Hot air drying system heated by double energy sources

A hot air drying and dual-energy technology, which is applied to the drying machine of static materials, heating to dry solid materials, drying solid materials, etc., can solve the problems of low energy efficiency ratio, waste of energy, environmental pollution, etc., and achieve low operating costs and energy efficiency Higher effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

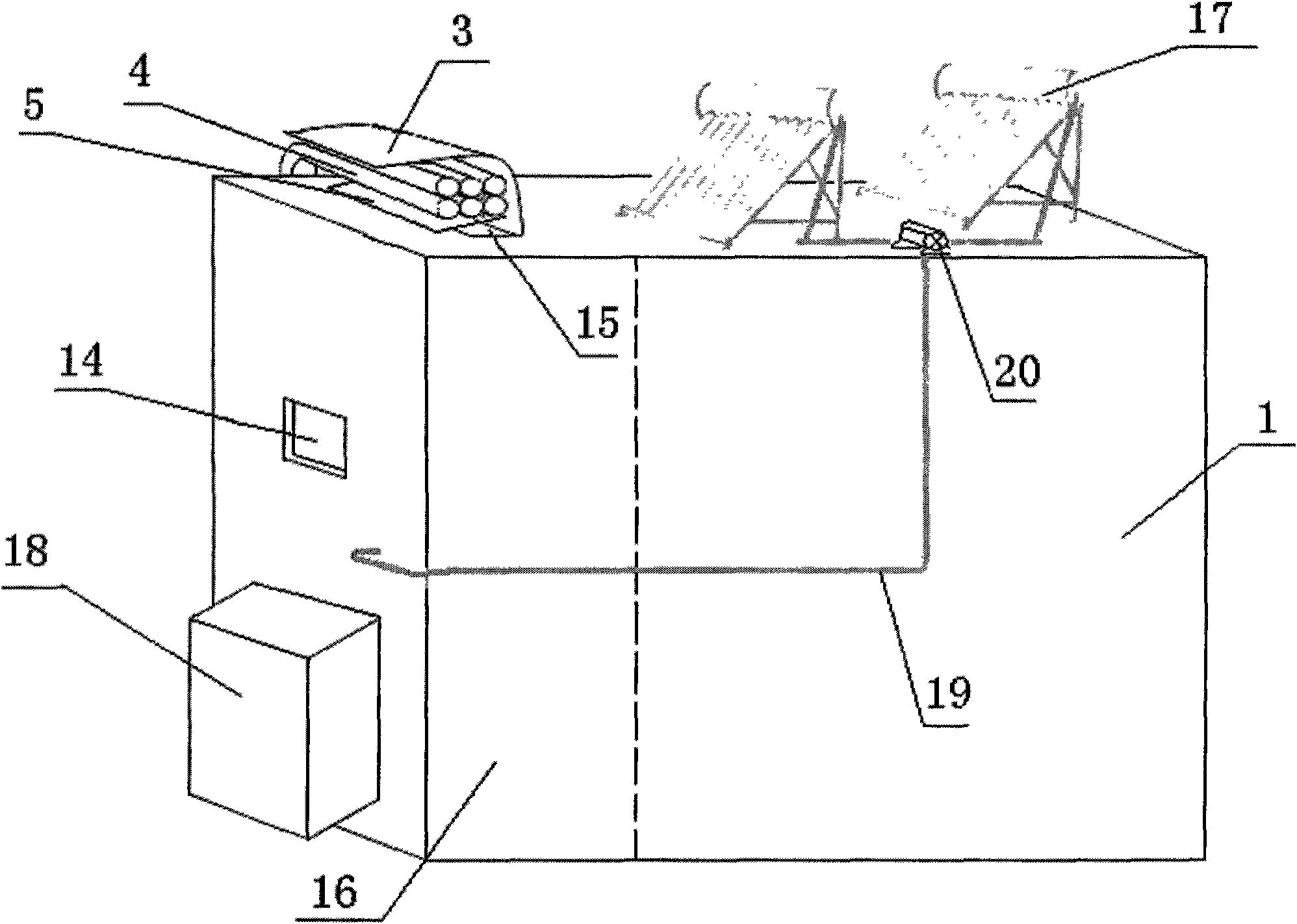

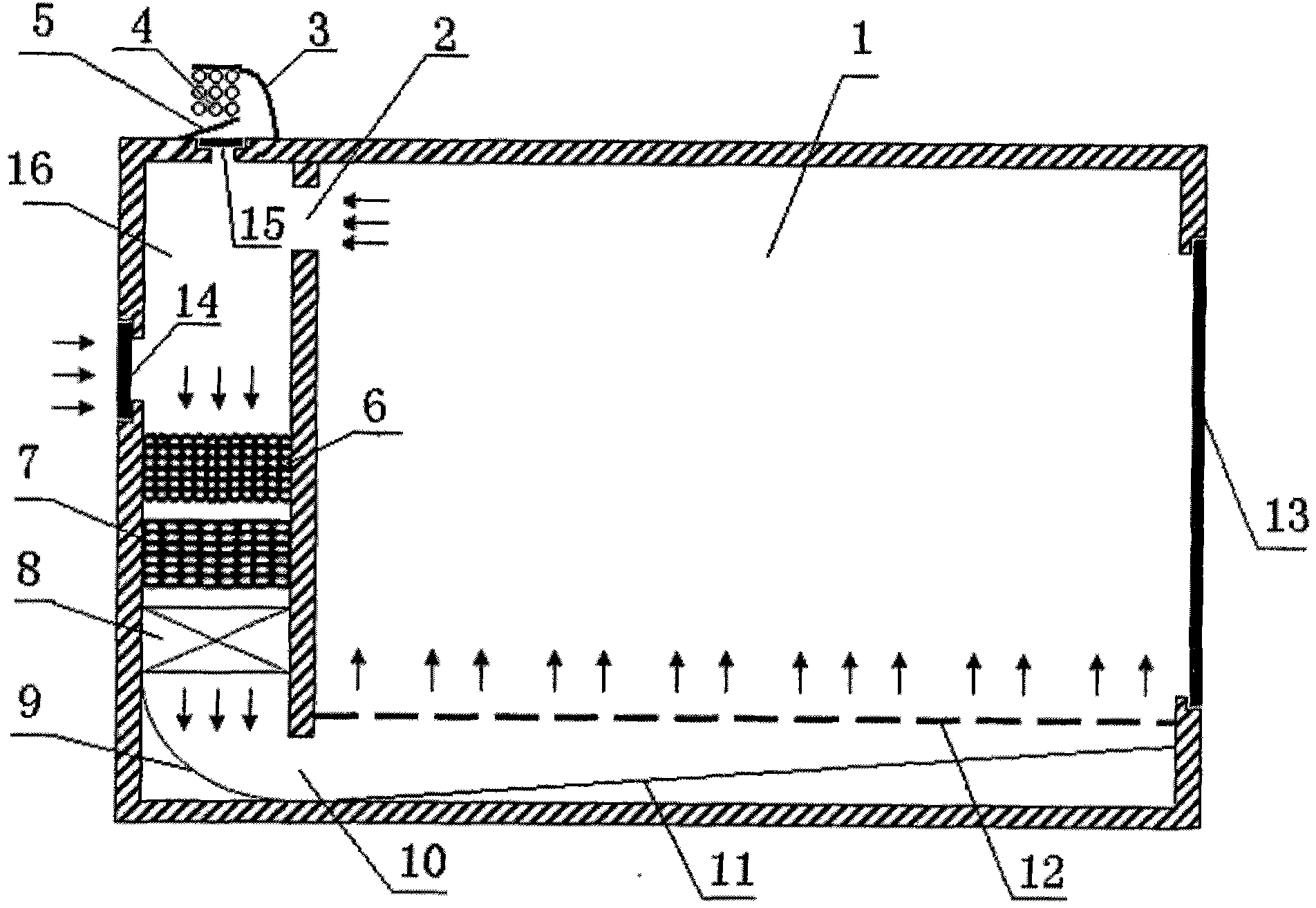

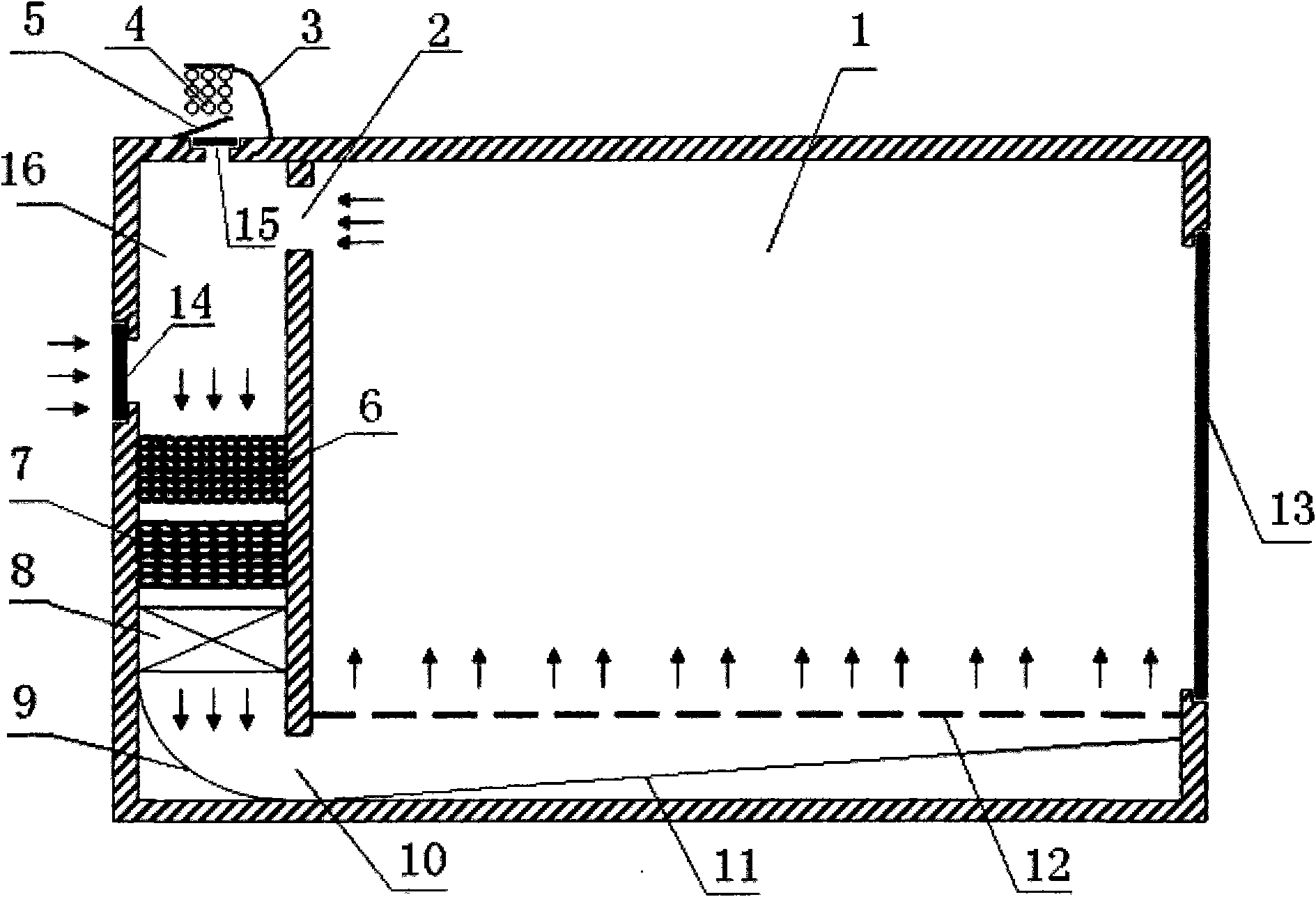

[0035] see figure 1 , figure 2 , reflecting a preferred structure of the present invention, is a tobacco barn made by adopting the technical solution of the present invention. The tobacco curing room includes a drying chamber 1 and a heating chamber 16 connected by an air supply duct 10 and a return air duct 2, the heating chamber 16 is provided with a new air outlet 14, and a dehumidification vent 14 which can be closed is provided above the heating chamber 16. Port 15, a waste heat recovery device is installed above the moisture discharge port 15, including heat absorbing pipe 4, condensed water deflector 5 and hot and humid air deflector 3, and one end of heat absorbing pipe 4 is connected to the return air duct. The barn also includes a solar heat collector, an air source heat pump 18 and a condenser fan 8, and the value range of the ratio of the heat exchange area of the condenser 7 of the air source heat pump 18 to the input power of the compressor is 5.3-11m 2 Betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com