Al/La co-doped high-nickel ternary precursor with core-shell structure and preparation method thereof, and positive electrode material

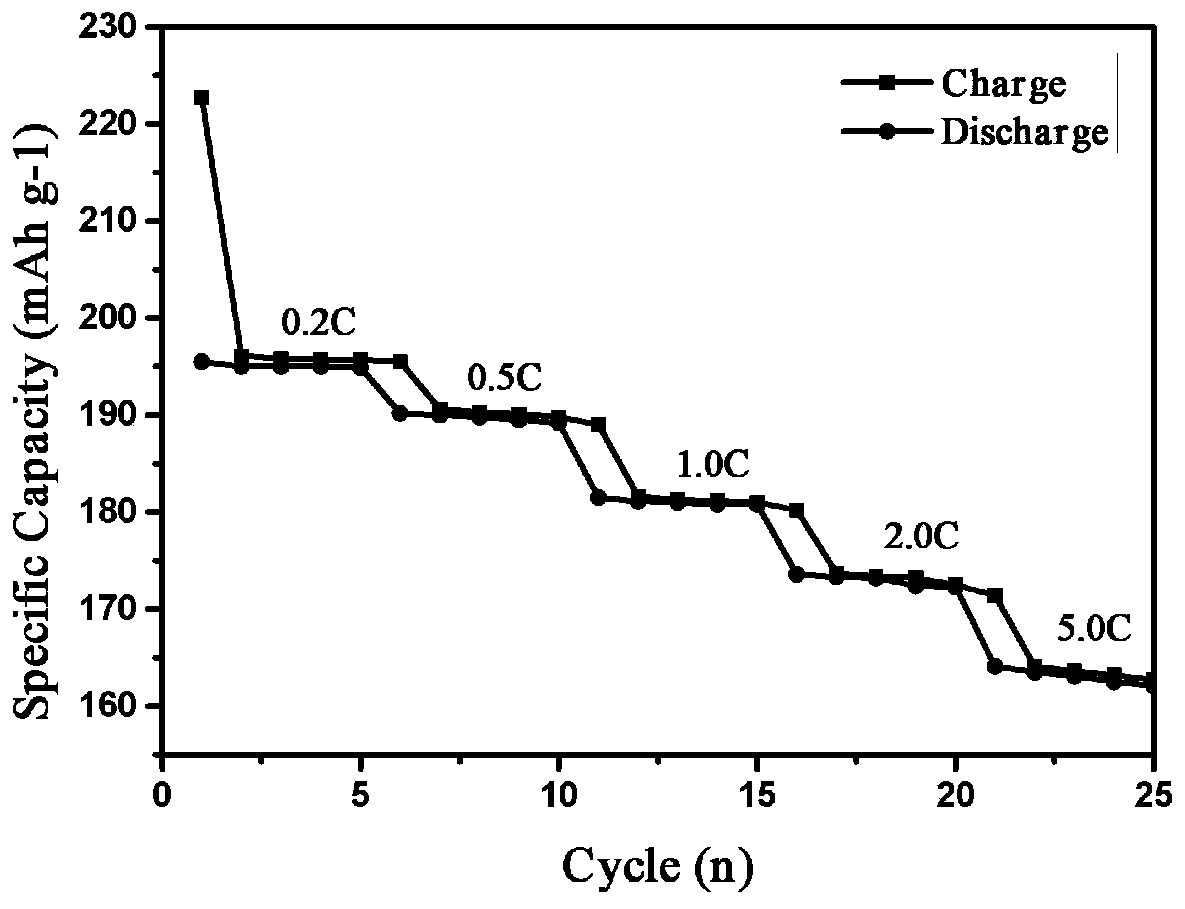

A core-shell structure and positive electrode material technology, applied in the direction of structural parts, chemical instruments and methods, electrical components, etc., can solve the problems of blocked core and shell transmission channels, and cannot fundamentally improve the electrochemical performance of materials, so as to improve the average Oxidation state, suppression of Jahn-Teller effect, and effect of improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

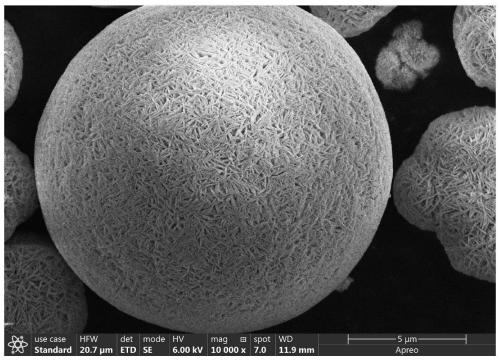

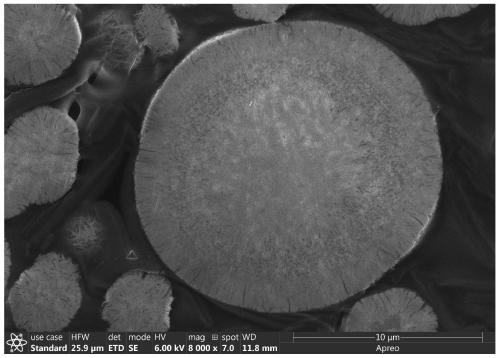

[0039] A method for preparing a core-shell structure Al / La co-doped high-nickel ternary precursor, comprising the following steps:

[0040] (1) Mix industrial 28% ammonia water with deionized water, and adjust the ammonia concentration to 10mol / L; mix NaOH with deionized water, and adjust the concentration to 4mol / L;

[0041] (2) Prepare soluble nickel sulfate, cobalt sulfate, manganese sulfate and aluminum sulfate solutions with a molar ratio of Ni:Co:Mn=0.7:0.2:0.1 and a total concentration of 2mol / L, and dissolve the above salt solution in hot water at 70°C in, stir until completely dissolved;

[0042] (3) Fill the 650L reaction kettle with hot water, adjust the stirring speed of the reaction kettle to 300rpm, pass ammonia water and NaOH aqueous solution into the reaction kettle in sequence, adjust the ammonia concentration to 8-8.5g / L, and the pH to 10.95;

[0043] (4) Add the mixed salt solution, ammonia water and NaOH solution in step (2) into the reaction kettle toget...

Embodiment 2

[0054] A method for preparing a core-shell structure Al / La co-doped high-nickel ternary precursor, comprising the following steps:

[0055] (1) Mix industrial 28% ammonia water and deionized water to adjust the concentration to 10mol / L; mix NaOH and deionized water to adjust the concentration to 4mol / L;

[0056] (2) Prepare soluble nickel sulfate, cobalt sulfate, manganese sulfate and aluminum sulfate solutions with a molar ratio of Ni:Co:Mn=0.8:0.1:0.1 and a total concentration of 2mol / L. The above salt solutions are dissolved in hot water at 70°C , stir until completely dissolved;

[0057] (3) Pour hot water into the 50L reactor, adjust the stirring speed of the reactor to 700rpm, pass ammonia water and NaOH aqueous solution into the reactor in sequence, adjust the ammonia concentration to 6-6.5g / L, and pH to 11.2 ;

[0058] (4) Add the mixed salt solution, ammonia solution and NaOH solution in step (2) into the reaction kettle, control the pH of the reaction process at ab...

Embodiment 3

[0064] A method for preparing a core-shell structure Al / La co-doped high-nickel ternary precursor, comprising the following steps:

[0065] (1) Mix industrial 28% ammonia water and deionized water to adjust the concentration to 10mol / L; mix NaOH with deionized water to adjust the concentration to 4mol / L;

[0066] (2) Prepare soluble nickel nitrate, cobalt nitrate, manganese nitrate and aluminum sulfate solutions with a molar ratio of Ni:Co:Mn=0.6:0.2:0.2 and a total concentration of 2mol / L. The above salts are dissolved in hot water at 70°C. Stir until completely dissolved;

[0067] (3) Put full hot water into the 50L reaction kettle, adjust the stirring speed of the reaction kettle to 600rpm, pass ammonia water and NaOH aqueous solution into the reaction kettle in sequence, control the ammonia concentration to 6-6.5g / L, and the pH to 11.0;

[0068] (4) Add the mixed salt solution, ammonia solution and NaOH solution in step (2) into the reaction kettle, control the pH of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com