Method for obtaining high air temperature with low calorific value gas and high-temperature combustion air

A technology of combustion-supporting air and low calorific value, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of poor combustion and energy storage effect of top-fired hot blast stoves, increased maintenance and operation costs, and high investment costs, and achieves the idea of Unique and practical, conducive to widespread promotion and application, and the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

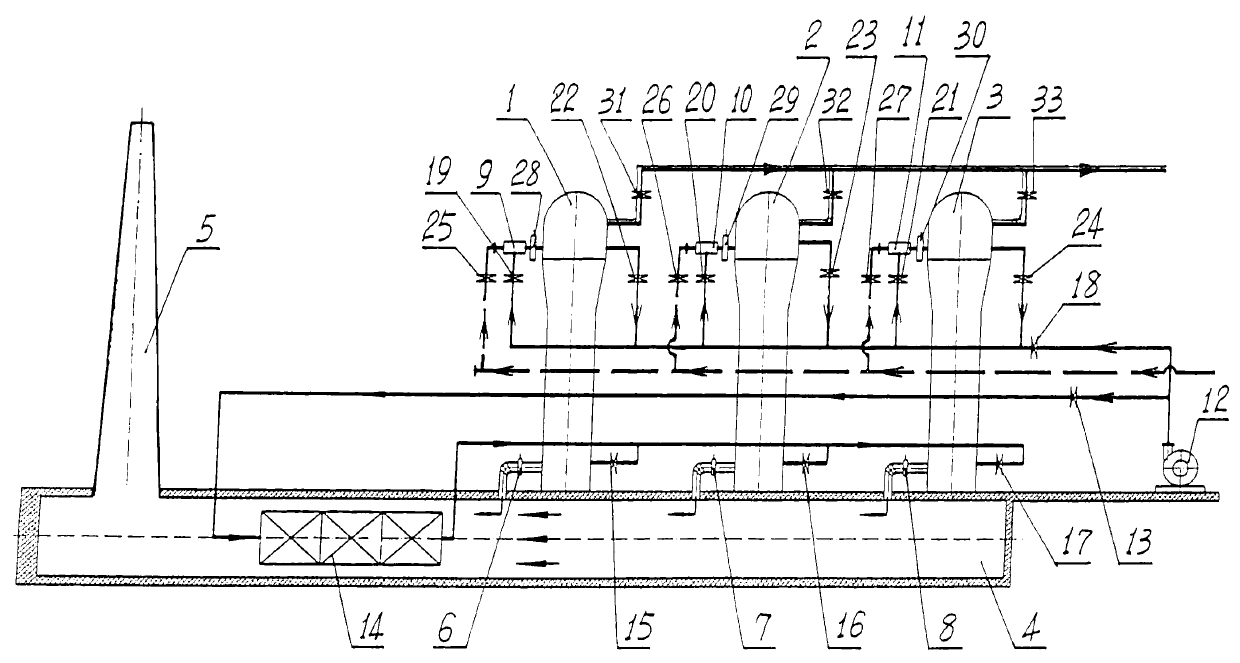

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0027] A method for obtaining high air temperature by using low-calorific-value gas and high-temperature combustion-supporting air, the method comprising the following steps:

[0028] ①. The air at normal temperature is sent through the heat exchanger 14 in the flue 4 to obtain low-temperature combustion-supporting air;

[0029] ②. Pass the low-temperature combustion-supporting air through the regenerator bed of the hot blast stove that has just sent the air to obtain high-temperature combustion-supporting air;

[0030] ③. Send the high-temperature combustion-supporting air and low calorific value gas into the hot blast stove burner to obtain the required high flame combustion temperature and required high top temperature, and then obtain the required high blast temperature.

[0031] In the method for obtaining high air temper...

specific Embodiment approach 2

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0033] A device for realizing the method of obtaining high wind temperature by using low-calorific-value gas and high-temperature combustion-supporting air, that is, a device for obtaining high-wind temperature by using low-calorific-value gas and high-temperature combustion-supporting air. A furnace 1, B furnace 2, The C furnace 3 and the chimney 5 are all arranged on the flue 4, and the side of the lower end of the A furnace 1, the A valve 6, and the flue 4 are fixedly connected by pipelines, and the side of the B furnace 2 lower end, the B valve 7, The flue 4 is fixedly connected through pipelines, the side of the lower end of the C furnace 3, the C valve 8, and the flue 4 are fixedly connected through pipelines, and its fan 12, D valve 13, heat exchanger 14, E valve 15 and A furnace 1 The other side of the lower end, and th...

specific Embodiment approach 3

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0035]In the method of obtaining high wind temperature with low-calorific-value gas and high-temperature combustion-supporting air, in order to make reasonable use of the flue gas temperature in the flue 4, the fan 12, the D valve 13, and the H valve 18 are always in the normally open state, so as to pass The heat exchanger 14 in the flue 4 makes the temperature of the exhausted flue gas effectively and fully utilized; at the same time, the wind coming out of the heat exchanger 14 passes through the heat storage body of the top-fired hot blast stove itself in series to realize Fully warm up again;

[0036] ①, A furnace process optimization:

[0037] First open the W valve 33, close the C valve 8, G valve 17, N valve 24, close the K valve 21, Q valve 27, T valve 30 so as to stop the work of the C burner 11, and the wind source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com