A kind of method for preparing supercapacitor by polypyridyl metal-organic framework ni-mof

A technology of supercapacitors and organic frameworks, applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of short cycle life and low power of energy storage devices, and achieve good energy storage effect, long service life, and fast response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

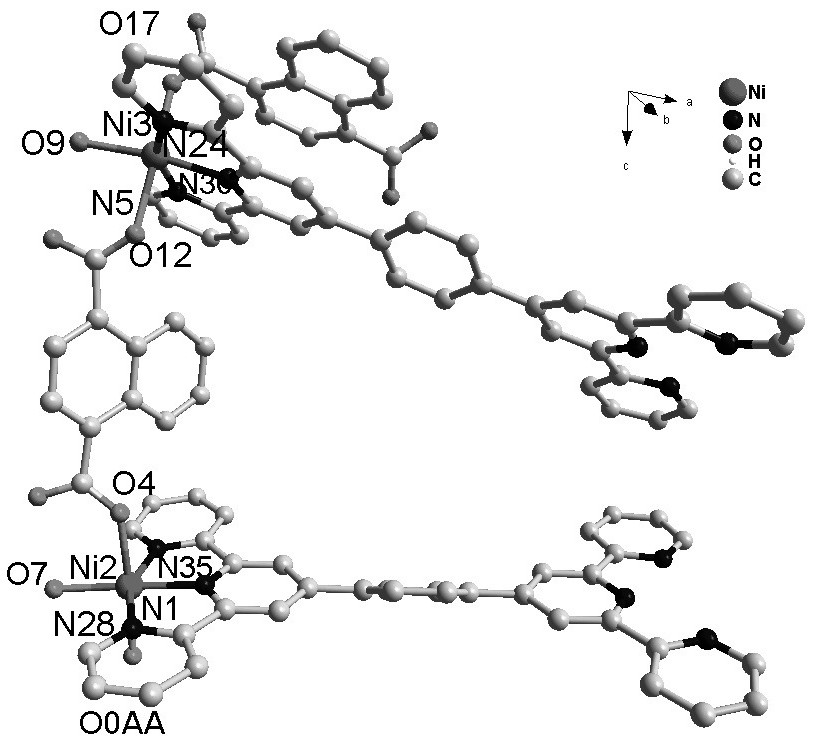

[0038] Such as Figure 5 Shown, a kind of polypyridyl metal-organic framework Ni-MOF prepares the method for supercapacitor, comprises the steps:

[0039] The first step, organic building unit: the mass of 1,4-naphthalene dicarboxylic acid is 0.005g and the mass of 1,4-bis(2,2':6',2"-terpyridine-4'-yl) benzene Put 0.001g into an open glass bottle, add 5mL of distilled water;

[0040] The second step, inorganic building unit: add nickel-based metal salt Ni(Ac) to the open glass bottle 2 0.02g, and put the open glass bottle into the plastic liner, put the liner into the autoclave, and screw it tightly;

[0041] The third step, hydrothermal reaction: the temperature set in the constant temperature oven is 150°C, and the reaction time is 72h, and the high-pressure reactor is placed in the constant temperature oven for reaction, and the yellow dendritic polypyridyl metal organic framework is prepared. Material Ni-MOF;

[0042] The fourth step, collection: dry the polypyridyl me...

Embodiment 2

[0071] A kind of polypyridyl metal organic framework Ni-MOF prepares the method for supercapacitor, comprises the steps:

[0072] The first step, organic building unit: weigh Ni(Ac) according to the ratio of parts by mass 2 20 parts, 4 parts of 1,4-naphthalene dicarboxylic acid, 0.8 parts of 1,4-bis(2,2':6',2"-terpyridine-4'-yl)benzene, 1,4-naphthalene dicarboxylic acid 4 parts and 0.8 parts of 1,4-bis(2,2':6',2"-terpyridine-4'-yl)benzene were put into an open glass bottle, and 5 mL of distilled water was added;

[0073] The second step, inorganic building unit: adding nickel-based metal salt Ni(Ac) 2 20 parts, and put the glass bottle into the plastic liner, and put the liner into the autoclave;

[0074] The third step, hydrothermal reaction: the temperature set in the constant temperature oven is 130°C, and the reaction time is 60h, and the reaction is carried out in the constant temperature oven to prepare yellow dendritic Ni-MOF;

[0075] The fourth step, collection: dr...

Embodiment 3

[0079] A kind of polypyridyl metal organic framework Ni-MOF prepares the method for supercapacitor, comprises the steps:

[0080] The first step, organic building unit: weigh Ni(Ac) according to the ratio of parts by mass 2 20 parts, 6 parts of 1,4-naphthalene dicarboxylic acid, 1 part of 1,4-bis(2,2':6',2"-terpyridine-4'-yl)benzene, 1,4-naphthalene dicarboxylic acid 6 parts and 1 part of 1,4-bis(2,2':6',2"-terpyridine-4'-yl)benzene were put into an open glass bottle, and 5 mL of distilled water was added;

[0081] The second step, inorganic building unit: adding nickel-based metal salt Ni(Ac) 2 20 parts, and put the glass bottle into the plastic liner, and put the liner into the autoclave;

[0082] The third step, hydrothermal reaction: the temperature set in the constant temperature oven is 150°C, and the reaction time is 80h, and the reaction is carried out in the constant temperature oven to prepare yellow dendritic Ni-MOF;

[0083] The fourth step, collection: dry the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com