Passivation material capable of repairing cadmium and copper-polluted acidic soil as well as preparation method and application of passivation material

A technology of acidic soil and cadmium copper, applied in the restoration of polluted soil, soil conditioning materials, chemical instruments and methods, etc., to achieve the effect of improving soil pH, improving product quality, and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

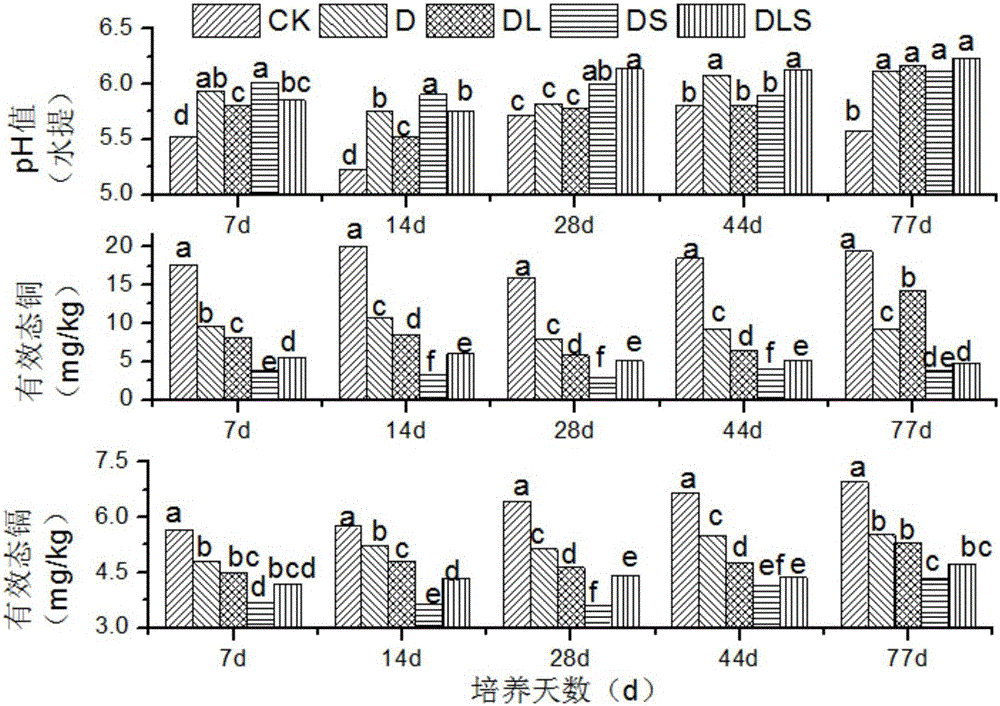

[0030] The formula screening experiment of embodiment 1 passivation material

[0031] Soil was collected in a typical cadmium-copper polluted acidic soil farmland. Farmland soil was used as the control (CK), and the passivation material treatment included the application of biomass power plant ash (D). The biomass power plant ash was mixed with lime (DS) and apatite (DL) in a mass ratio of 3:1. The mass ratio of ash, lime and phosphorite was 6:1:1 (DLS), and there were 5 treatments in total, and each treatment was repeated 3 times. Pass the air-dried polluted soil through a 10-mesh sieve, add 2 g of treatment materials per 1 kg of soil, that is, each treatment material accounts for 0.2% of the soil mass, and mix evenly. Constant temperature and humidity (temperature 25°C, humidity 40%) cultured for 77 consecutive days, samples were taken for analysis every 7 days, and the results showed that: on the 14th day, the soil pH increased the most with DS treatment, followed by DLS t...

Embodiment 2

[0032] Embodiment 2 Particle size selection experiment

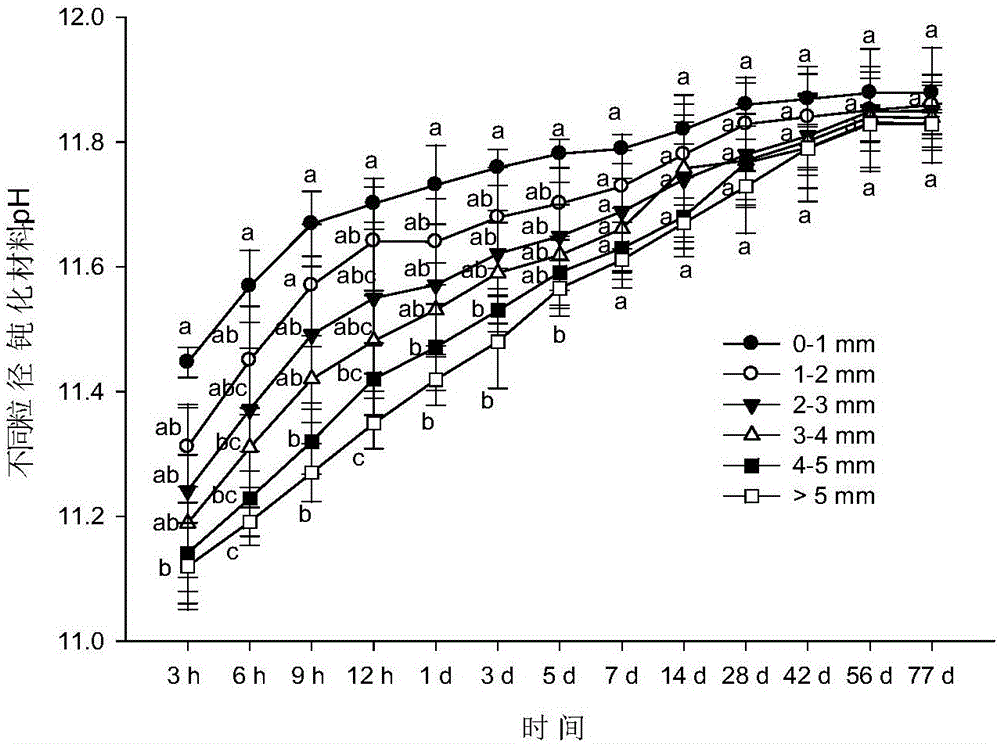

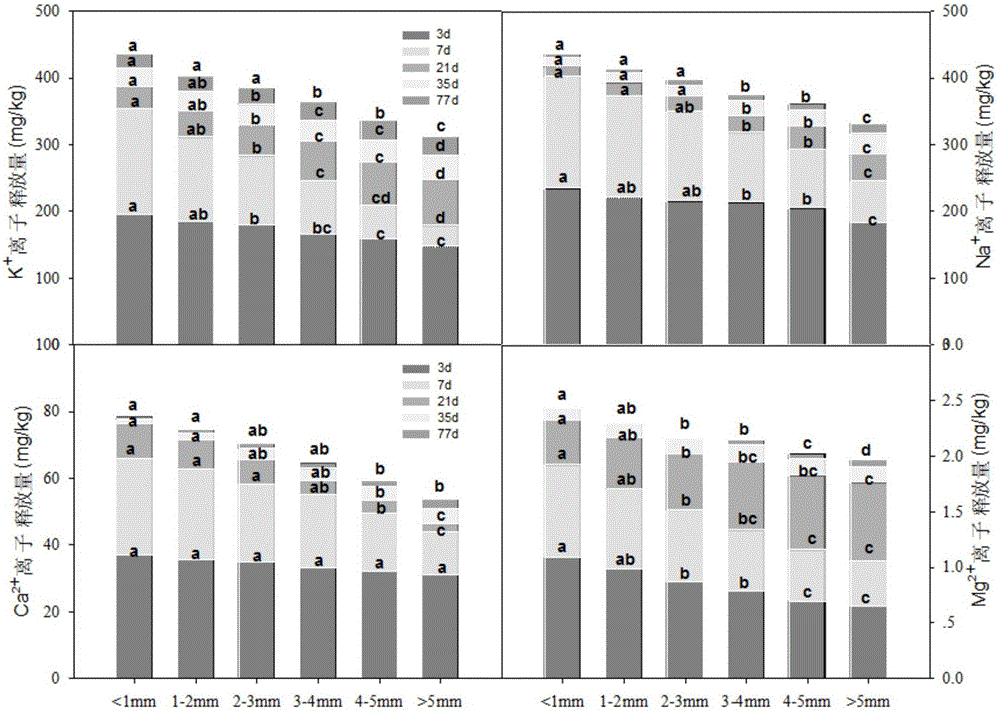

[0033] Use the centrifugal granulator and rounder to control the temperature of 50℃~60℃, rotational speed 20r / min, moisture 40%, and no binder or any colloid to form the screened passivation material, resulting in 0mm~1mm, 1mm~ 2mm, 2mm~3mm, 3mm~4mm, 4mm~5mm, >5mm six kinds of passivation materials. Weigh 5g of passivation materials with 6 particle sizes, place them in 100mL deionized water, and incubate at a constant temperature of 25°C. and 77d to measure the solution pH ( figure 2 ), and the base ions (K + 、Na + , Ca 2+ and Mg 2+ )content( image 3 ).

[0034] The results showed that the pH value gradually increased with time, the larger the particle size, the smaller the pH value, and the pH value of all particle sizes was always maintained at 11.1-11.9. At the 3rd hour, there was no significant difference in the pH values of 4mm~5mm and >5mm particle sizes, and the difference was significant with other pa...

Embodiment 3

[0035] The preparation of embodiment 3 passivation material

[0036] 1. Passivation material formula: prepared from biomass power plant ash, lime and apatite, without adding any binder, and the mass percentage of each material is: 70wt.%≤biomass power plant ash≤80wt.%, 10wt.%≤lime≤15wt.%, 10wt.%≤phospholime≤15wt.%, pH 12.0, particle size ≤3mm.

[0037] 2. Preparation of passivation material includes the following steps:

[0038] 1) Dry raw materials: dry the raw materials of each component until the moisture content is not higher than 1%, so as to maintain the inherent activity of the raw materials of each component;

[0039] 2) Sieving: all materials are passed through a 60-mesh sieve so that the materials can be evenly mixed;

[0040] 3) Ingredients: Weigh out each material according to the mass ratio mentioned above, place them in a blender, and stir for 2-3 minutes to mix evenly;

[0041] 4) Granulation: use a centrifugal granulator and a rounding machine to control the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com