Preparation method and electrochemical performance test method of manganese dioxide-based composite material applied to supercapacitor

A manganese dioxide-based supercapacitor technology, applied in the field of material chemistry, can solve the problems of short cycle life and low power density of energy storage equipment, achieve good energy storage characteristics, high cycle life, and improve overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of synthetic steps of manganese dioxide-based composite material applied to supercapacitor is as follows:

[0027] Weigh 50 mg of titanium carbide MXene, mix it with 50 ml of distilled water in a beaker, and place the beaker in an ultrasonic cleaner for ultrasonic vibration for 60 minutes to prepare a titanium carbide MXene suspension. Then weigh 200 mg of potassium permanganate powder, add 250 ml of distilled water, and stir to make potassium permanganate solution. Finally, the two are mixed in a sealed beaker, and placed on a magnetic stirrer for 36 hours at room temperature to obtain a black manganese dioxide-based composite material MnO 2 / Ti 3 C 2 . The obtained samples were collected through repeated washing with three times of distilled water and drying in a constant temperature oven at 50°C.

Embodiment 2

[0029] A kind of electrochemical performance test procedure of manganese dioxide-based composite material applied to supercapacitor is as follows:

[0030] The first step is to prepare before the experiment. Mix and grind the prepared manganese dioxide-based composite material, acetylene black, and polytetrafluoroethylene emulsion at a mass ratio of 16:3:1, and add absolute ethanol as a dispersant during the grinding process. Subsequently, the ground mixture is coated with two sheets of nickel foam of the same specification (the specification is 2 cm * 1 cm * 0.1 cm), and it is placed in a tablet press with a pressure of 5 MPa and squeezed for 1 minute. , made of electrode sheet.

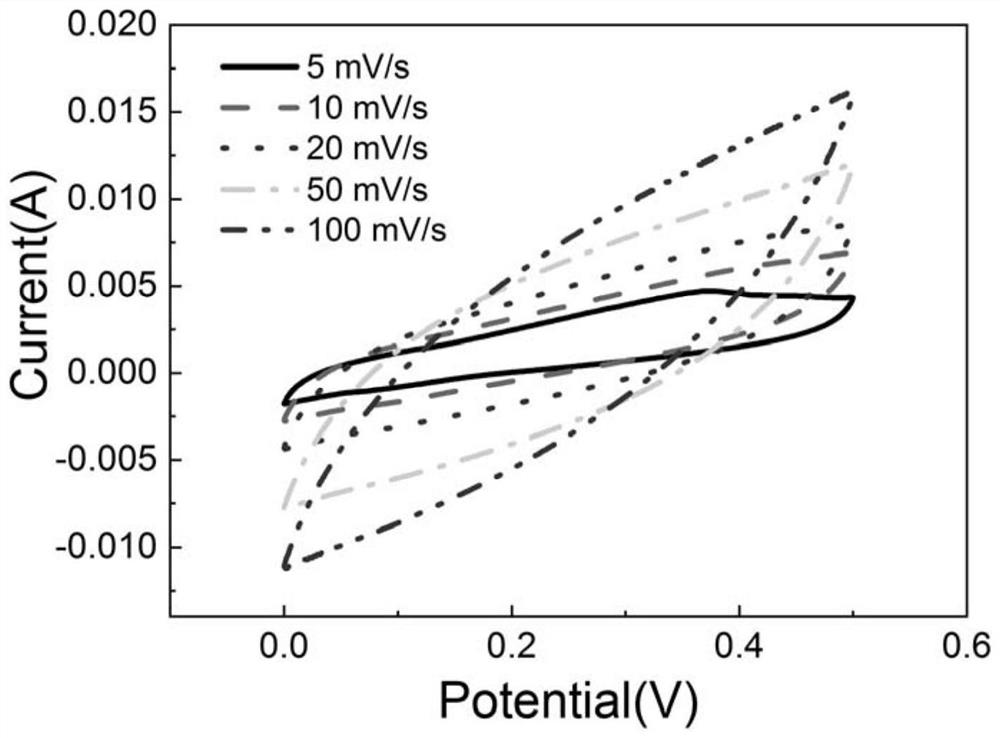

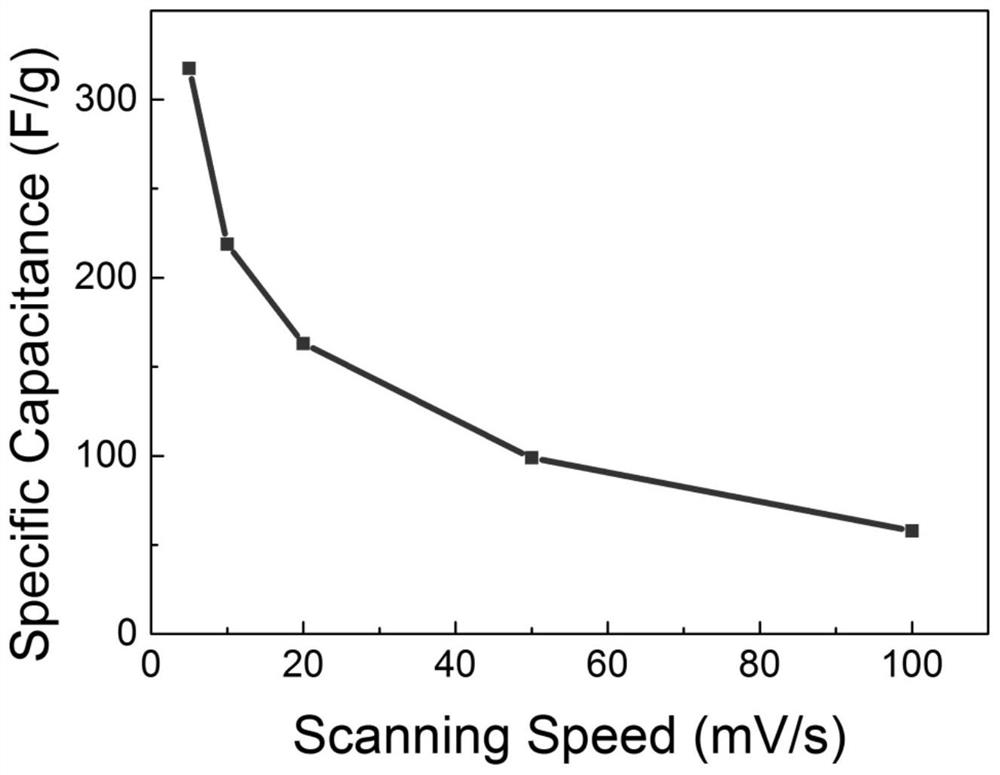

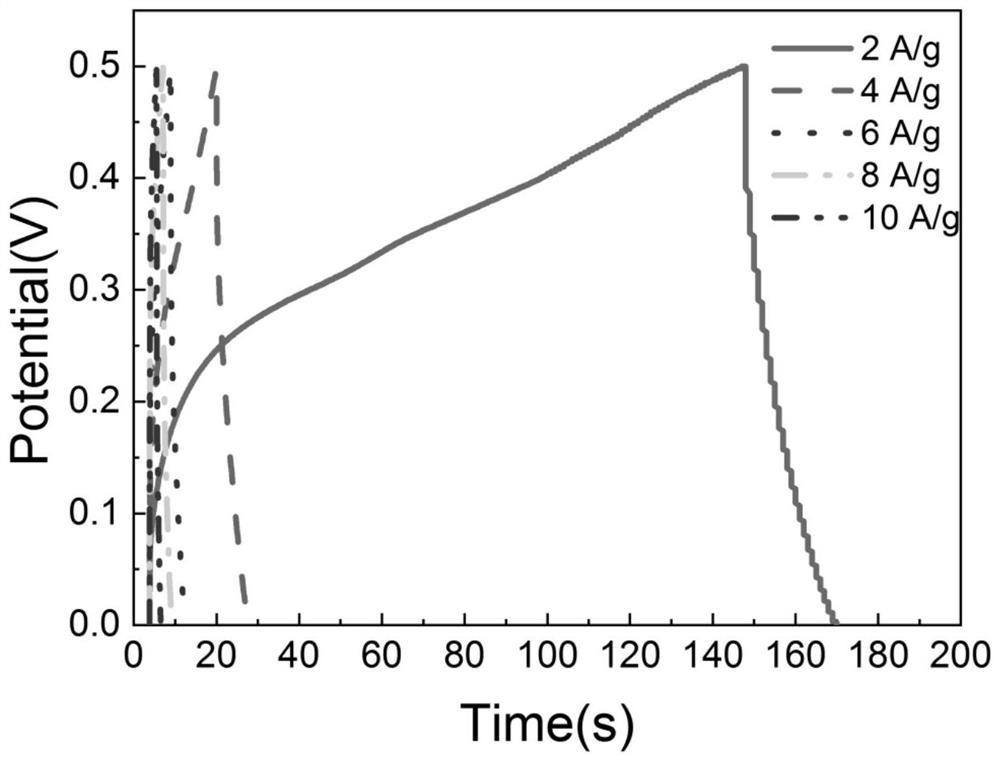

[0031] The second step is electrochemical testing. The electrode sheet was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode, 1mol / L Na 2 SO 4 The solution was used as an electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com