Method for preparing flame retardant epoxy resin from modified graphene

A kind of epoxy resin, graphene technology, applied in the field of flame retardant epoxy resin prepared by modified graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with examples.

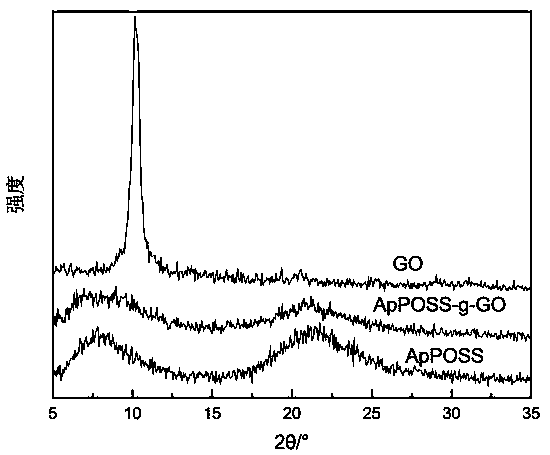

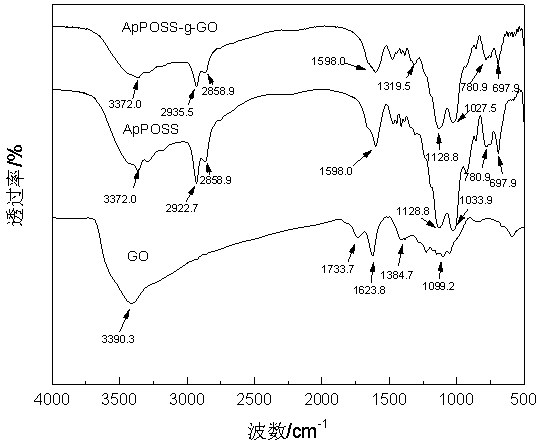

[0022] Preparation of graphene oxide: Graphite has high chemical stability and weak reactivity. Using natural flake graphite as raw material, the modified Hummers method is used to prepare graphite oxide. By oxidizing graphite with strong acid, oxygen-containing groups are inserted between graphite layers to increase the distance between graphite layers, and graphite oxide suspension is obtained. Subsequently, the suspension was acid-washed and washed with water to remove residual strong acid, and after centrifugal dispersion and ultrasonic stripping, a graphene oxide suspension was obtained. Finally, freeze-dry to obtain graphene oxide.

[0023] Specific preparation example:

[0024] Weigh 7.5g of potassium peroxodisulfate and 7.5g of phosphorus pentoxide into a 250ml three-necked flask, add 40ml of concentrated sulfuric acid and stir evenly, weigh 10g of graphite powder and slowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com