Patents

Literature

254results about How to "Reduce return rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

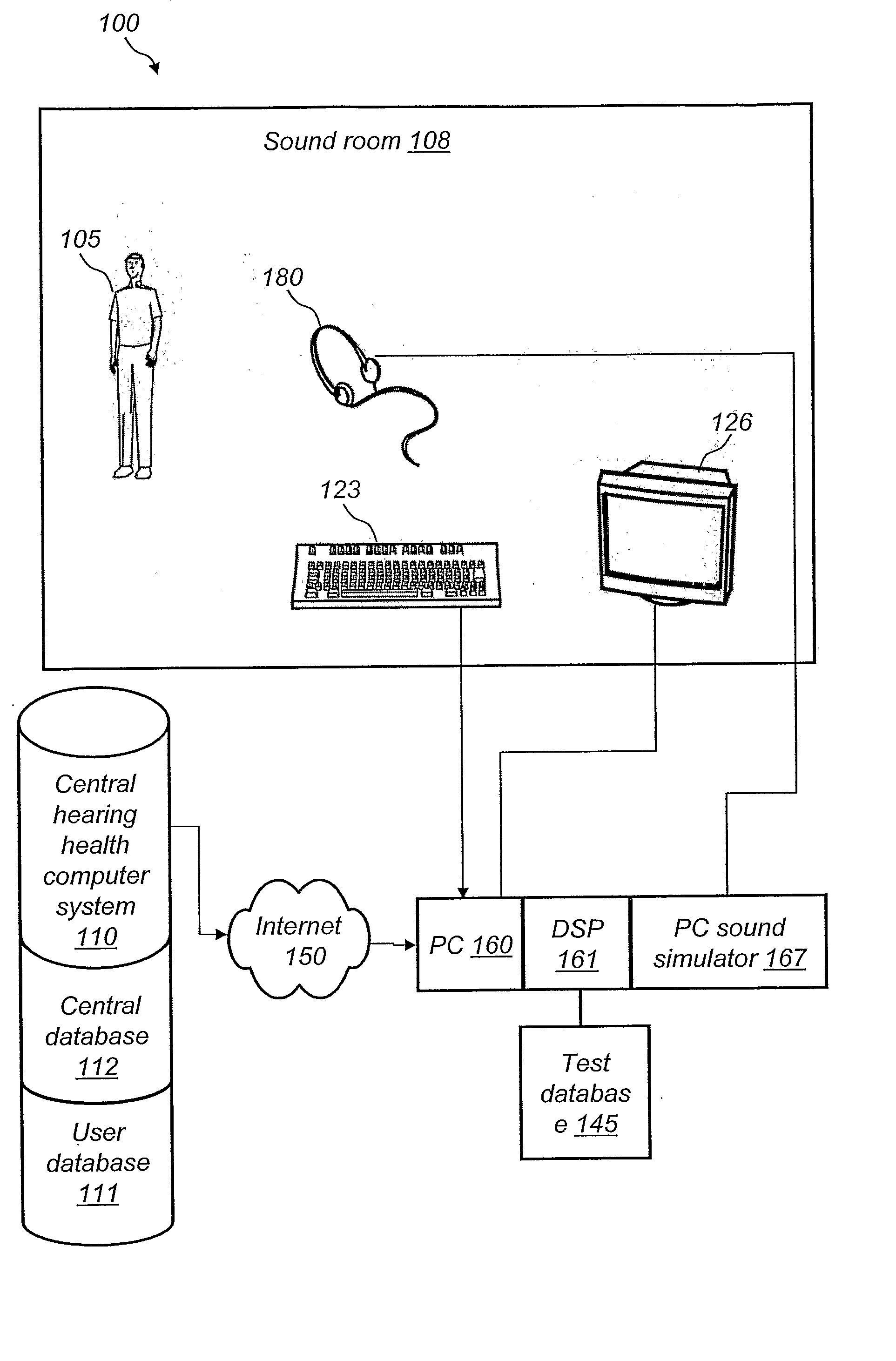

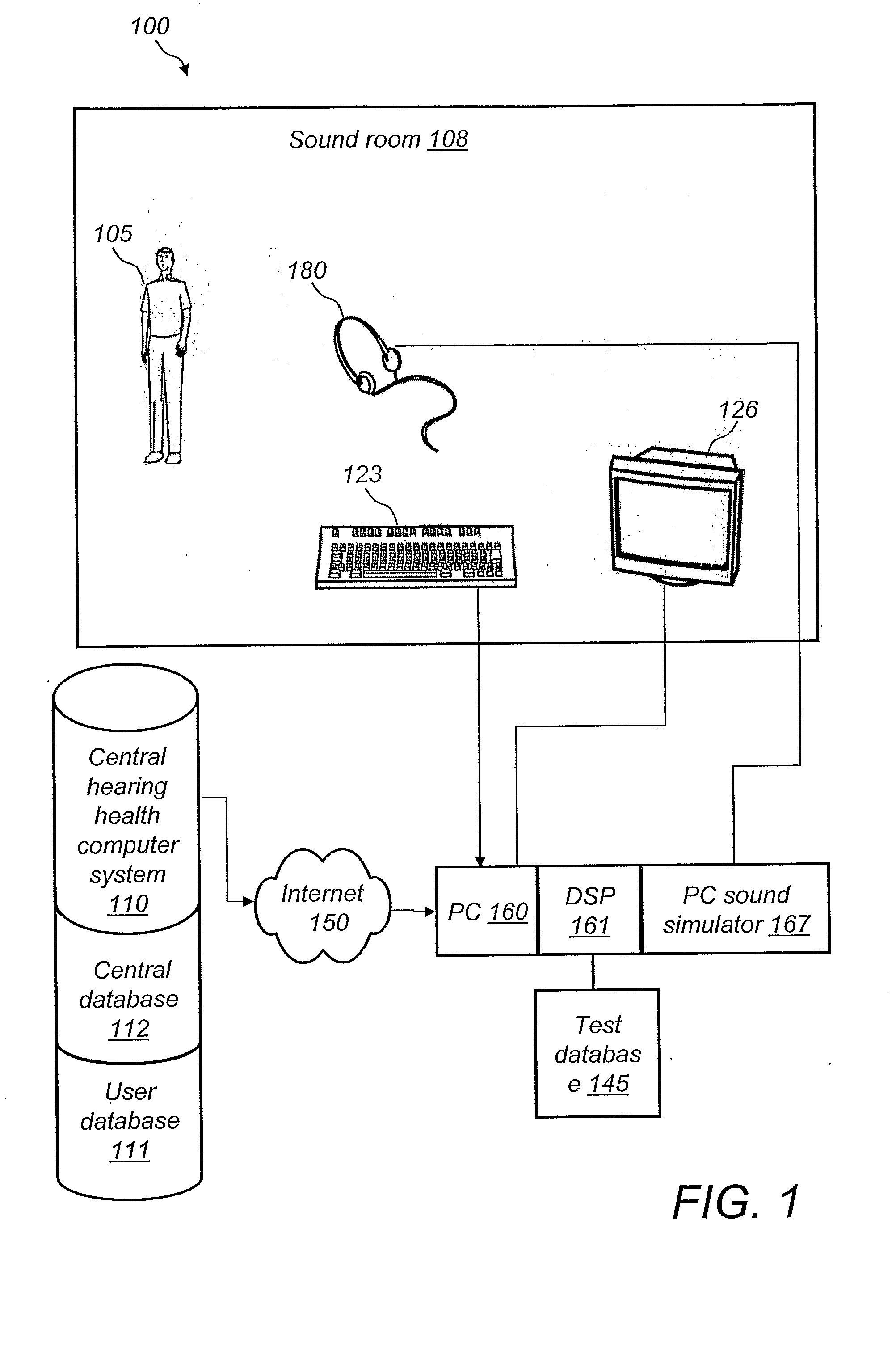

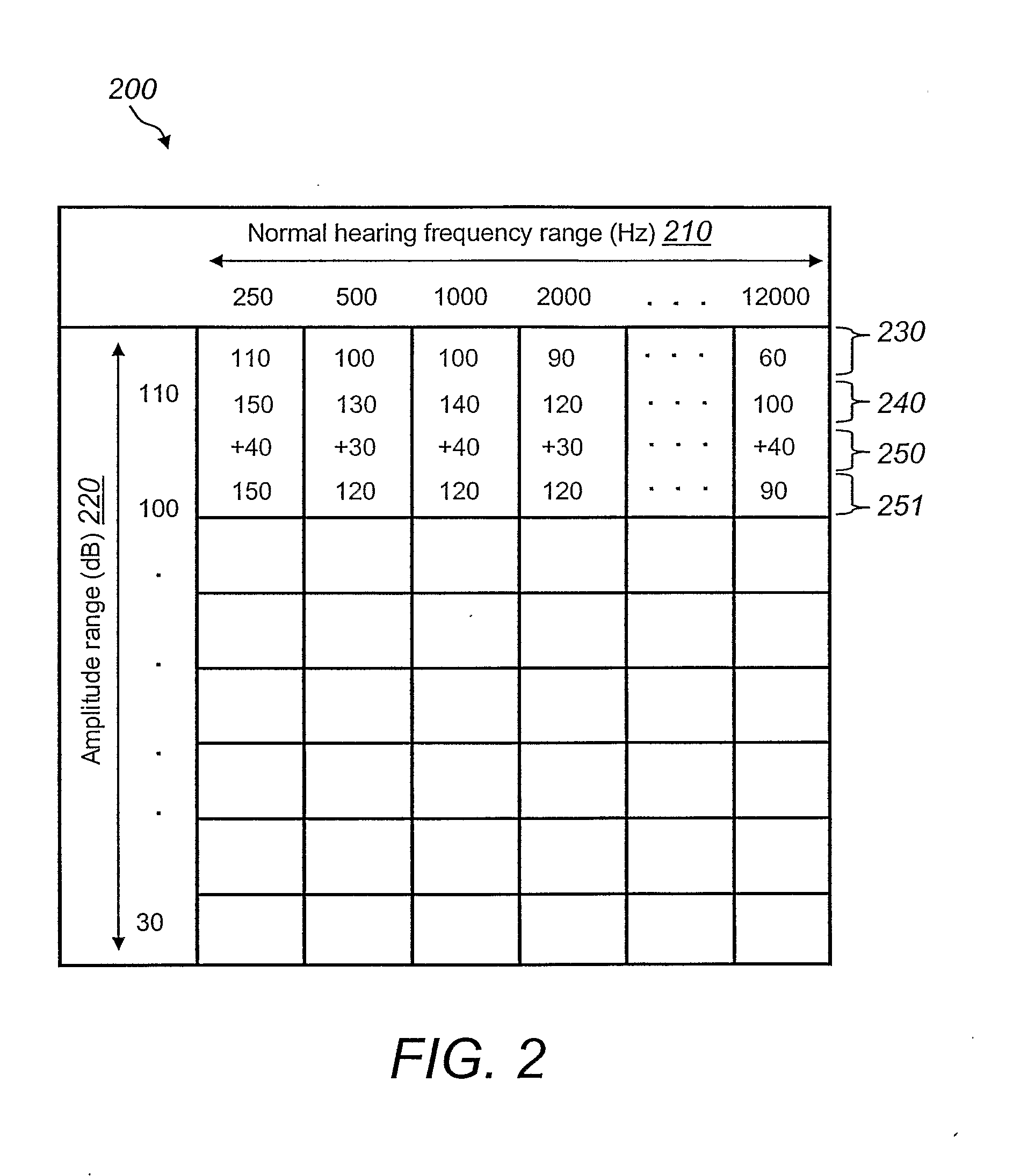

Hearing Device Sound Simulation System and Method of Using the System

InactiveUS20080165978A1Easy to hearReduce return rateDiagnostic recording/measuringSensorsSpeech claritySoftware

The present invention relates to hearing aid training systems (100). More particularly, the present invention relates to the simulation of a hearing aid environment (108) prior to a user's (105) purchase of a hearing aid. To create the simulated environment, the user's hearing profile (111) is collected from all prior hearing tests. Prior hearing tests include information on all aspects of the user's hearing, such as frequency and speech intelligibility. The software program (126) of this invention, and the audiologist using the software program (126), analyzes the user's hearing profile and creates a simulation that demonstrates to the user how he or she would hear with a hearing aid. Furthermore, this invention provides a way to make additional adjustments to the hearing aid's DSP data based upon user preferences prior to ordering the individual customized hearing aid.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

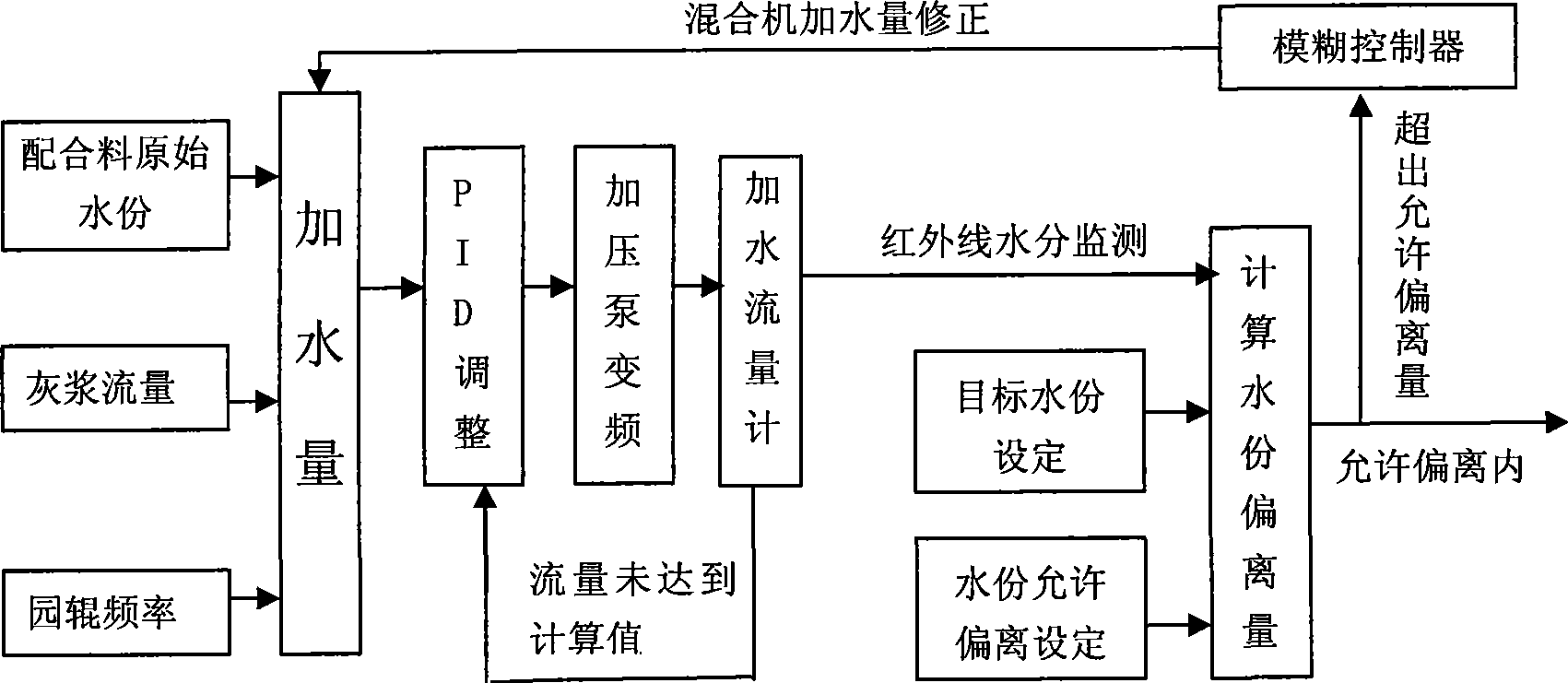

Humidity control method for mixture used in sintering production

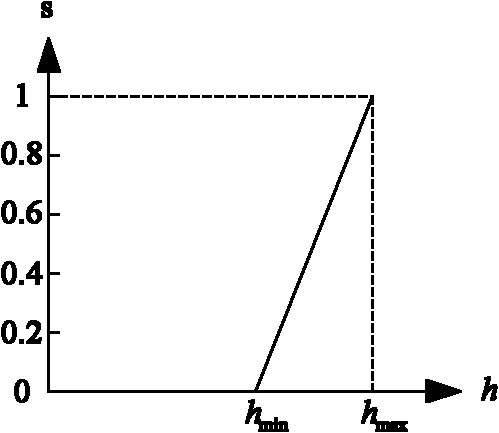

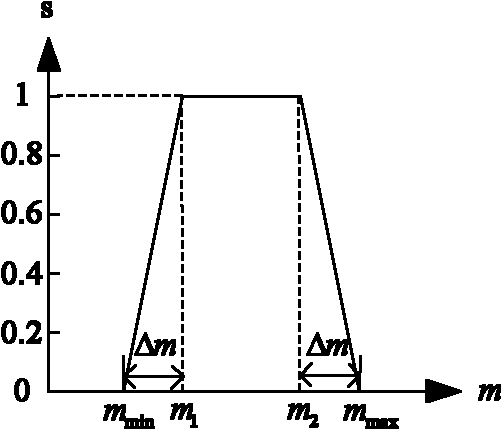

ActiveCN101477378AReduce regulatory disturbancesMeet production requirementsControlling ratio of multiple fluid flowsAdaptive controlAutomatic controlData acquisition

The invention relates to a method for controlling moisture of a mixture for sintering production, and belongs to the technical field of automatic monitoring and intelligent control of mixture moisture. The method adopts a PLC system and a development tool. The control process comprises data acquisition, signal display, data processing, manual input of information, model operation and adjustment for fuzzy control, control quantity output, model self-adapting, and judgment and correction of manual intelligent mode. The method achieves automatic dynamic control of water adding amount of the sintered mixture to make the mixture moisture meet sintering production demand, displays data such as real-time moisture, water adding amount and the like of the material in the production process, and displays operation mode and the like. The method has the advantages that the method is suitable for control of the water adding amount in a mixing process using various sintering production process raw materials, can design an independent control system or can be realized by using the PLC control system based on automatic control of the production process, is limited little by field conditions, is suitable for new projects and reformed projects, and has low cost.

Owner:首钢股份公司迁安钢铁公司

Preparation method of actinidia arguta freeze-dried fruit powder

ActiveCN103431331ANo pollution in the processNo pesticide residueFood shapingFood preparationActinidiaFreeze-drying

The actinidia arguta is a specific precious wild resource. The meat of the actinidia arguta is jade green; the actinidia arguta tastes fine, juicy, fragrant and delicious; the sweetness and the sourness are proper; the nutrition is very rich; the actinidia arguta is a fruit well received by customers and is known as the king of fruits. Wild actinidia arguta resources are readily available in Changbai Mountains, but products of the actinidia arguta are few and cannot meet the consumption demands in different seasons, so that the demands of the customers for wild actinidia arguta products are suppressed. The invention discloses a preparation technology for Changbai-mountain pure natural wild actinidia arguta fruit powder. According to the technology, the freeze-dried fruit powder is prepared by selecting fresh and intact actinidia arguta, washing, smashing, pulping and concentrating the actinidia arguta, adding maltodextrin and performing vacuum freeze-drying on mixed fruit paste. The actinidia arguta freeze-dried fruit powder is high in nutrient value and is convenient food suitable for various groups of people.

Owner:通化百泉参业集团有限公司

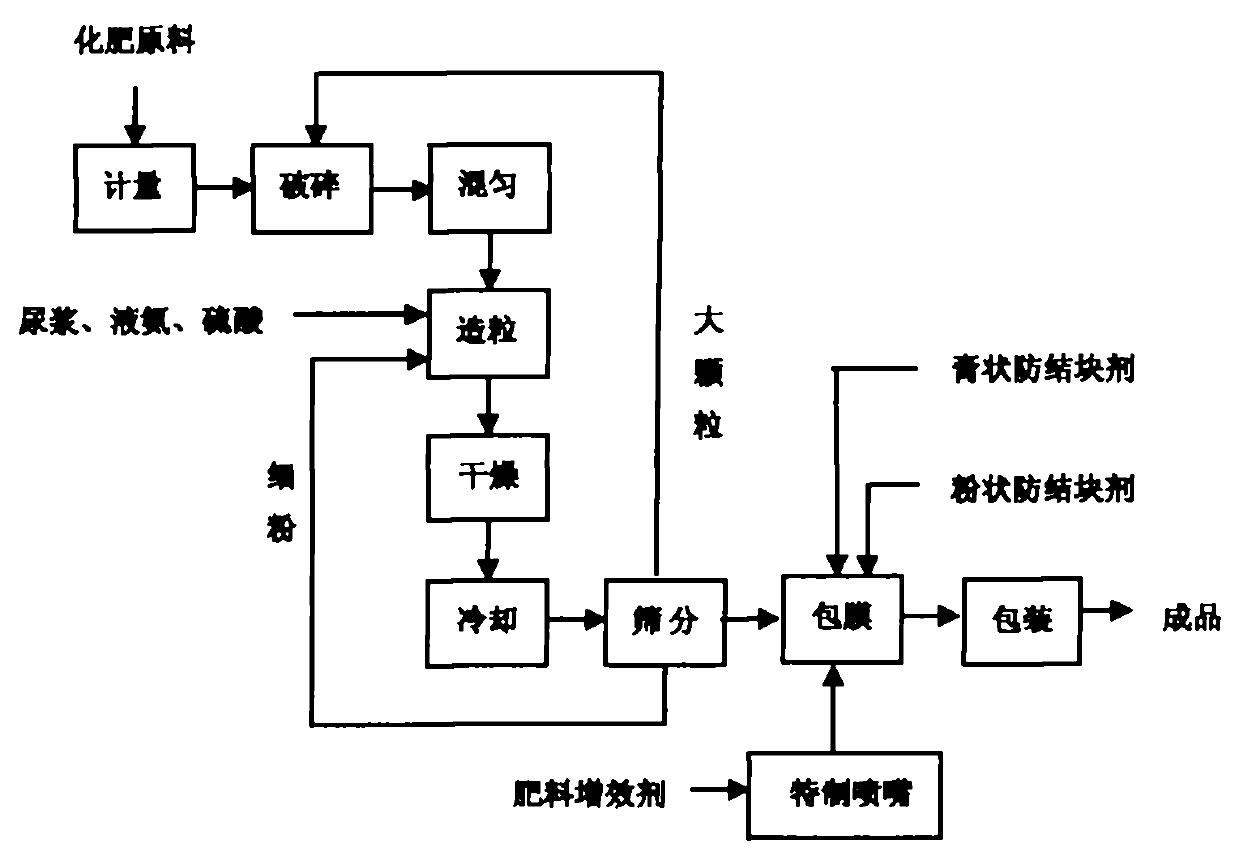

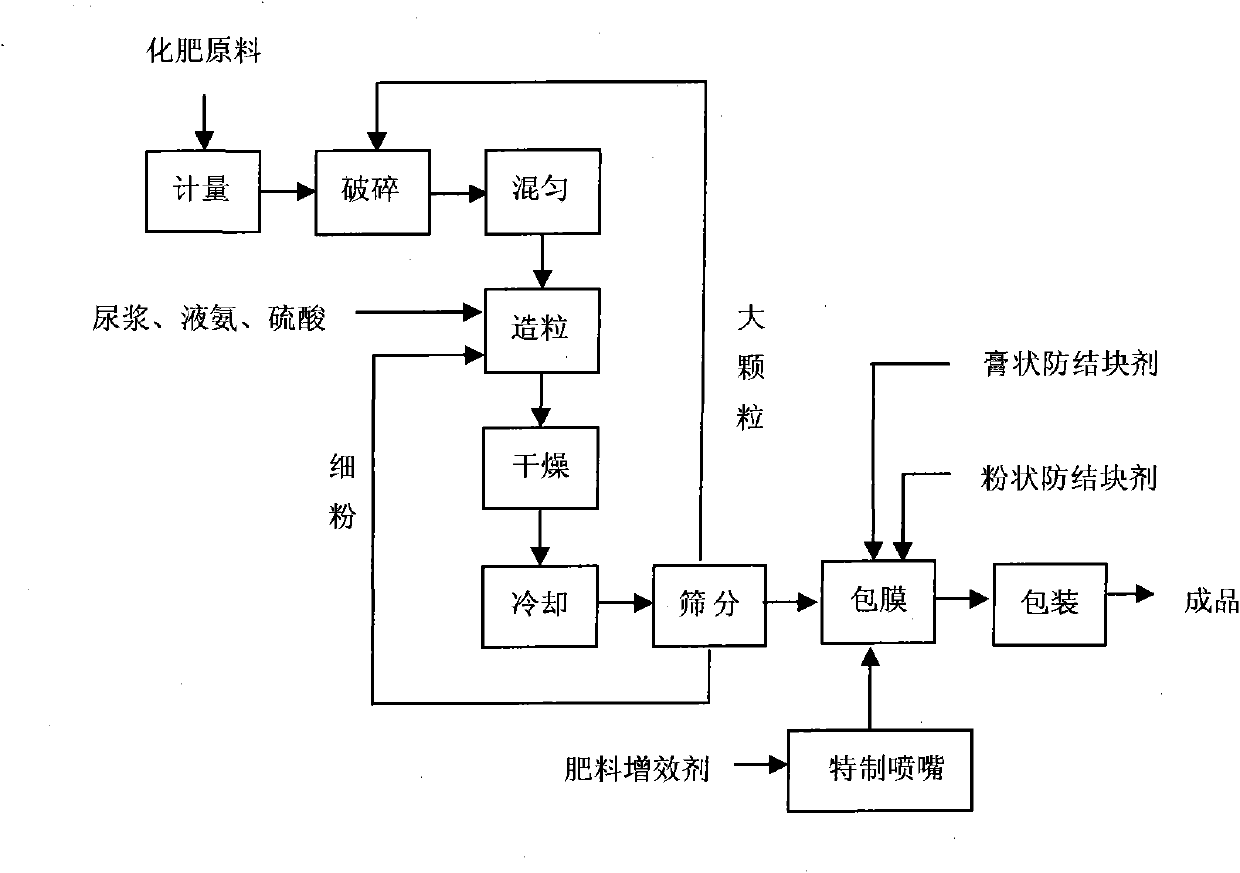

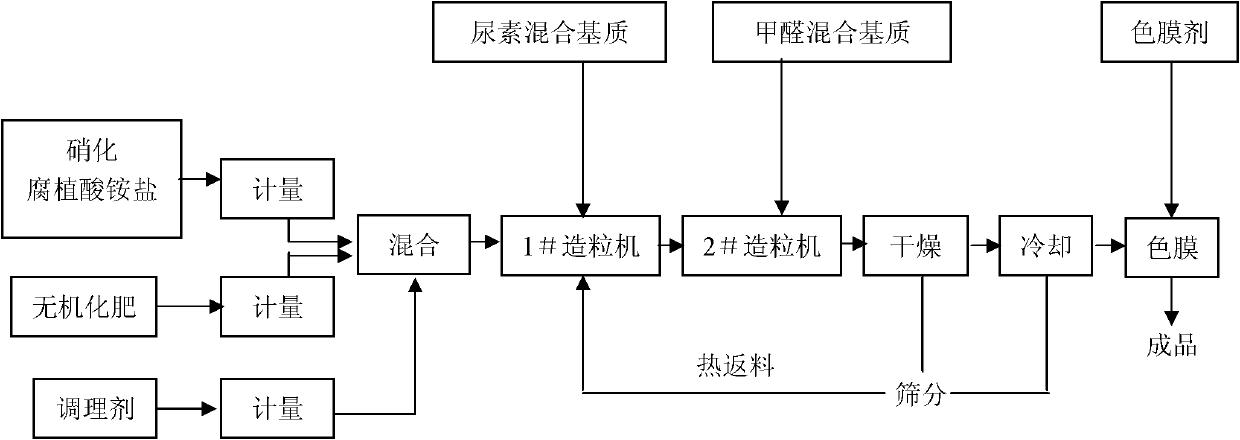

Filler-free synergistic compound fertilizer produced by urine syrup ammonia-acid method and production method thereof

The invention discloses a filler-free synergistic compound fertilizer produced by a urine syrup ammonia-acid method to pelletize and a production method thereof. The production method thereof comprises the following steps: selecting raw materials according to the product formulation, and metering, crushing and evenly mixing the raw materials; adopting the urine syrup ammonia-acid revolving drum pelleting process, carrying out first-segment drying, second-segment cooling and coarse and fine screening on the mixture, and then feeding the screened mixture into a coating machine; utilizing the front end of the coating machine to spray fertilizer synergist by a continuous pulverization coating method, utilizing the middle end of the coating machine to spray pasty anti-blocking agent, and utilizing the tail end of the coating machine to add powdery anti-blocking agent; and adequately stirring and packaging to obtain the finished product. The filler-free synergistic compound fertilizer produced by the pelleting process of the urine syrup ammonia-acid method has small investment, simple operation, low production cost, obvious energy conservation effect, beautiful product appearance, good dissolubility and improved nutrient utilization ratio; and after the filler-free synergistic compound fertilizer is applied to crops, production and income are increased.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

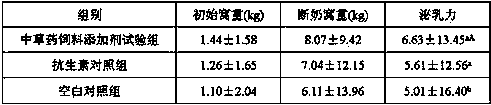

Anti-cracking method for quickly frozen glue pudding

The invention provides an anti-cracking method for quickly frozen glue pudding of low production cost and high product quality. In order to reach the goal, the invention adopts the following technical scheme that: 1-8 percent of DHC-F7101 modified starch and 1-8 percent of trehalose by weight percent are added in glutinous rice flour and are evenly mixed. By adopting the technical scheme, the water retaining capacity and the low-temperature stability of the glutinous rice flour are good, and the damage rate and the frost cracking rate caused by water loss and product temperature fluctuation during processing, storage, logistics and sales of the quickly frozen flue pudding are well improved. The glue pudding is prevented from being cracked, so the production cost is reduced, the return rate is reduced, the product quality is improved and the product shelf life is prolonged.

Owner:河南省淇县永达食业有限公司

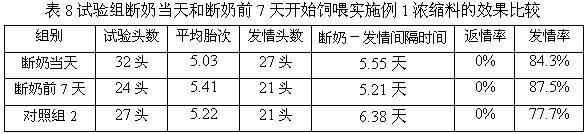

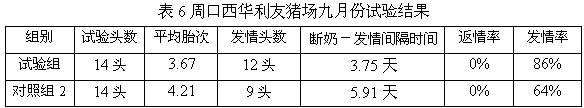

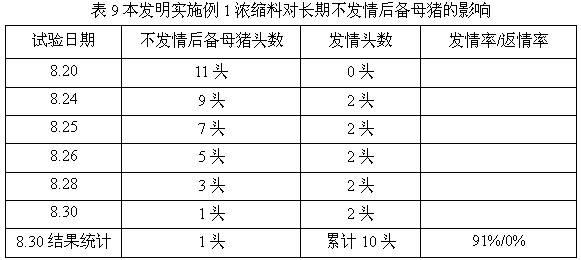

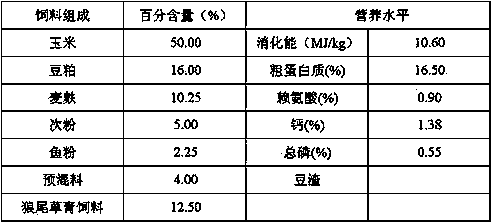

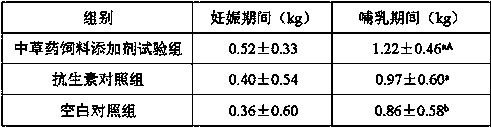

Concentrated feed for barren sows

ActiveCN102038114AChange in adhesionSpeed up dischargeAnimal feeding stuffAccessory food factorsSodium bicarbonateAnimal science

The invention relates to a concentrated feed for barren sows, and per 1,000 parts by weigh of the concentrated feed comprises the following raw materials in parts by weight: 490 to 510 parts of puffed bean pulps, 240 to 260 parts of puffed soybeans, 70 to 90 parts of fish meals, 3 to 5 parts of microbial ecological agents, 15 to 25 parts of glucoses, 35 to 45 parts of mountain flour, 35 to 45 parts of calcium hydrophosphate, 10 to 20 parts of table salt, 3 to 4 parts of sodium bicarbonate, 3 to 7 parts of composite trace elements, 0.6 to 0.7 parts of chromium picolinate, 5 to 8 parts of compound amino acid, 0.006 to 0.01 parts of folic acid, 0.9 to 1.5 parts of boar composite many-dimensions, 0.3 to 0.4 parts of vitamin E, 1 to 2 parts of vitamin C, 0.9 to 1.5 parts of beta-carotene, 1 to 2 parts of flavoring agents, 0.09 to 0.15 parts of phytase, 1 to 2 parts of ethoxy quinoline, 2 to 3 parts of choline chloride, and the balance of carriers. In case of adding 30 percent of the concentrated feed into daily fodders for sows, the interval time from ablactation to oestrus can be shortened, thereby improving the oestrous rate, litter size and the like of the sows.

Owner:河南雄峰科技股份有限公司

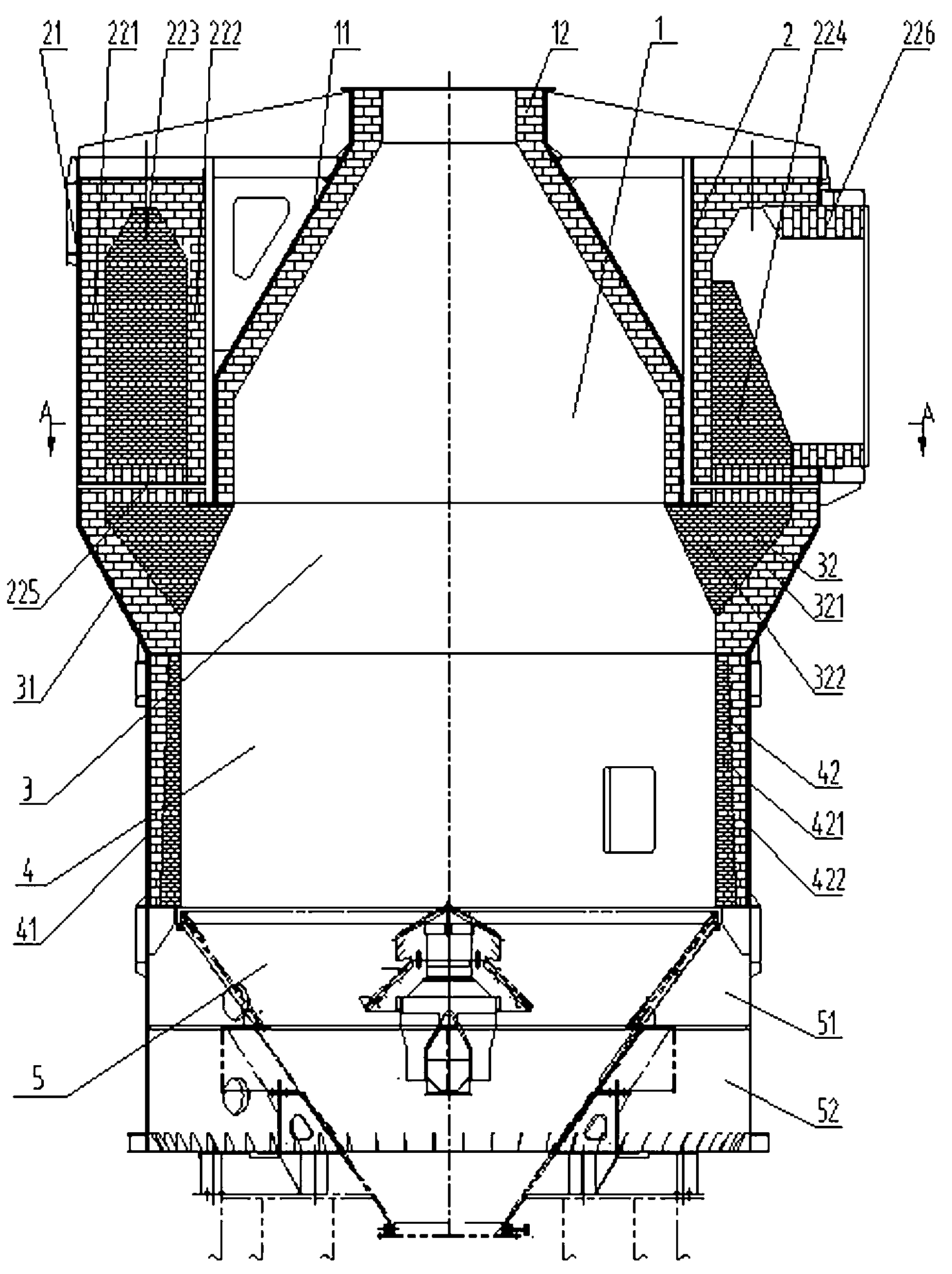

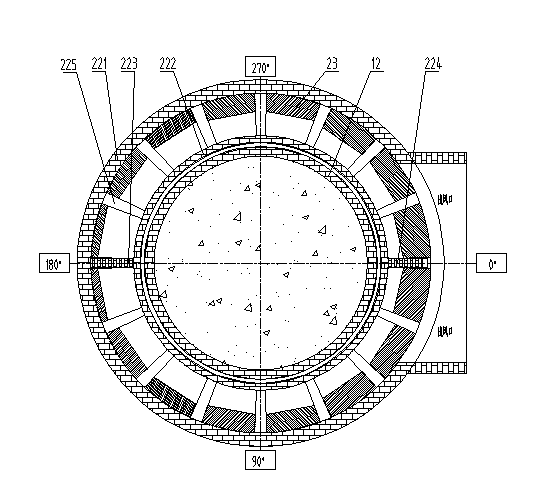

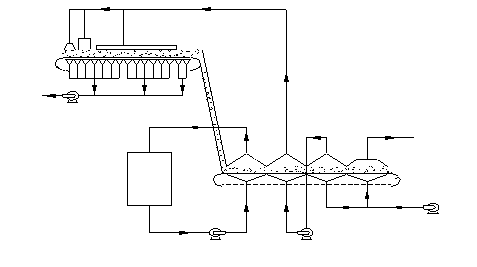

Sintered ore cooling furnace

ActiveCN103234361AAvoid volatilitySimple structureIncreasing energy efficiencyHandling discharged materialCounter flowMaterial distribution

The invention discloses a sintered ore cooling furnace device. The device is composed of a pre-storage area, an annular air flue area, a chute area, a cooling area and an air chamber. High-temperature sintered ores are continuously and evenly distributed into a cooling furnace for cooling through a charging port above the pre-storage area by a material distribution device, high-temperature sintered ores are subjected to counter-flow heat exchange with low-temperature air blown from the bottom of the furnace in the cooling area of the cooling furnace, sintered ores are cooled to below 180 DEG C, low-temperature ores are discharged by a discharging device, the low-temperature air is heated to about 600 DEG C through counter-flow heat exchange and enters a waste heat recycling system through an air outlet, and hot air and hot sintered ores are effectively sealed inside the cooling furnace in the whole process. By the aid of the device, on the premise that the quality of sintered ores is guaranteed or improved and the return fine rate is reduced, the efficiency of recycling of waste heat of sintered ores is improved to the maximum extent.

Owner:中信重工工程技术有限责任公司

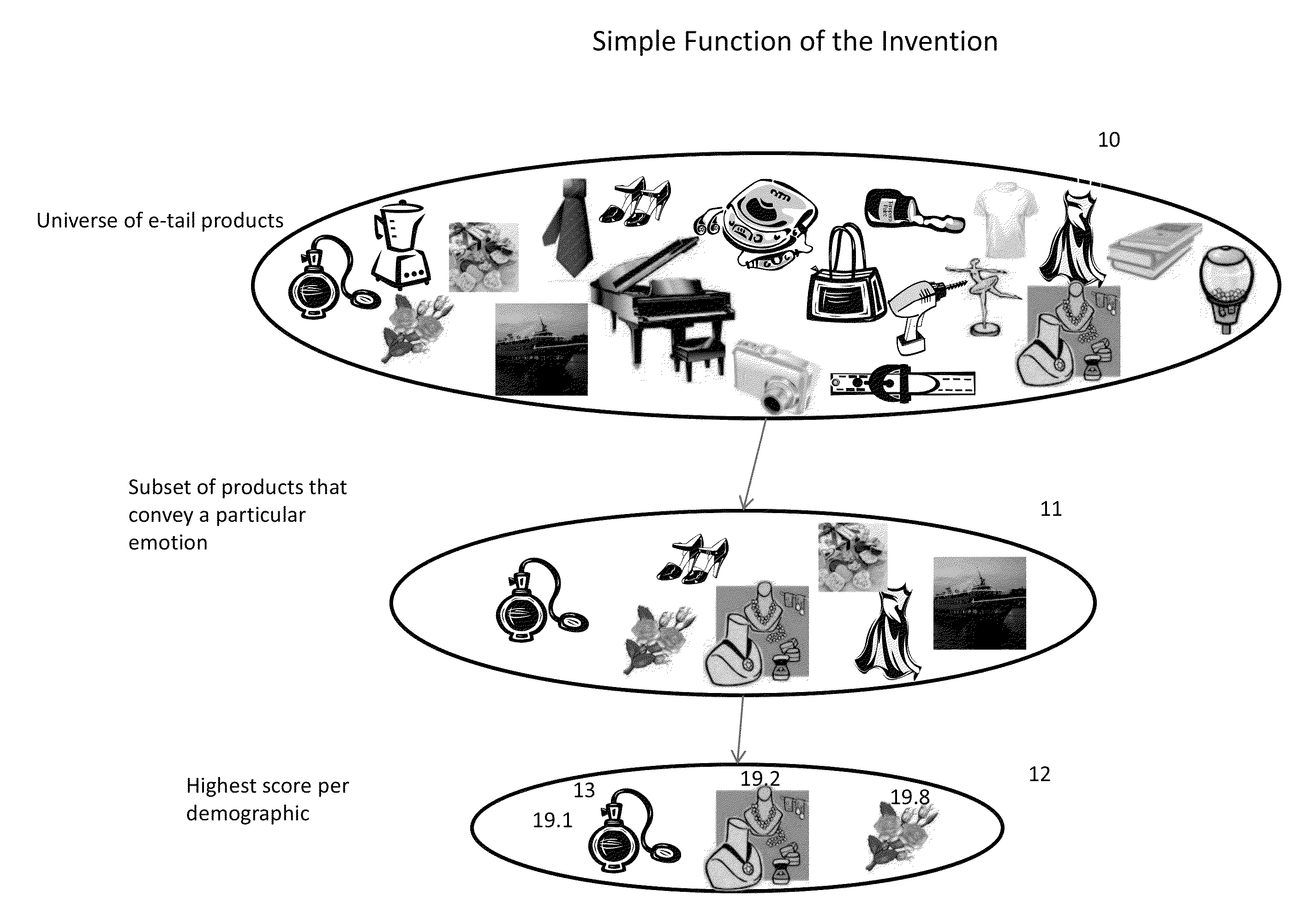

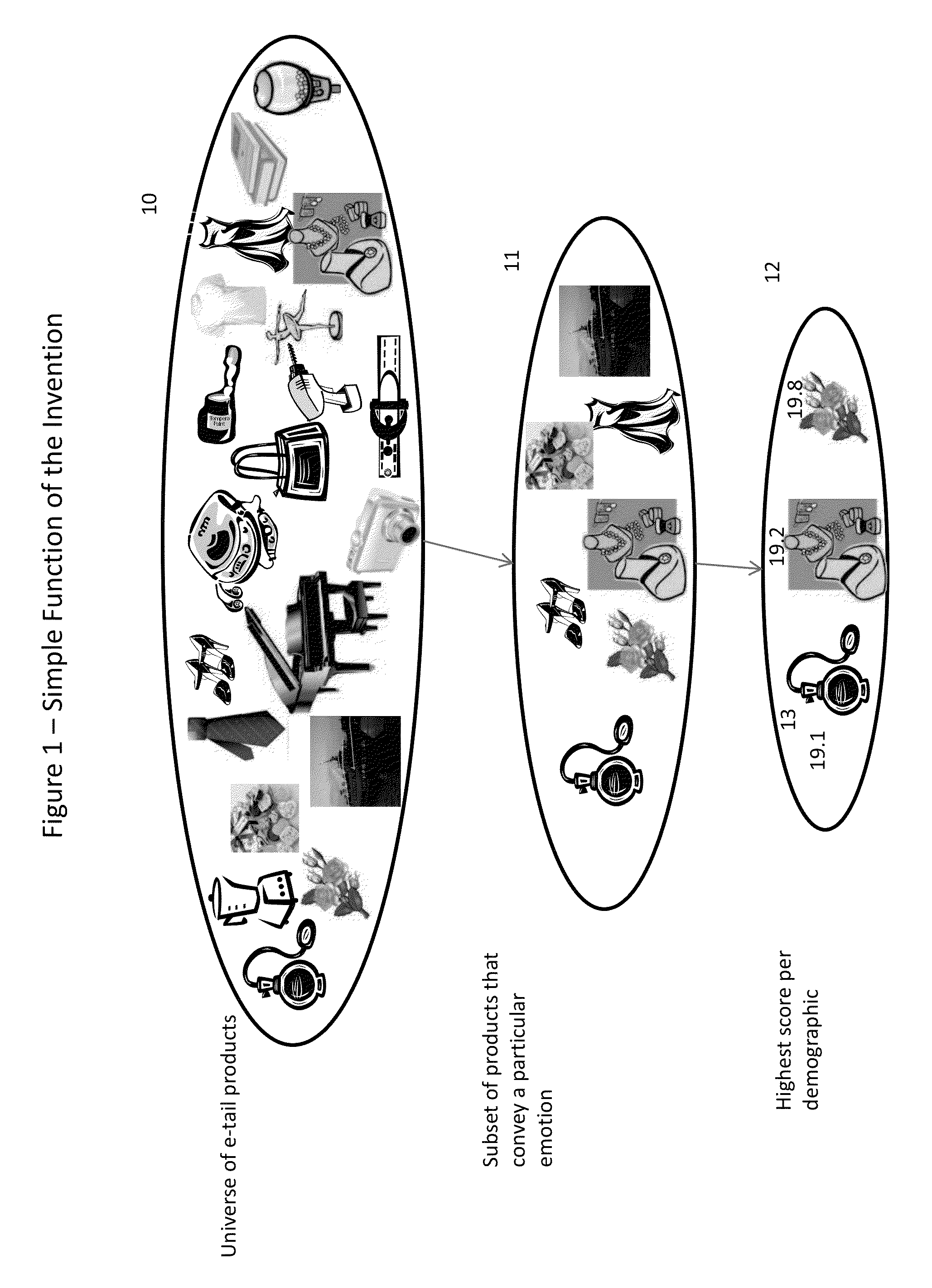

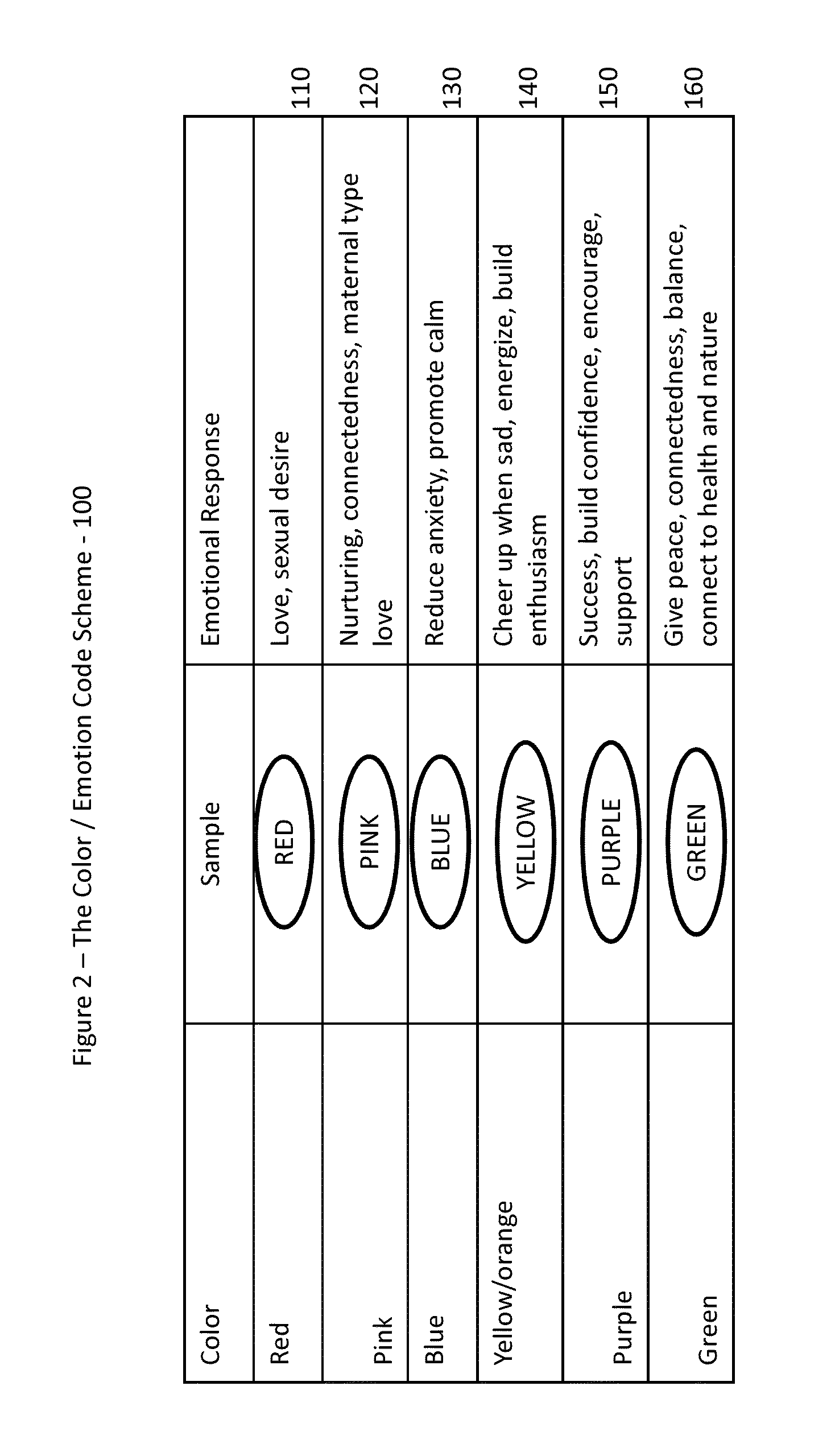

System and method to evaluate, present, and facilitate the advertisement and purchasing of products and services based on the emotion evoked in a recipient upon receipt of the product or service

InactiveUS20140108135A1Simplify a very common purchase desireLess interestAdvertisementsBuying/selling/leasing transactionsRankingPurchasing

A method of quantifying and attaching the emotional state of receiving a product or service purchased online so that a buyer who lacks history with a particular product or service can be assured of satisfaction with by that product or service because of emotional satisfaction ratings from all purchasers of the same demographic, which also provides advertisers great feedback on the likelihood of advertising of that product to that demographic leading to a product purchase so therefore generating an advertising fee based on the ranking of emotional state change each product / service provides the end user.

Owner:TECH 4 PROFIT

Adhesive for granular fertilizer and preparation method for adhesive

The invention provides an adhesive for a granular fertilizer and a preparation method thereof. The adhesive comprises the following components in parts by weight: 35 to 45 parts of starch, 1 to 5 parts of phosphate, 0.1 to 3 parts of an oxidant, 0.1 to 1 part of a coupling agent and 40 to 60 parts of water. The preparation method comprises the following steps of: adding the water into the starch to be in a slurry state, rising the temperature to be at 40 to 60 DEG C, adjusting the pH value of a system to be at 8 to 11, adding 1 to 5 parts of the phosphate and 0.1 to 3 parts of the oxidant for reaction for 10 to 30min, adding 0.1 to 1 part of the coupling agent for reaction for 15 to 60min to obtain modified starch emulsion, performing pregelatinization reaction and drying on the modified starch emulsion by a double-roller dryer to obtain modified starch blocks, and grinding and screening to obtain the adhesive with certain granularity. The adhesive is used for preparing the granular fertilizer is high in adsorption activity, high in adhering force, high in granulation balling rate and low in return rate; obtained granules are high in intensity; and a phenomenon that the granular fertilizer is easy to smash during transportation can be solved.

Owner:广西农垦明阳生化有限公司

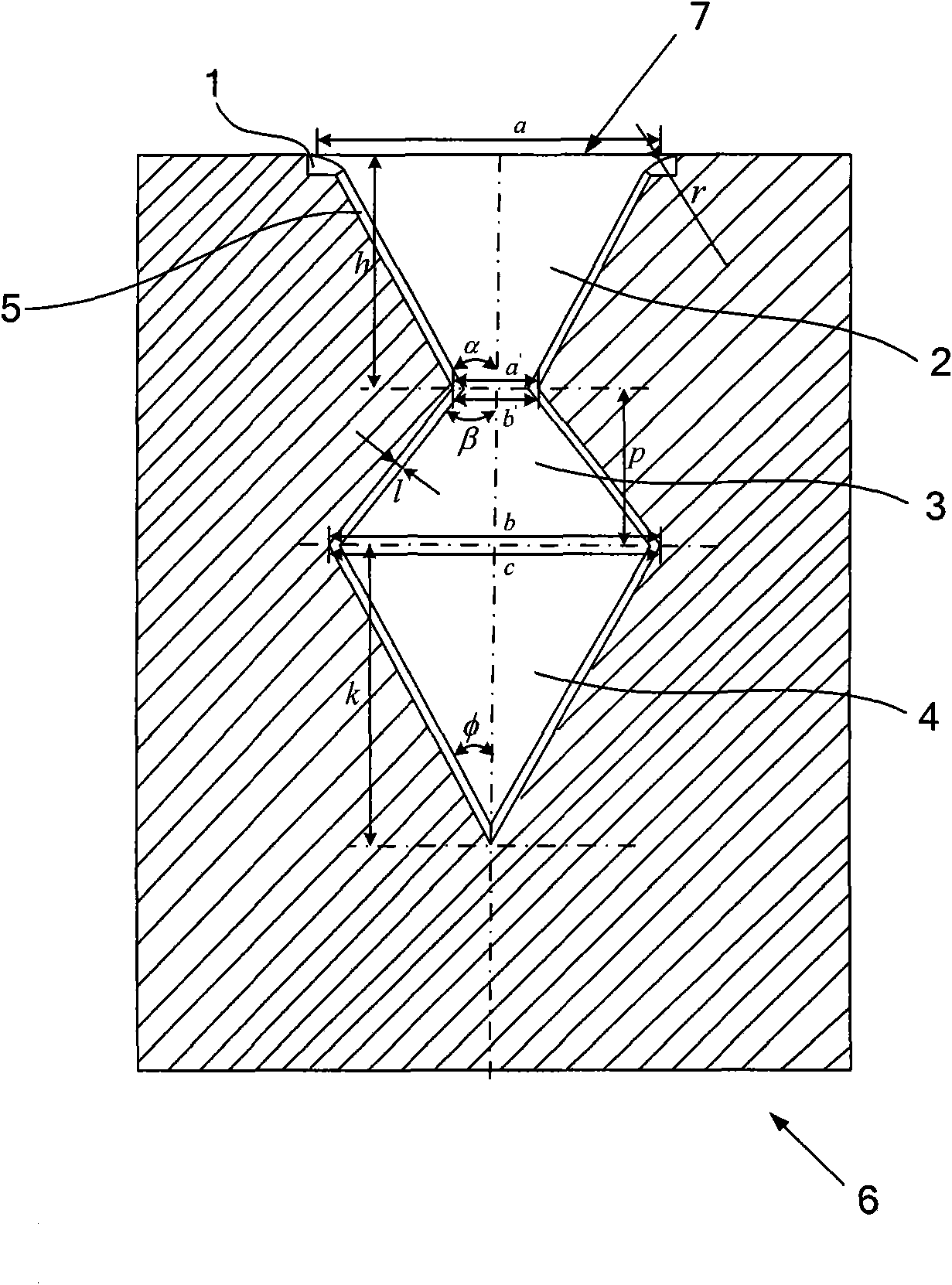

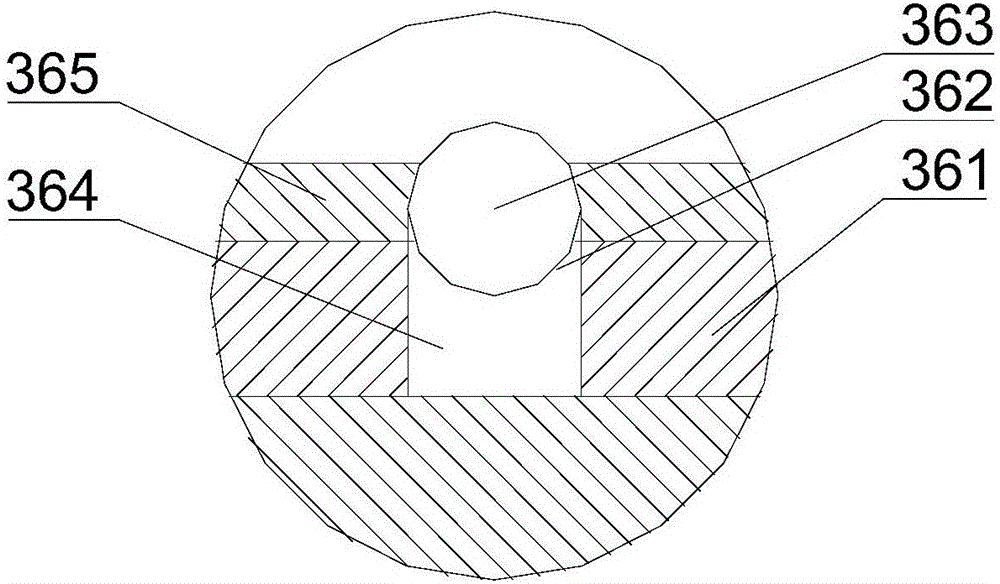

Millimeter wave blackbody radiation calibration source with biconical cavity serial structure

InactiveCN101666684AReduce return rateImprove temperature consistencyRadiation pyrometryAbsorption ratioBlack-body radiation

The invention discloses a millimeter wave blackbody radiation calibration source with a biconical cavity serial structure, which is cylindrical as a whole and has a cylindrical structure made of metalmaterial. An integrated cavity structure connected in series by a lip, a circular cavity, a transition section and a conical cavity which are all in rounding off from top to bottom is arranged in thecenter of a cylinder, and the opening surface of the cavity is arranged in the center of the top of the cylinder. A cavity inner wall wave-absorbing material coating is made of wave-absorbing material coated on the inner wall of the cavity according to the required thickness. The invention lowers the probability that radiation energy incident from the opening surface is reflected and returned from the opening surface during transmission in the cavity so that the radiation energy is reflected many times in the cavity and absorbed. Through controlling the coating depth, the invention solves theproblem that the consistency of temperatures of blackbody calibration sources is influenced due to overlarge coating depth and poor thermal conductivity while improving the absorptivity of the cavityinner wall of the blackbody radiation calibration source to the radiation energy.

Owner:BEIHANG UNIV

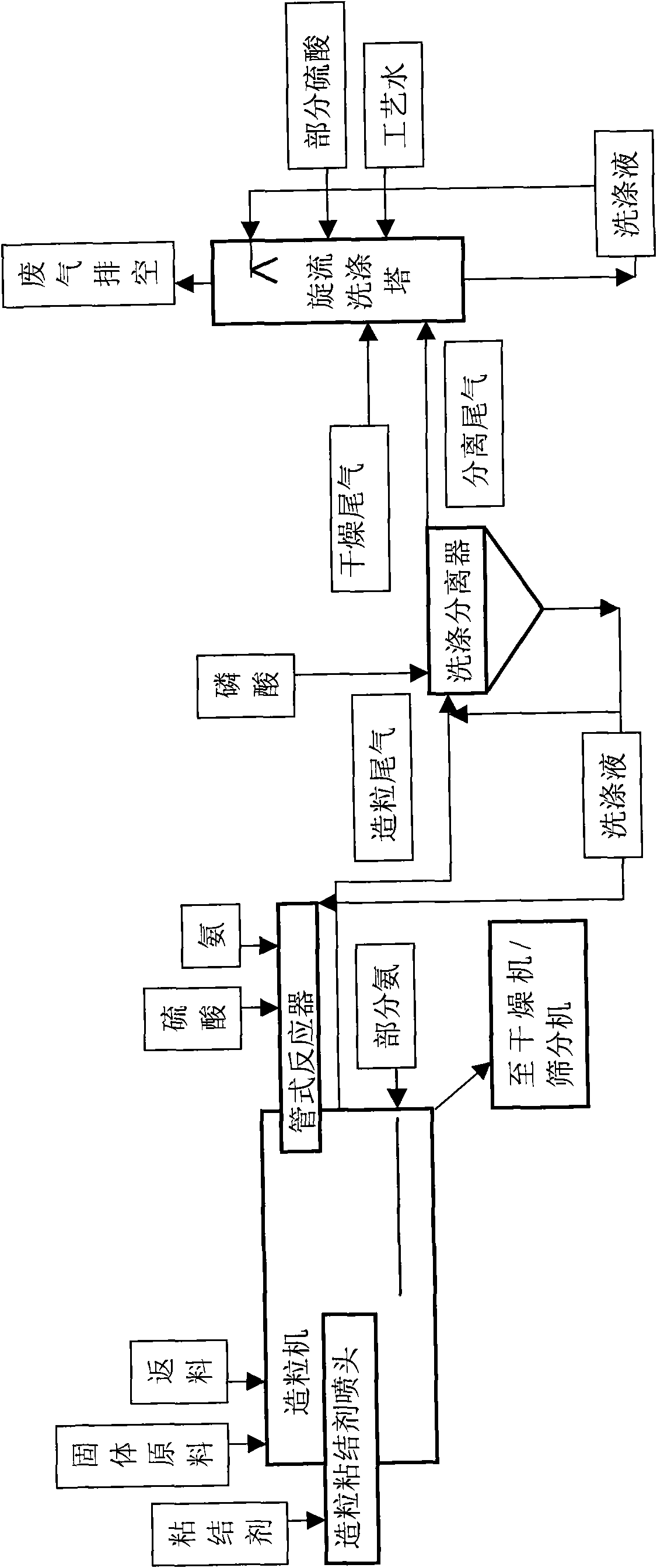

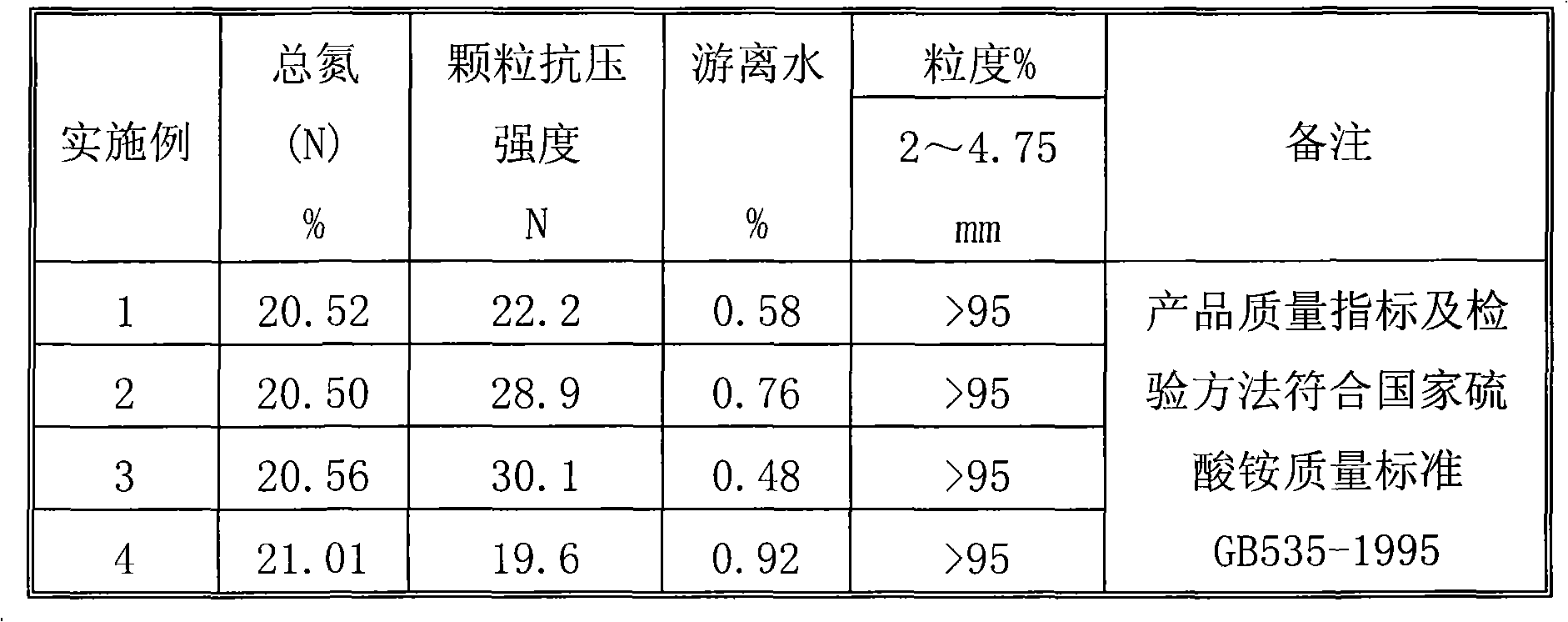

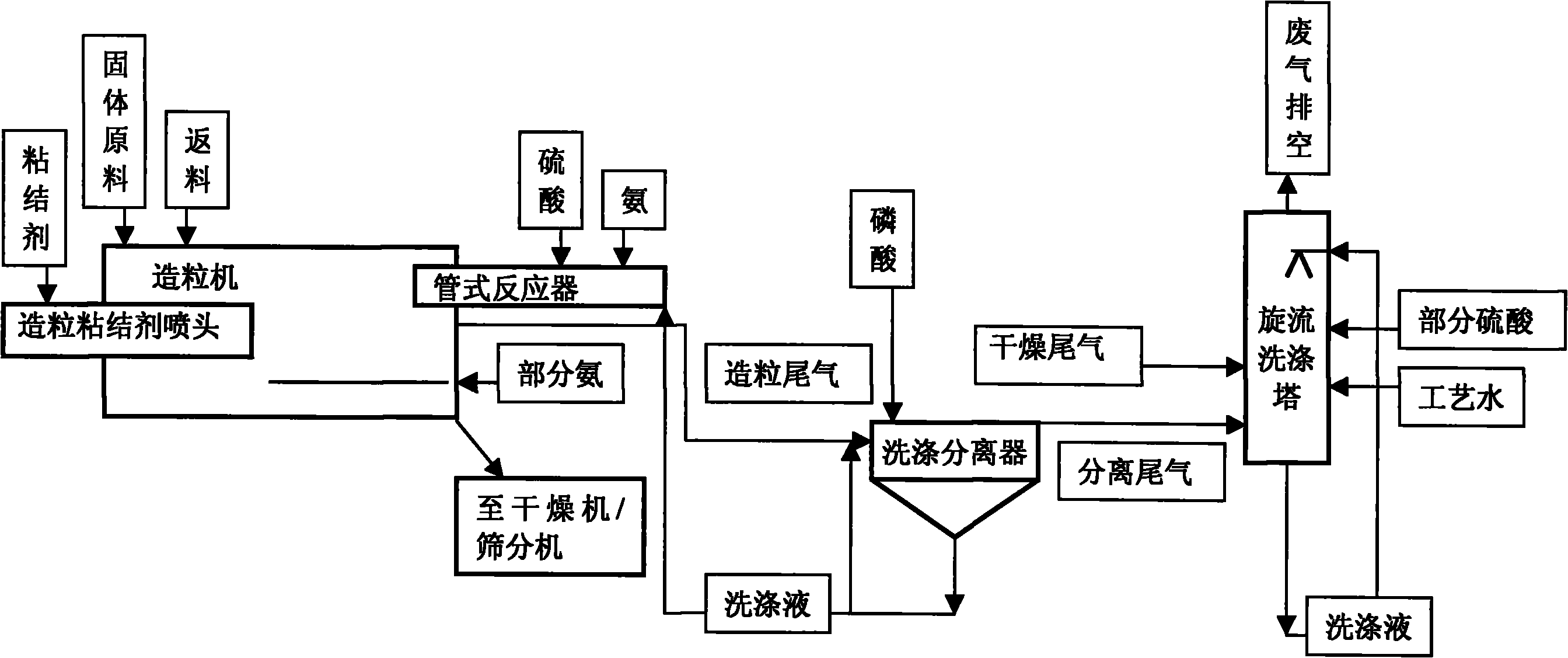

Preparation method of large-particle ammonium sulfate

InactiveCN101850989AReduce reaction loadControl water balanceAmmonium salt fertilisersAmmonia compoundsSlurryWater balance

The invention relates to a preparation method of large-particle nitrogenous fertilizers, in particular to a preparation method of large-particle ammonium sulfate, which comprises the following steps: firstly, adding 25-60 parts by weight of sulfuric acid, 7.6-16.5 parts by weight of ammonia and washing liquid from a gas-liquid separator to a tubular reactor for neutralization reaction; spraying high-temperature slurry formed after the reaction into a pelletizer; wherein, simultaneously, a solid material bed which comprises 20-70 parts by weight of solid material and rolls together with returns in the pelletizer can be installed in the pelletizer; spraying a pelleting binder through a spray nozzle and spraying the ammonium through an ammonium spraying shaft for pelleting to form wet solid material; fractionating the dried material after entering a sieving machine to sieve qualified particles and then cooling the particles to obtain the product. The invention reduces the reaction load of the tubular reactor; the system returns ratio is reduced, and the water balance is easier to control; simultaneously, the production cost is reduced, and recycling and the high-value utilization of industrial byproducts are realized by utilizing by-product powdery ammonium sulfate.

Owner:河北天人化工股份有限公司

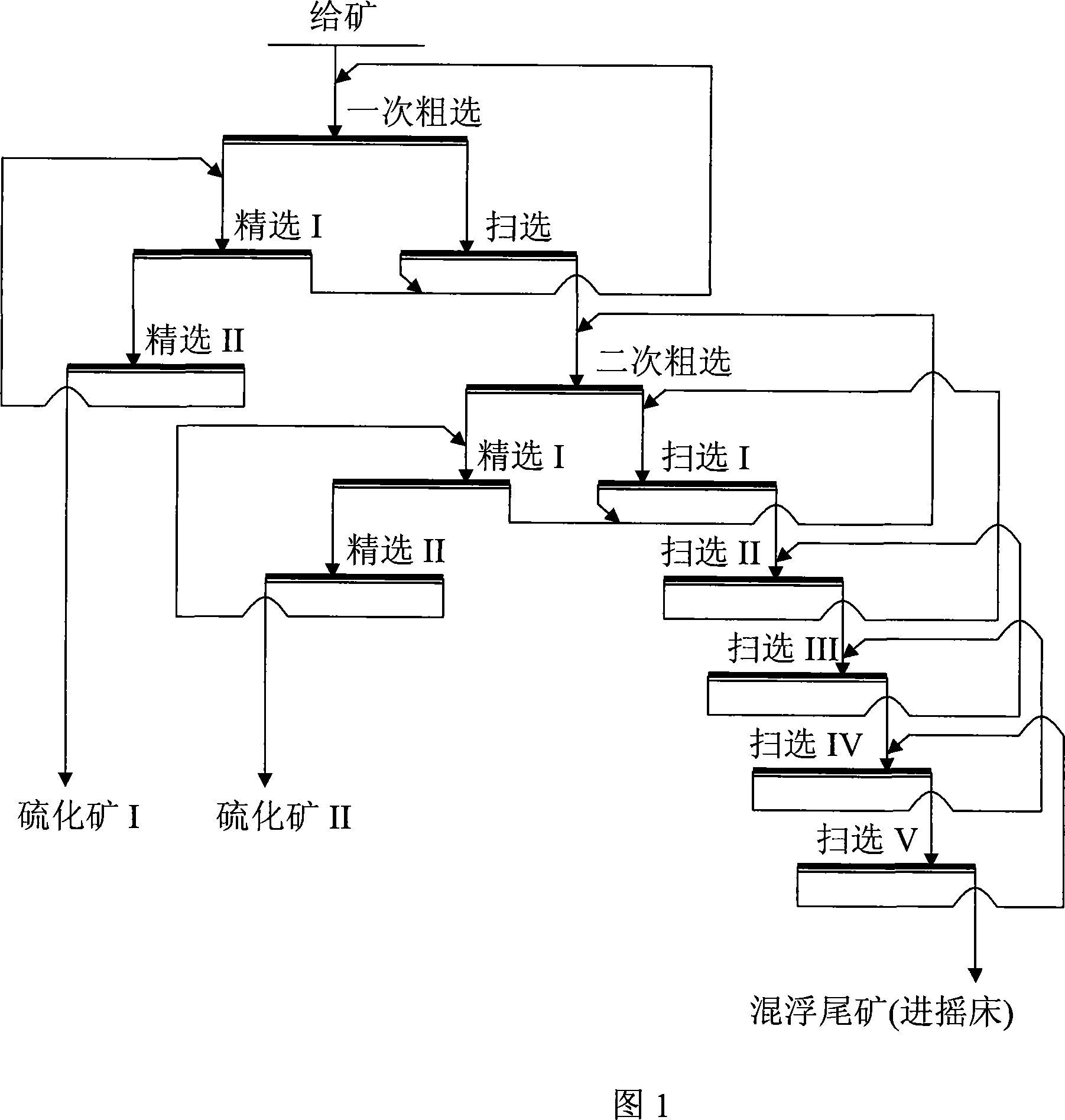

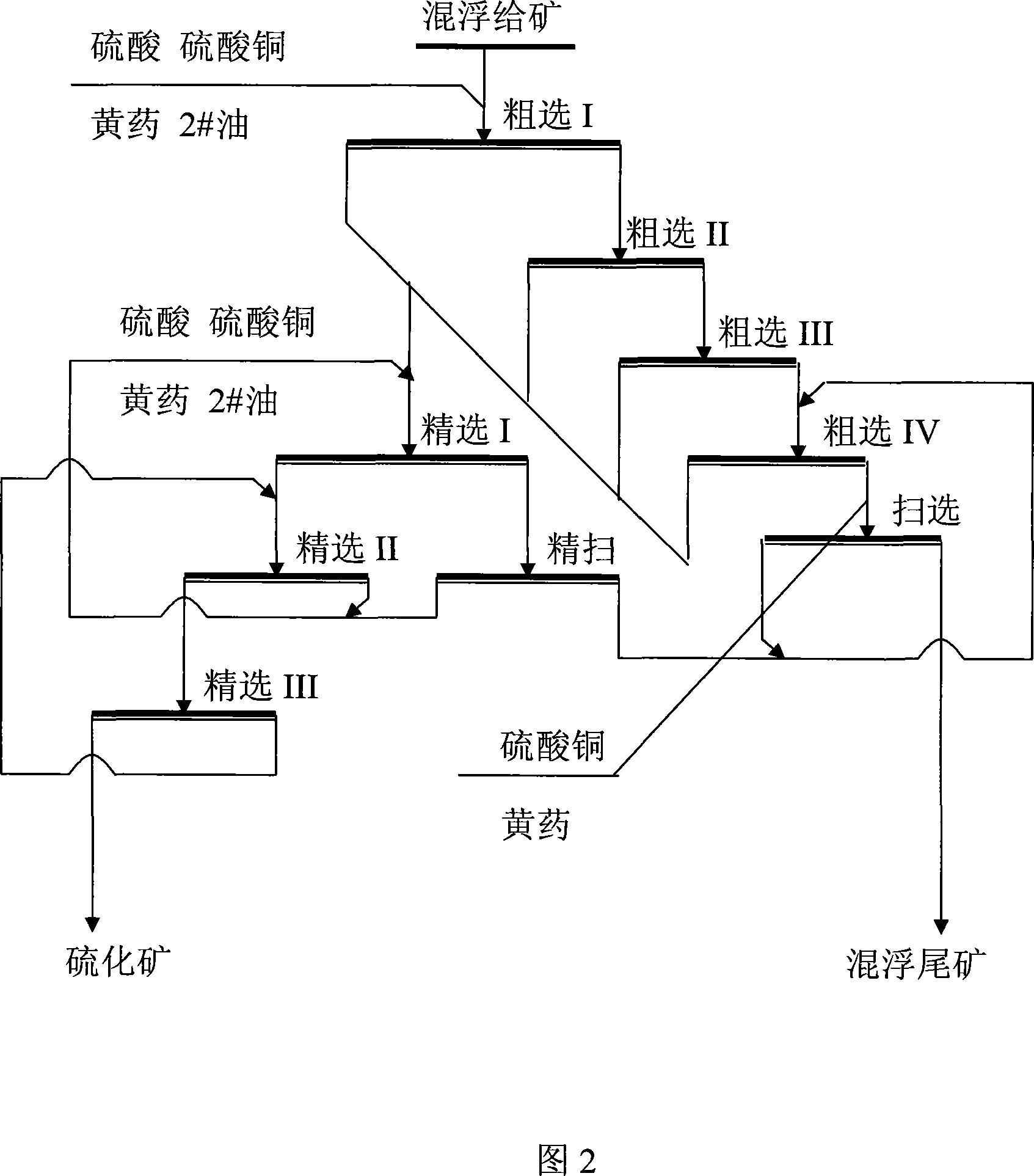

Novel technics of rough-flotation high concentration high-efficient flotation

The present invention relates to bulk floatation process of different kinds of sulfide mineral. The bulk floatation process includes four times of roughing to separate out the floatation tailing, collecting the foamed concentrate from the four times of roughing and concentrating. During the four times of roughing, the floatation strength, the floatation agent amount and the floatation period are increased gradually, so as to float out different floatable minerals in different floatation steps. The bulk floatation process has enhanced separation between the sulfide minerals and the oxide minerals, raised metal sulfide mineral recovering rate, raised floatation efficiency and capacity of ensuring the recovery of cassiterite in the post operation. The foamed concentrate are further separated in three times of concentration and once scavenging to decrease the entrained cassiterite in the sulfide minerals and raise the quality of sulfide concentrate.

Owner:广西华锡矿业有限公司铜坑矿业分公司

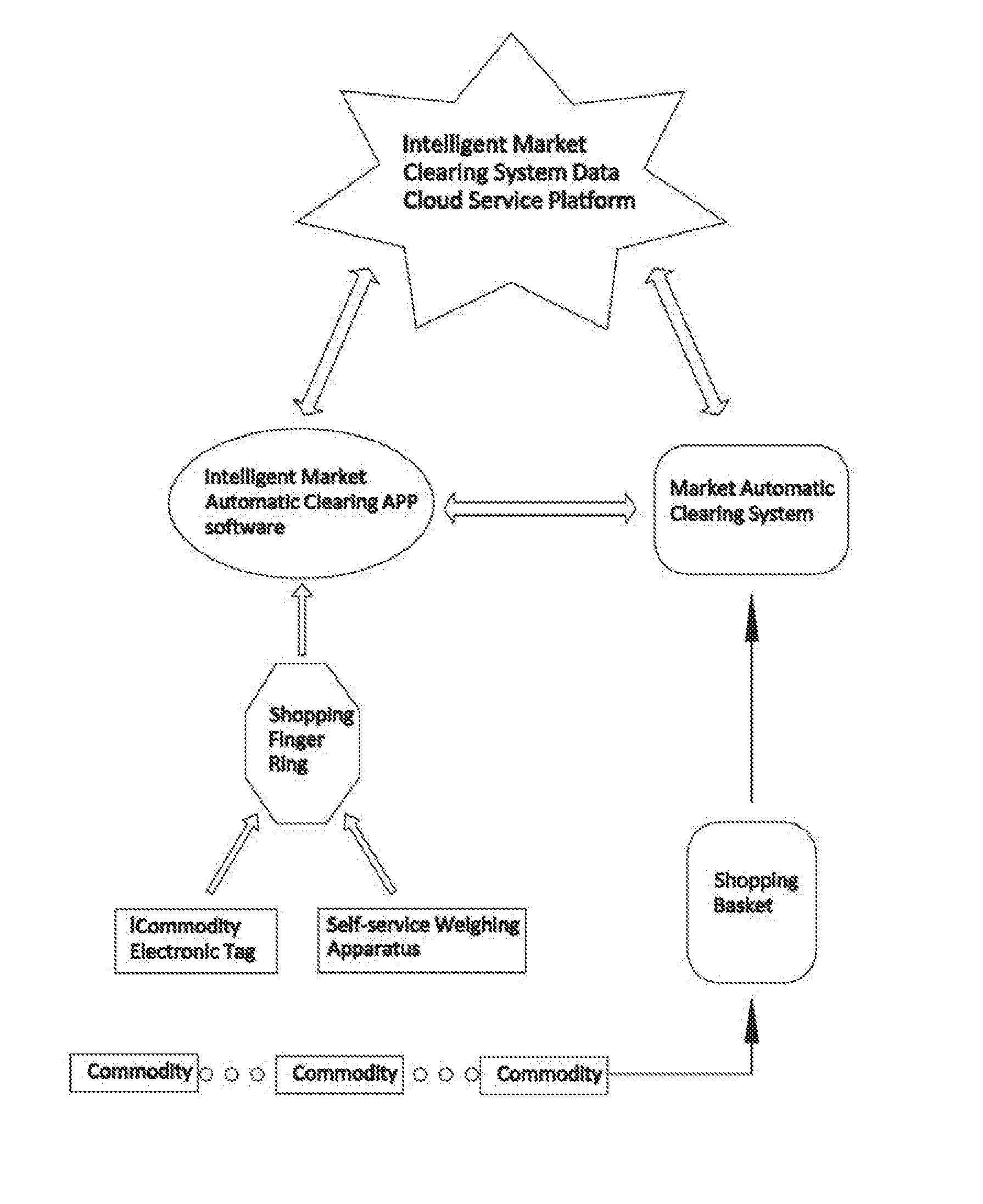

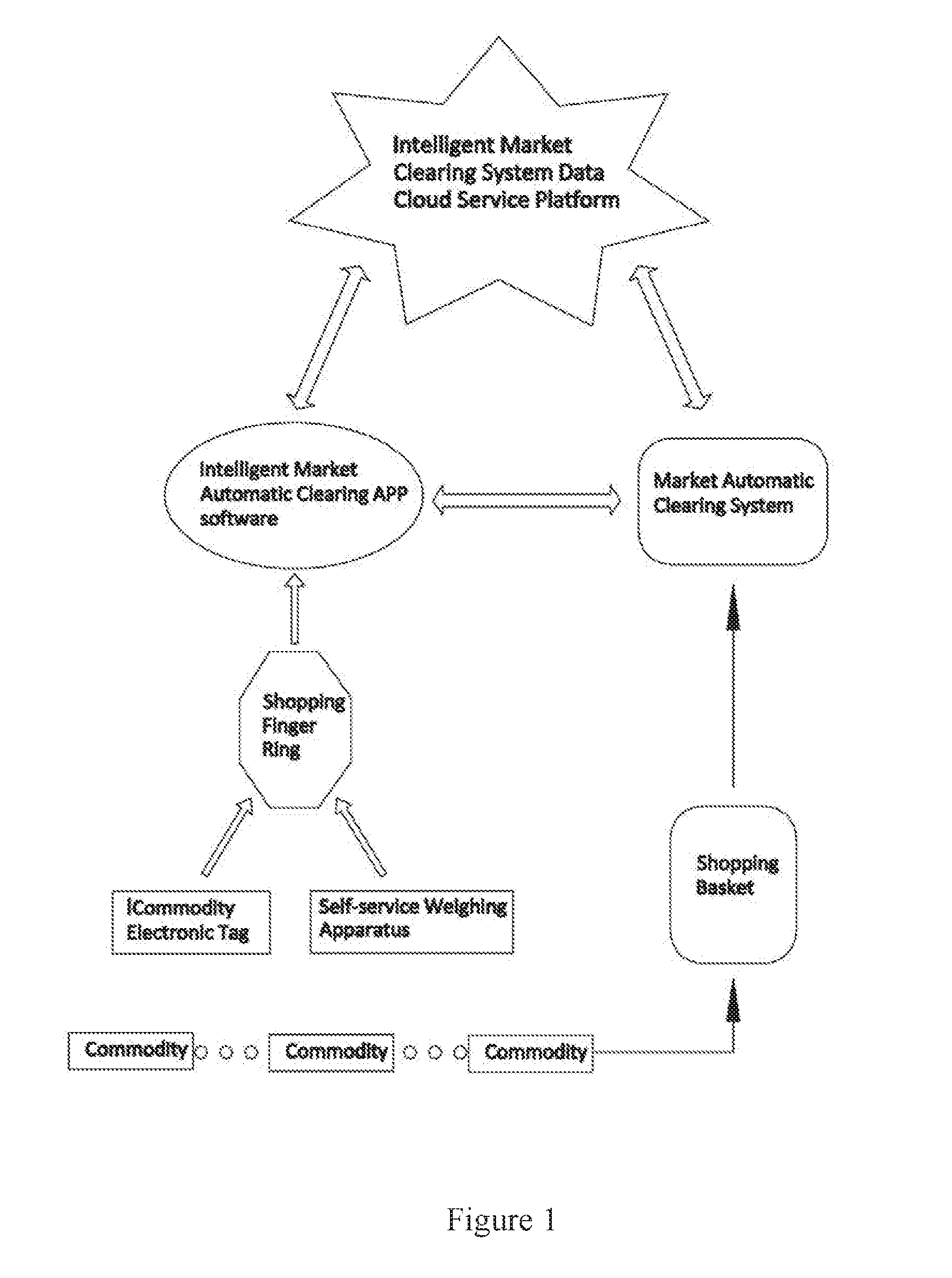

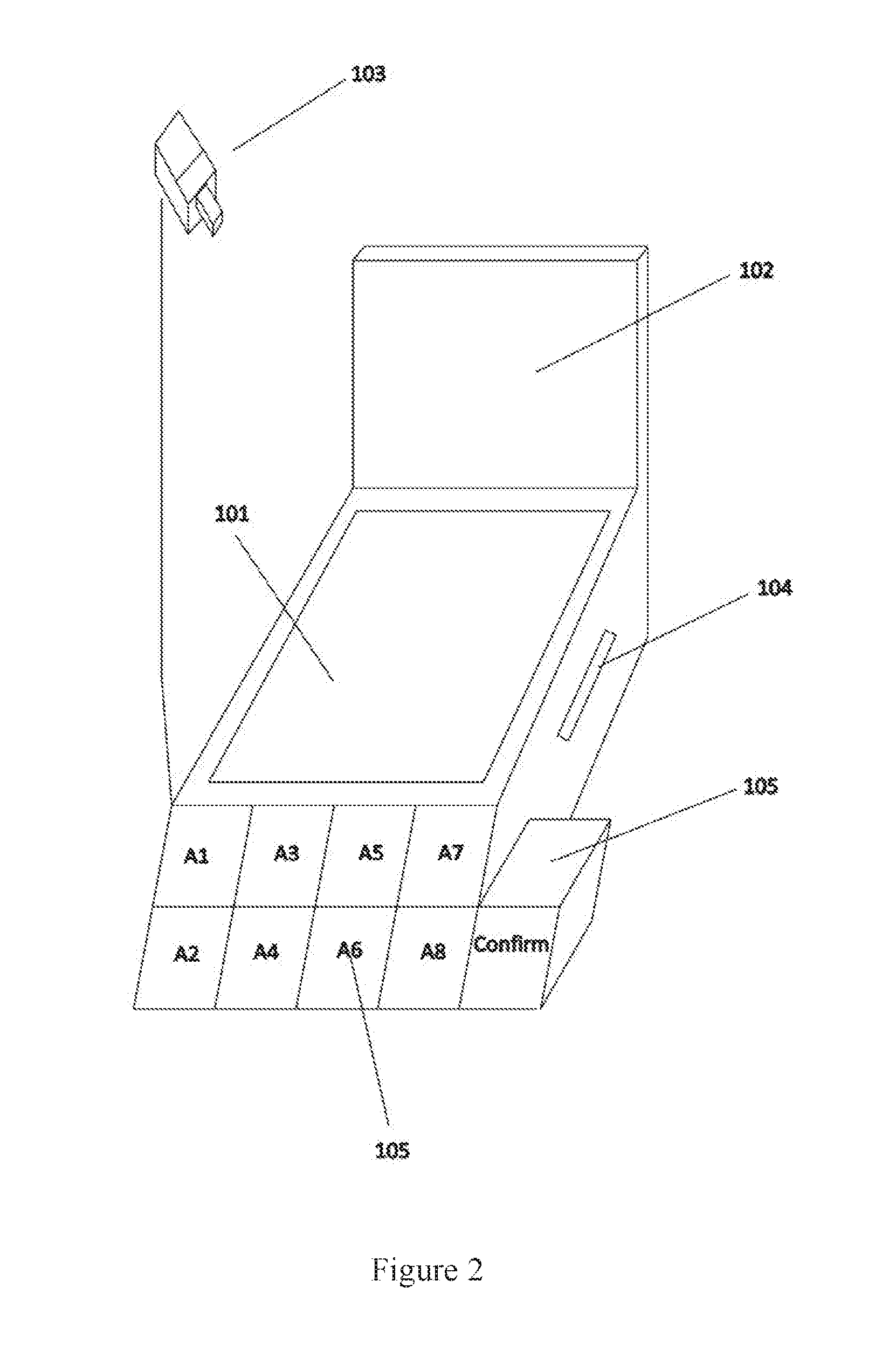

Intelligent market automatic clearing system and implementation method therefof

ActiveUS20170046767A1Relieve management pressureReduce labor costsCash registersPayment architectureShopping basketMarket place

The present invention relates to an intelligent market automatic clearing system comprises a device part and a system part, wherein the device part comprises commodity electronic price tags, a self-service weighing apparatus, a shopping ring, a mobile phone, a shopping basket and a market automatic clearing device. The system part comprises intelligent market automatic clearing APP software, an intelligent market clearing system and an intelligent market clearing system data cloud service platform. The market automatic clearing device comprises a shopping basket moving frame, a visual recognition apparatus, a mechanical commodity picking apparatus, a bar code and RFID recognition apparatus table, an anti-theft decoding apparatus, a mechanical packaging apparatus table, a clearing table, an anti-theft detection door and an automatic channel door.

Owner:XIAO DAN

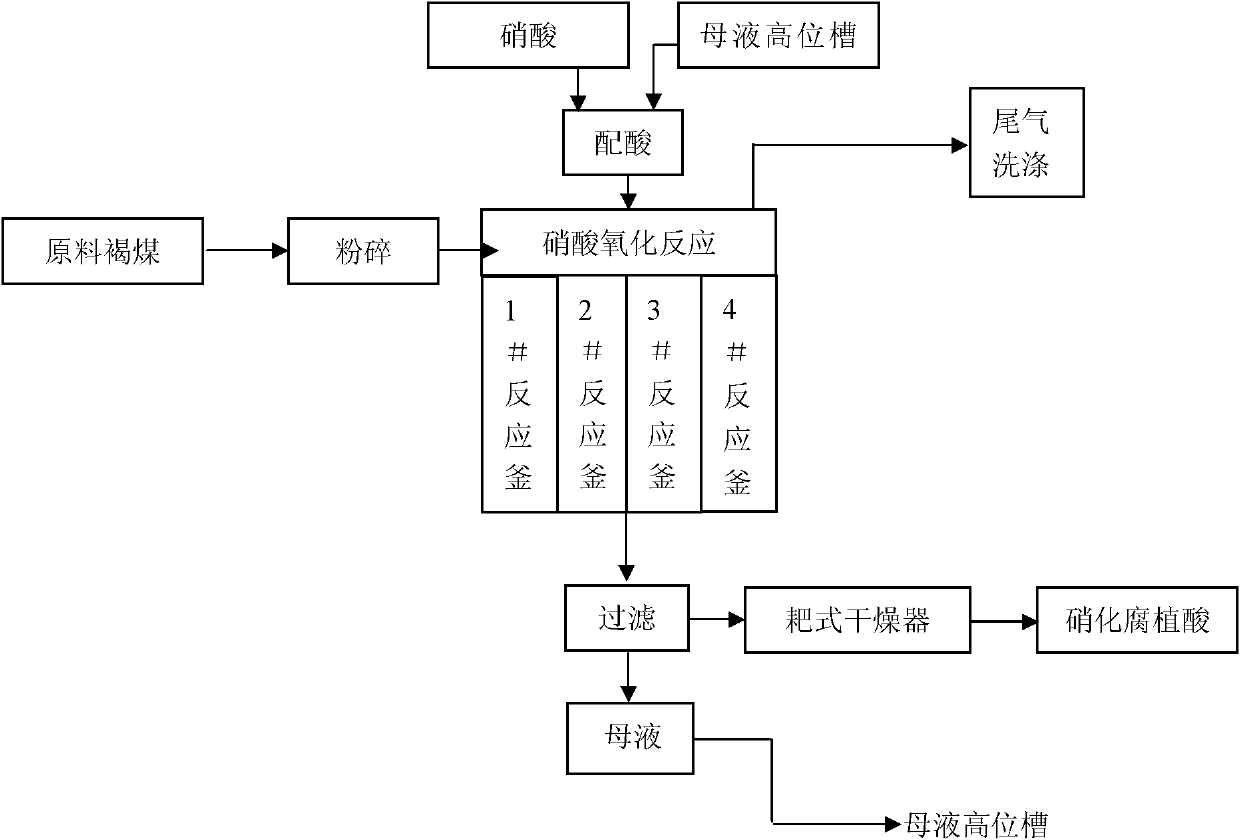

Preparation process for organic-inorganic compound fertilizer

InactiveCN101948349ASave resourcesIncrease profitFertiliser formsFertilizer mixturesOrganic matterOrganic inorganic

The invention discloses a preparation process for an organic-inorganic compound fertilizer. The preparation process comprises the following steps of: after reacting nitric acid with lignite, obtaining lignite nitrification humic acid-containing organic matter precipitate by filtering and separating; matching the lignite nitrification humic acid with an inorganic fertilizer; respectively preparing into lignite nitrification humate-urea secondary fertilizer granules and lignite nitrification humate-formaldehyde sustained-release composite granules; and obtaining the organic-inorganic compound fertilizer. A humic acid raw material is extracted by oxidizing the lignite with the nitric acid, so that the humic acid and fulvic acid are improved remarkably; and therefore, the production cost of a humid acid fertilizer can be reduced and resource is saved. The organic-inorganic compound fertilizer can improve soil nutrient status and granular structures and meets the growth demand of crops.

Owner:NORTHWEST A & F UNIV +1

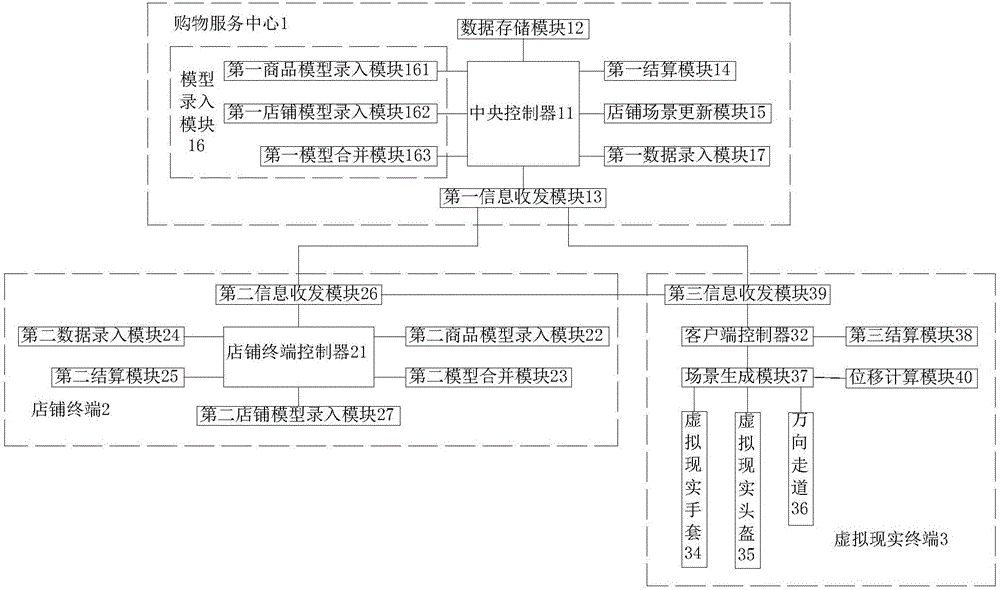

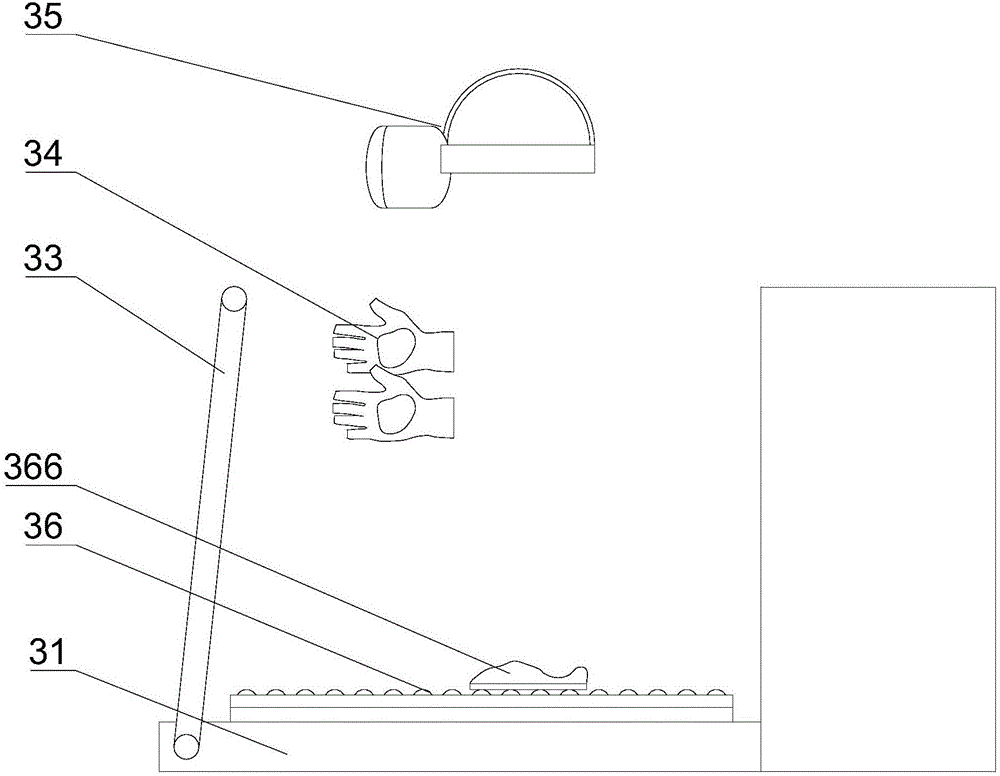

E-commerce display system based on 3D display

ActiveCN106327299AConvenient shoppingImprove experienceBuying/selling/leasing transactionsComputer graphics (images)E-commerce

The invention provides an E-commerce display system based on 3D display. The E-commerce display system comprises a shopping service center and at least one virtual reality terminal; a data storage module, a first information receiving-transmitting module, and a first settlement module are connected to the central controller; a scene generation module in the virtual reality terminal is in wireless connection or in wired connection with a virtual reality glove, a virtual reality helmet and an universal walkway; the scene generation module, a third settlement module, and the third information receiving-transmitting module are connected to a client terminal controller; and a handrail, the universal walkway, the scene generation module and the settlement module are installed on an installation rack. The E-commerce display system based on 3D display can simulate an image that the user is supposed to see in a real scene, and, on the other hand, the E-commerce display system realizes interaction between the user and a shop / a commodity and improves shopping experience.

Owner:BINZHOU UNIV

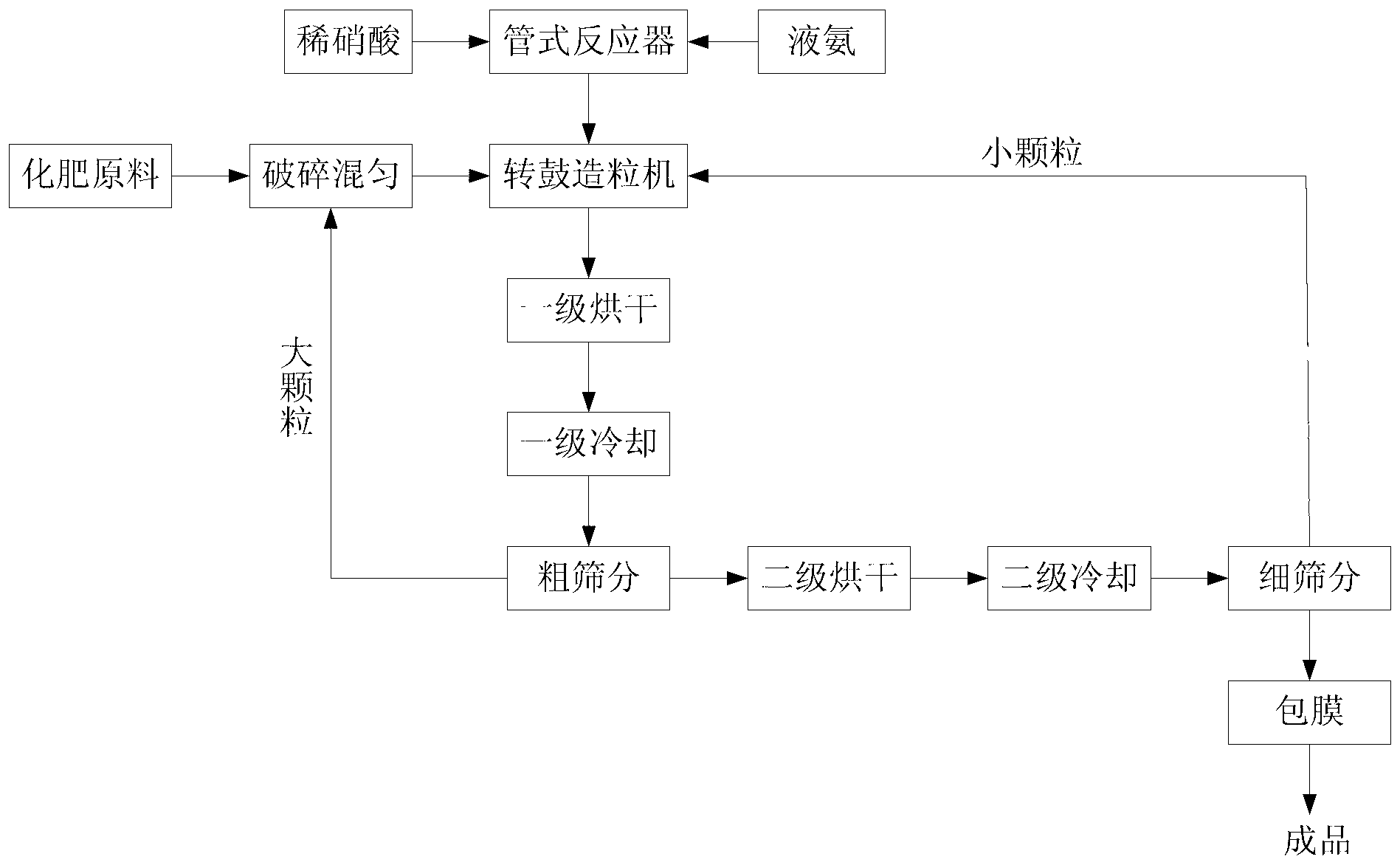

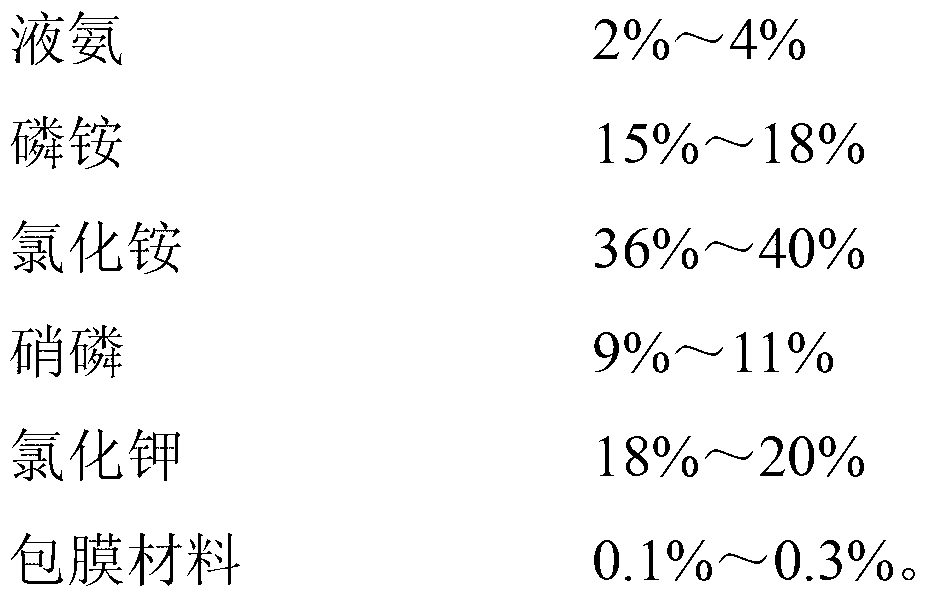

High-concentration compound fertilizer and production method thereof

ActiveCN103232293AHigh strengthImprove solubilityFertilizer mixturesHigh concentrationChemical reaction

The invention provides a high-concentration compound fertilizer and a production method thereof. The production method comprises the following steps of: smashing materials, and uniformly mixing; weighting ammonium dihydrogenphosphate, ammonium chloride, nitrophosphate, potassium chloride in a formula proportion, smashing, uniformly mixing, feeding the mixture into a rotor drum granulator; feeding liquid ammonia and dilute nitric acid into a tubular reactor for carrying out amino acid reaction; pelleting in a rotary drum, namely, after the liquid ammonia and the dilute nitric acid react in the tubular reactor, spraying into the rotor drum granulator, and pelleting by the chemical reaction of the liquid ammonia and the dilute nitric acid; drying, cooling and screening pelleted particles, wherein the particles with qualified particle size enter a coating machine, the large particles return to be smashed, and the small particles return to the granulator; coating by an anti-blocking agent; and spraying the anti-blocking agent into the coating machine for coating, thus obtaining the high-concentration compound fertilizer. According to the production method, the pelleting temperature is increased by using the chemical reaction heat between the nitric acid and ammonia, the characteristic of the material is improved, the production capacity of devices is improved, and the production cost is reduced.

Owner:嘉施利(应城)化肥有限公司

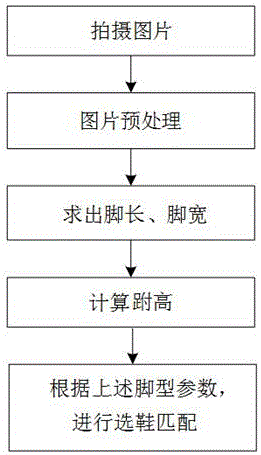

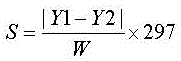

Foot shape data acquisition method based on pictures

InactiveCN106127773AEasy extractionImprove online shoe shopping experienceImage enhancementImage analysisCouplingData acquisition

The invention discloses a foot shape data acquisition method based on pictures. The method comprises five steps of picture shooting, picture pretreatment, foot length and width calculation, tarsus height calculation and shoes selecting and coupling. Firstly, two foot shape pictures are shot and pretreated to extract foot shape contour data; according to two sets of the foot shape contour data, the foot length, the foot width and the front tarsal bone bump height are calculated respectively to obtain corresponding foot shape parameters; and finally, according to data of the gender, age and foot shape parameters of a user, coupling with the brand and pattern of some pair of shoes on an online mart is conducted to recommend the optimal size for the user. The invention can conveniently and rapidly extract the foot shape data, can accurately perform size coupling of shoes of different brands and types according to the foot shape data, and can greatly improve the online shoes purchasing experience and reduce the rate of returns as the user selects unsuitable sizes in online shopping. The method is advantaged by simple operation, convenient usage and low cost.

Owner:BEIJING 3DWORLD SCI & TECH CO LTD

Sow aphrodisiac medicament

InactiveCN101912509ANo reactivityDecreased feed intakeSexual disorderPlant ingredientsTreatment effectEpimedium

The invention discloses a sow aphrodisiac medicament, which is prepared from raspberry, tuber onion seed, cherokee rose fruit, south dodder seed, medlar, prepared rehmannia root, cinnamomvine, psraleae, epimedium herb, medicinal indianmulberry root, songaria cynomorium herb, szechwan tangshen root, largehead atractylodes rhizome, poria, liquoric root and Chinese angelica. The raw materials are crushed, sieved and mixed with the conventional feed so as to feed sows. One-year three-phase trial treatment and trial production prove that the medicament has the advantages of reducing return rate, non-pregnancy rate and dystocia rate, improving farrowing rate, obviously improving economic benefit, along with obvious aphrodisiac effect, more stable treatment effect than a hormone aphrodisiac, economy and cheapness.

Owner:CHANGZHI SUBURB ZETOU CULTURE

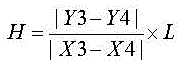

Preparation method for granulating fine-particle fuel for sintering of iron ore in advance

InactiveCN104313313AHigh strengthReduce return rate and solid fuel consumptionIron ore sinteringParticle material

The invention discloses a preparation method for granulating a fine-particle fuel for sintering of iron ore in advance and belongs to the technical field of preparation of a fuel for metallurgical production. By adoption of the preparation method, the content of micro-fine particle materials with the granularity being less than 0.5mm in the fuel for sintering of the iron ore can be effectively reduced. The preparation method comprises the following steps of: firstly sieving crushed fuel by adopting a sieving tool with the grading point being 0.5mm, collecting sieved fuel with the particle size being not more than 0.5mm to obtain the micro-particle fuel; then adding a binding agent with the mass ratio being 0.5%-2% into the micro-particle fuel collected in the step a, spraying water, and uniformly stirring to obtain a mixture of the binding agent and the micro-particle fuel; and then feeding the mixture prepared in the step b into a fine-particle making machine and preparing into fine-particle fuel with the particle size being not less than 0.5mm in advance so as to finish the preparation work of granulating the disposable micro-particle fuel into balls in advance.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

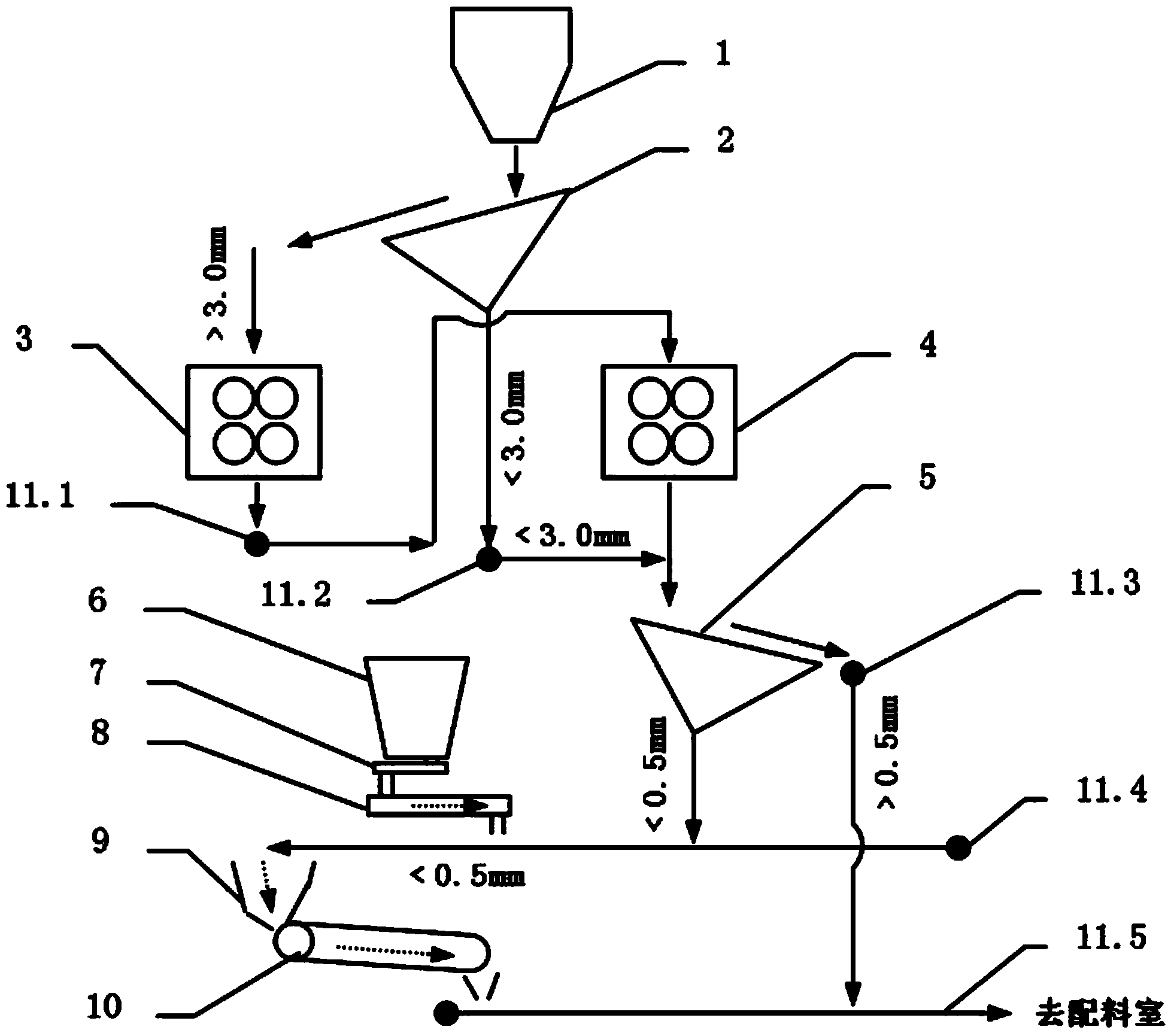

Sintering distribution process optimized control method based on multi-objective genetic algorithm

The invention discloses a sintering distribution process optimized control method based on a multi-objective genetic algorithm, which is characterized by comprising the following steps: 1, building an optimization model of segregation distribution, namely establishing a sample collection by using a large-flue negative pressure, the rotation speed of a nine-roller distributor, the feed level of a feed tank and the depth of a feed bed and establishing a segregation distribution comprehensive satisfaction function; and 2, with a goal of optimizing segregation distribution comprehensive satisfaction, constructing the optimization model on the basis of the principle of the multi-objective genetic algorithm so as to optimize the set values of the depth of the feed bed and the rotation speed of the nine-roller distributor. In the invention, the set values of the depth of the feed bed and the degree of segregation are optimized according to the actual conditions of sintering distribution, so that the setting of the depth of the feed bed and the degree of segregation always adapts to the change of working conditions, and the advantage of deep-feed bed sintering is fully played.

Owner:CENT SOUTH UNIV

Ultra-thick bed sintering method for reducing sinter return ratio and employing presintering

The invention discloses an ultra-thick bed sintering method for reducing sinter return ratio and employing presintering; ignition temperature is optimized, a suitable amount of insulation covers are provided, high-oxygen hot air is introduced, surface ignition quality of upper and lower beds of sinter can be effectively improved, mineralizing time of surface sinter can be extended, and cold brittleness of the sinter is reduced; through reasonable coal allocation and water regulation for the upper bed of sinter mixture and reducing the amount of rolls of a distributor, better breathability is provided for the upper bed of sinter mixture; according to the features of the upper bed of mixture, bed combustion and particle size deviating is inhibited, and the bed never combusts too fast; through comprehensive technical means, it is possible to effectively decrease the return ratio of the upper bed of sinter and the whole bed of sinter.

Owner:ANGANG STEEL CO LTD

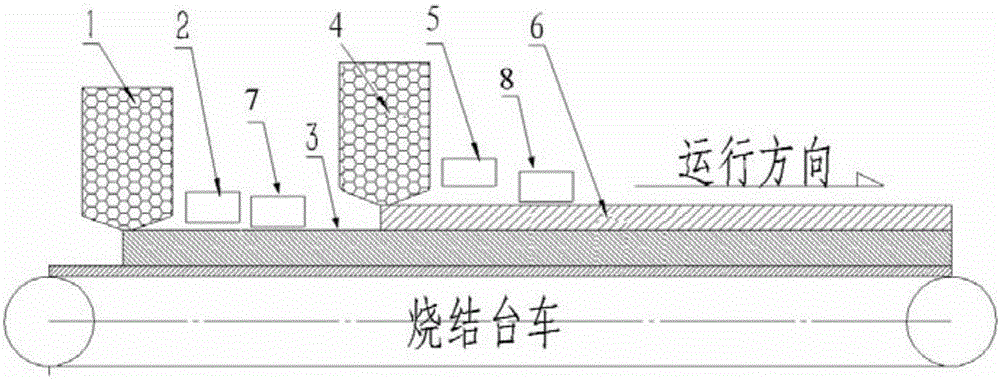

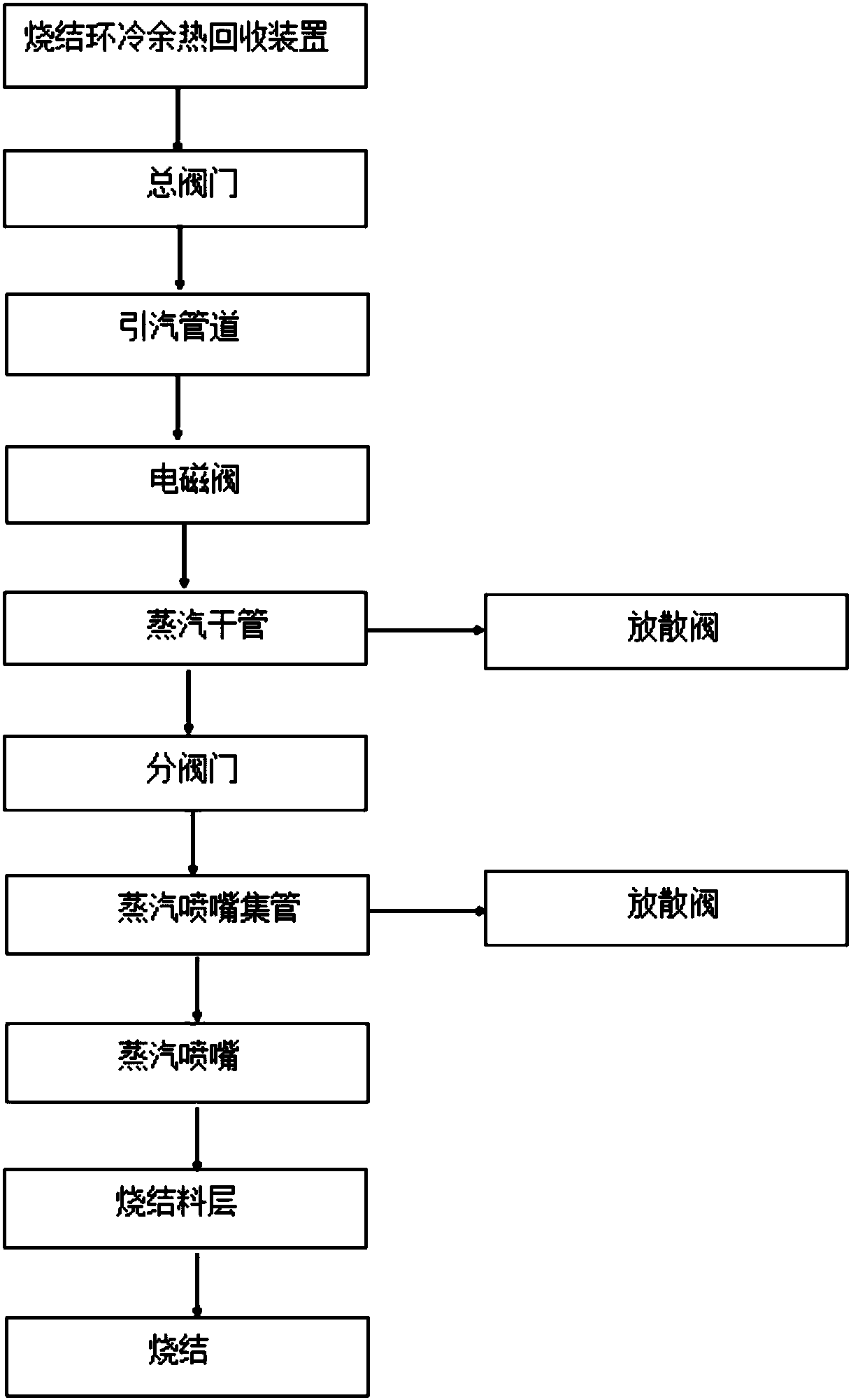

Belt-type sintering machine material layer steam jetting humidifying device and humidifying method

InactiveCN108458593AIncrease heat exchange rateImprove utilization factorFurnace typesNon-combustible gases/liquids supplySolid fuelEngineering

The invention discloses a belt-type sintering machine material layer steam jetting humidifying device and a humidifying method. The belt-type sintering machine material layer steam jetting humidifyingdevice comprises a steam introducing system and a steam jetting system; the steam introducing system comprises a steam introducing pipeline and steam drying pipes; an inlet of the steam introducing pipeline is connected with a steam source; introduced steam enters the steam drying pipes; the steam drying pipes are arranged at the parts, in the advancing direction of a sintering machine, of the two sides of a sintering machine trolley; the steam jetting system comprises a plurality of nozzle collecting pipes; a plurality of steam nozzles are arranged on the nozzle collecting pipes; and the nozzle collecting pipes are arranged on the steam drying pipes. The heat exchange rate of a sintering material layer is increased obviously, the vertical sintering speed of the sintering is increased, and the utilization coefficient of the sintering machine is further increased; and sintering solid fuels are facilitated being thoroughly burnt, heat generated by burning the sintering solid fuels is increased, the quality stability of sintering ore is ensured, and the guarantee is provided for further reducing the sintering solid fuel consumption.

Owner:SHANDONG IRON & STEEL CO LTD

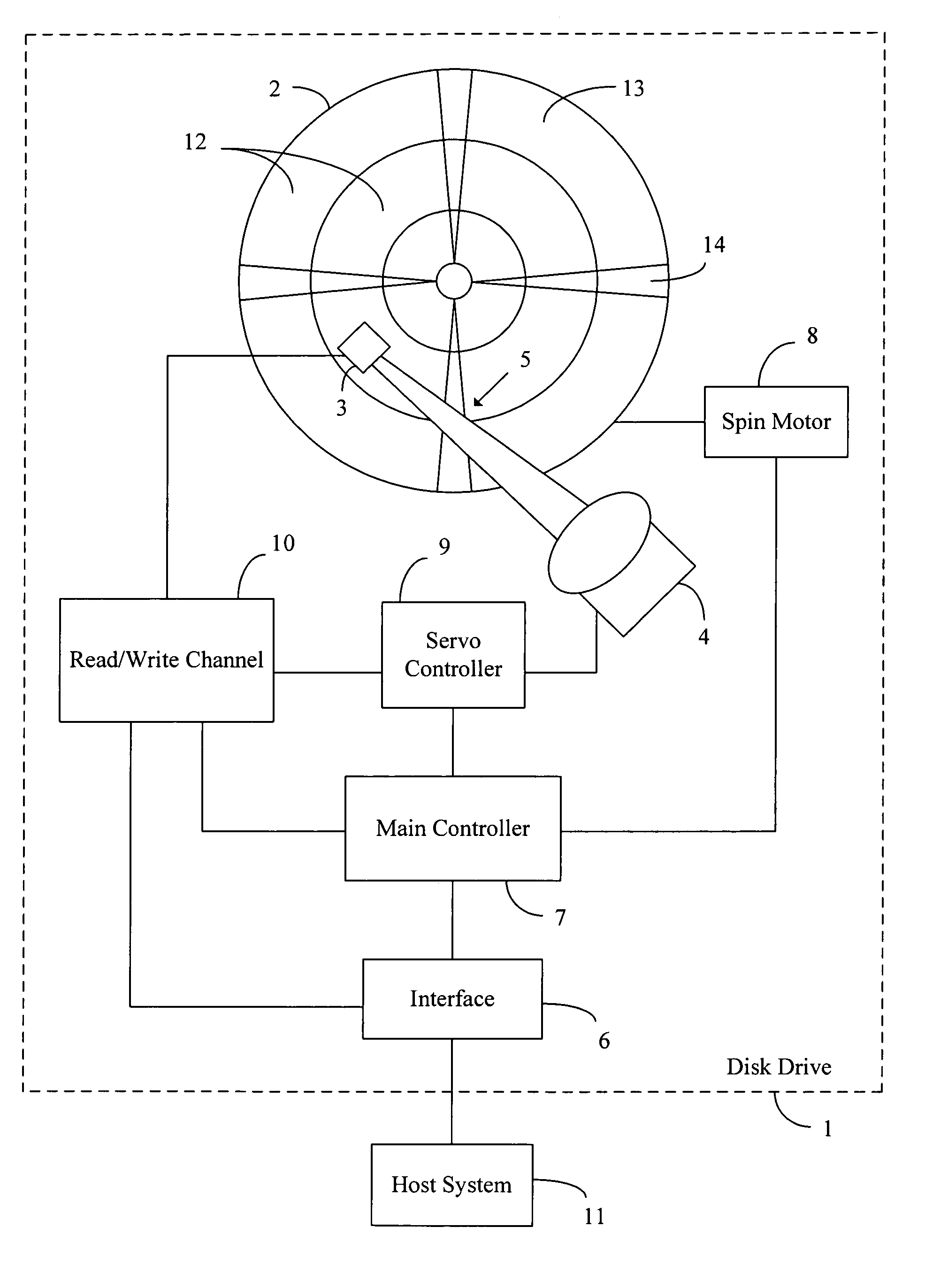

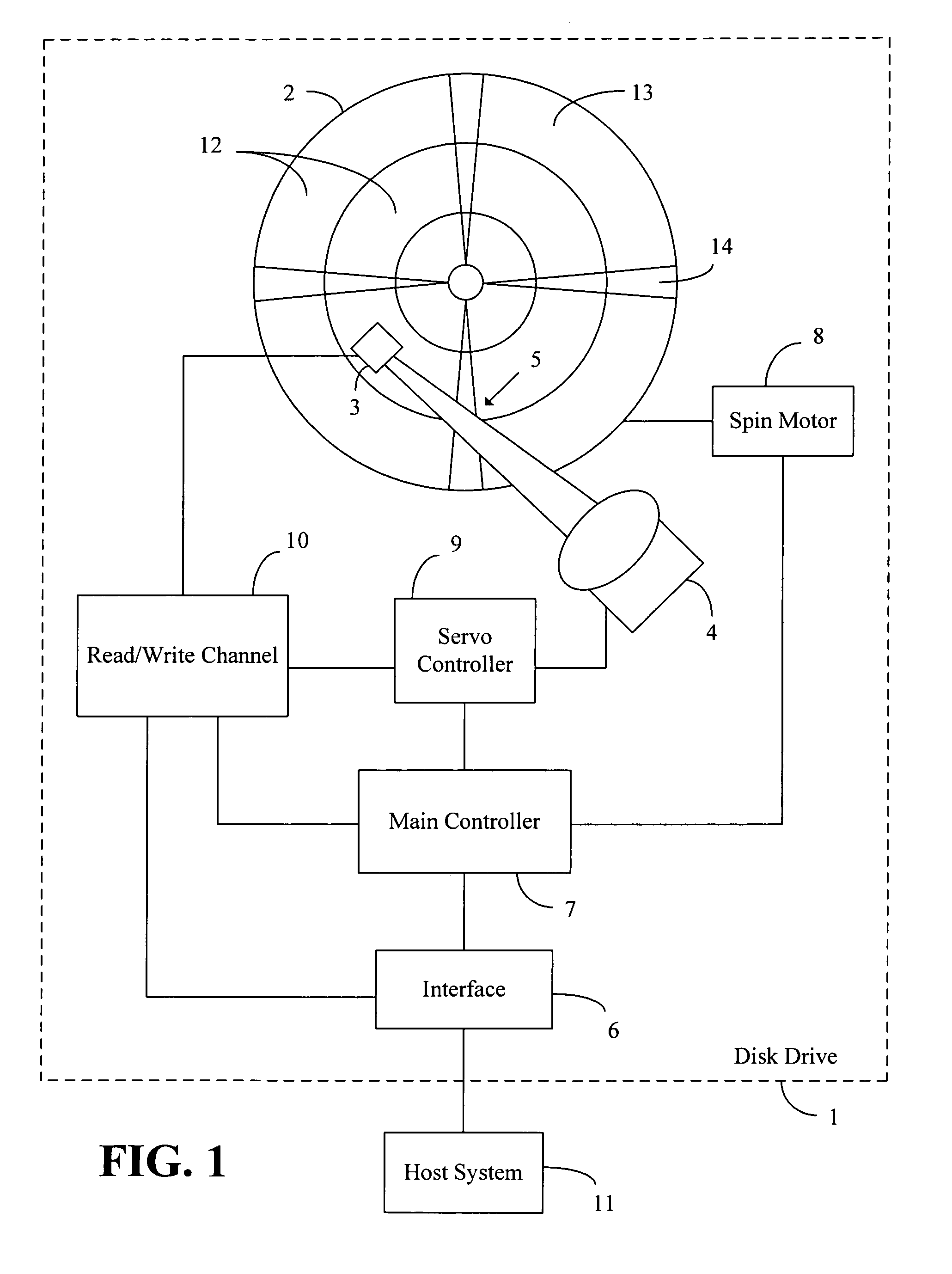

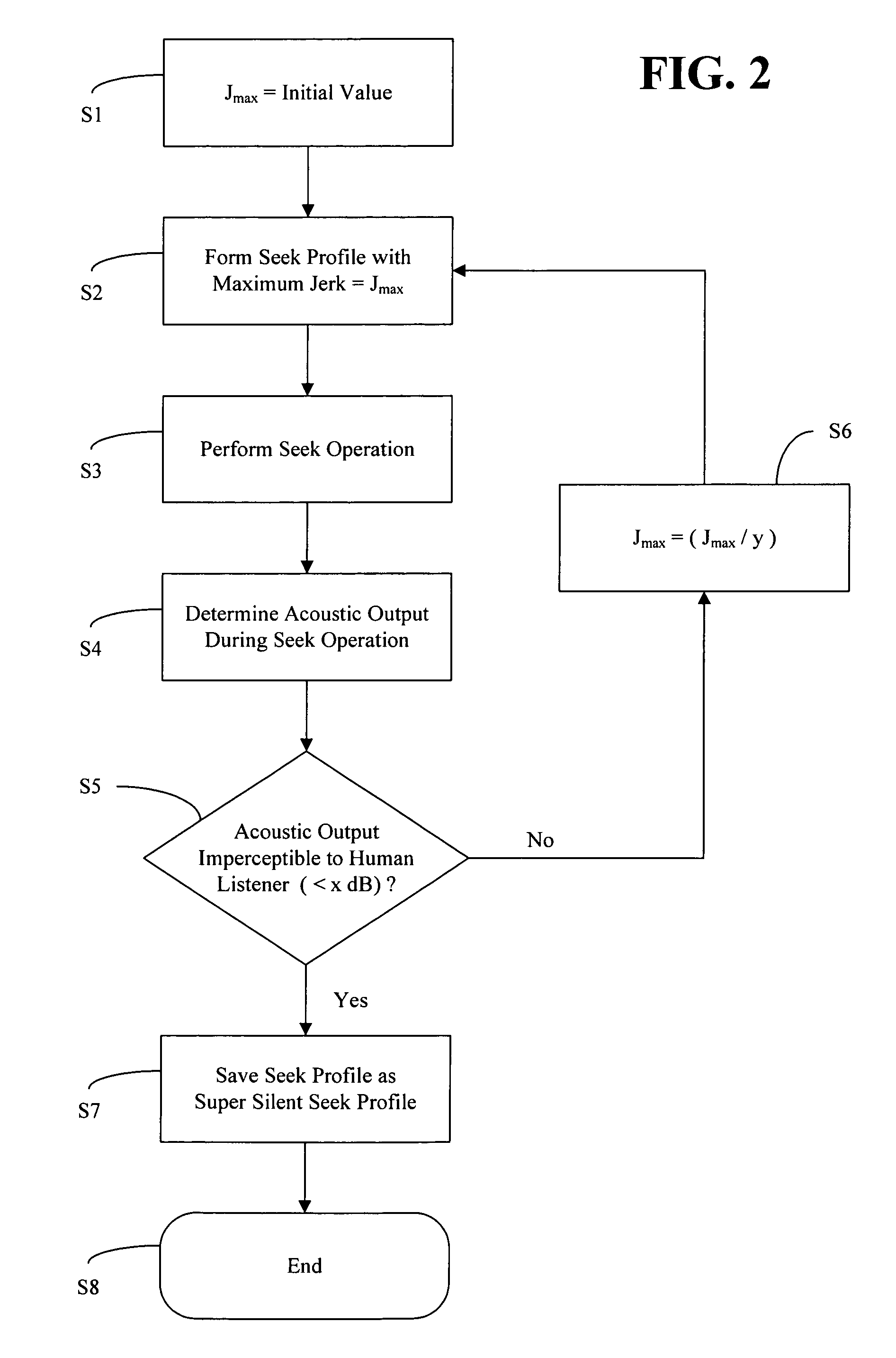

Disk drives and methods allowing for super silent seeks

InactiveUS7289291B1Lower Level RequirementsConfidenceUndesired vibrations/sounds insulation/absorptionRecord information storageMaster controllerActuator

A disk drive includes a disk, a head, an actuator, and a servo controller. The servo controller controls a movement of the actuator based on a super silent seek profile to cause the actuator to perform a super silent seek in which an acoustic output due to the movement of the actuator is imperceptible to human listeners. A maximum jerk of the super silent seek profile may be less than a maximum jerk of a silent seek profile divided by ten. A snap associated with the super silent seek profile may be always less than a particular snap level, such that any change in the jerk associated with the super silent seek profile is gradual. The disk drive may further include a main controller that is configured to receive a command from an operating system, a user, and the like to perform a seek in a super silent seek mode.

Owner:MAXTOR

Feed additive for breeding porcupine sows and application of feed additive

The invention discloses a feed additive for breeding porcupine sows and an application of the feed additive. Membranous milkvetch root, fiveleaf gynostemma herb, motherwort herb, Chinese angelica, epimedium herb, cowherb seeds, Mongolian dandelion herb, heartleaf houttuynia herb, largehead atractylodes rhizome, hawthorn fruit, Chinese magnoliavine fruit and liquorice root are taken as formula raw materials. According to the invention, the porcupine sows are fed after the feed additive is mixed with a basic feed and uniformly blended during the period from 25d before mating to ablactation of piglets; the feed additive can not only improve immunity and disease resistance of porcupine, but also improve the feed intake and the litter size of the sows as well as the survival rate of the piglets, has a certain treatment effect against birth diseases of the sows and has relatively good application prospects.

Owner:FUJIAN AGRI & FORESTRY UNIV

Quick-frozen anti-cracking dumpling wrapper

The invention relates to dumpling wrapper, solves the technical problems that wrapper of existing quick-frozen dumplings is easy to crack during cold storage, and the existing quick-frozen dumplings are easy to break, and provides quick-frozen anti-cracking dumpling wrapper. The quick-frozen anti-cracking dumpling wrapper is made by mixing flour, potato modified starch and quality improver, adding water to make dough and pressing the dough. The quick-frozen anti-cracking dumpling wrapper is characterized in that based on 100 parts of flour, 5-15 parts of the potato modified starch is added, 1.5-2 parts of the quality improver is added, 40-55 parts of the water is added, the quality improver is made by mixing composite phosphate, curdlan and ascorbic acid according to a portion of 2:3:1. Shelf life of dumplings made of the quick-frozen anti-cracking dumpling wrapper can be prolonged effectively, quality of the dumplings can be improved, and return rate can be reduced.

Owner:TAIXIANG GRP TECH DEV

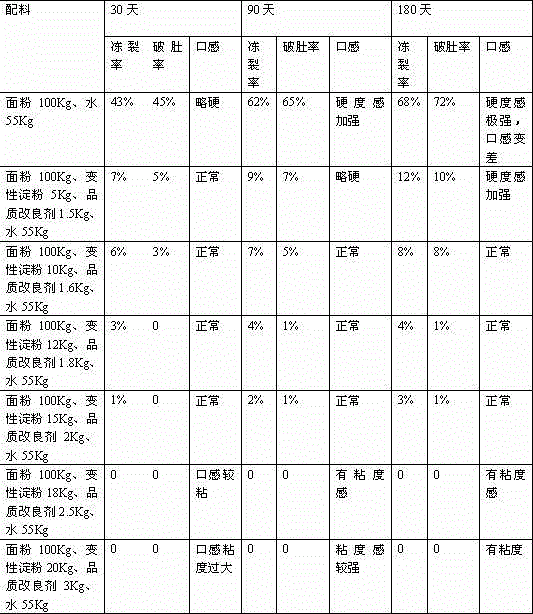

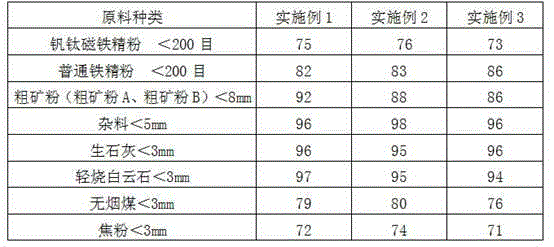

Medium-titanium high-strength sintered ore and preparation method thereof

The invention discloses a medium-titanium high-strength sintered ore which is formed by sintering the following ingredients by weight percentage: 78-86% of iron-bearing material, 9-12% of quicklime, 1-4% of lightly fired dolomite and 4-6% of fuel, wherein the iron-bearing material comprises the following components by weight percentage: 40-50% of vanadium titanium magnetite concentrate, 5-20% of common fine iron powder, 25-40% of coarse ore powder and 0-8% of miscellaneous material. The sintered ore is produced by taking a vanadium titanium magnetite and the vanadium titanium magnetite concentrate as main raw materials; the pelletizing performance of a mixture is improved by reasonably preparing and adding other iron ore powder and fluxes; component and phase composition of the sintered ore is controlled; an influence of higher TiO2 content in the sintered ore on the quality of the sintered ore is reduced; a tumbler index of the sintered ore reaches above 77% when the medium-titanium sintered ore is produced; the sintered ore is high in cold strength and low in return rate; and the sintered ore is smelted via a blast furnace, so that a fuel ratio is reduced and a utilization coefficient is increased.

Owner:HEBEI IRON AND STEEL

Compound fertilizer containing efficient binder and production method of composite fertilizer

ActiveCN103011958AImprove adhesionHigh drum granulation rateFertilizer mixturesPhosphateINCREASED EFFECT

The invention discloses a granular compound fertilizer prepared by using modified starch as a binder. The compound fertilizer is characterized by comprising the following raw materials in parts by weight: 15-40 parts of nitrogenous fertilizer, 20-40 parts of phosphatic fertilizer, 20-42 parts of potash fertilizer and 0.5-2.0 parts of binder. The raw materials of the binder consist of 35-45 parts by weight of starch, 1-5 parts by weight of phosphate, 0.1-3 parts by weight of oxidant, 0.1-1 part by weight of coupling agent and 40-60 parts by weight of water. The binder contained in the granular compound fertilizer has good adhesion capability, so the granular compound fertilizer disclosed by the invention has the advantage that adhesive capability is good, the rotary drum granulation pelletizing ratio is high and the material returning rate is reduced; the pertinence is strong and the fertilizer efficiency is completely releases, so that the soil is hard to harden and the yield-increasing effect is prominent; and the virtuous circle of the soil nutrient can be maintained, the water and nutrient retention capability of the soil is improved and the resistance of the crops is enhanced.

Owner:广西农垦明阳生化有限公司

Method for clearing Android system passwords

InactiveCN102999335ASolve the problem of not being able to use the deviceReduce return rateSpecific program execution arrangementsPasswordApplication software

The invention relates to the technical field of the Android operating system, and specifically relates to a method for clearing Android system passwords. The method comprises the following steps of: after the user connects the Android system with the computer system through a USB (Universal Serial Bus) wire, installing a password input recognition module application program in an APK format in the Android system; when the password input recognition module identifies password input from the user, popping up a password forget option; guiding the user to open the USB debug mode through the password forget option; sending an ADB command to the Android system through the computer system by the user; and deleting the password file of the Android system through the ADB command by running the SHELL command of the Android system. The password forgetting problem of the Android system can be solved simply and quickly by the method without altering the data of the mobile phone of the user and affecting the Android device system with any damage; and therefore, unnecessary trouble of the user is prevented and the return probability of the device manufacture is also reduced.

Owner:东莞康特尔云终端系统有限公司

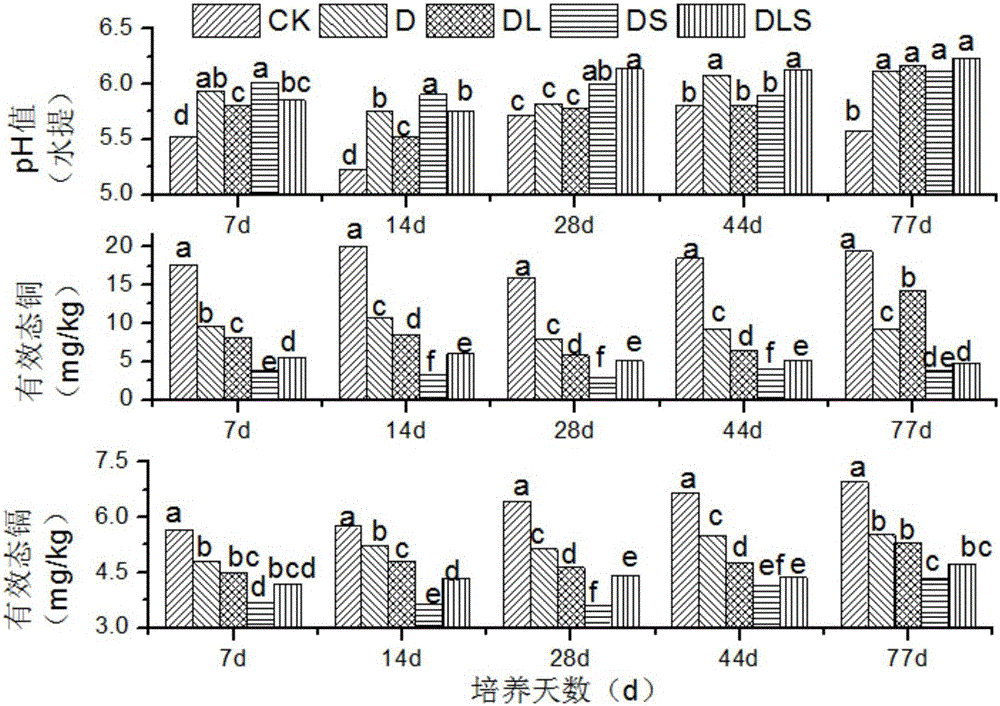

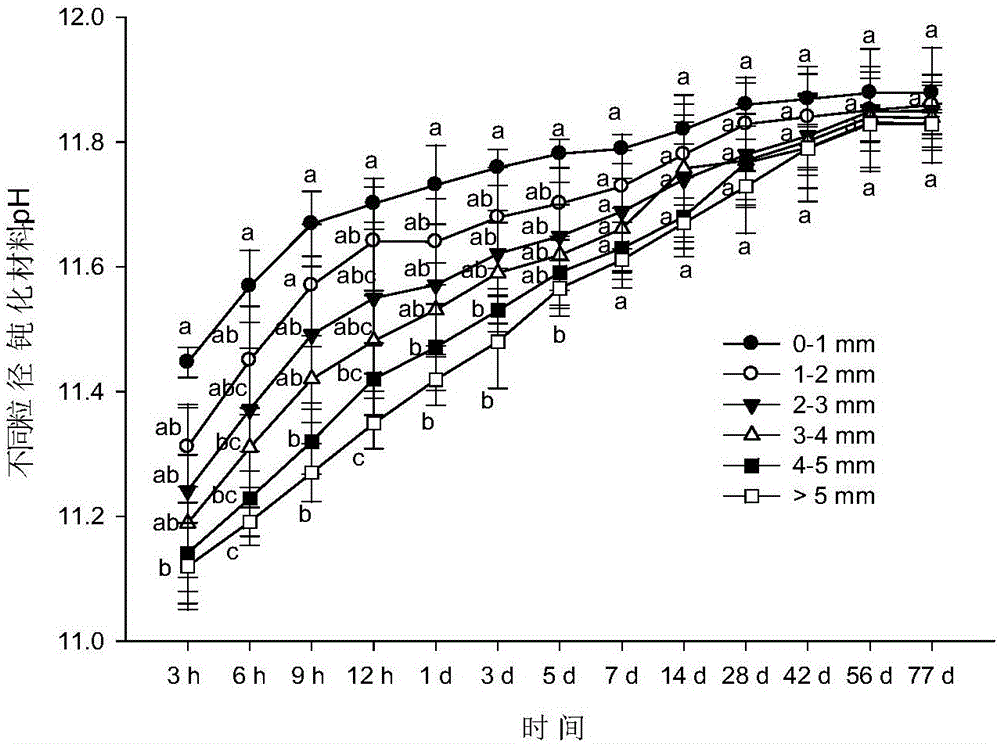

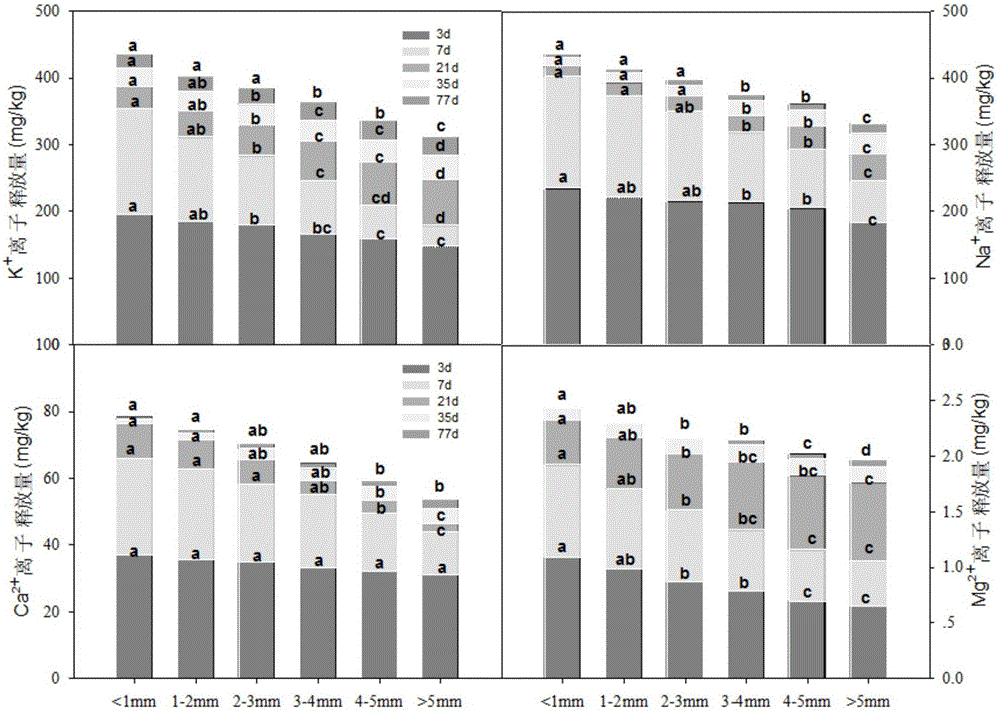

Passivation material capable of repairing cadmium and copper-polluted acidic soil as well as preparation method and application of passivation material

ActiveCN105670636AWide variety of sourcesEasy accessAgriculture tools and machinesOther chemical processesEconomic benefitsColloid

The invention provides a passivation material capable of repairing cadmium and copper-polluted acidic soil as well as a preparation method and application of the passivation material. The pH value of the passivation material is 10 to 13; the passivation material is prepared from the following raw materials in percentage by mass: more than or equal to 60 percent and less than or equal to 85 percent of biomass power plant ash, more than or equal to 10 percent and less than or equal to 25 percent of lime, and more than or equal to 5 percent and less than or equal to 15 percent of phosphorus lime. The passivation material takes the green and cheap biomass power plant ash as the main raw material, the biomass power plant ash is mixed with the lime and the phosphorus lime, any binding agent or a colloid auxiliary material is not added, and spherical grains are prepared; the granulation rate of the raw materials is more than 95 percent and the material returning rate is low. Negative influences of the auxiliary materials including the binding agent and the like can be avoided, and a raw material washing phenomenon is avoided; the application amount of the passivation material is less and only occupies 0.2 percent to 0.6 percent of the mass of soil of a plough layer; a heavy metal passivation effect is remarkable and stable, and the growth of plants is accelerated, so that the aim of efficiently and lastingly repairing the heavy metal cadmium and copper-polluted acidic soil in situ at a low cost is realized, and economic benefits, ecological benefits and a repairing effect are integrated.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Quick-frozen dumpling wrappers and preparation method thereof

The invention discloses quick-frozen dumpling wrappers, which comprise the following components in part by weight: 100 parts of flour, 5 to 8 parts of modified starch and 0.3 to 0.8 part of modifier. The dumpling wrappers can be prevented from being cracked, the production cost and reject rate are reduced, the product quality is improved, and the shelf life of products is prolonged.

Owner:河南省淇县永达食业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com