Patents

Literature

77results about How to "Increase wind temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

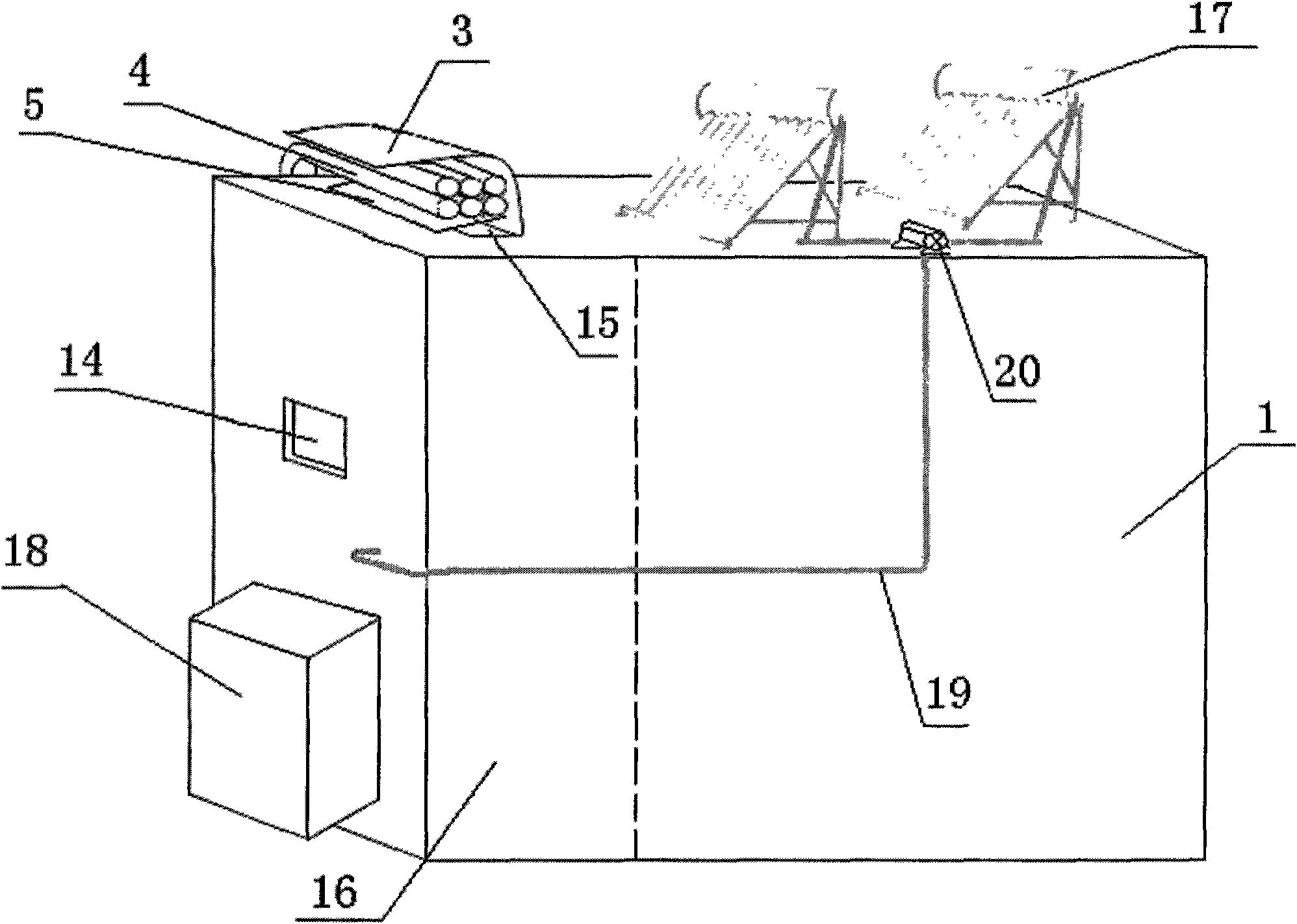

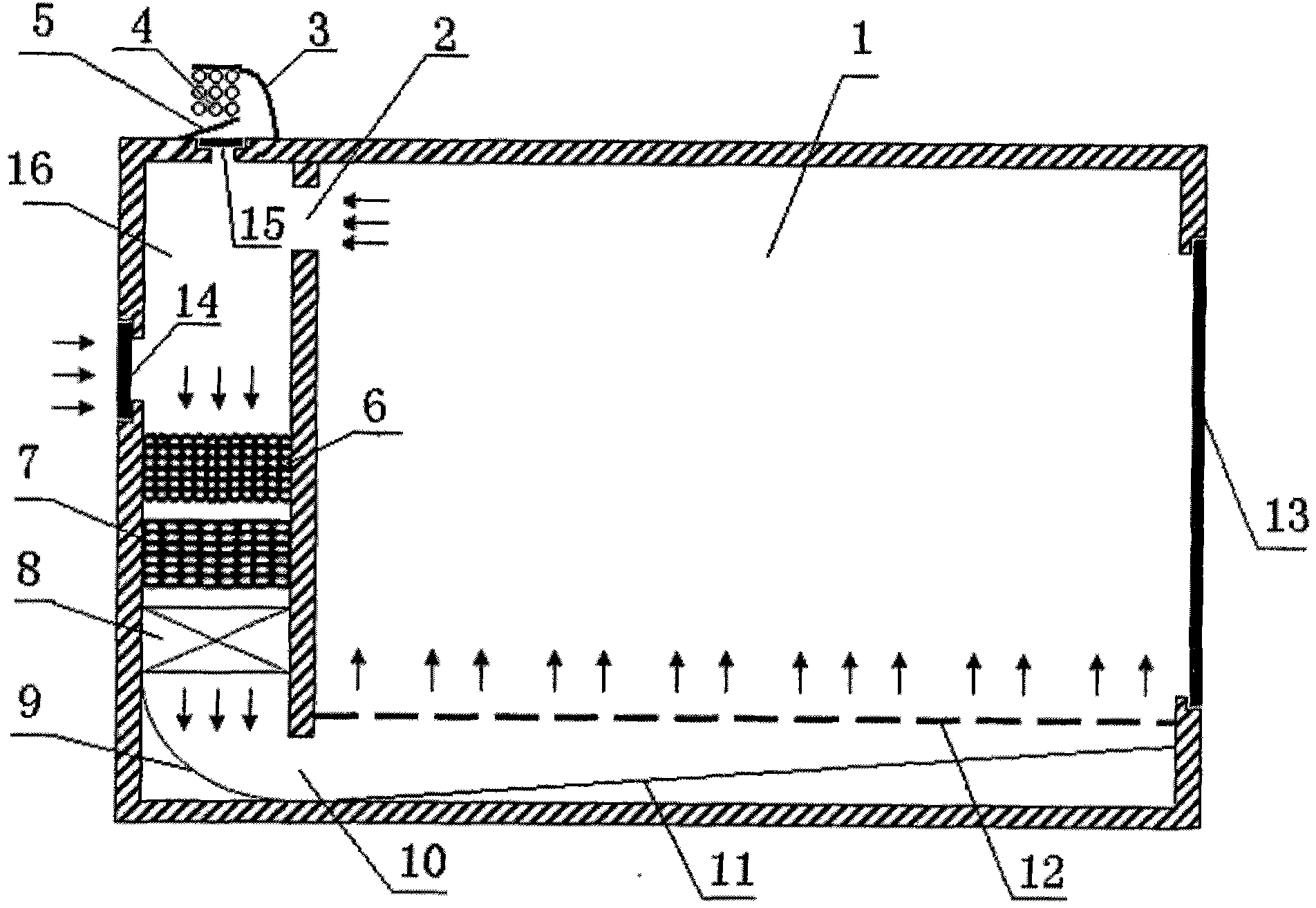

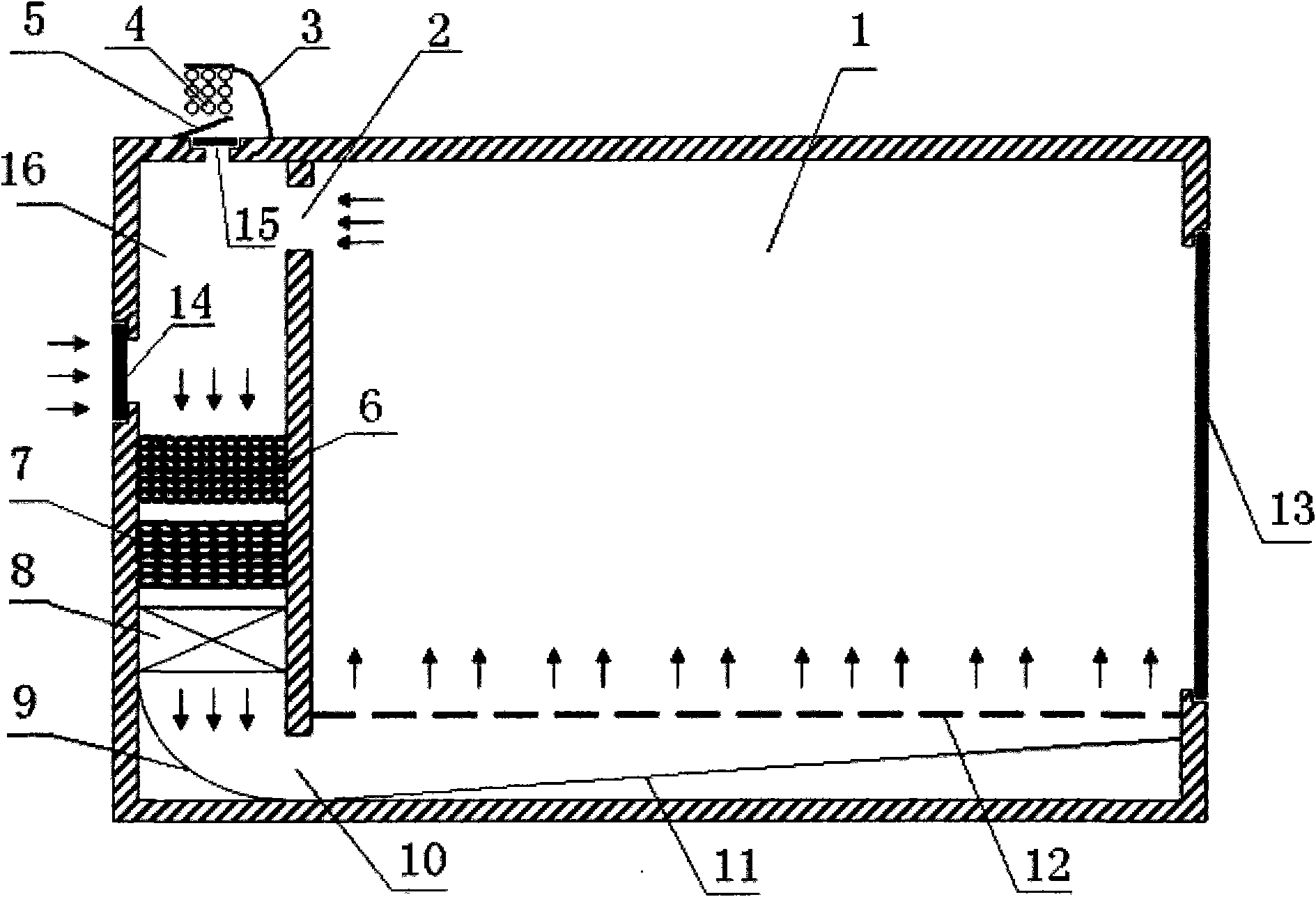

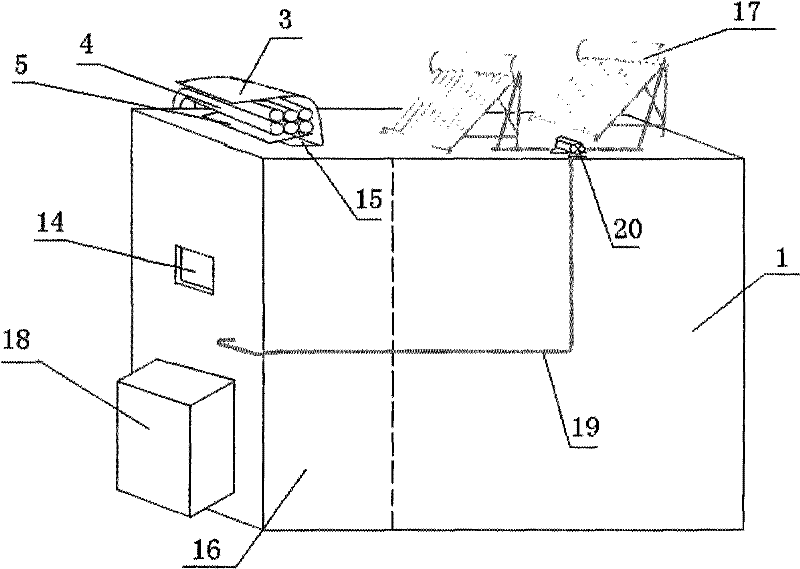

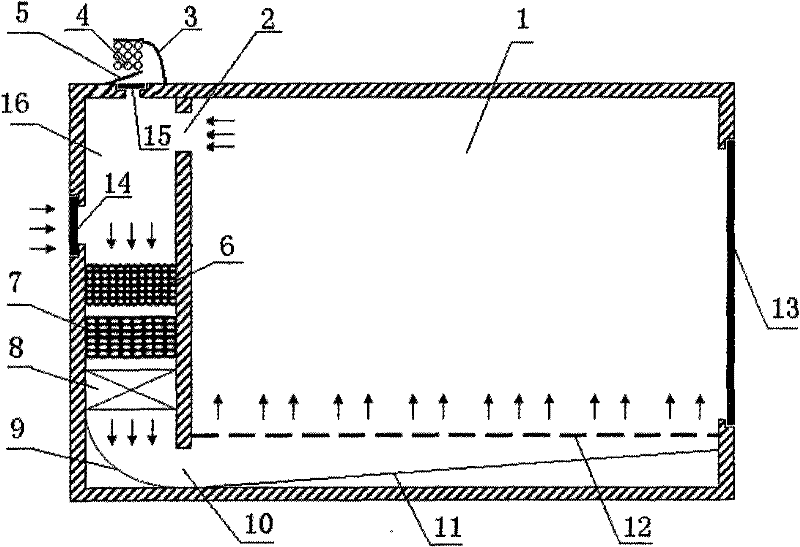

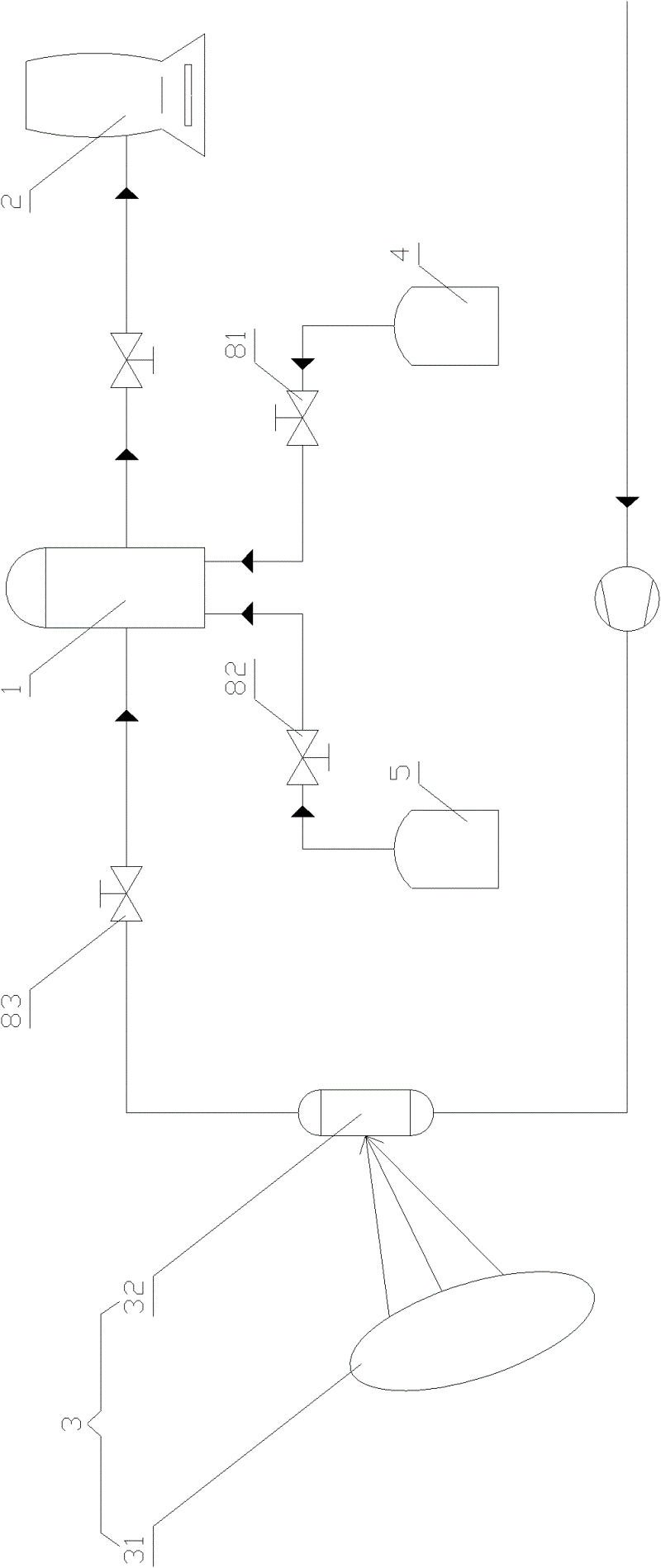

Hot air drying system heated by double energy sources

InactiveCN101936644AIncrease the heat exchange areaReduce deliveryTobacco preparationDrying solid materials with heatPlate heat exchangerBusiness efficiency

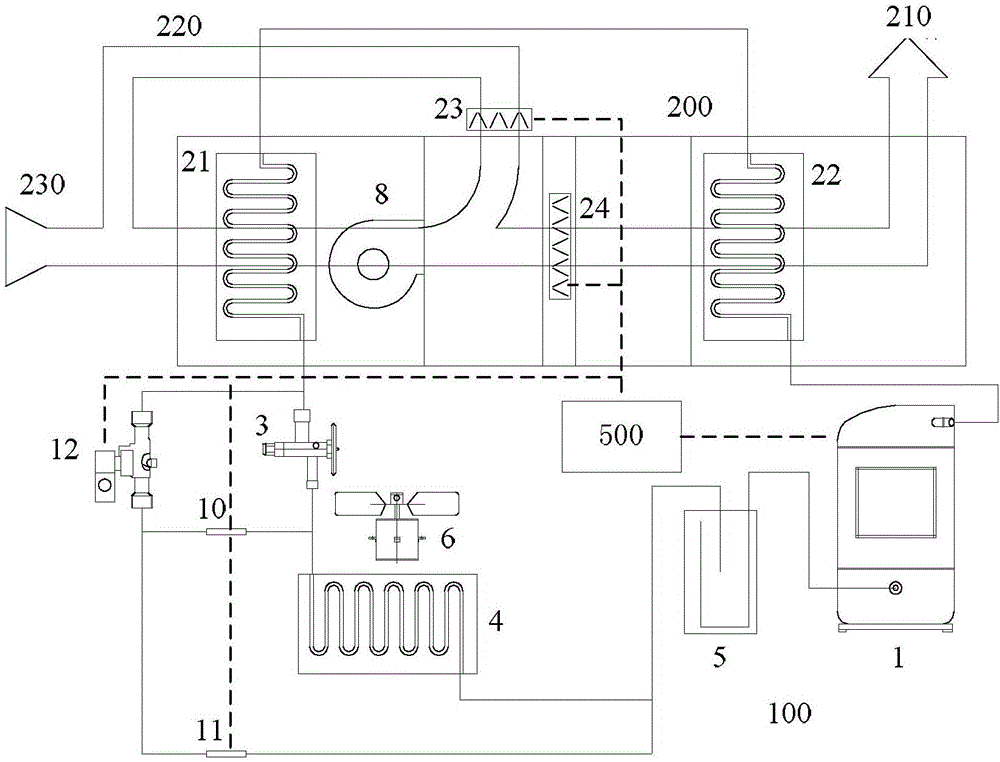

The invention discloses a hot air drying system heated by double energy sources, which comprises a heating chamber with a fresh air opening, a drying chamber, a solar heating device, an air source heat pump and a condenser fan of the air source heat pump, wherein the upper part of the heating chamber or the drying chamber is provided with a dehumidifying opening; a condenser and the condenser fan of the air source heat pump are arranged in the heating chamber; a hot water heat exchanger of the solar heating device is arranged at the front end of an air inlet of the condenser in the heating chamber; the condenser fan supplies air in an induced draft way; the ratio of the heat exchange area of the condenser to the input power of a compressor is 5.3 to 11 m<2> / kw; the ratio of the heat exchange area of the hot water heat exchanger to the input power of the compressor is not less than 1.5 m<2> / kw; and the total pressure of the condenser fan is 100 to 400 Pa. The hot air drying system heated by the double energy sources makes full use of solar energy as a hot air heat source for drying, solves the problems of the independent use of the solar energy, achieves high energy efficiency ratio by adopting the air heat pump as the hot air heat source, is energy-saving, environmentally-friendly and low in running cost, and manifests the advantages of the combined use of the air source and the solar energy in oven-drying.

Owner:湖南省浏阳市择明热工器材有限公司

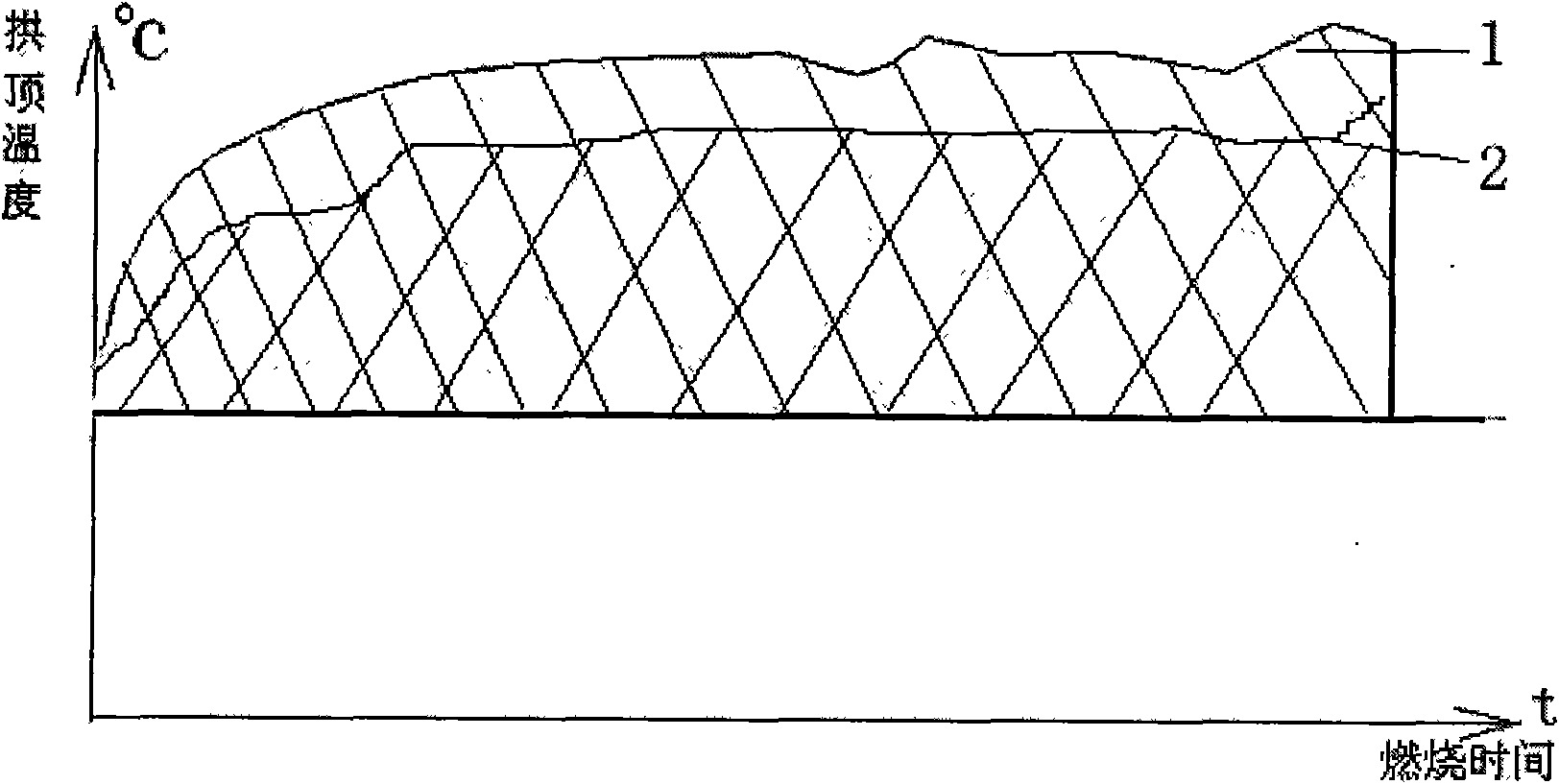

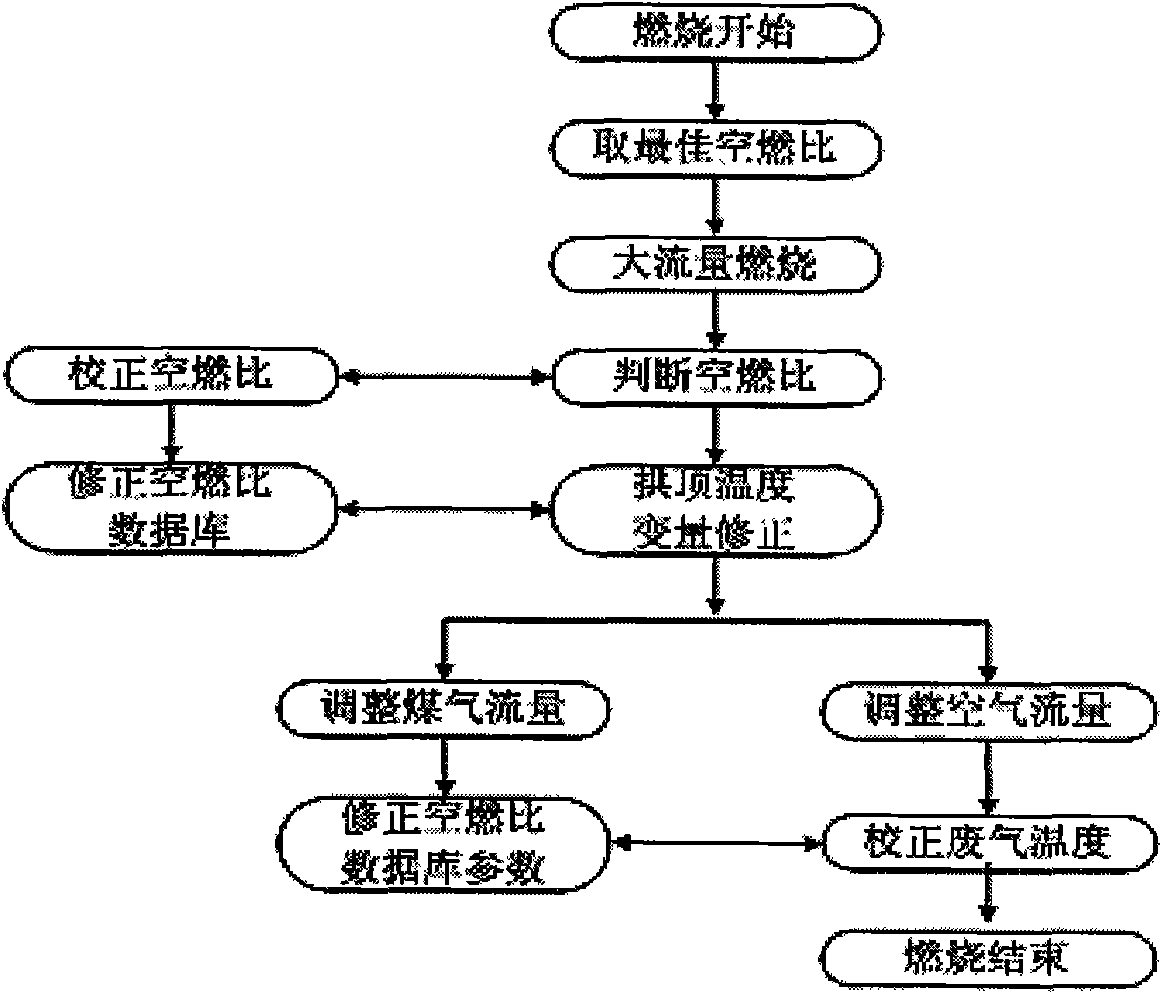

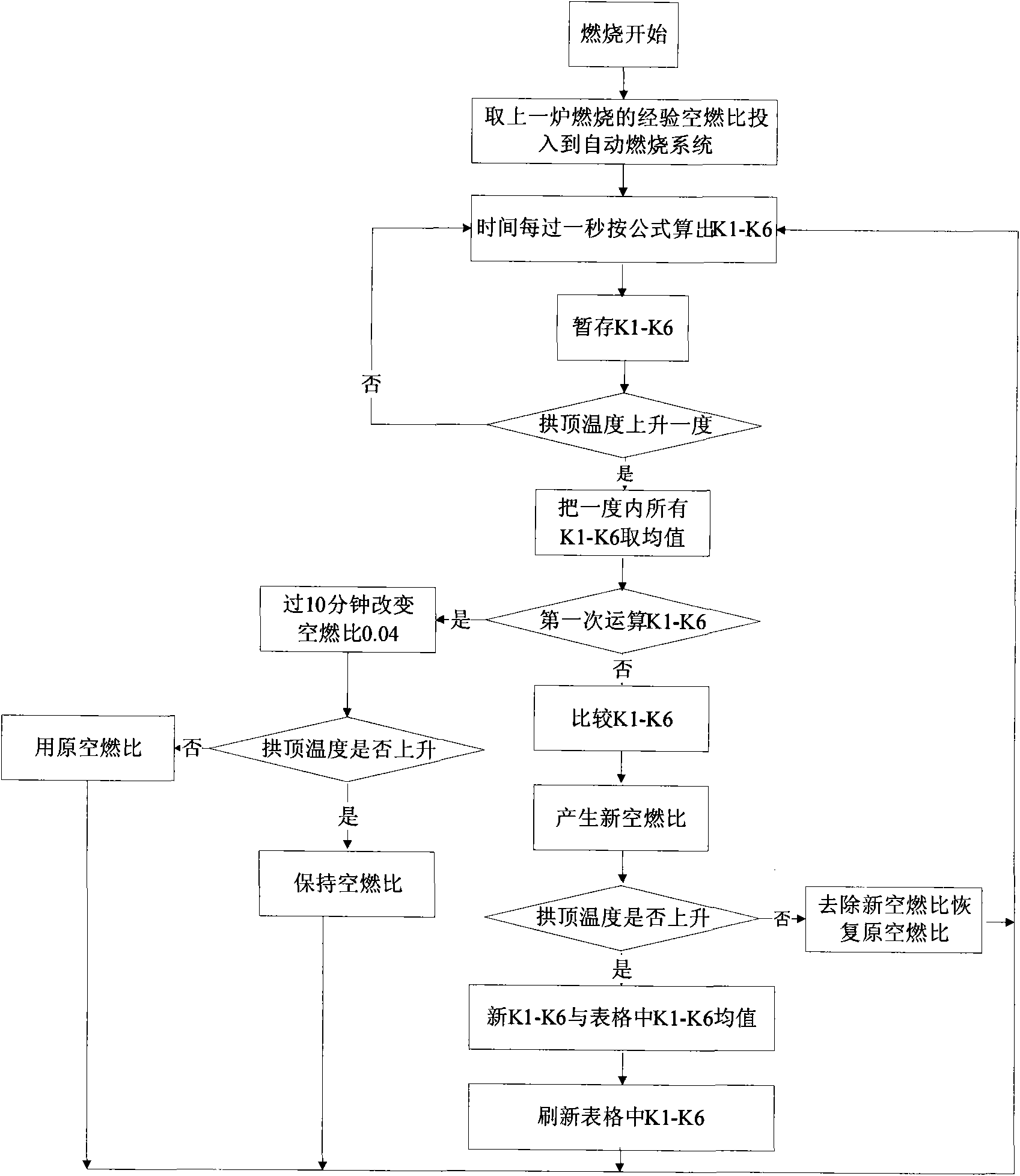

Self-optimizing combustion control method of blast-furnace hot blast stove

InactiveCN101684944AExtend your lifeIncrease wind temperatureFuel supply regulationArray data structureExhaust fumes

The invention relates to an automatic combustion control technology of a blast-furnace hot blast stove. The invention discloses a self-optimizing combustion control method of a blast-furnace hot blaststove. Air-fuel ratio K is used for replacing gas calorific value, current waste gas temperature subtracts waste gas temperature of the previous several minutes, the obtained value divides the current vault temperature, and then the obtained value subtracts the vault temperature value of the previous several minutes to replace an air excess coefficient; according to the current gas pressure, theinfluence coefficient of the vault temperature by calorific value of gas, the influence coefficient of the vault temperature by combustion time and the influence coefficient of the vault temperature by gas flow are calculated; the calculated coefficients are aligned into a sequence; from the point that the vault temperature is higher than 1100 DEG C, the coefficient in the vault temperature is averaged when the vault temperature rises by 1 DEG C, and the array of a group of coefficients is formed when temperature changes by 1 DEG C; when the vault temperature changes by 1 DEG C, the calculatedcoefficient array is compared with the array corresponding to the vault temperature in a sequence group produced by combustion in the previous round; and a new air-fuel ratio is calculated. The invention is easy to realize and has high reaction speed.

Owner:BAOSHAN IRON & STEEL CO LTD

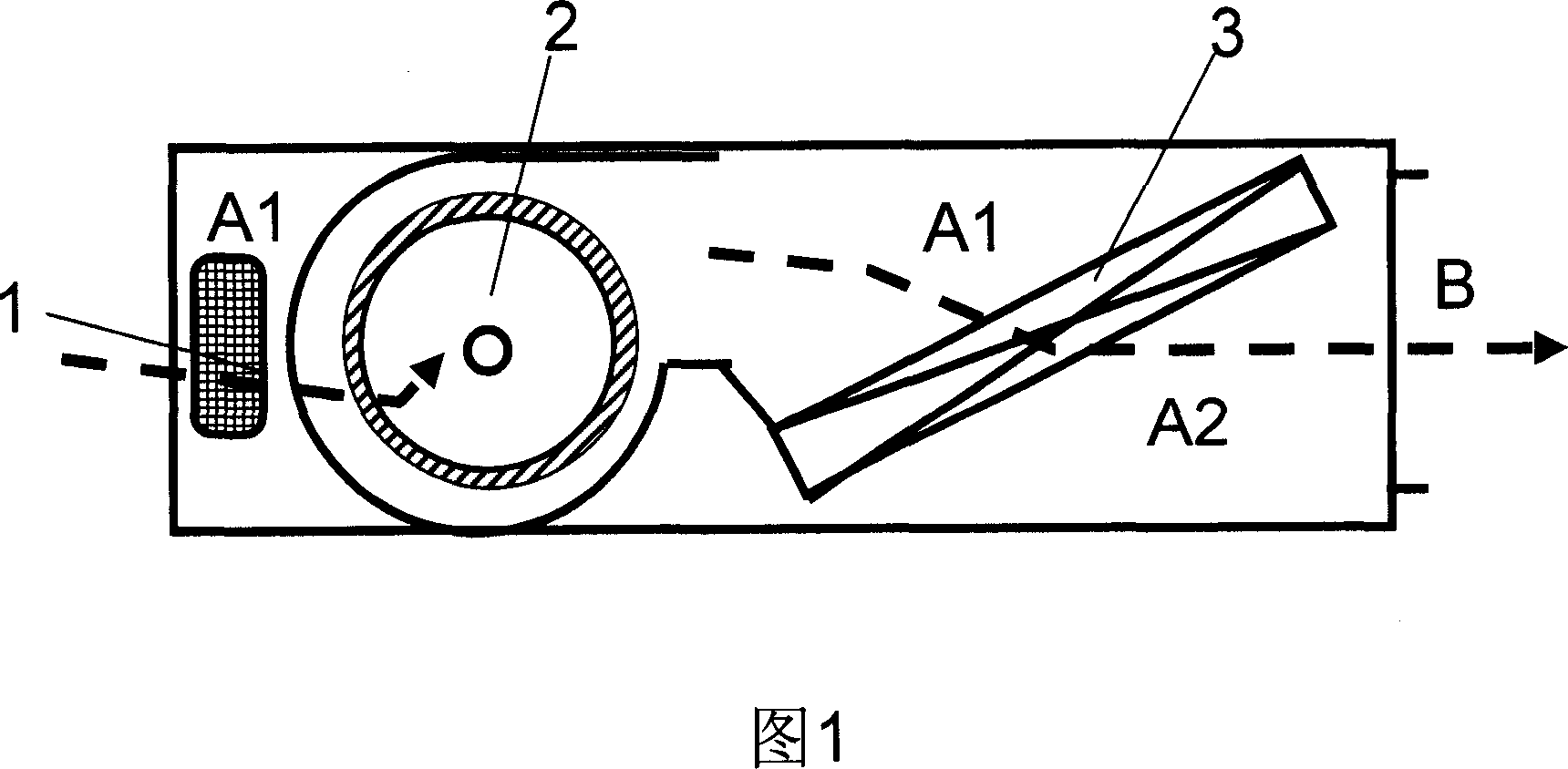

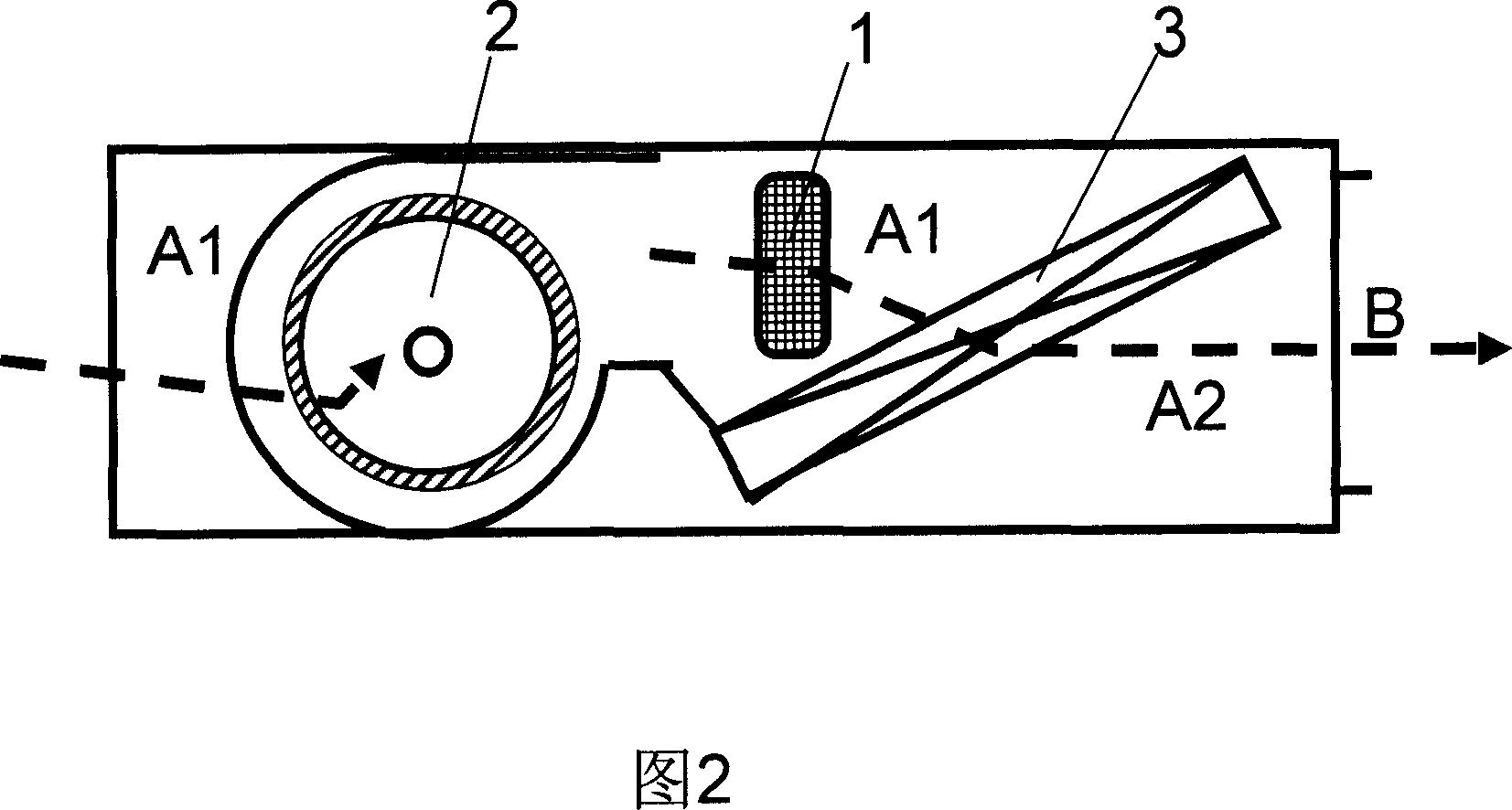

Air conditioner and controlling method therefor

InactiveCN1991255AIncrease wind temperatureHigh work pressureSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringHeat exchanger

The invention relates to an air conditioner, comprising indoor unit and outdoor unit. Indoor heat exchanger and air supply apparatus are set in the indoor unit. Thereinto, there is at least a heating device in the indoor device and the heating device runs during defrosting of said air conditioner. The heating device is set at the upstream or downstream of indoor heat exchanger. The invention provides a control method of air conditioner. The method comprises defrosting of air conditioner when achieving the condition of defrosting and running of heating device at least when said air conditioner defrosts. The air conditioner and the control method of invention can shorten the defrosting time and make the indoor temperature not decrease. Furthermore, it can make the temperature in door improve quickly under the low temperature.

Owner:PANASONIC CORP

Hot blast stove burning method

InactiveCN1888083AIncrease oxygen enrichment rateRaise the combustion temperatureBlast furnace detailsHeating stovesCombustionControl system

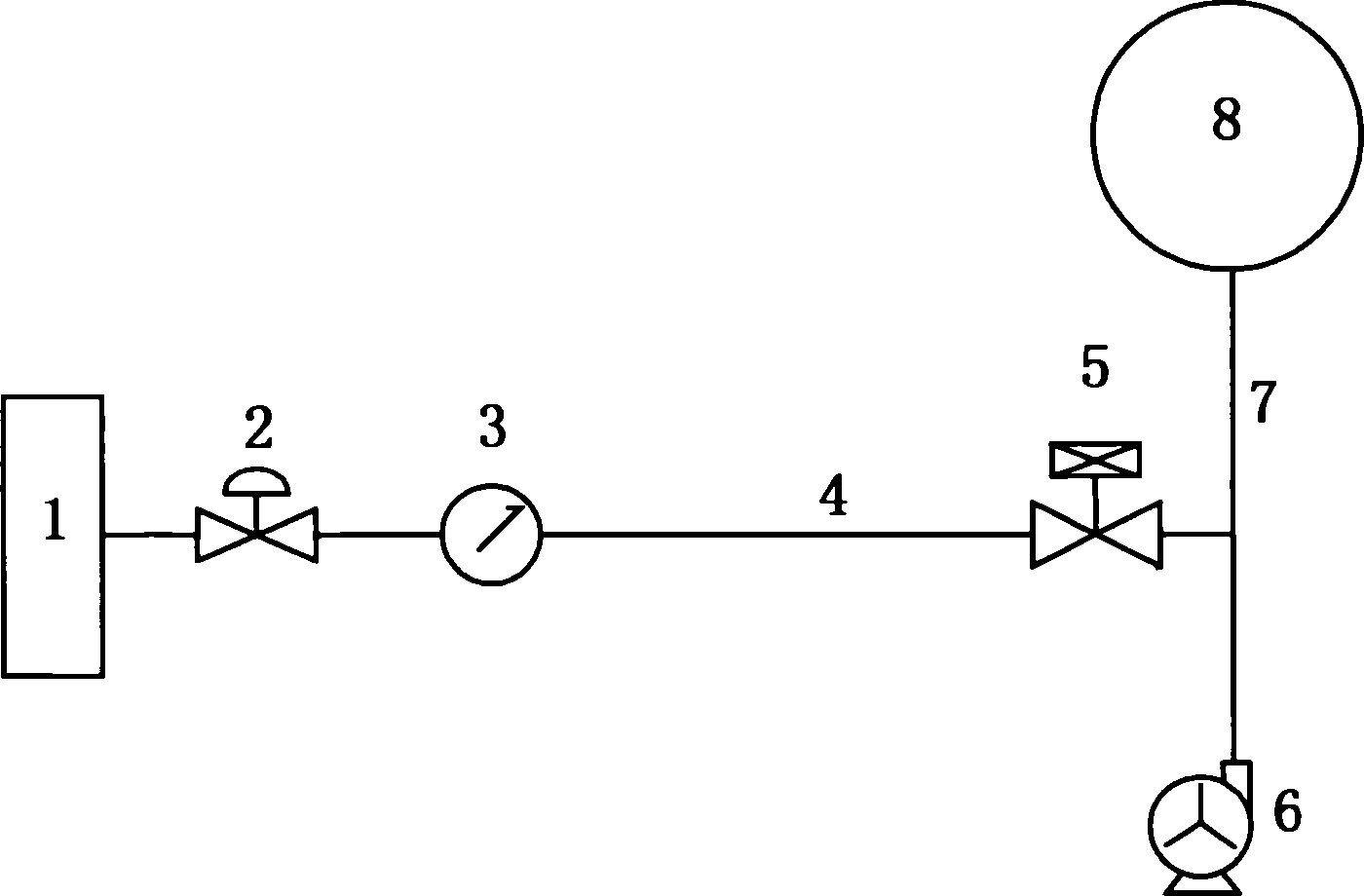

The hot blast stove burning method belongs to the field of blast furnace iron smelting technology in metallurgic industry, and aims at raising the hot blast temperature. The method is that in the main pipeline for conveying combustion supporting air to the hot blast stove, one oxygen pipeline with flow regulating valve, flow meter and control valve is connected for mixing oxygen in the flow rate of 20-12 cu m / min, with the oxygen being led out from the oxygen packet of blast furnace. Mixing oxygen to the combustion supporting air and controlling the oxygen amount automatically with the hot blast stove controlling system can raise the oxygen content in the combustion supporting air and raise hot blast temperature.

Owner:TIANJIN TIANTIE METALLURGICAL GRP

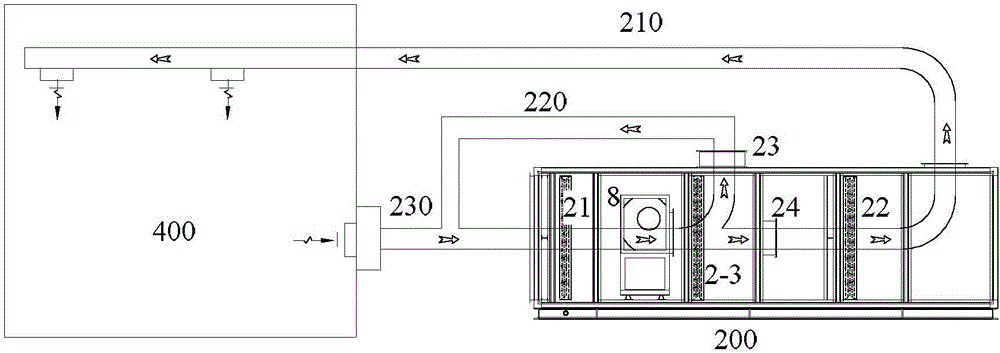

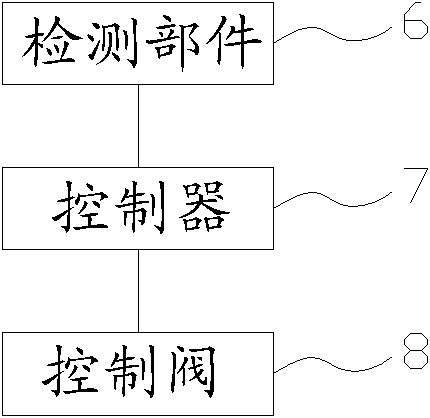

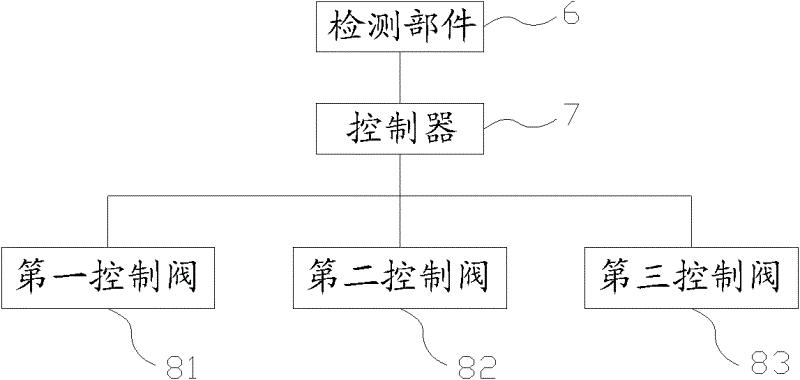

Control method and control device of heat pump type dual-cycle hot air drying system

ActiveCN106643107AImprove energy efficiencyGuaranteed temperature change requirementsMechanical apparatusHeat pumpsAir volumeEngineering

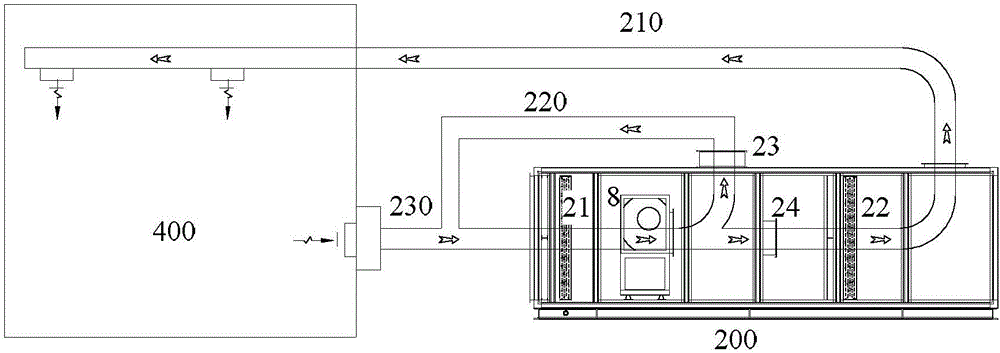

The invention provides a control method and a control device of a heat pump type dual-cycle hot air drying system and relates to an air or gas supply or control device for drying a solid material or product, in particular to a control method and a control device of a heat pump type dual-cycle hot air drying system. The control method comprises the following steps that a temperature control parameter is configured, and a preset temperature control curve parameter is saved; air outlet temperature and drying room temperature and humidity are detected and monitored; the set temperature is dynamically adjusted according to a preset temperature control curve; a dual-cycle dynamic operating mode of the system is selected according to current set temperature. The control device utilizes a microprocessor to achieve program control, an inner cycle loop for large-volume circulation is established, condensing latent heat of a refrigerant is fully absorbed to improve basic air temperature, and high-temperature hot air is obtained through secondary heat exchange of an air supply circulation loop; the air outlet volume is automatically adjusted and controlled by adopting dual-path air volume to ensure the change demand for air outlet temperature and drying room temperature. The reliability of the product can be ensured, the unit energy efficiency can be also achieved, and the purpose of energy consumption is reduced.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

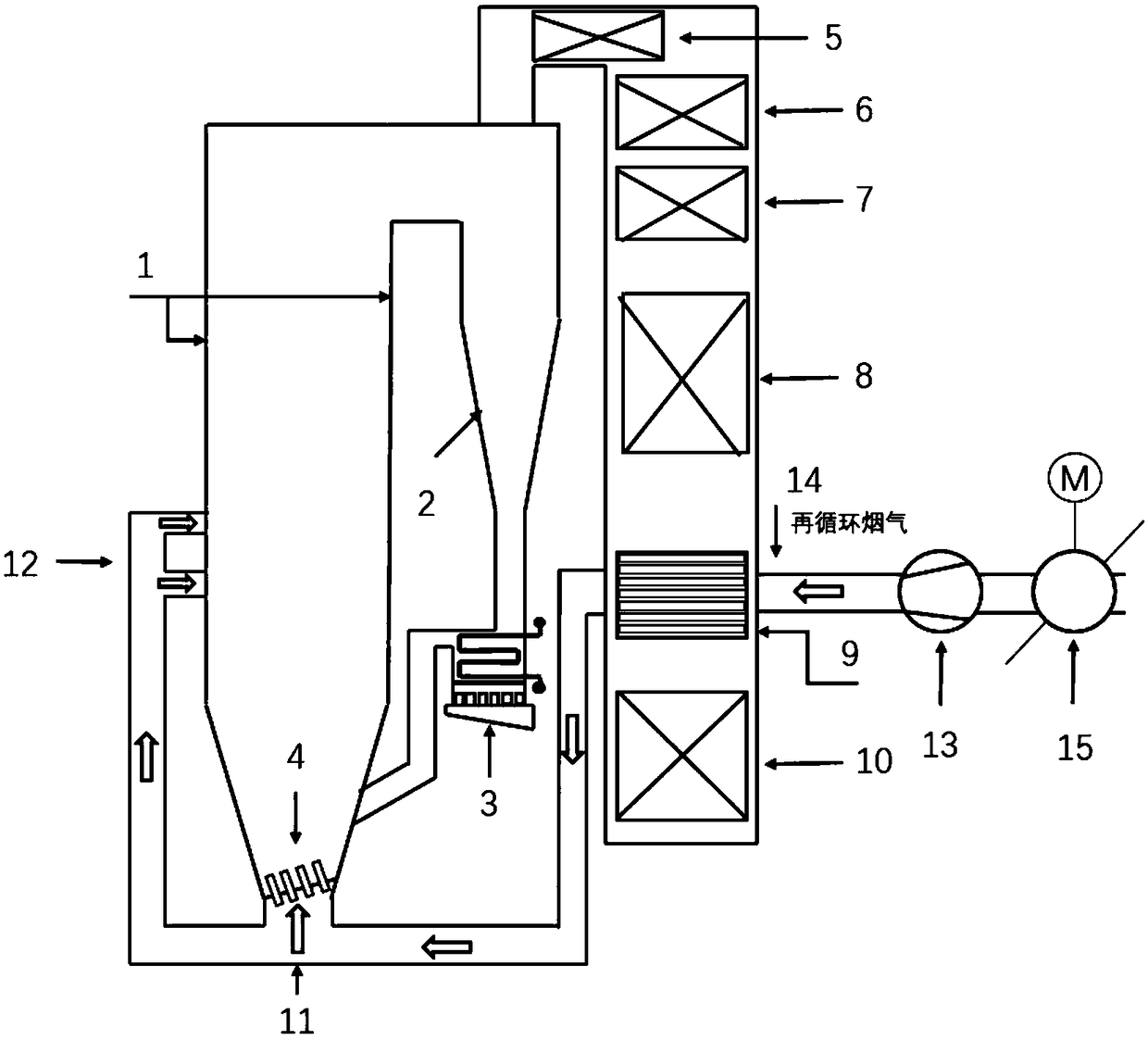

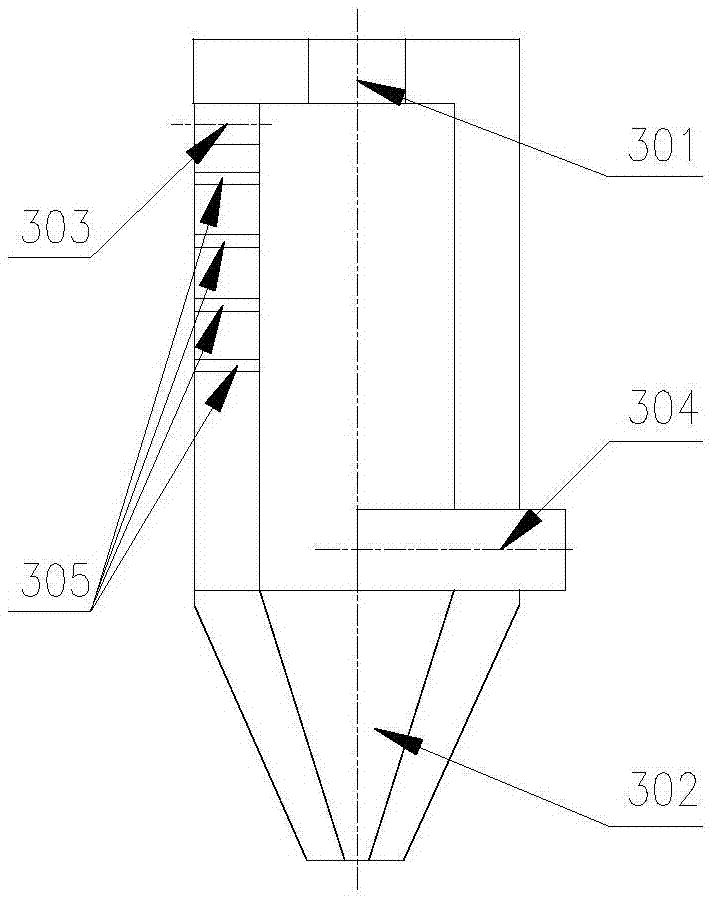

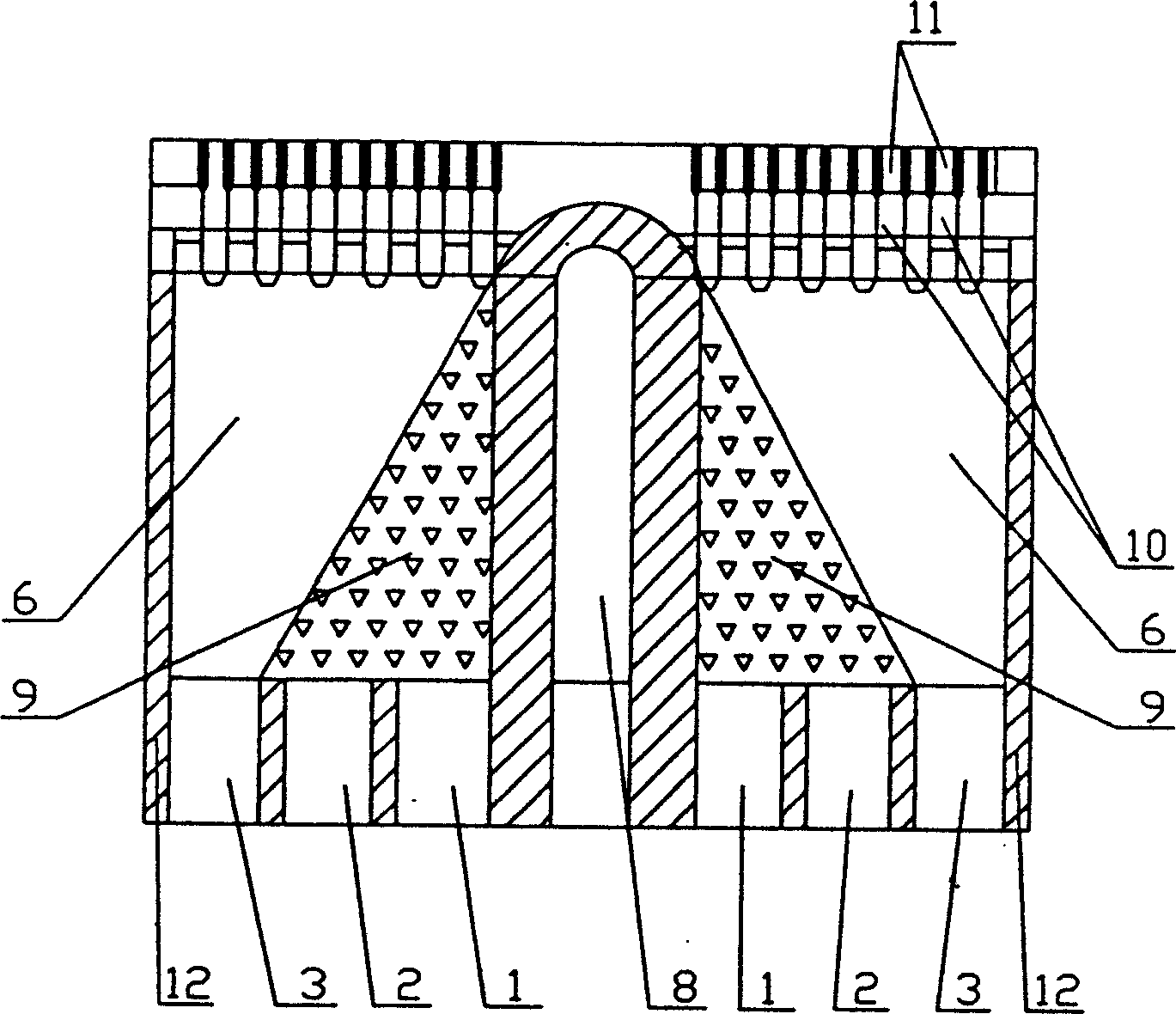

Circulating fluidized bed boiler applicable to garbage incineration

InactiveCN108758651AOvercoming the problem of insufficient combustion temperatureReduce heat absorptionFluidized bed combustionIncinerator apparatusAir volumeEvaporation

The invention discloses a circulating fluidized bed boiler applicable to garbage incineration. The circulating fluidized bed boiler applicable to garbage incineration comprises a hearth, an air distribution device, a separator, a material return valve, an external bed heat exchanger, a tail flue, a water-cooling pipe bundle, an evaporation pipe bundle, a low-temperature superheater, a coal economizer, a recirculating smoke heat exchanger, an air pre-heater and the like. According to the circulating fluidized bed boiler applicable to garbage incineration, an in-boiler water-cooling wall is completely poured-covered with a refractory material, so that a high combustion temperature of the circulating fluidized bed boiler is ensured. Meanwhile, recirculating smoke is heated by virtue of hot smoke in the tail flue, so that charge heat is increased, and the combustion stability of garbage incineration in the circulating fluidized bed boiler is further improved. The heated recirculating smokeis mixed with primary air and secondary air, so that a primary air amount used for fluidization is reduced while an air temperature is increased, the effect of enhanced graded combustion is further achieved, and the original generation of NOx is reduced. The problem of insufficient heating surface in the heat-insulation hearth is solved through arranging a high-temperature superheater in an external bed; and meanwhile, the problems of high-temperature corrosion of smoke, and coking in a biomass and garbage incineration process, are greatly solved.

Owner:HUANENG CLEAN ENERGY RES INST

High coke oven gas mixing air supply device of blast furnace hot blast system

InactiveCN101709346ASimple structureEasy to set up and installBlast furnace detailsHeating stovesCoke oven gasElectricity

The invention relates to a high coke oven gas mixed air supply device of a blast furnace hot blast system. A blast furnace gas transmission main pipe is connected with a mixed gas transmission header pipe by a flow electrical adjustment valve; a bypass pipe is communicated with a blast furnace gas transmission main pipe and the mixed gas transmission header pipe and is formed by connecting a blast gas branch pipe, an ejector and a mixed gas branch pipe; the ejector is connected with the blast gas branch pipe through a first electrical closing valve, is connected with the mixed gas branch pipe through a second electrical closing valve, and is connected with a third electrical closing valve through a coke oven gas flow electrical adjustment valve; and the two flow electrical adjustment valves and the three electrical closing valves are connected with a central controller. The injection ratio is changed by the quantity of the blast furnace gas distributed to a bypass pipe from the blast furnace gas transmission main pipe, so that the pressure fluctuation of mixed gas is minimized; the invention not only improves the pressure lower limit value of the mixed gas, but also enhances the calorific value of the mixed gas, thereby being beneficial to the stable combustion of a hot blast furnace and optimizing the technical and economic index of the blast furnace production.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

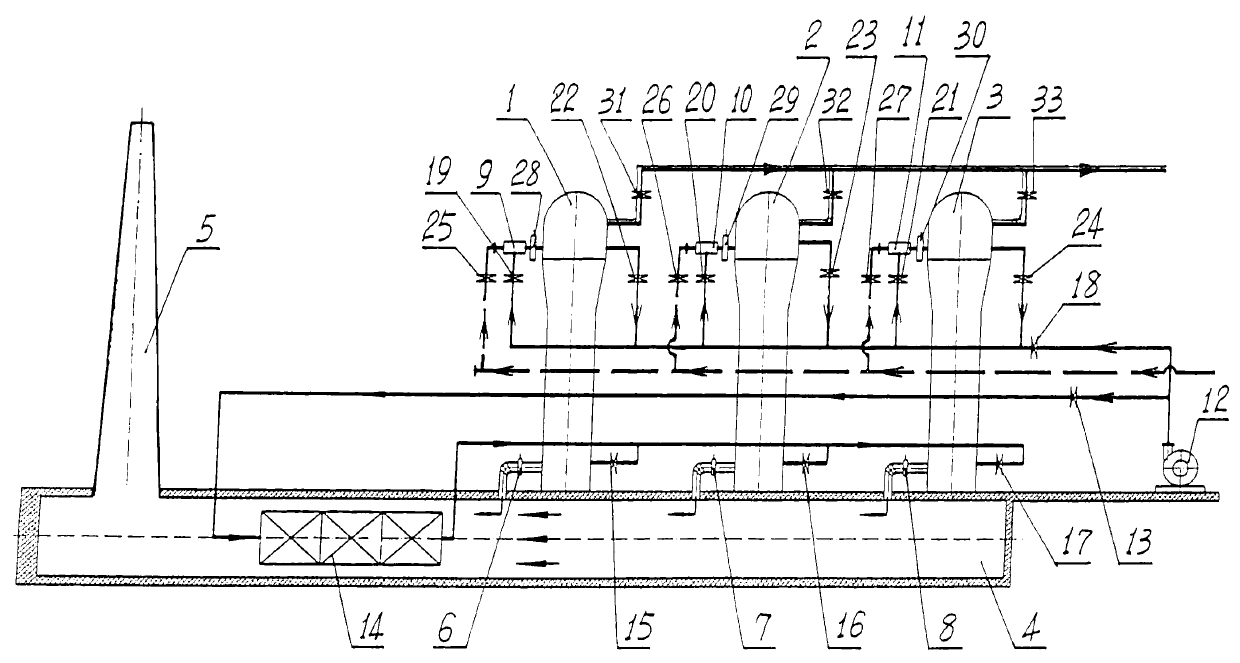

Ceramic energy-saving furnace kiln capable of high-efficiently replaying, recovering and cooling waste heat

ActiveCN106440836AReduce pollutionReduce fuel consumptionEnergy industryIncreasing energy efficiencyCombustionSlow cooling

The invention discloses a ceramic energy-saving furnace kiln capable of high-efficiently replaying, recovering and cooling waste heat. The ceramic energy-saving furnace kiln capable of high-efficiently replaying, recovering and cooling the waste heat comprises a rapid cooling zone, a slow cooling zone and a tail cooling zone. Tail cooling zone draught hoods, a tail cooling zone exhaust pipe and a heat-extraction fan are arranged on the tail cooling zone; a slow cooling zone discharge pipe, a plurality of slow cooling zone air supply pipe groups, a plurality of slow cooling zone discharge pipe groups, a slow cooling zone exhaust pipe and a heat exchange fan are arranged on the slow cooling zone; a combustion fan, an air supply main pipe and a nozzle are arranged on the rapid cooling zone; and a rapid cooling zone air supply pipe group and a rapid cooling zone discharge pipe group are arranged on the air supply main pipe. By adopting the ceramic energy-saving furnace kiln capable of high-efficiently replaying, recovering and cooling the waste heat provided by the invention, a pipeline structure for recovering hot air is formed through a high-efficiently continuous replaying manner, cooling heat generated when ceramics are cooled at each stage is fully recycled, the combustion consumption during a drying and sintering process is remarkably reduced, the pollution on the environment caused by a heat source can be effectively reduced, and the product quality can also be improved.

Owner:DLT TECH CO LTD

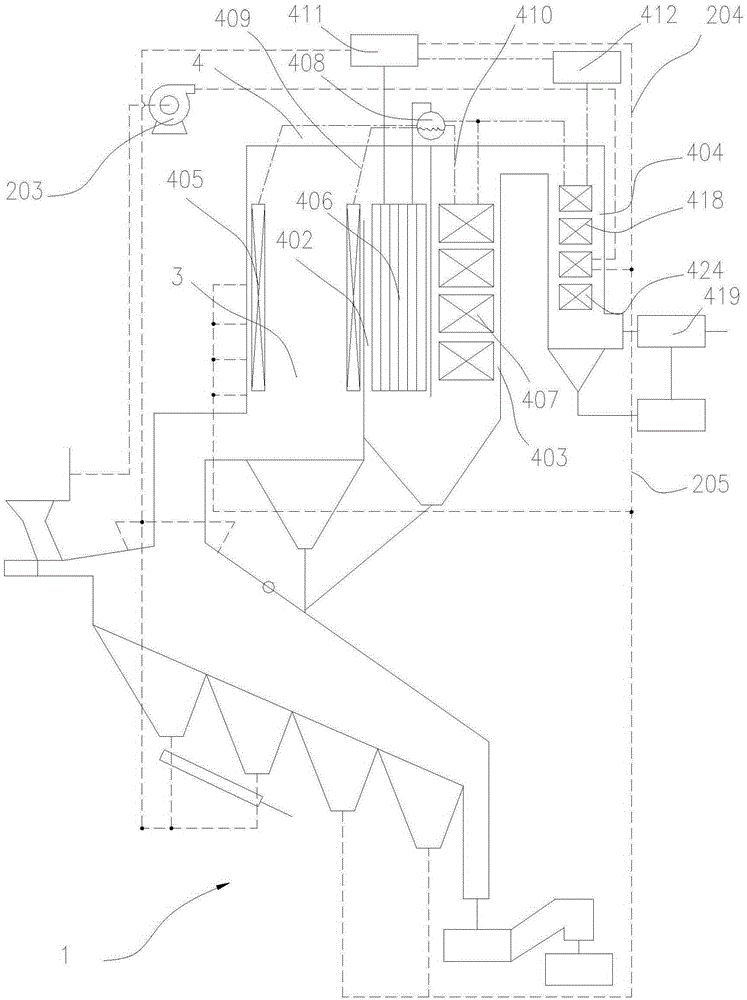

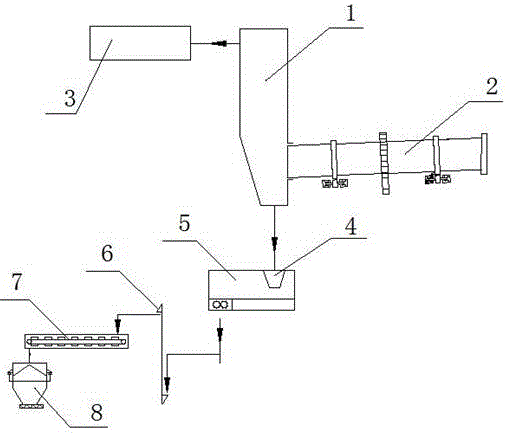

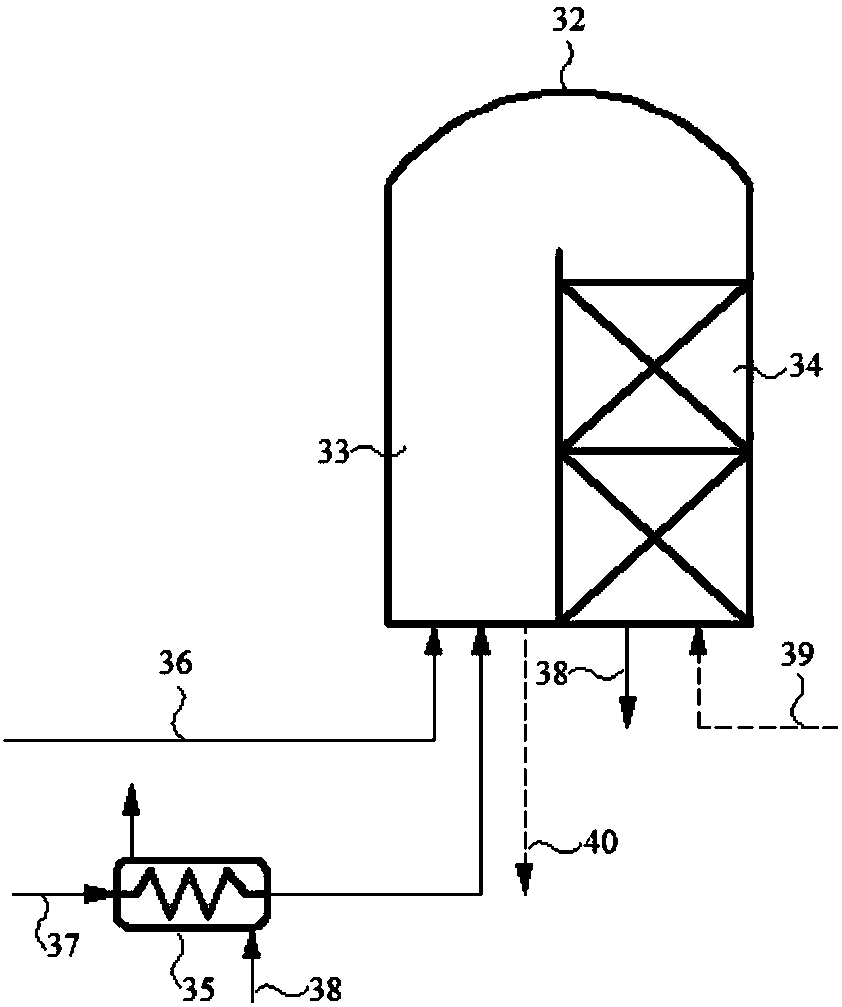

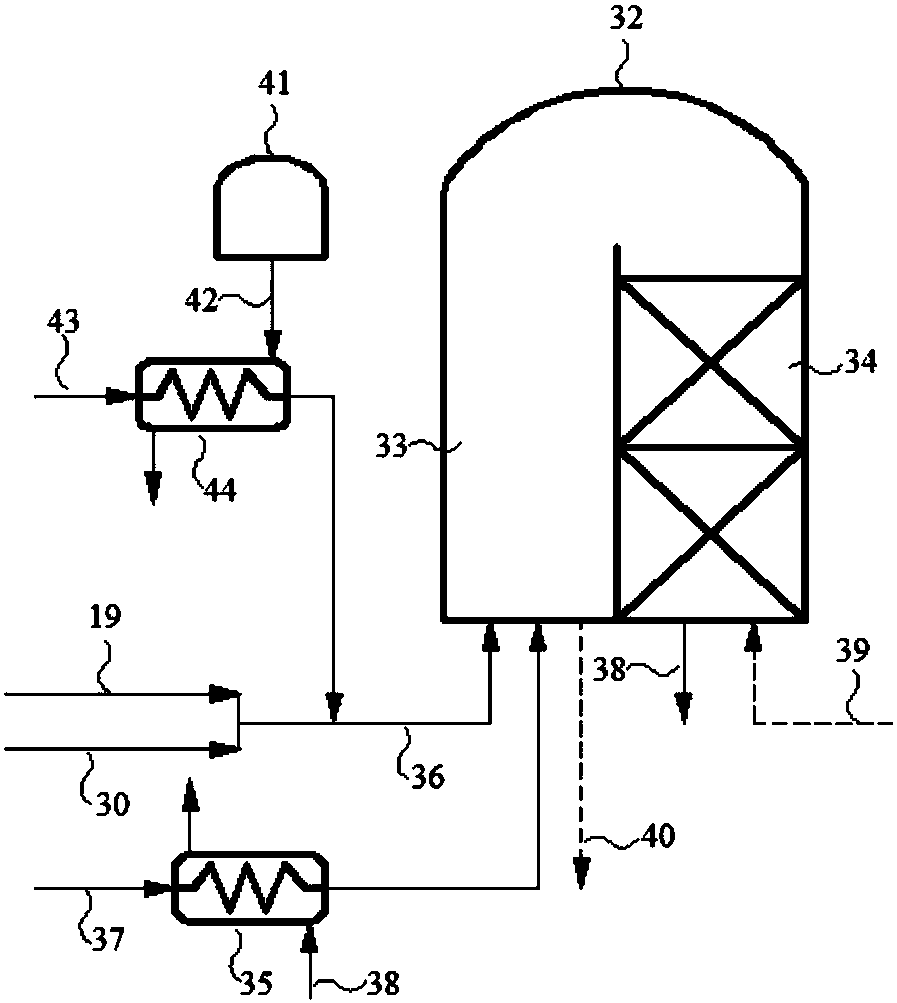

Oxidized pellet production process and system using chain grate-rotary kiln system

ActiveCN110894573AReduce wind temperatureIncrease wind temperatureRotary drum furnacesThermodynamicsProcess engineering

The invention discloses an oxidized pellet production process using a chain grate-rotary kiln system, which comprises the following steps: (1) green pellets are dried, preheated and oxidized through achain grate, then materials passing through the chain grate are conveyed to the rotary kiln to be roasted and then conveyed to an annular cooler to be cooled, and pellet ore is obtained; 2) hot air exhausted from the first circular cooling section is conveyed to the rotary kiln, the hot air exhausted from the rotary kiln is conveyed to a second preheating section, and the hot air exhausted from the second preheating section is conveyed to an air draft drying section in an air draft manner; 3) hot air exhausted from the second annular cooling section is conveyed to the first preheating sectionin an air blowing manner; and 4) the hot air exhausted from the third annular cooling section is conveyed to an air blast drying section in an air blast manner. According to the scheme, hot air is blown into the first preheating section, so that the air pressure in the first preheating section is greater than that of the second preheating section, and gas in the first preheating section does notneed to be denitrified; and meanwhile, a stable hot air area is formed in the first preheating section, and the preheating effect of upper-layer and lower-layer pellets is guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Closed-loop steel sintered red ore cooling device and process method thereof

ActiveCN106123609AIncrease productionGood qualityHandling discharged materialCooling methodsCold air

The invention discloses a closed-loop steel sintered red ore cooling device. The device comprises a device body, a heat exchange cavity arranged in the device body, a feeding inlet formed in the upper end of the device body, a uniform distributor arranged at the lower end of the feeding inlet, a discharging outlet formed in the lower end of the body, a uniform temperature device and at least one fire grate. The uniform temperature device is arranged on the device body and communicates with a cold air outlet. The at least one fire grate is movably installed in the heat exchange cavity. Each fire grate and the heat exchange cavity form an obliquely-downward angle, and the fire grates are parallel to each other. A pushing device is arranged at the front end of each fire grate. A hopper is arranged at the tail end of each fire grate. The device replaces a cooling section of an original sintering machine or a ring cooling machine. Compared with an original cooling mode, the device is high in yield, good in quality and low in energy consumption. Compared with the original cooling mode, the yield of a marching type sintering machine can be increased by 30%-40%, zone firing is increased by 5%-10%, and energy consumption only accounts for about 50% of the original cooling mode.

Owner:BEIJING RUIDA HONGXIN TECH CO LTD

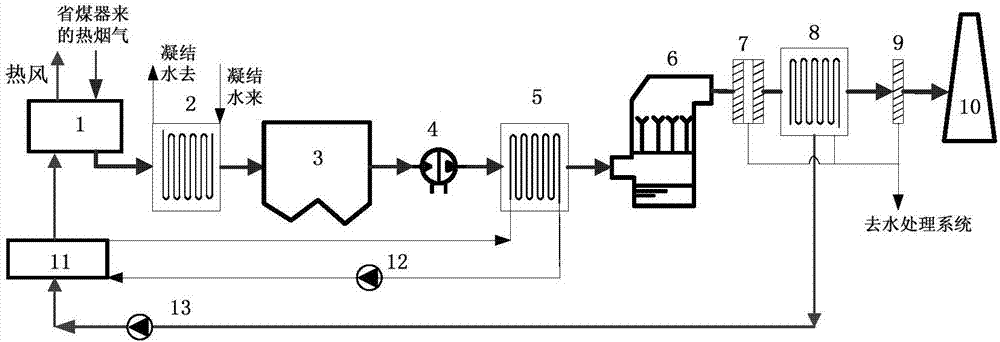

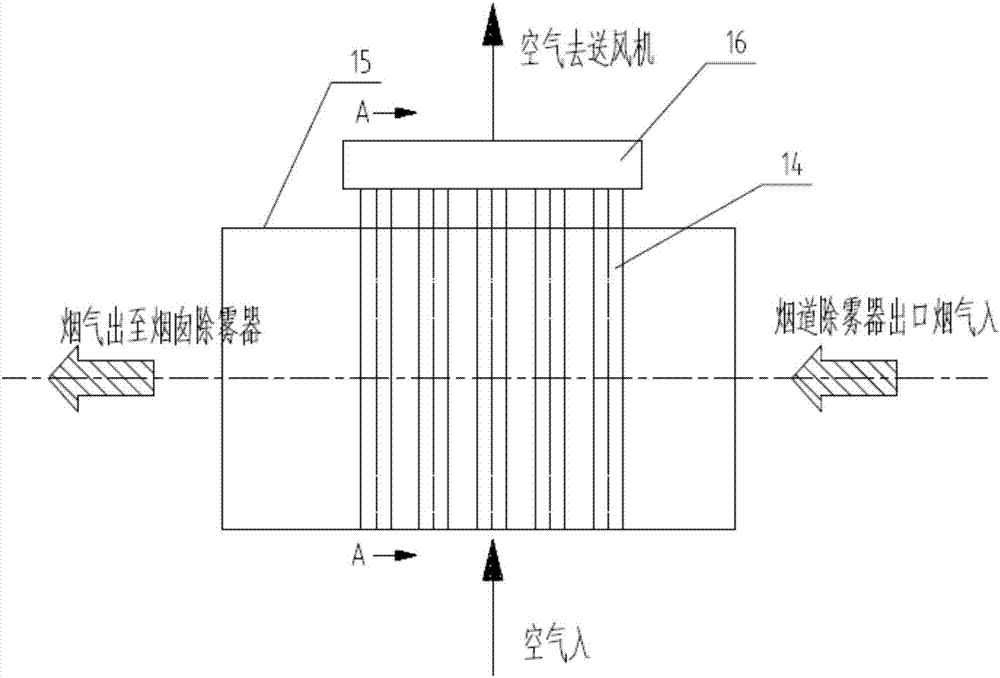

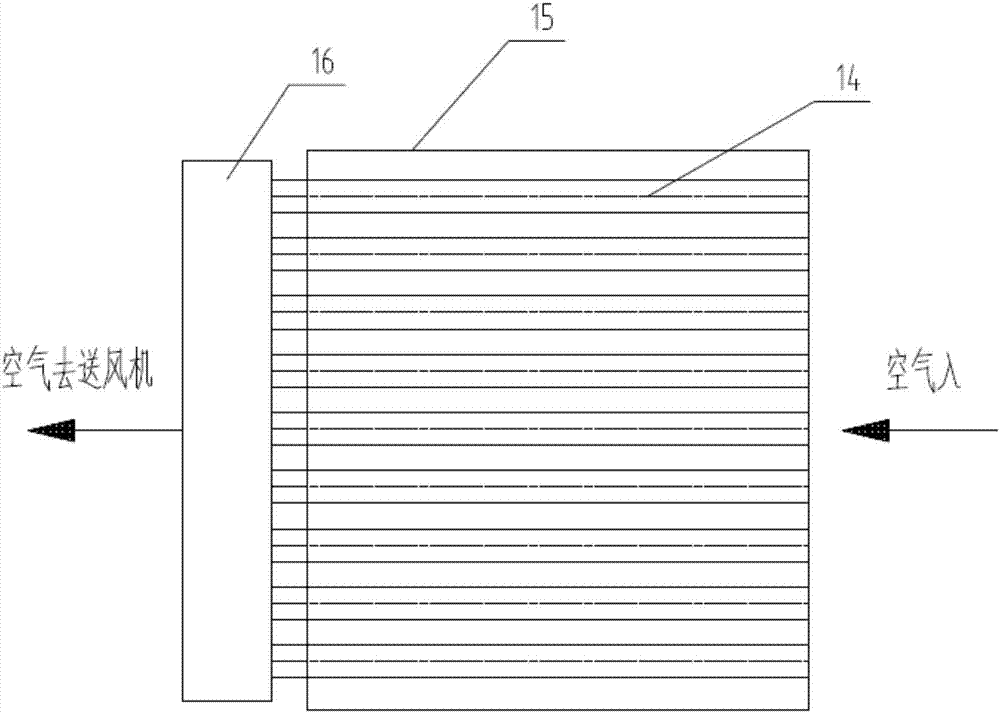

Energy and water saving system for wet desulphurization system

ActiveCN106979530AReduce the temperatureIncrease temperatureGas treatmentEmission preventionHandling systemAir heater

The invention discloses an energy and water saving system for a wet desulphurization system. The energy and water saving system comprises a first-level flue gas cooler, a flue gas input pipeline, a flue gas pretreatment system, a second-level flue gas cooler, a desulphurization tower, a flue mist eliminator, a flue gas condenser, a chimney mist eliminator, a chimney and a steam air heater. Through the energy and water saving system, the supplementary water capacity of the desulphurization tower can be effectively decreased, meanwhile, waste heat of flue gas at an inlet of the chimney is recycled, moreover, the cost is low, and the phenomena of white smoke and stack rain of the chimney can be effectively relieved.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

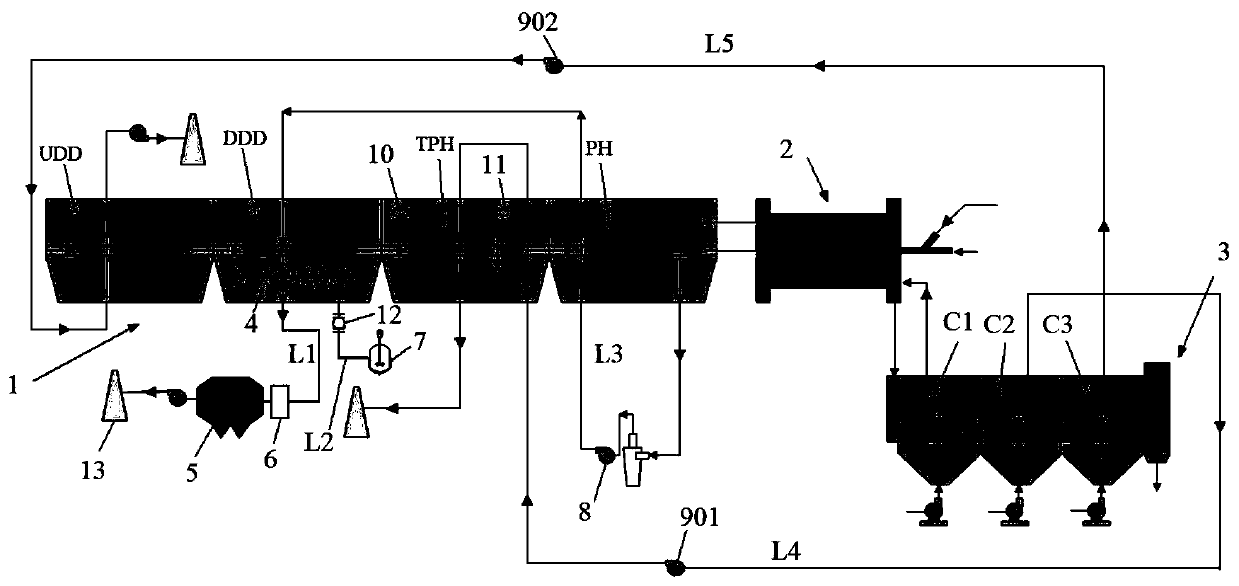

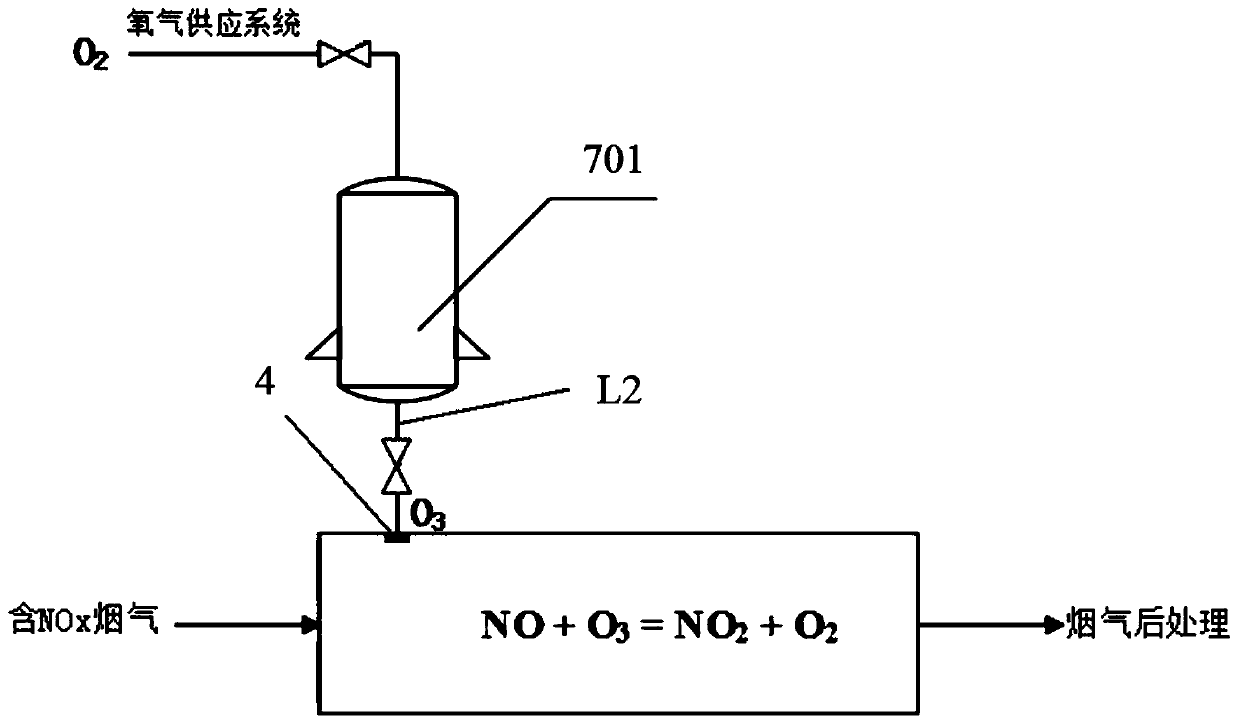

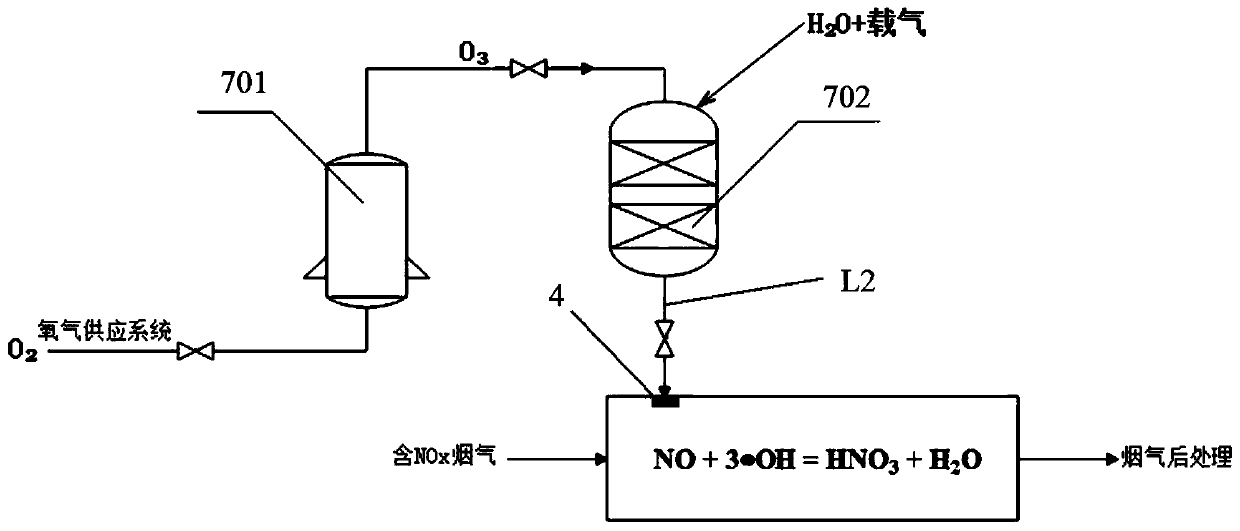

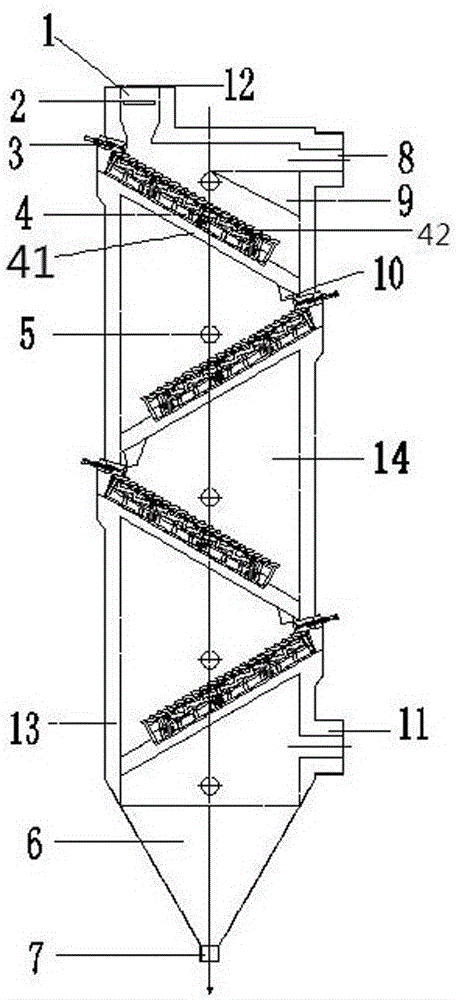

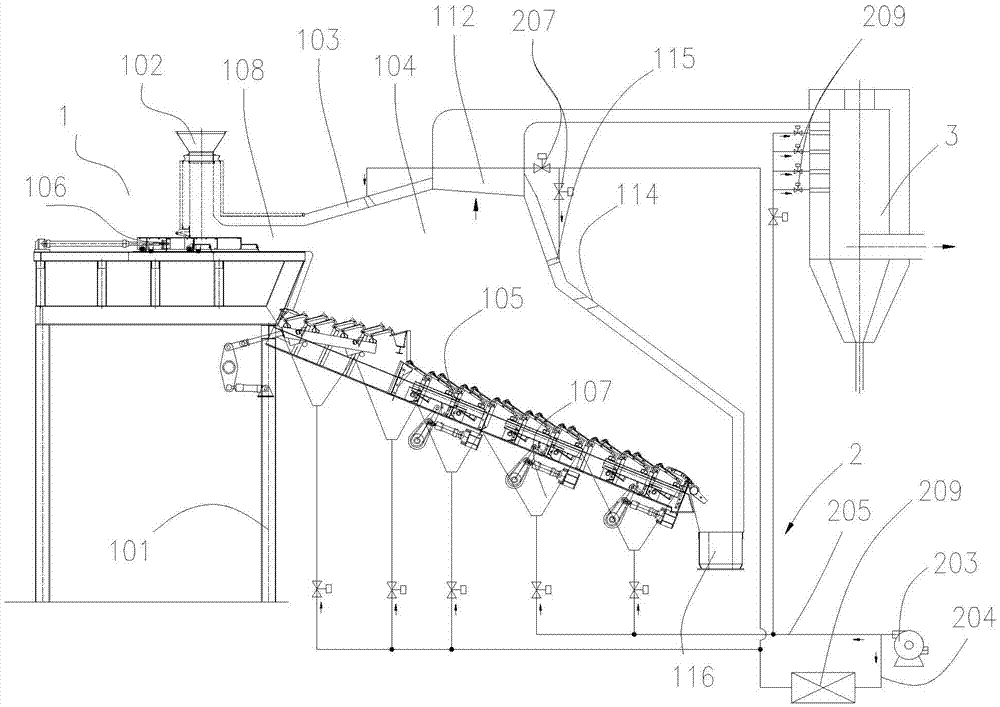

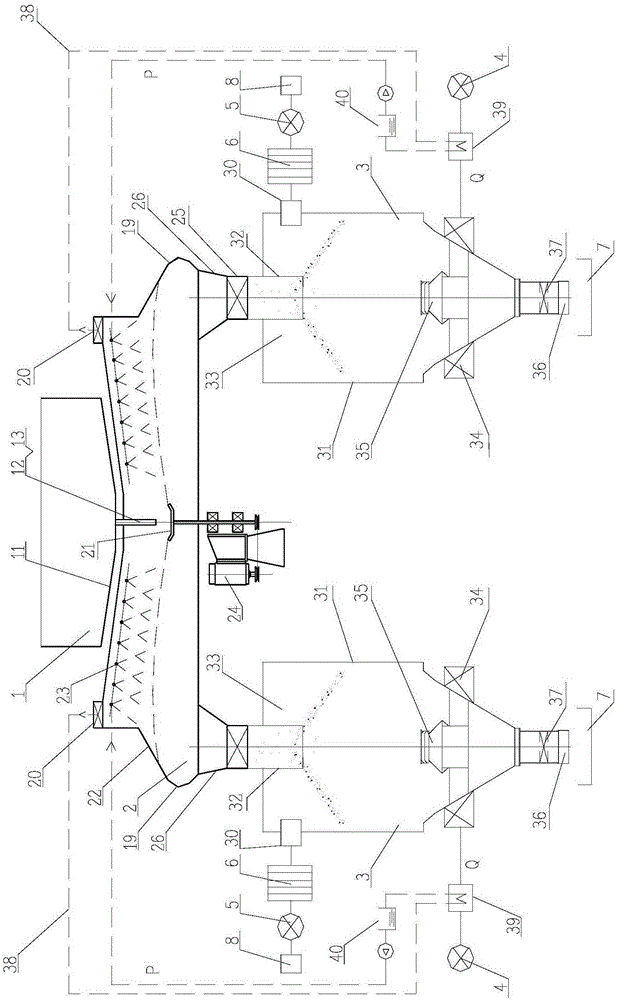

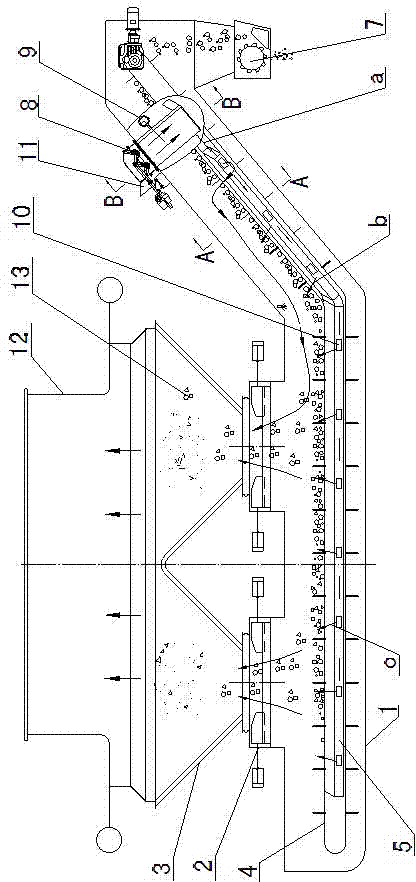

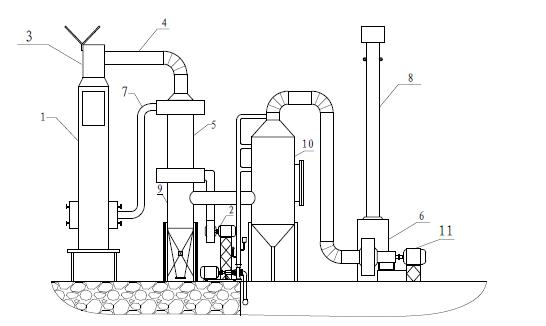

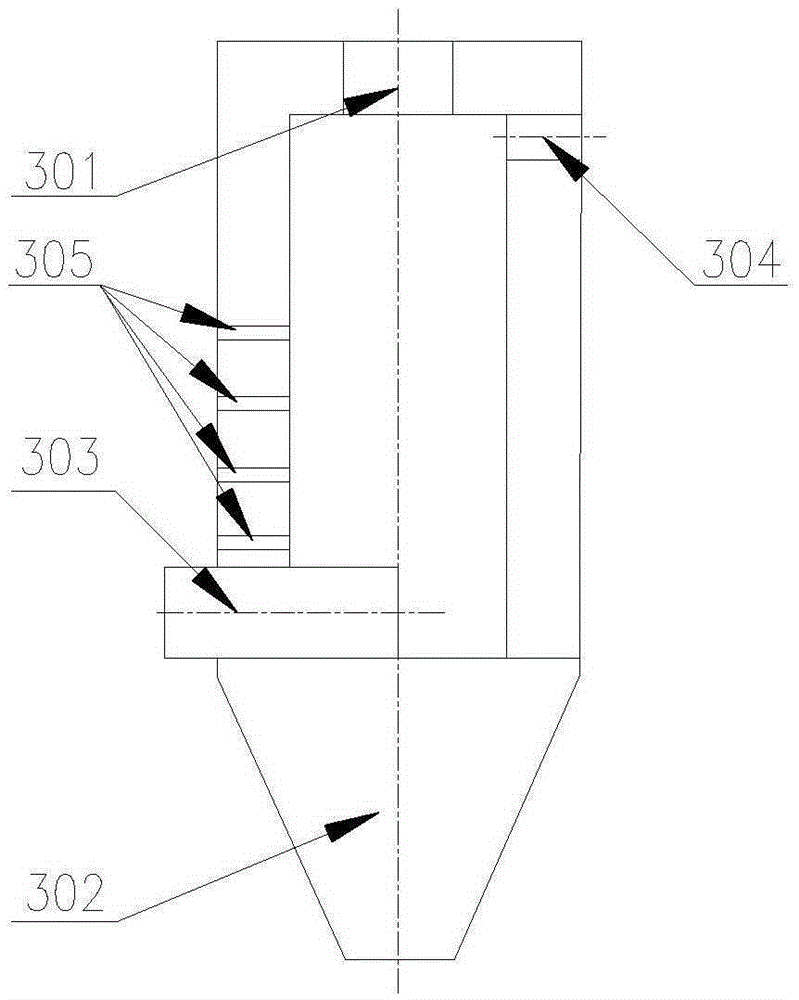

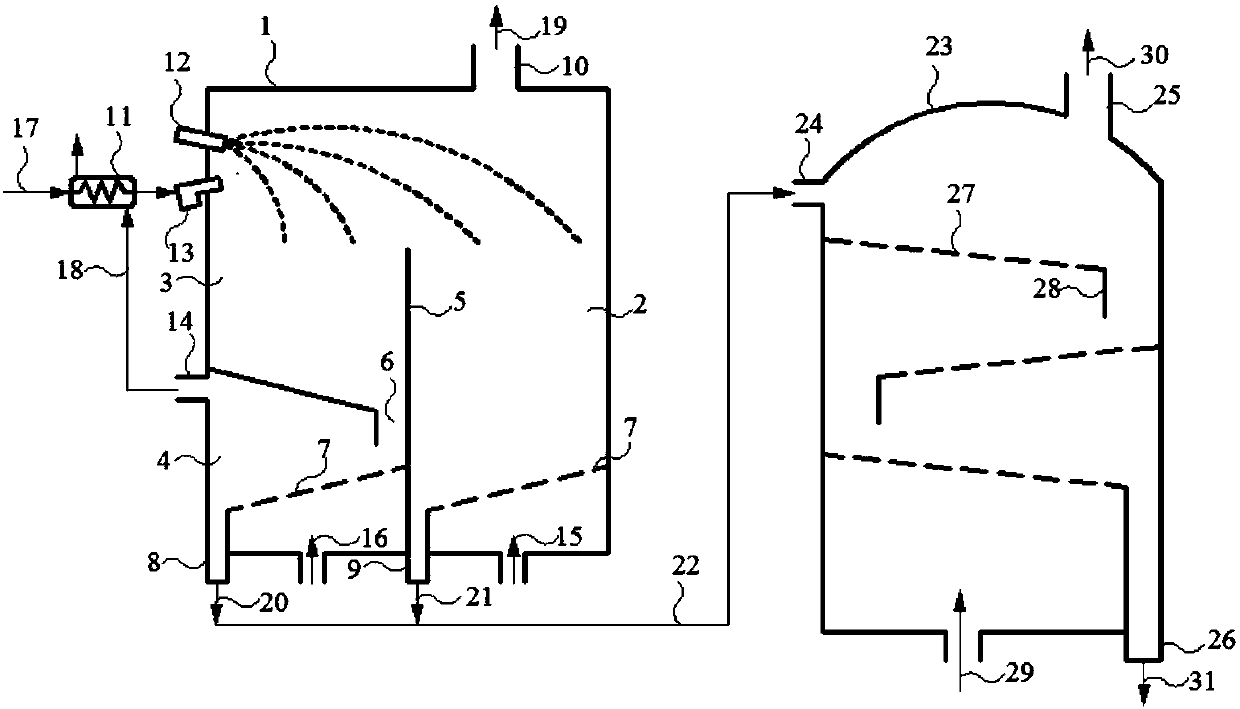

Mechanical grate type single-furnace garbage gasifying incineration system and disposal method thereof

ActiveCN105444183AImprove recycling efficiencyEmission reductionIncinerator apparatusCombustion chamberFlue gas

The invention discloses a mechanical grate type single-furnace garbage gasifying incineration system which comprises a gasifying incinerator, a cyclone combustion chamber and an air supply system, wherein the gasifying incinerator comprises a feed hopper and a furnace body; a stockpile sealing segment is arranged between the feed hopper and the furnace body; the upper end of the furnace body is arched and provided with a first flue gas outlet; and the cyclone combustion chamber is used for secondary combustion and is provided with a flue gas inlet connected with the first flue gas outlet. A garbage disposal method comprises the following steps: Step A, starting and drying the incinerator; Step B, burning garbage in a furnace chamber; Step C, realizing continuous garbage gasifying incineration disposal; and Step D, shutting down the mechanical grate type single-furnace garbage gasifying incineration system after the garbage and garbage residues burn out. By the use of the mechanical grate type single-furnace garbage gasifying incineration system, large-scale continuous garbage gasifying incineration disposal can be realized, the garbage disposal capacity and the garbage transport capacity are higher, the heat recovery efficiency is high, and the emission of pollutants is effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Blast furnace slag dry granulation and heat recovery system and method

The invention discloses a blast furnace slag dry granulation and heat recovery system and method in the field of blast furnace ironmaking. The system comprises a heat preservation buffer tank, a granulation device and a heat exchange tank; a slag discharging pipe is arranged at the bottom of a tank body of the heat preservation buffer tank, and a plug bar is arranged in the slag discharging pipe; the granulation device comprises a granulation bin, a spraying device is arranged at the upper portion of the interior of the granulation bin, a rotational granulation rotary disc is arranged, an unloading chute is arranged at the bottom, and a slag grain collecting opening is formed in the tail end of the unloading chute; and the heat exchange tank comprises a heat exchange tank body, a cooling air inlet is formed at the lower portion of the heat exchange tank body, and a hot air exhaust opening is formed at the upper portion of the heat exchange tank body. By means of the blast furnace slag dry granulation and heat recovery system and method, contradiction between the blast furnace slag cooling speed and the recovery waste heat quality is overcome, and the running using rate and the heat recovery using rate of a blast furnace slag dry granulation device are improved. Meanwhile, slag grain raw materials rich in glass body and capable of meeting the requirement for cement production can be obtained from treated slag grains more easily.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

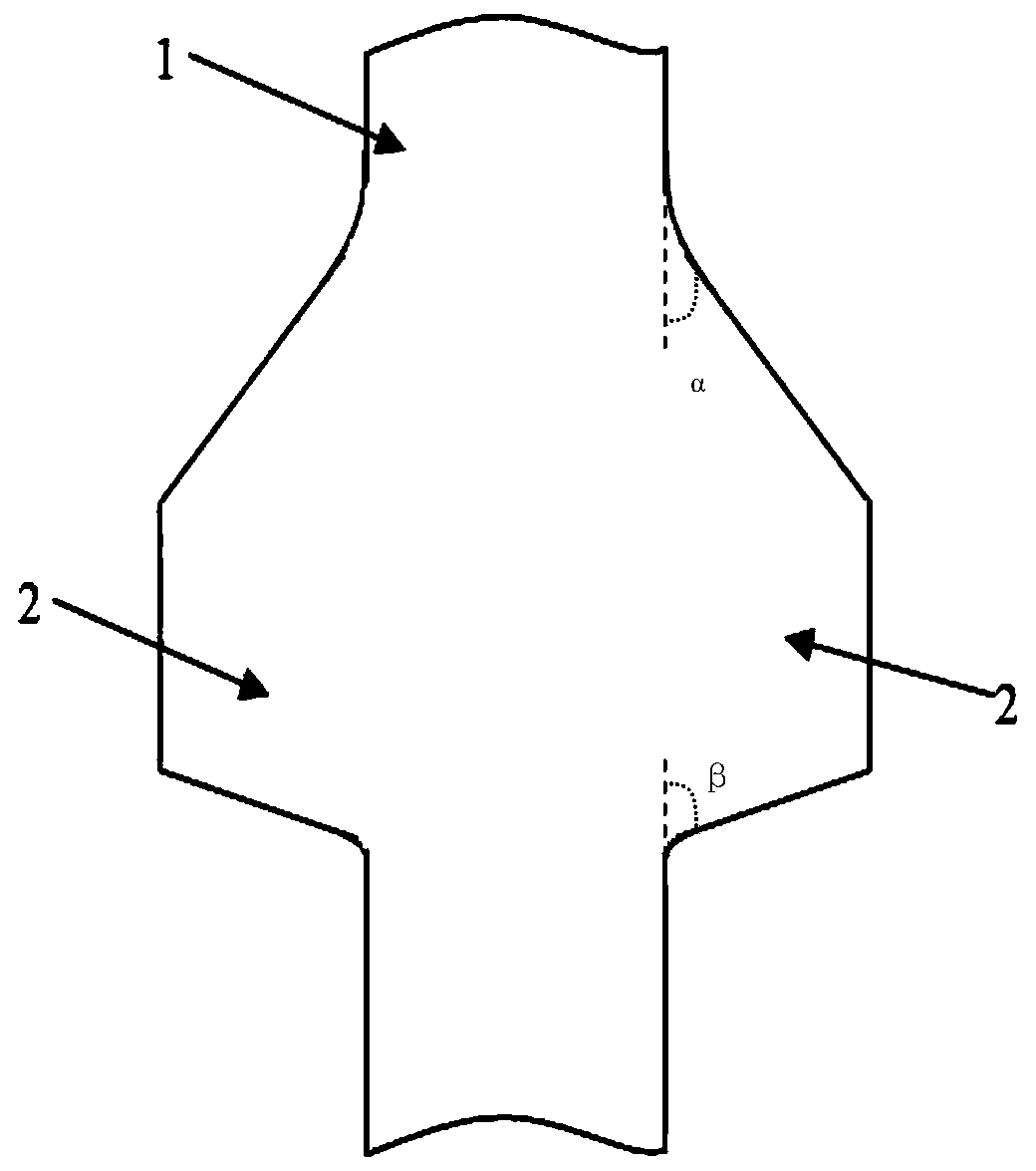

Method for stepwise cooling cement clinker

The invention provides a method for stepwise cooling a cement clinker. The method is characterized by comprising steps of (1) first-stage quick cooling; (2) clinker crushing; and (3) second-stage conventional cooling. The cooling method comprises first-stage cooling and second-stage cooling, and the cooling volume of the two cooling stages can be controlled independently, so that the stability of the system is improved, and air mixing among air openings can be avoided; air entering a first-stage cooler is subjected to heat exchange to form high-temperature hot air which is completely used for supplying secondary and tertiary air for a system, wherein the average temperature after the secondary air and the tertiary air are mixed can be more than 1050 DEG C, so that the heat recovery efficiency of the cooler can be over 85 percent; a crushing step is executed before second-stage cooling, so that the contact area of the clinker and cooling air in a second-stage cooler can be increased, the air entering the second-stage cooler is only 0.6-0.8Nm<3> / kg.cl, and the air volume is remarkably reduced; furthermore, the temperature of formed hot air is remarkably increased, so that caloric content in the clinker is recycled as much as possible; and the total cooling air volume in the two cooling stages can be controlled under 1.5Nm<3> / kg.cl, and the total air volume is remarkably reduced.

Owner:SINOMA TECH & EQUIP GRP

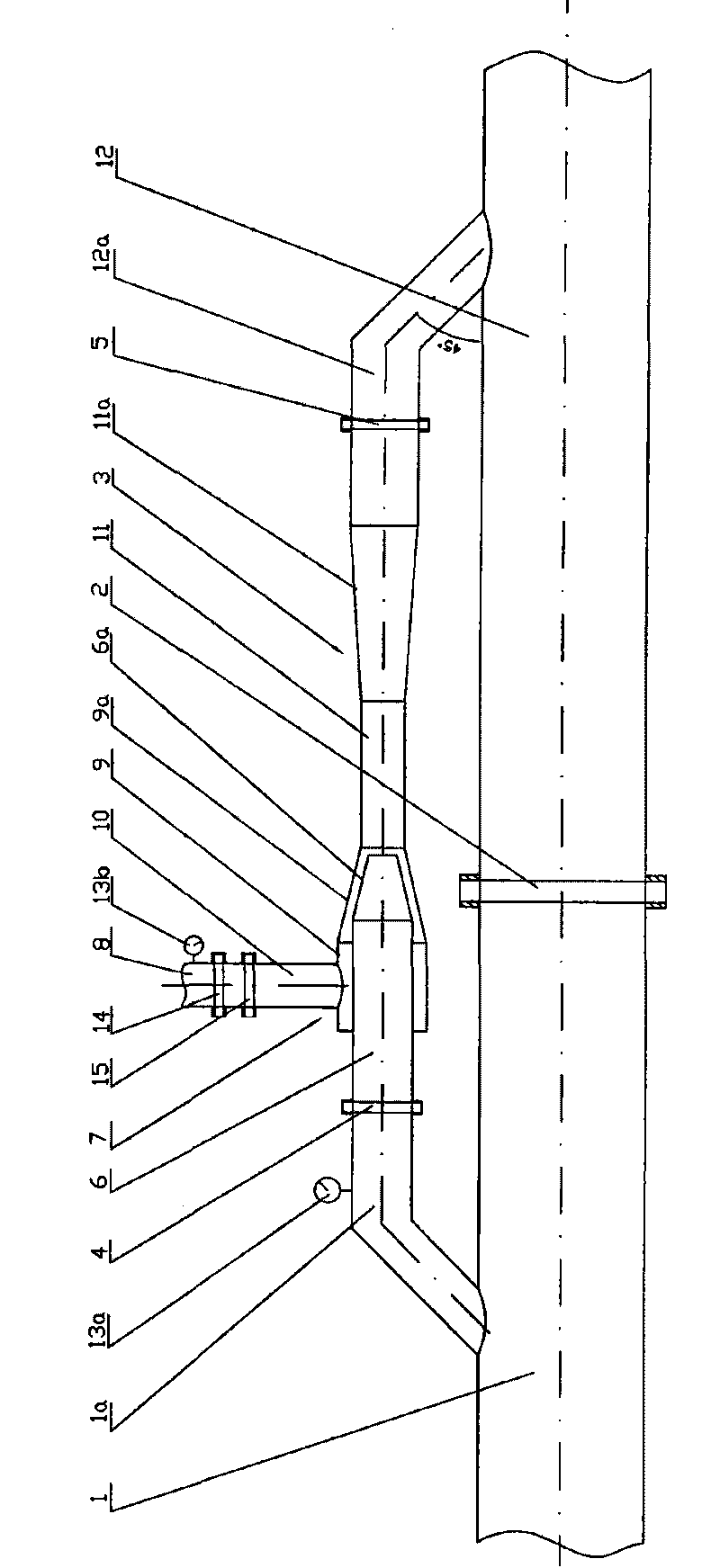

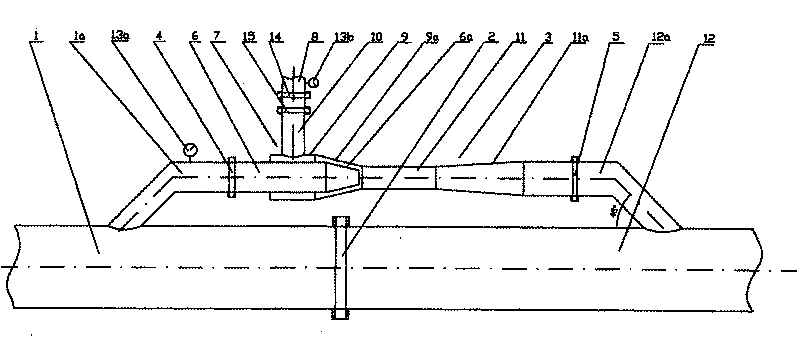

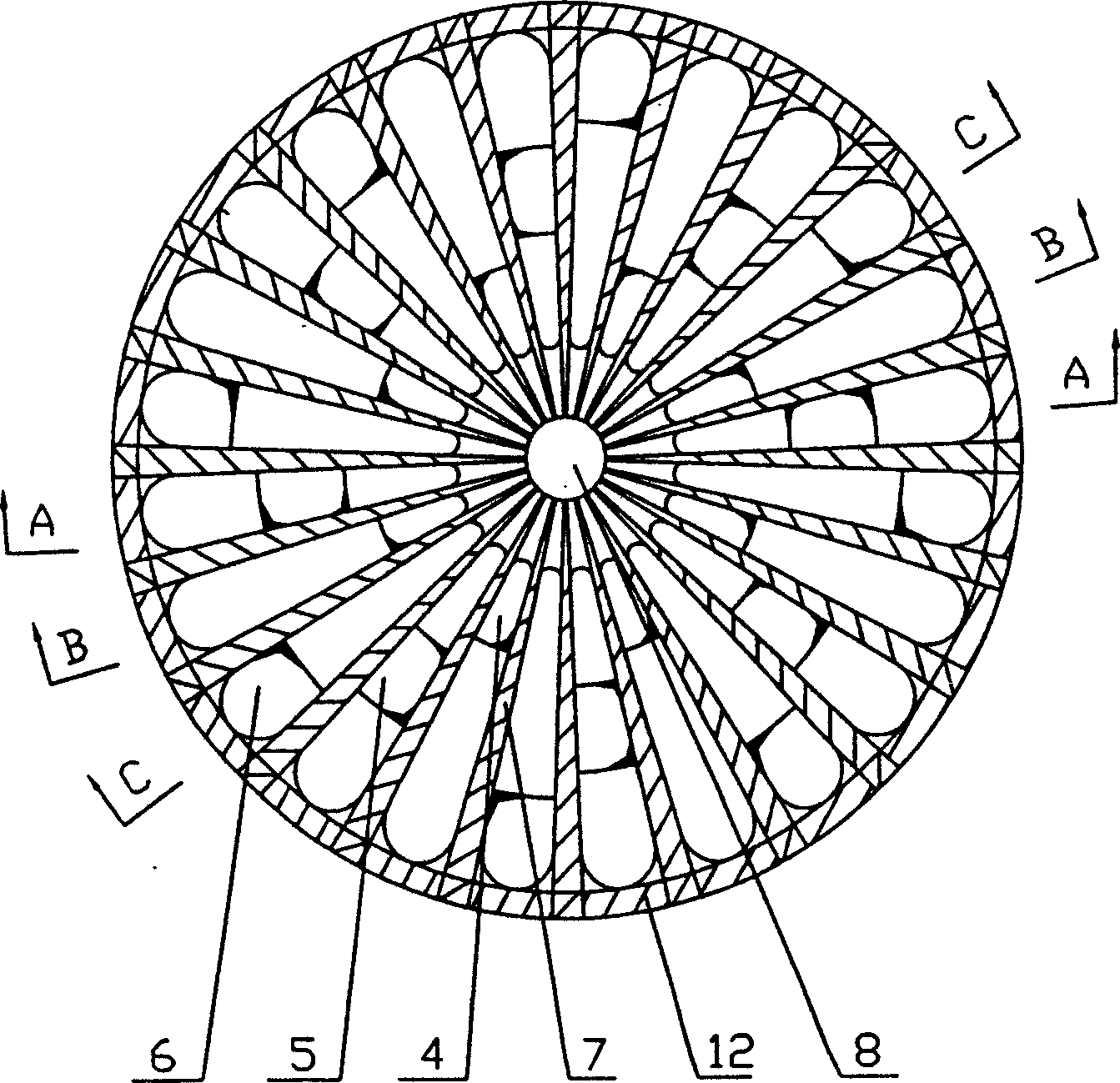

Gas mixed burner with three-way

The invention is a three-gas mixed burner. And blast-furnace gas circuit, combustion supporting air circuit and coke-oven gas circuit, which are formed by isolation of furnace walls and inner walls, are arranged at the bottom of the burner, flow guide columns are in the center of the circuit; furnace walls and inner isolating walls compose blast-furnace gas channel, combustion supporting air channel and coke-oven gas channel, which are radiation in shape and staggered mutually, the blast-furnace gas channel communicates with the blast-furnace gas circuit, the combustion supporting air channel communicates with the combustion support air circuit, the coke-oven gas channel communicates with the coke-oven gas circuit, three channels at the upper part of the furnace wall are provided with annular channels communicating with them, and the annular channels are equipped with communicating sector jet holes. The advantages are full combustion, high thermal value, low CO content, low cost.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

Charging material for blast-furnace smelting and blast-furnace smelting method

InactiveCN107586903AHigh degree of reductionReduce return rateBlast furnace detailsAlkalinityIron powder

The invention discloses a charging material for blast-furnace smelting and a blast-furnace smelting method. The charging material for blast-furnace smelting comprises components in parts by weight asfollows: 60-85 parts of alkaline sintered ore, 10-20 parts of acid pellets and 0-5 parts of geological minerals, wherein alkalinity of the alkaline sintered ore is 2.2-2.3, and alkalinity of the acidpellets is 0.2-0.4; the alkaline sintered ore is prepared from 40-50 parts by weight of vanadium bearing titanomagnetite, 5-10 parts by weight of common fine iron powder, 5-15 parts by weight of boron-bearing iron ore powder, 1-5 parts by weight of SiC powder and 6-10 parts by weight of CaO as raw materials through sintering; the acid pellets are prepared from 50-60 parts by weight of the vanadiumbearing titanomagnetite, 5-10 parts by weight of common fine iron powder, 1-2 parts by weight of magnesite, 3-5 parts by weight of dolomite and 1-2 parts by weight of bentonite as raw materials through sintering. According to the blast-furnace smelting method adopting the charging material for blast-furnace smelting, liquidity of iron slag can be guaranteed, a slag charge structure is changed, slag basicity is reduced, effective availability of the charging material for blast-furnace smelting is improved, blast-furnace smelting efficiency is improved, and smelting cost is reduced.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

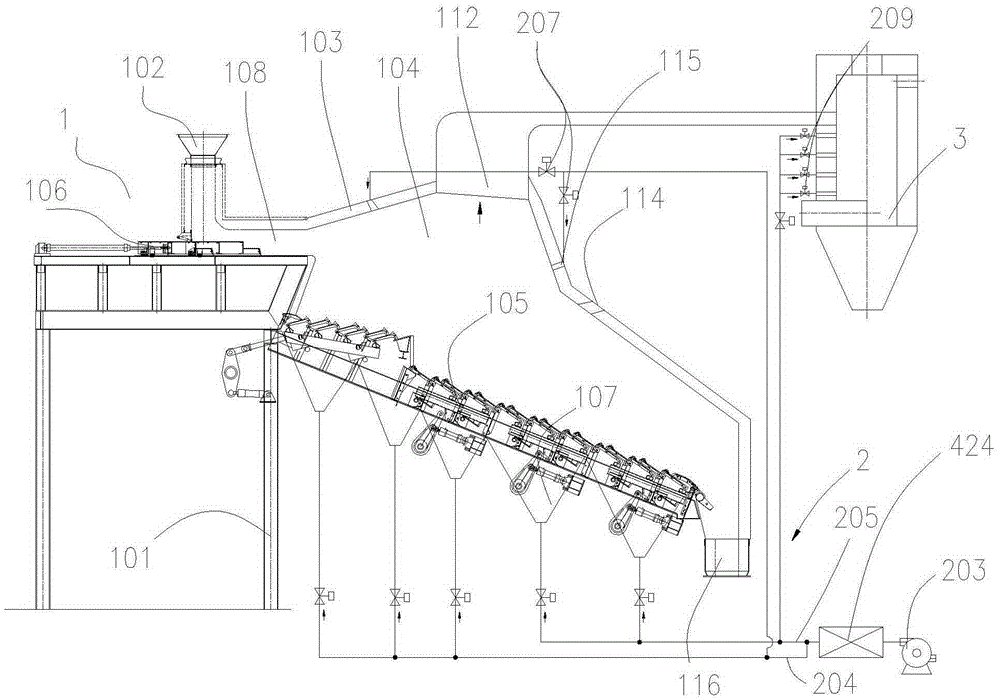

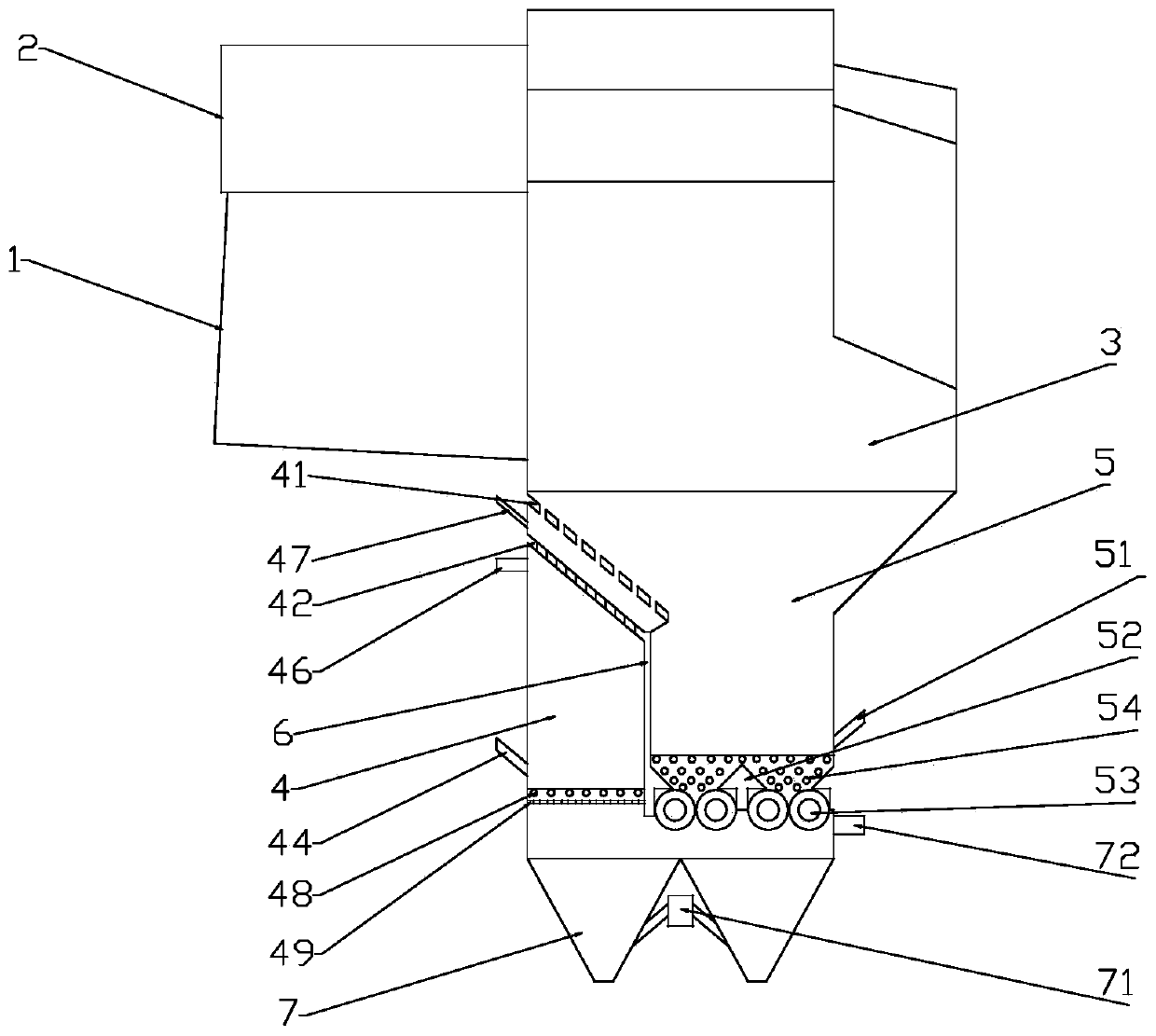

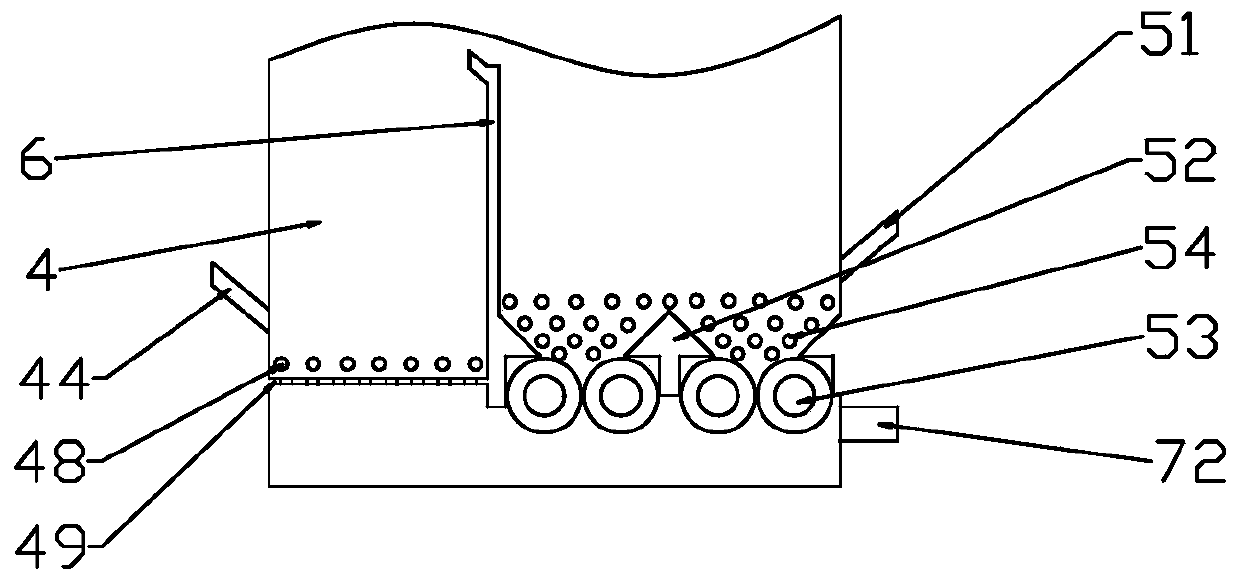

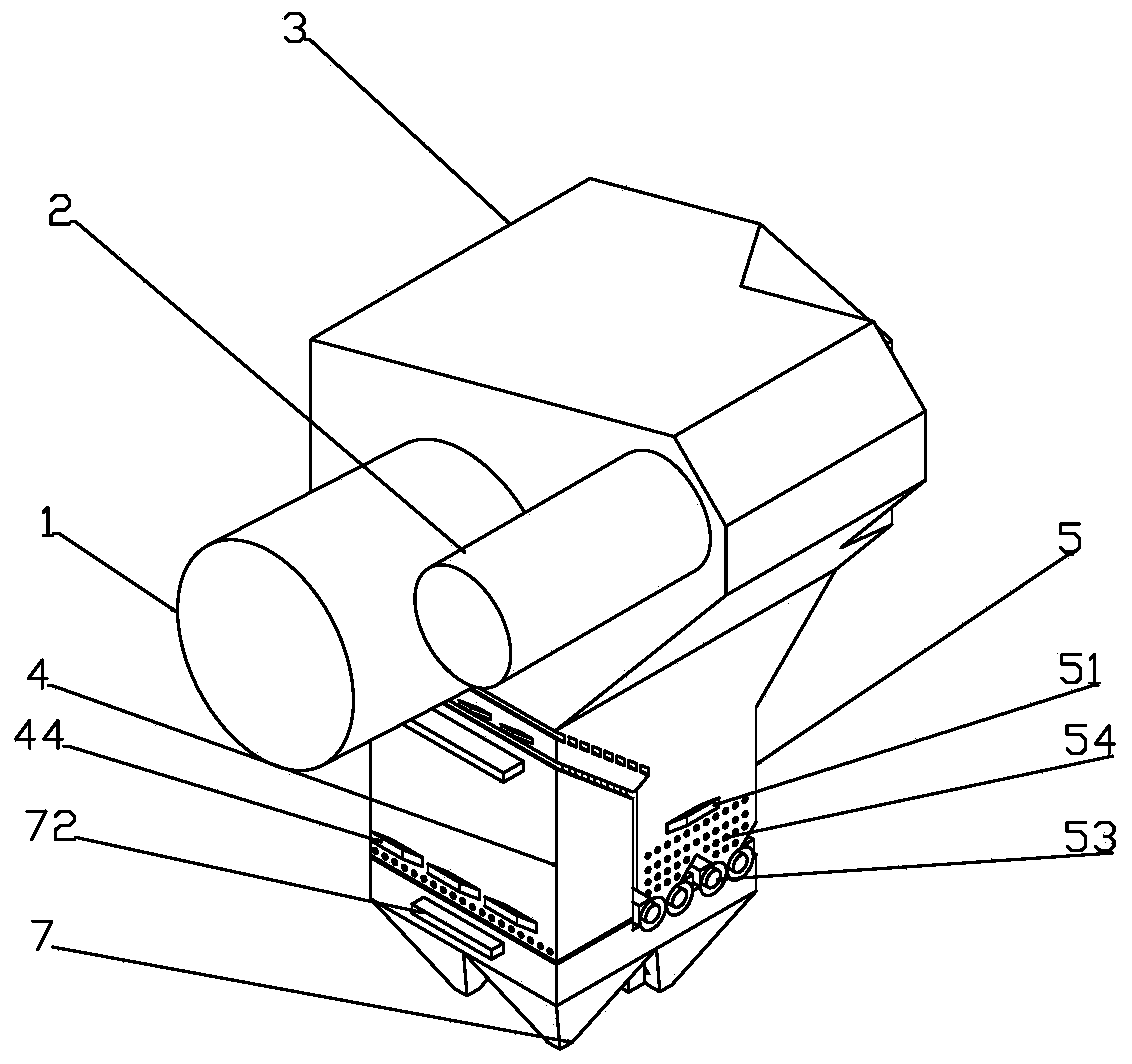

Air cooling dry type slag conveying system of coal-fired boiler

ActiveCN103574626ANo cooling dead angleImprove cooling effectLighting and heating apparatusAir volumeSlag

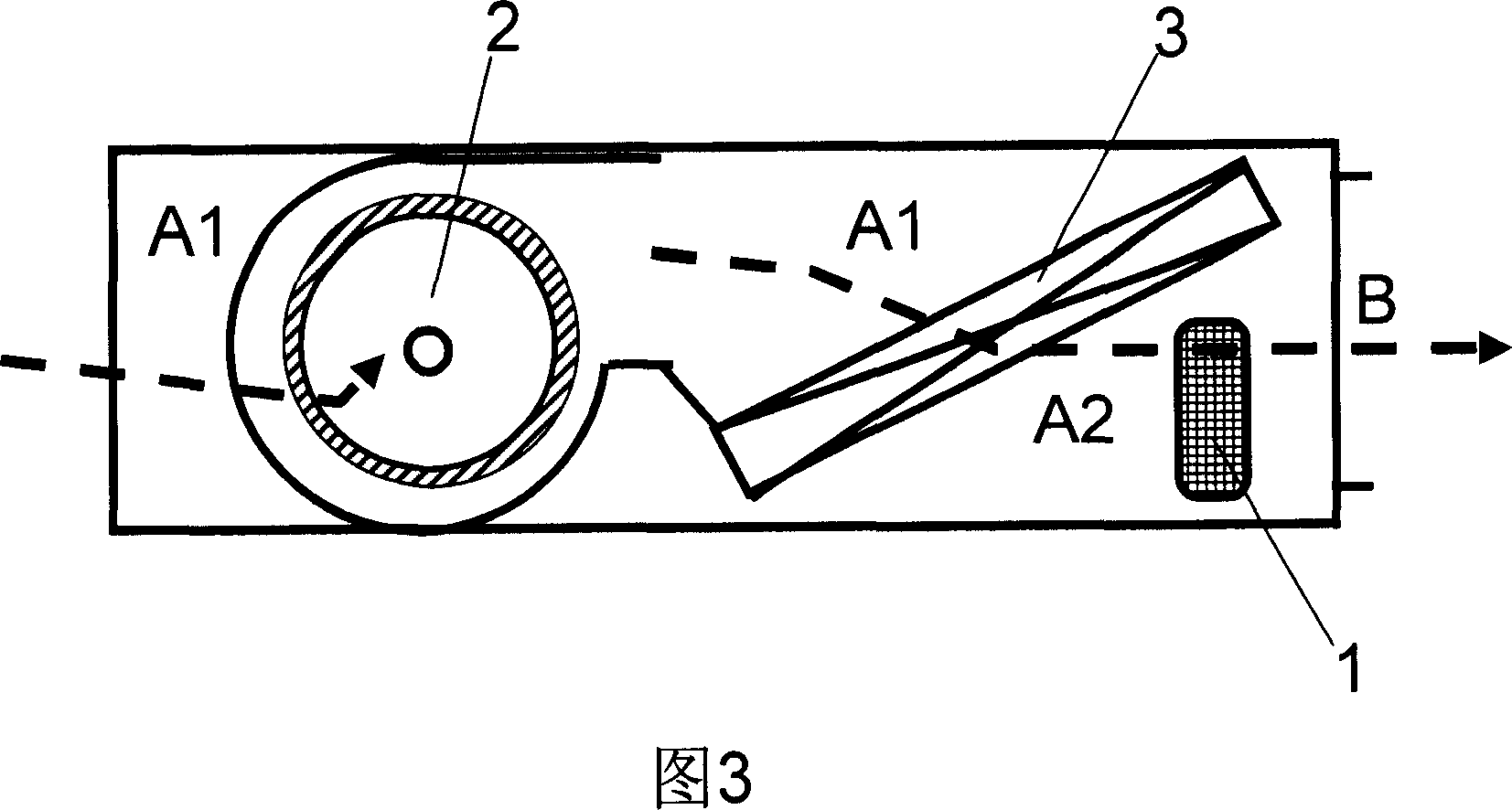

An air cooling dry type slag conveying system of a coal-fired boiler comprises a machine shell, a large slag extrusion device installed above the tail portion of the machine shell, a slag bucket located above the large slag extrusion device and installed on the machine shell, an ash slag material conveying belt located below the large slag extrusion device and installed on the machine shell, a primary air pipe which is located between an entry strip ash slag material conveying belt and a return strip ash slag material conveying belt, installed on the machine shell and provided with a plurality of small air ports, an ash stopping plate installed on the small air ports of the primary air pipe, a slag smashing machine installed below the head of the machine shell, an automatic flow regulating valve installed in an air inlet in the head of the machine shell, and a flow meter installed on an air port below the automatic flow regulating valve. The air cooling dry type slag conveying system of the coal-fired boiler is good in cooling effect, rapidly raises air temperature, controls air volume accurately, enables the heat efficiency of the boiler to be high, saves energy, protects the environment, is high in conveying efficiency, is long in service life, and can be widely applied to the slag conveying process of the coal-fired boiler.

Owner:QINGDAO DANENG ENVIRONMENTAL PROTECTION INC

An energy-saving and environment-friendly cupola

InactiveCN102278875APlay the effect of energy saving and emission reductionReduce dosageCombustion processIndirect carbon-dioxide mitigationThermal energyFurnace temperature

The invention discloses an energy-saving and environment-friendly cupola. By adding equipment such as heat exchangers and dust collectors, the tail gas of the furnace is treated with heat energy recycling, dust removal and desulfurization, etc., so as to achieve energy saving (reduce coke consumption), It also has the effect of reducing pollution emissions (high-temperature gas, SO2, dust). At the same time, due to the use of hot air inlet technology, the furnace temperature is increased, the reject rate of casting products is reduced, and economic benefits are increased.

Owner:王洪旗

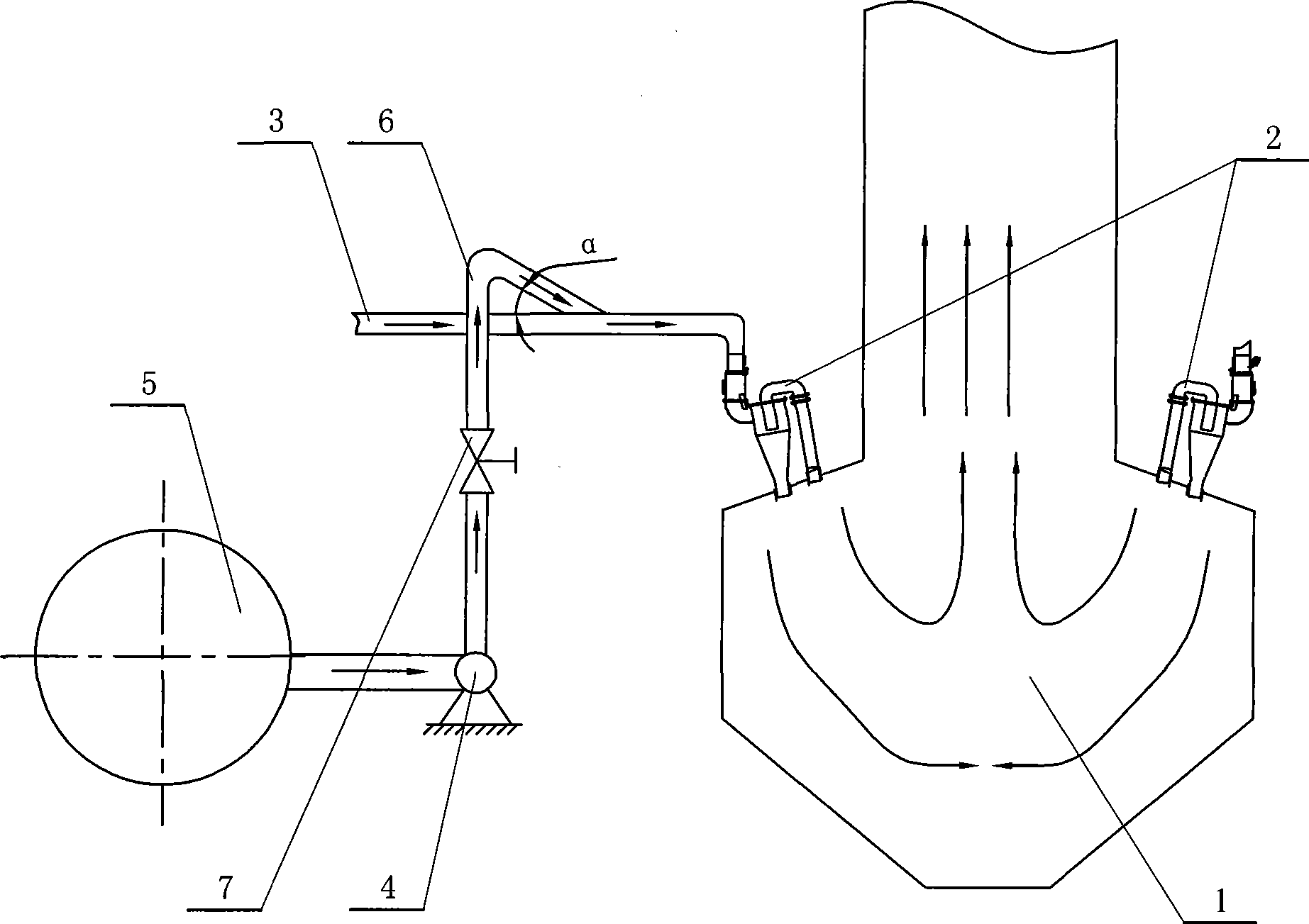

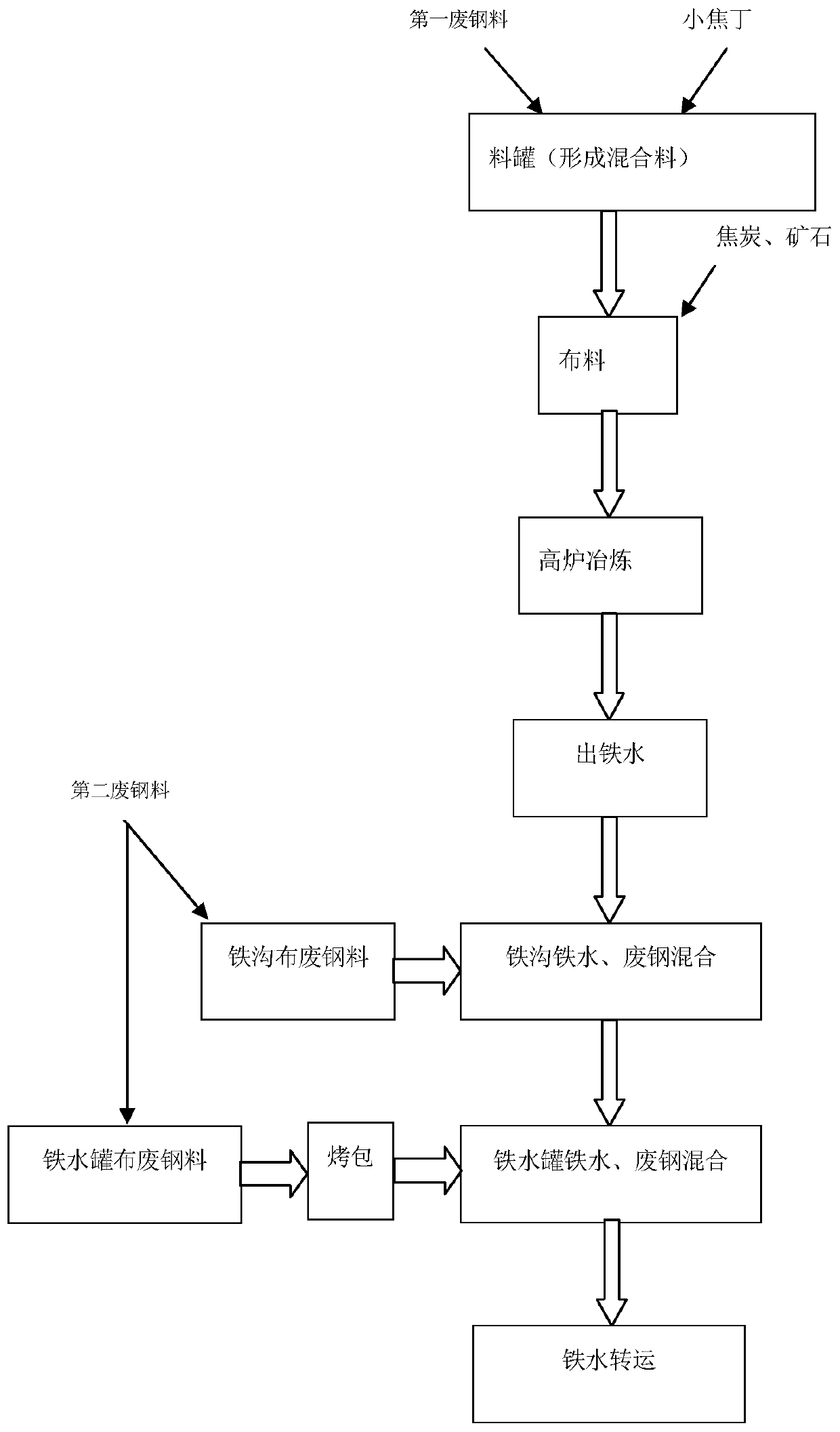

Method and apparatus for improving primary air breeze gas flow temperature of W-shaped flame boiler

ActiveCN101430098APromote precipitationSimple methodCombustion processIndirect carbon-dioxide mitigationAir volumeCombustor

A method and a device for improving the primary air pulverized coal airflow temperature of a W-shaped flame boiler relate to the method and the device for improving primary air auxiliary hot air of the W-shaped flame boiler. The method and the device are designed against the problems of poor combustion stability and poor ignition capacity of the W-shaped flame combustion technology. The method is as follows: auxiliary air is led out by a hot air pipe, the air temperature is 320-370 DEG C, the auxiliary air is introduced into a primary air pipe before entering a burner and mixed with primary air with the air temperature of 100-110 DEG C and the air speed of 22.0-23.0m / s, the amount of the auxiliary air which is introduced into the primary air pipe accounts for 19-21 percent of the amount of the primary air, the air temperature of the primary air which enters the burner is 140-160 DEG C, and the air speed is 32.0-33.0m / s. The device is as follows: the hot air pipe is communicated with the primary air pipe by an induced draft fan and an auxiliary air pipe, the primary air pipe is communicated with the burner, and an included angle alpha between the direction of the auxiliary air which is introduced into the primary air pipe from the auxiliary air pipe in the method and the device and the flow direction of pulverized coal in the primary air pipe is 25-35 degrees. The method and the device reduce the heat needed by ignition and realize the purposes of easy ignition and stable combustion.

Owner:HARBIN INST OF TECH

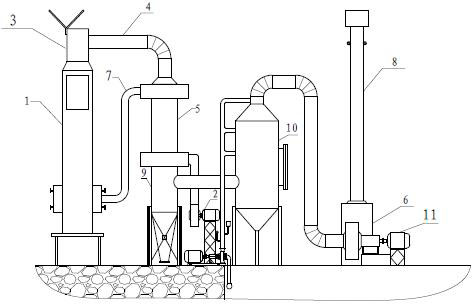

Mechanical grate-type garbage single-furnace gasifying incineration and boiler system

The invention discloses a mechanical grate-type garbage single-furnace gasifying incineration and boiler system which is smaller in transformation heat efficiency loss and higher in heat recovery rate. The system comprises a gasifying incineration furnace, a boiler system and an air supply system, wherein the gasifying incineration furnace comprises a material feeding cabin and a furnace body; a material stacking sealing section is arranged between the material feeding cabin and the furnace body; the upper end of the furnace body is upwards convex and is provided with a first smoke outlet; the boiler system comprises a boiler body; the boiler body comprises a cyclone combustor, a furnace chamber a and a furnace chamber b which are communicated with one another; a water-cooling wall is arranged in the cyclone combustor; a superheater is arranged in the furnace chamber a; an evaporator is arranged in the furnace chamber b; the smoke inlet of the cyclone combustor is connected with the first smoke outlet; the top end of the boiler body is provided with a steam pocket; a steam-water inlet is formed in the steam pocket; the steam pocket is connected with water-cooling wall and the water inlet of the evaporator for outputting water; the water-cooling wall and the steam outlet of the evaporator are connected with the steam inlet of the steam pocket for steam backflow; and the saturated steam outlet of the steam pocket is used for outputting superheated steam through the superheater.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Dangerous waste incineration system

InactiveCN106090938AReduce moisture contentReduce volumeRotary drum furnacesIncinerator apparatusCombustion chamberSlag

The invention relates to the technical field of dangerous waste treatment, in particular to a dangerous waste incineration system. The dangerous waste incineration system comprises a rotary kiln and a secondary combustion chamber. A kiln tail of the rotary kiln is connected with a slag inlet of the secondary combustion chamber. The dangerous waste incineration system further comprises a grate type air cooler. A slag outlet of the grate type air cooler is connected with a slag outlet of the secondary combustion chamber. A slag outlet of the grate type air cooler is connected with the feeding end of conveying equipment through a bucket elevator. The discharging end of the conveying equipment is connected with an ash-slag bin. The grate type air cooler is adopted as an ash-slag cooling device, water resources are saved, the water content in the ash slag is greatly reduced, the ash slag landfill cost is saved, and energy consumption is reduced.

Owner:CBMI CONSTR

Hot air drying system heated by double energy sources

InactiveCN101936644BIncrease the heat exchange areaReduce deliveryTobacco preparationDrying solid materials with heatBusiness efficiencyPlate heat exchanger

Owner:湖南省浏阳市择明热工器材有限公司

Production technique for improving heat exchange efficiency of heat pipe type preheater of hot air furnace

ActiveCN105018665AImprove heat transfer efficiencyDoes not affect normal productionBlast furnace detailsHeating stovesEnvironmental resistanceEngineering

The invention relates to a production technique for improving the heat exchange efficiency of a heat pipe type preheater of a hot air furnace. The production technique for improving the heat exchange efficiency of the heat pipe type preheater of the hot air furnace comprises the technological steps that firstly, the reason for the reduction of the heat exchange effect is found out; secondly, the reduction of the heat exchange efficiency is confirmed; thirdly, the operation condition of working media in a heat pipe is confirmed; fourthly, a large amount of non-condensable gas in the heat pipe is exhausted; fifthly, fluid working media are supplemented; and finally, the maintenance effect is evaluated. According to the production technique, the operation is easy and convenient; the investment is small; the high benefits can be achieved continuously; the environment friendliness, equipment and wind temperature quality are not affected; the highly-efficient application of the preheater can be prolonged; and the investment for replacing the heat pipe or the whole preheater equipment is reduced.

Owner:SGIS SONGSHAN CO LTD

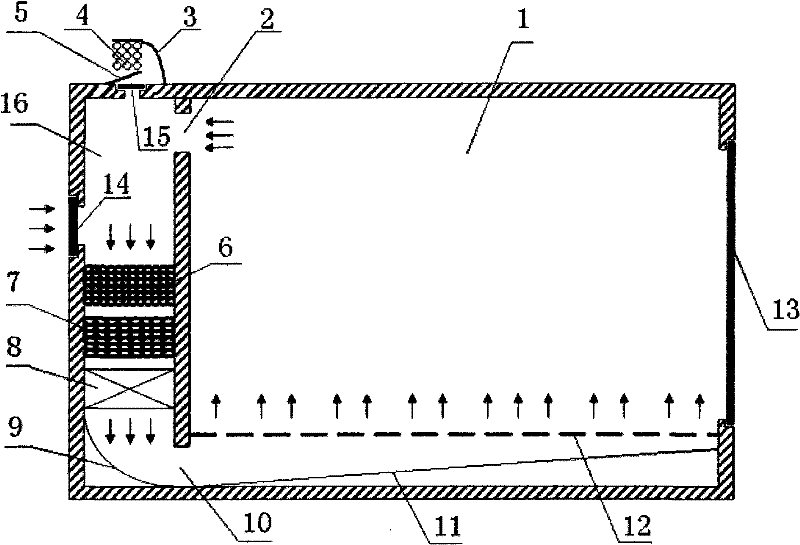

Method for producing molten iron by adding scrap steel into blast furnace

ActiveCN110129499AImprove productivityIncrease temperatureBlast furnace detailsDischarge devicesSocial benefitsEconomic benefits

The invention relates to a method for producing molten iron by adding scrap steel into a blast furnace. The method mainly comprises the steps of mixing, distributing, smelting, iron runner modification, iron runner distribution, molten iron ladle distribution, molten iron ladle baking and tapping and the like. According to the method, the scrap steel is added in different modes in different opportunities in a blast furnace smelting process, so that the technical effects that the overall smelting time is shortened, the tapping amount is improved, the utilization amount of the coke is greatly saved, and the downstream degree of the blast furnace and the like are improved. According to the method, the utilization rate of scarp steel can be greatly improved, more industry and domestic scarp steel can be digested, energy consumption can be reduced, emission of harmful substances is reduced, the development requirements of environmental protection and energy conservation are met, and important social benefits are achieved while the blast furnace economic benefits are increased.

Owner:德龙钢铁有限公司 +1

Joint heat regenerative system

PendingCN107388230AImprove combustion effectImprove drying outputSteam engine plantsFeed-water heatersAir preheaterJoint heat

The invention discloses a joint heat regenerative system which comprises a high-pressure cylinder of a steam turbine, a main steam pipeline, a conventional last-stage steam extraction pipeline, an additional pipeline, heat exchangers, a feed water heater and a steam-side adjusting valve. The additional pipeline is additionally arranged on the main steam pipeline, main steam in the main steam pipeline is used as a heat source for the heat exchangers, exhausted steam of the heat exchangers is used as a heat source for the feed water heater, and the steam-side adjusting valve is arranged on the additional pipeline and is used for adjusting main steam in the additional pipeline, so that steam extraction pressures adjusted by the steam-side adjusting valve can be controlled, outlet temperatures of the feed water heater can be controlled, and requirements on ultimate feed water temperatures can be met. The joint heat regenerative system has the advantages that heat of steam of boilers can be recycled at starting phases of units by the aid of the joint heat regenerative system, and the problems of low pulverized coal burnout rates, black smoke of fuel oil and easiness in low-temperature moisture condensation, ash clogging, corrosion and the like of equipment such as air preheaters of tail flues in starting phases can be solved by the aid of the joint heat regenerative system.

Owner:冯煜珵

Heat energy recycling method and device for molten metallurgical slag

ActiveCN107806769AImprove heat transfer performanceGood dispersionCharge manipulationIncreasing energy efficiencyThermal energyMetallurgical slag

The invention relates to a heat energy recycling method and device for molten metallurgical slag. The heat energy recycling method for the molten metallurgical slag is at least composed of the moltenmetallurgical slag heat energy recycling process that heat energy is recycled from the molten metallurgical slag to generate high-temperature gas and the heat energy utilization process. Heat energy recycling of the molten metallurgical slag is at least composed of the molten metallurgical slag granulating process that the molten metallurgical slag flowing out from a metallurgical furnace is cooled rapidly to generate metallurgical slag granulated particles and the granulated particle cooling process of further cooling the metallurgical slag granulated particles obtained in the metallurgical slag granulating process. The molten metallurgical slag is blown away through granulating airflow to form the metallurgical slag granulated particles, and the metallurgical slag granulated particles fall and are collected in a large-particle area and a small-particle area which are divided in the particle flying-out direction. The small particles directly enter into the granulated particle coolingprocess or other heat-exchange processes, the large particles enter into the secondary granulating process, and the mode that air, or water or a mixture of the water and the air makes direct contact with the large particles is adopted during secondary granulating. Material recycling of the molten metallurgical slag and high-value utilization of the heat energy are achieved, and the method is provided for metallurgical energy saving and emission reduction, consumption reduction and effect increasing.

Owner:TIANJIN UNIV

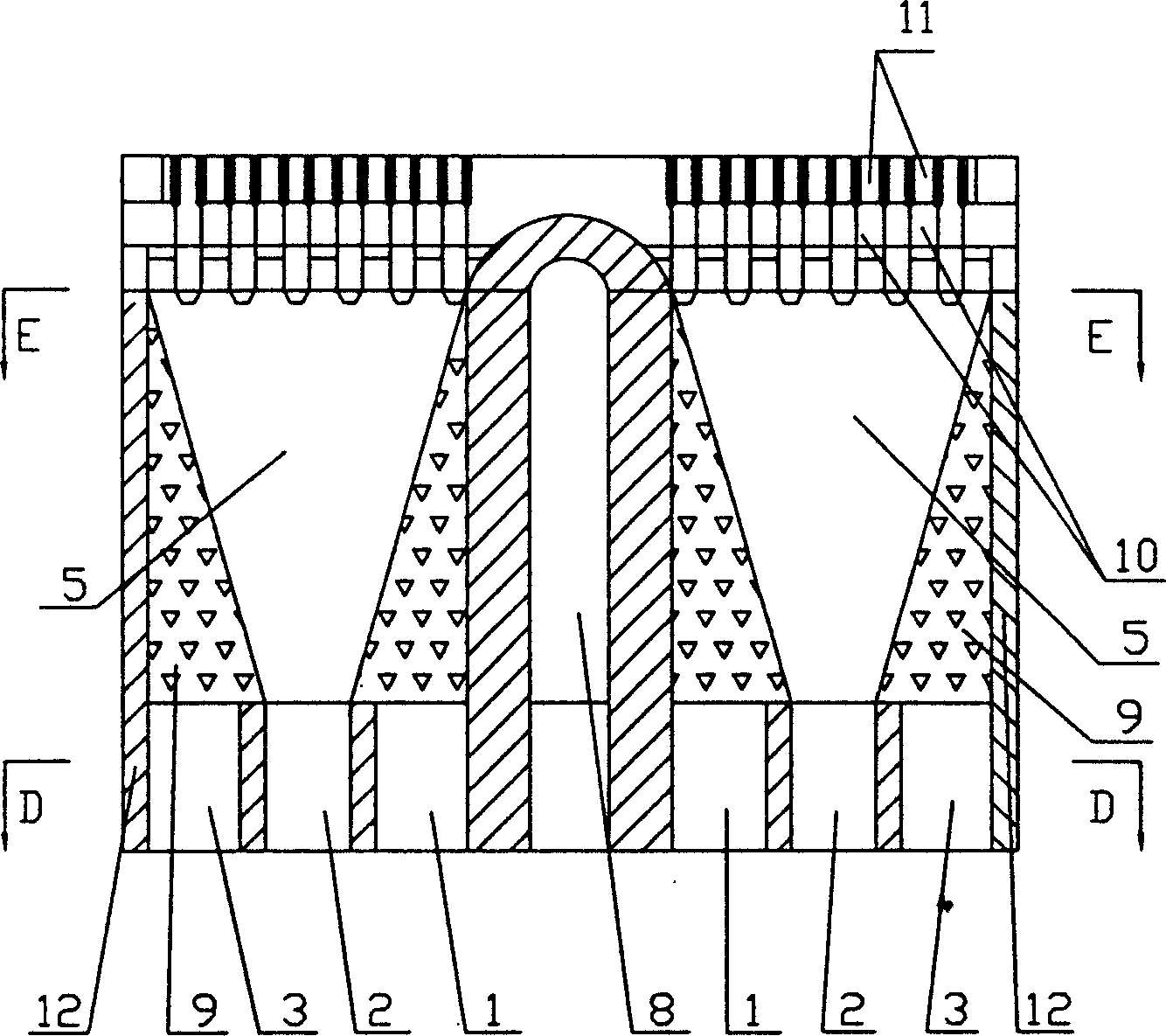

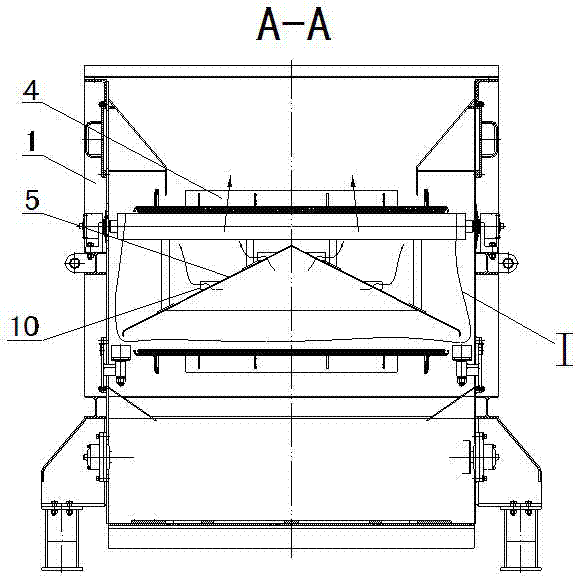

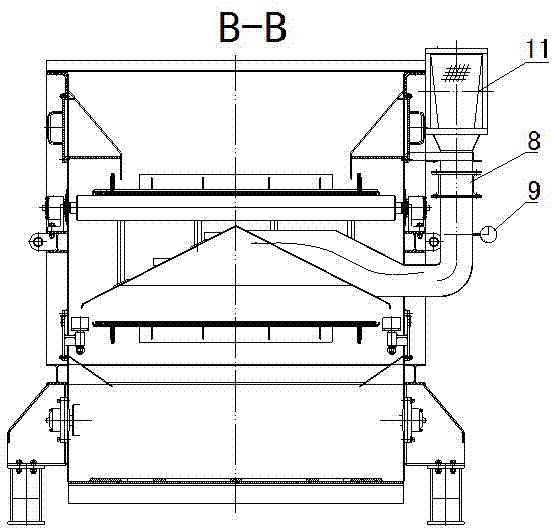

Vertical cement clinker grate-type particle grading cooler and cooling method

The invention belongs to the field of cement sintering equipment, and particularly relates to a vertical cement clinker grate-type particle grading cooler. The upper layer of the cooler is a wicket cover; a fine material cooling area is arranged on the lower part, close to one side of a rotary kiln, of the wicket cover, a coarse material cooling area is arranged on one side of the fine material cooling area, and the fine material cooling area and the coarse material cooling area are separated through a separating cooling wall; a two-stage screening grate plate for filtering clinkers is arranged at the upper end of the fine material cooling area in an inclined mode; a secondary cooling area for secondary cooling of all falling materials are arranged on the lower layer of the cooler, the secondary cooling area comprises a plurality of material falling ash buckets arranged at the bottom end of the cooler, and the cooled clinkers are finally collected through the material falling ash buckets into a drag chine conveyor on the lower part of the cooler. According to the vertical cement clinker grate-type particle grading cooler, the clinkers are cooled respectively in grades, the good heat exchange effect can be achieved, meanwhile the material layer obstruction of the clinkers is lowered, and the purposes of energy saving and consumption reduction are achieved; and the process of countercurrent flow of the clinkers and air for two times is achieved, and the cooling effect is good.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Method for obtaining high air temperature with low calorific value gas and high-temperature combustion air

InactiveCN103343177AGood energy storage effectReduce operating costsBlast furnace detailsHeating stovesThermal energyEngineering

The invention relates to a method for obtaining high air temperature with low calorific value gas and high-temperature combustion air, and relates to the technical field of heat energy. The method comprises the following steps of: firstly, sending normal temperature air to a heat exchanger in a flue to obtain low-temperature combustion air; secondly, enabling the low-temperature combustion air to pass through a regenerator bed layer of a hot blast stove which just complete the air supply to obtain the high-temperature combustion air; thirdly, sending the high-temperature combustion air and the low calorific value gas to a burner of the hot blast stove to obtain a desired high flame burning temperature and a desired high top temperature, and then obtain a desired high air temperature. The method is used for supplying the air to a blast furnace, and has the advantages of energy conservation, emission reduction, and investment and occupied area saving.

Owner:ZHENGZHOU ANNEC IND

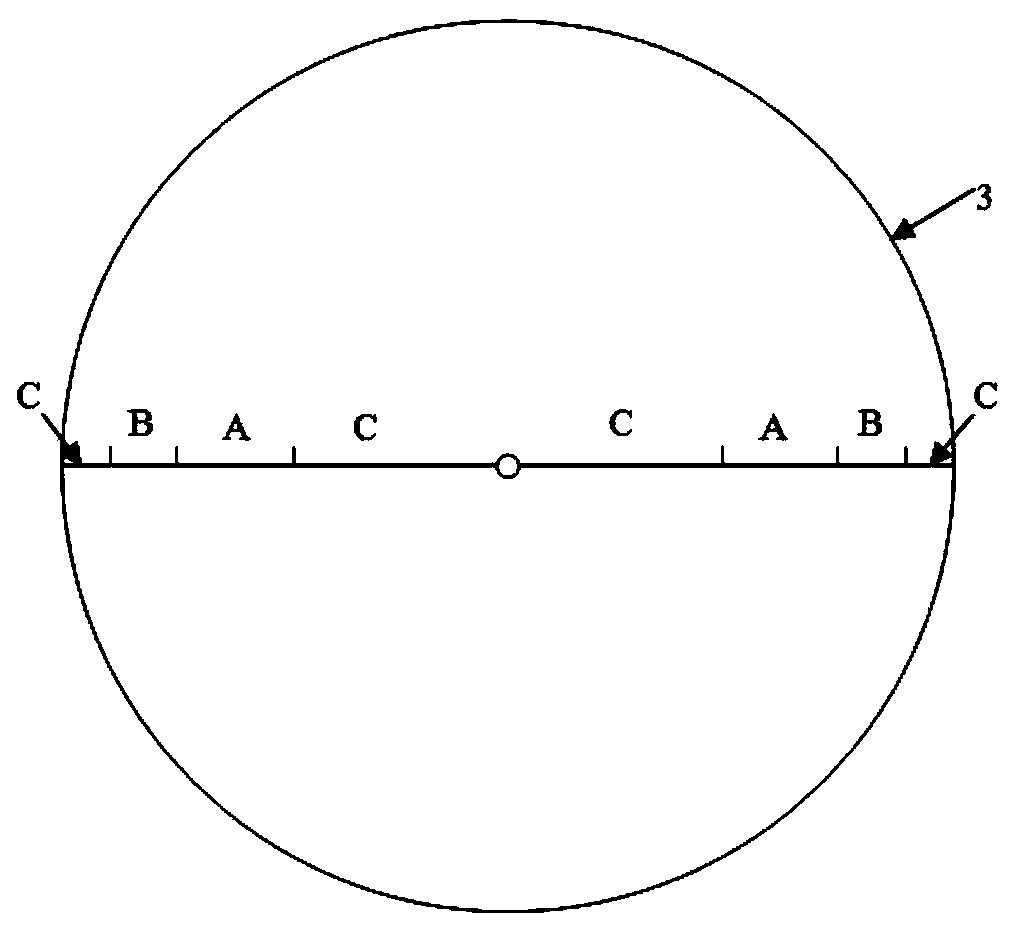

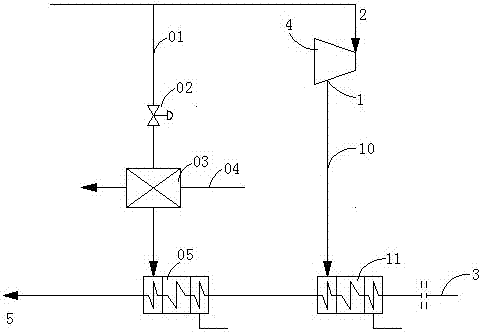

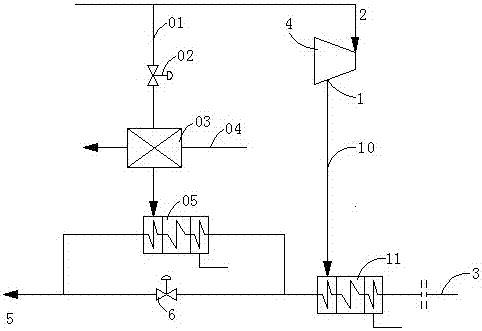

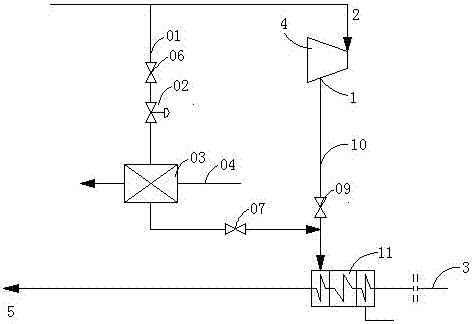

Blast furnace hot-blast stove combustion air preheating system and preheating method

InactiveCN102618682AIncrease wind temperatureIncrease production capacityBlast furnace detailsHeating stovesCombustionEngineering

The invention discloses a blast furnace hot-blast stove combustion air preheating system, comprising a hot-blast stove for burning the combustion air and blast furnace gases and a solar preheating device arranged at the air intake side of the hot-blast stove, wherein the combustion air after being heated by the solar preheating device enters into the hot-blast stove to burn with the blast furnace gases. The air which enters into the hot-blast stove is firstly heated by the solar preheating device and then enters into the hot-blast stove to significantly raise the temperature of the air and then raise the air temperature of the blast furnace, reduce the energy consumption of the iron-making process and improve the production capacity of the blast furnace. Simultaneously, the combustion air after being heated by the solar preheating device is directly conveyed into the hot-blast stove to burn with the blast furnace gases, thus the heat exchange problem is solved, there is no need to arrange extra heat exchange equipment, and the maintenance cost of the heat exchange equipment is saved. The solar preheating device has high heat-utilization efficiency and no environment pollution, can reduce the preheating cost of the blast furnace and simultaneously reduce the smelting cost. The invention further provides a preheating method based on the preheating system.

Owner:HANGZHOU SANHUA RES INST CO LTD

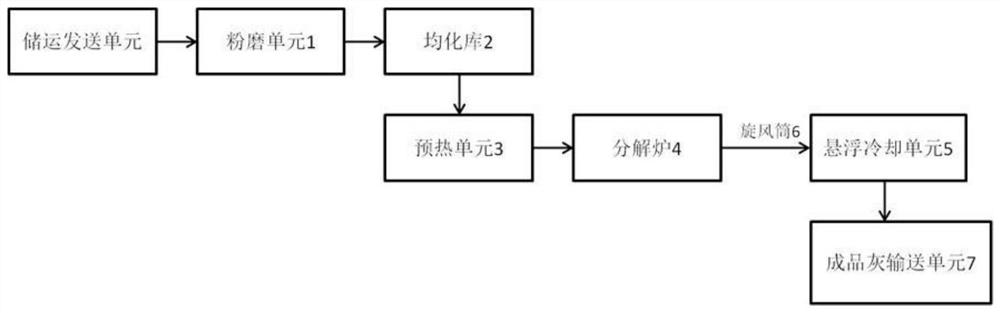

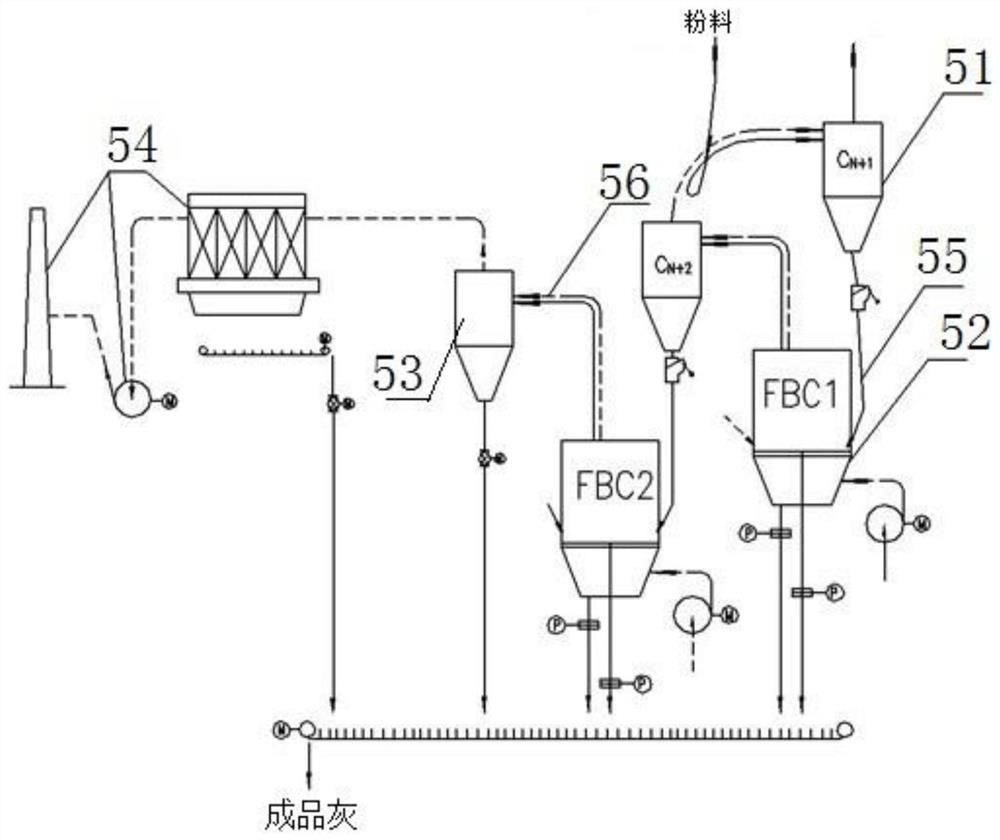

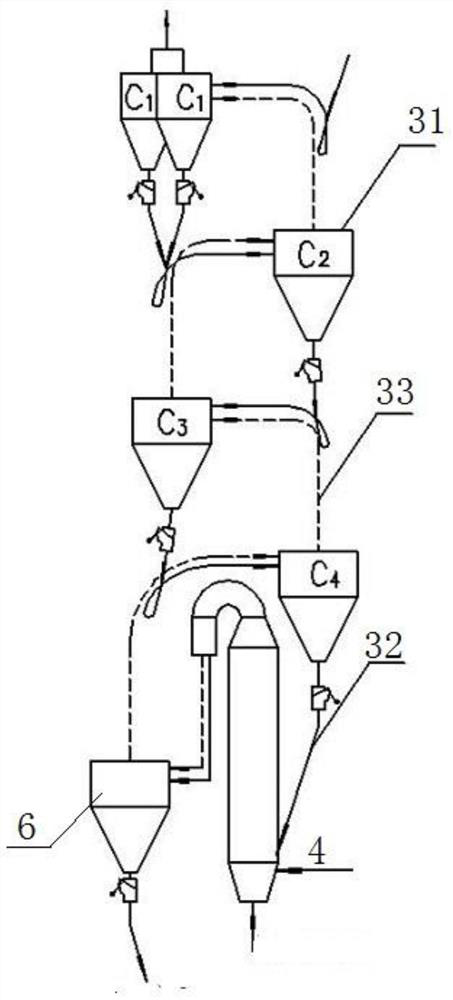

System and method for preparing powdery active lime by modifying cement clinker production line

The invention discloses a system and method for preparing powdery active lime by modifying a cement clinker production line. The system comprises a grinding unit and a homogenizing silo which are communicated with each other, and also comprises: a preheating unit for drying ground limestone powder, a decomposing furnace for calcining the limestone powder, and a suspension cooling unit for cooling the calcined limestone powder, wherein the material outlet of the decomposing furnace is connected with a cyclone cylinder for gas-solid separation, and the material outlet of the cyclone cylinder is connected with the material inlet of the suspension cooling unit. According to the method, by using suspension cooling, the overall heat exchange efficiency is high, energy consumption is low, heat of high-temperature lime at an outlet of the decomposing furnace is recycled to the maximum extent in a multi-stage cooling series connection mode, the cooling air volume is small, and the temperature of air returning to the decomposing furnace is high; and original equipment and systems of the cement clinker line can be fully utilized, so that the transformation amount is small, and the provided method enables the lime production capacity to be large.

Owner:SINOMA INT ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com