Energy and water saving system for wet desulphurization system

A water-saving system and wet desulfurization technology, applied in the direction of combustion method, separation method, chemical instrument and method, etc., can solve the problems of power plant operation difficulties and high investment, so as to alleviate the phenomenon of white smoke, improve the operating environment and reduce coal consumption and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

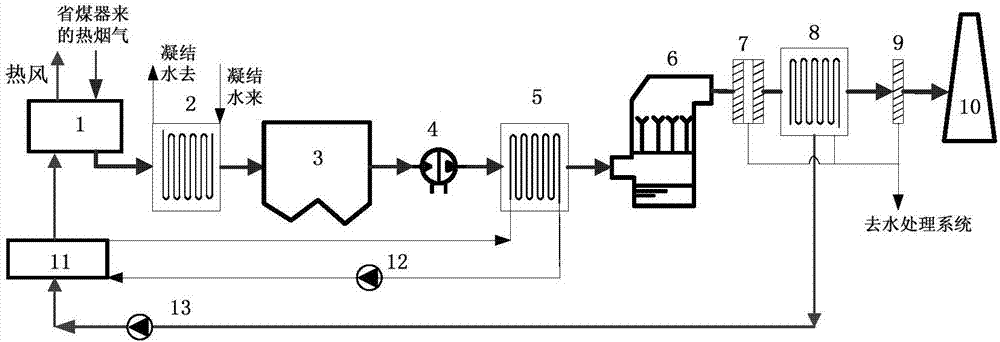

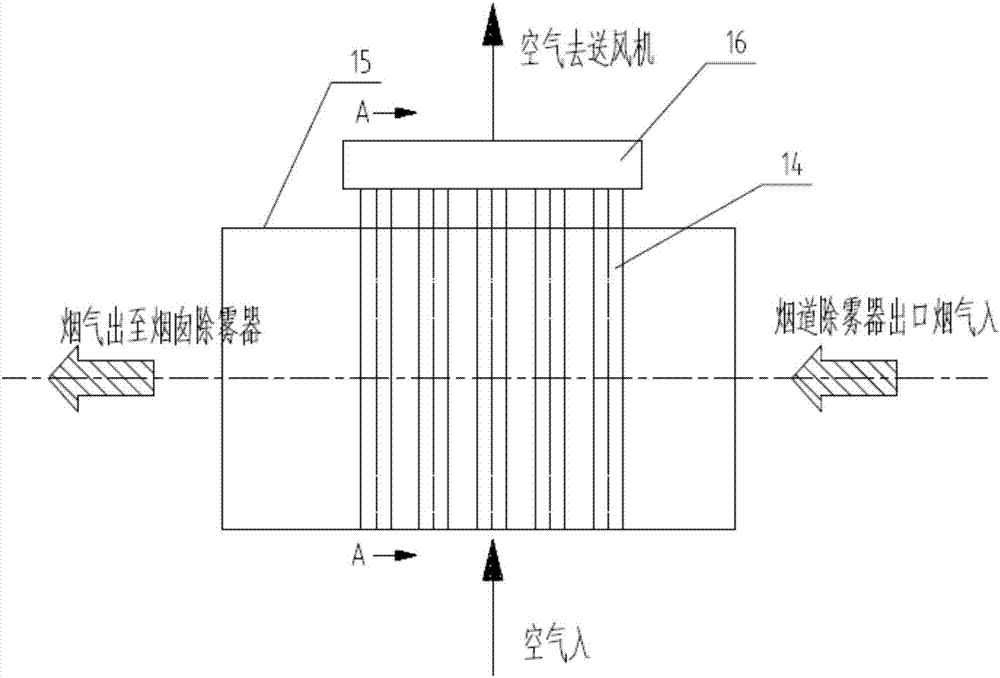

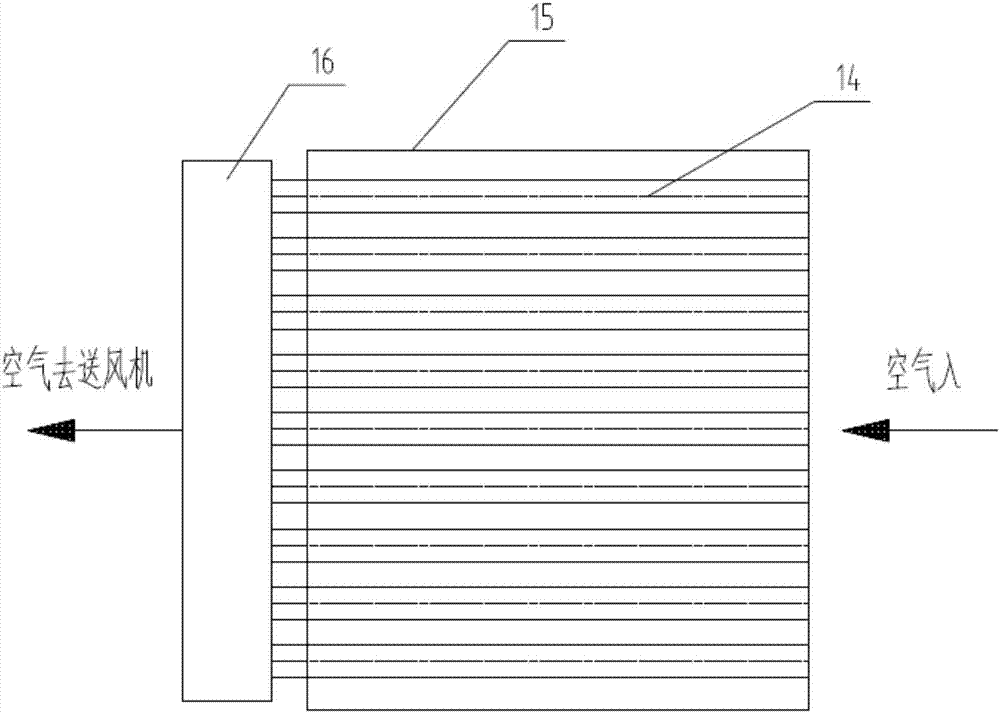

[0024] refer to figure 1 , figure 2 and image 3 , the energy-saving and water-saving system for wet desulfurization system according to the present invention includes a primary flue gas cooler 2, a flue gas input pipe, a flue gas pretreatment system, a secondary flue gas cooler 5, a desulfurization tower 6, a flue gas Road demister 7, flue gas condenser 8, chimney demister 9, chimney 10 and air heater 11; The outlet on the heat release side is connected to the heat release side inlet of the secondary flue gas cooler 5 through the primary flue gas cooler 2 and the flue gas pretreatment system in turn, and the heat release side outlet of the secondary flue gas cooler 5 passes through the desulfurization tower 6 and the flue gas demister 7 communicate with the flue gas inlet of the flue gas condenser 8, and the flue gas outlet of the flue gas condenser 8 communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com