Blast furnace slag dry granulation and heat recovery system and method

A technology of dry granulation and heat recovery, which is applied in the field of blast furnace ironmaking, can solve the problems of high investment and operation costs, high investment and operation costs, secondary bonding of slag particles, etc., to improve reliability and Durability and convenience of maintenance, realization of recycling, and the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The blast furnace slag dry granulation and heat recovery system and method described in the present invention will be further explained and described below in conjunction with the accompanying drawings and specific examples. However, the explanation and description do not constitute inappropriate technical solutions of the present invention. limited.

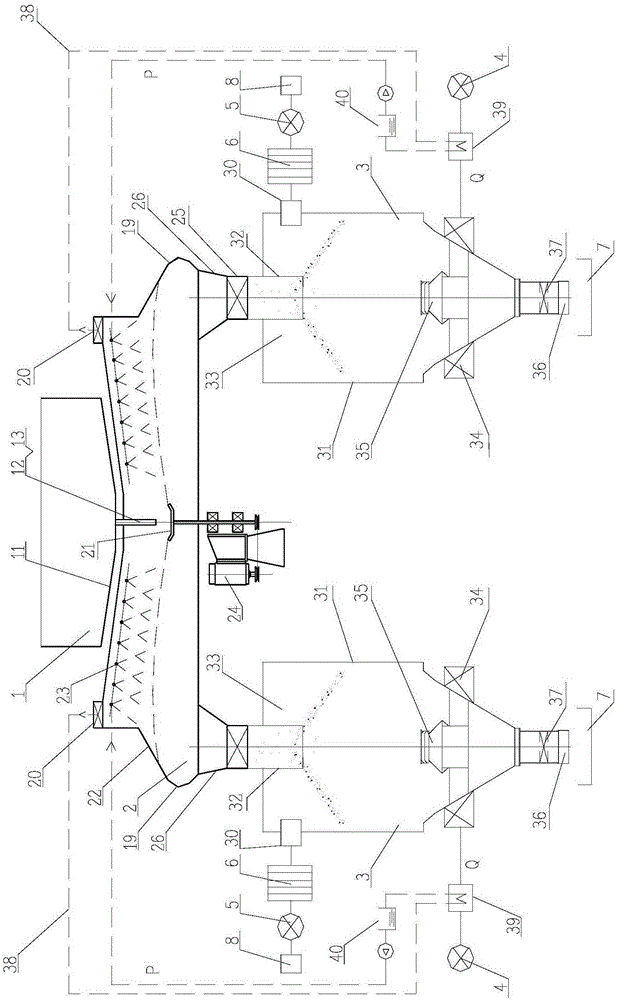

[0044] figure 1 It shows the structure of the blast furnace slag dry granulation and heat recovery system in an embodiment of the present invention.

[0045] Such as figure 1 As shown, the blast furnace slag dry granulation and heat recovery system includes a thermal insulation buffer tank 1, a granulation device 2, a heat exchange tank 3, a blast system 4, an induced draft system 5, a waste heat boiler 6, a belt conveyor 7 and a dust collector 8.

[0046] The thermal insulation buffer tank 1 includes a thermal insulation buffer tank body 11. The bottom of the thermal insulation tank 11 is provided with a slag lowering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com