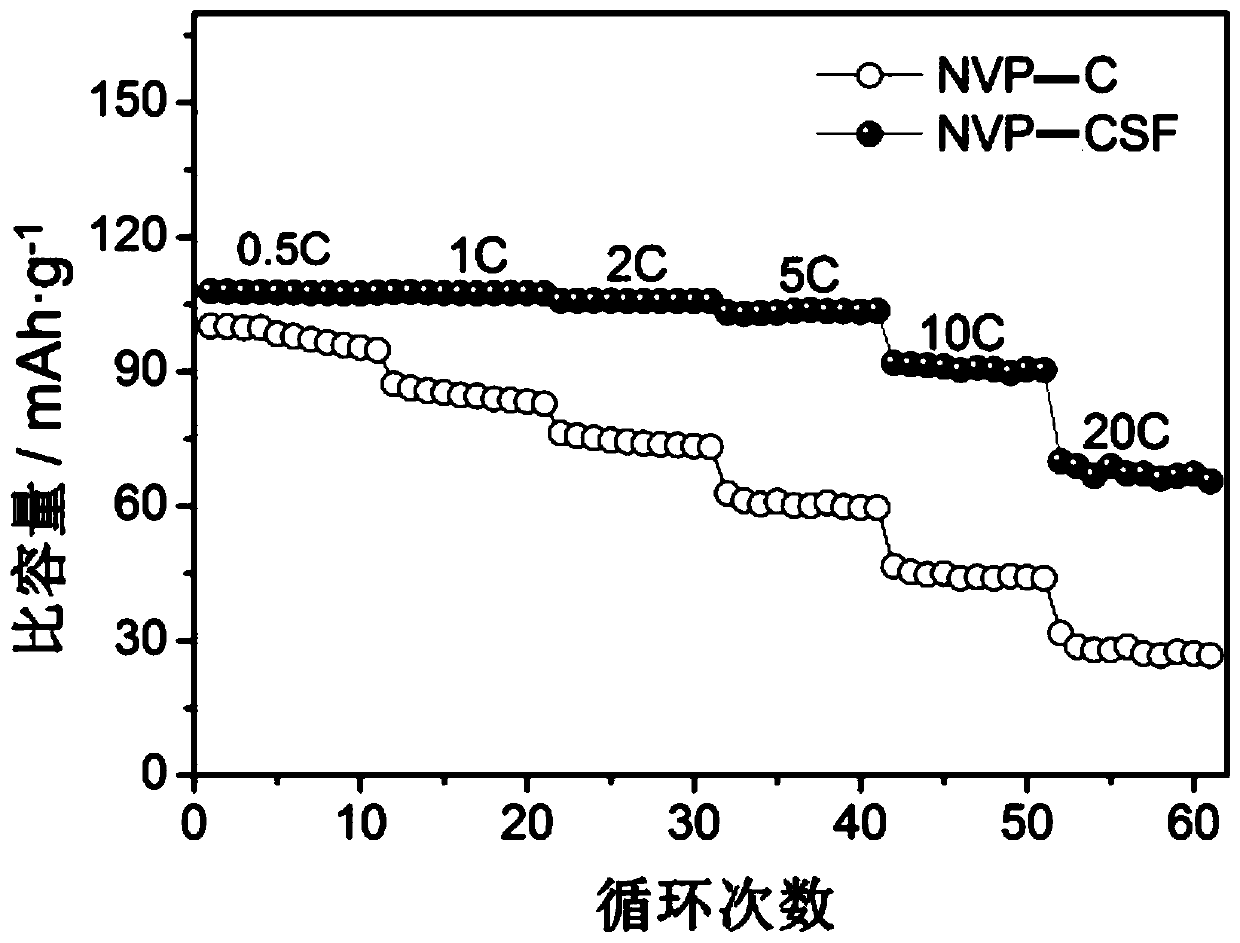

[0032] (1) According to the molar ratio of Na:V:P=3.05:2:3, weigh 122g sodium hydroxide, 182g vanadium pentoxide, 447.3g ammonium phosphate, ball mill for 0.5h, and dry to obtain sodium vanadium phosphate precursor powder ;

[0033] (2) The sodium vanadium phosphate precursor powder was pre-sintered at 400°C for 8 hours in a nitrogen atmosphere, and then sintered at 850°C for 10 hours to obtain the positive electrode material sodium vanadium phosphate;

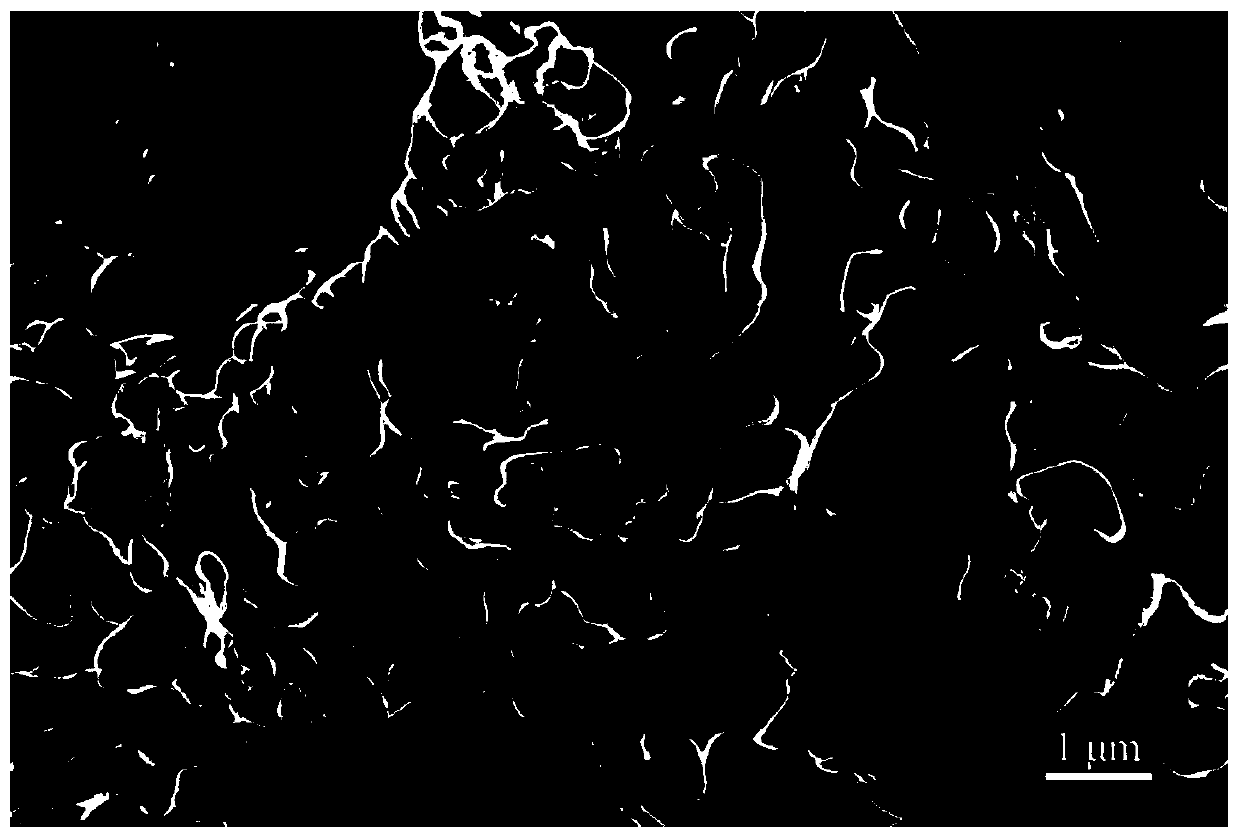

[0034] (3) According to the mass fraction of 5% sodium vanadium phosphate, dissolve 40.03g of citric acid in deionized water, then add 300g of sodium vanadium phosphate powder, stir in a water bath at 20°C for 1h, after the dispersion is uniform, continue to evaporate at 80°C Until a gel is formed, dried and ground to obtain a mixed powder.

[0035] (4) According to the molar ratio of elements S:F:C=0.05:0.03:1, weigh 1.6g of sulfur powder and 0.975g of polyvinylidene fluoride, grind them together with 240g of mixed powder, a...

Embodiment 2

[0041] 1) According to the molar ratio of Na:V:P=3:2:3.05, weigh 159g of sodium carbonate, 101.9g of vanadium powder, and 350.8g of ammonium dihydrogen phosphate, ball mill for 3 hours, and dry to obtain sodium vanadium phosphate precursor powder;

[0042]2) Pre-sintering the sodium vanadium phosphate precursor powder in an argon atmosphere at 550° C. for 2 hours, and then sintering at 900° C. for 6 hours to obtain sodium vanadium phosphate as a positive electrode material;

[0043] 3) According to the mass fraction of 10% sodium vanadium phosphate, dissolve 52.91g of Tween 20 in deionized water, then add 300g of sodium vanadium phosphate powder, stir in a water bath at 40°C for 0.5h, after the dispersion is uniform, continue to disperse at 100°C Evaporate to form a gel, dry and grind to obtain a mixed powder.

[0044] 4) According to the molar ratio of elements N:Se:C=0.1:0.05:1, weigh 12.01g of urea and 7.90g of selenium powder, grind them together with 240g of mixed powder,...

Embodiment 3

[0048] 1) According to the molar ratio of Na:V:P=3.05:2.02:3.02, weigh 259.22g of sodium nitrate, 236.30g of ammonium metavanadate, and 398.82g of diammonium hydrogen phosphate, ball mill for 2 hours, and dry to obtain the precursor of sodium vanadium phosphate powder;

[0049] 2) The sodium vanadium phosphate precursor powder was pre-sintered at 450°C for 5 hours in an argon-hydrogen mixed gas atmosphere, and then sintered at 650°C for 15 hours to obtain the positive electrode material sodium vanadium phosphate;

[0050] 3) According to the mass fraction of 20% sodium vanadium phosphate, dissolve 79.02g of stearic acid in ethanol, then add 300g of sodium vanadium phosphate powder, stir in a water bath at 80°C for 3h, after the dispersion is uniform, continue to evaporate at 90°C to A gel is formed, dried and ground to obtain a mixed powder.

[0051] 4) According to the molar ratio of elements F:S:N:C=0.03:0.05:0.06:1, weigh 3.9g polyvinylidene fluoride, 6.4g sulfur powder, 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com