Preparation method of large-particle ammonium sulfate

An ammonium sulfate, large particle technology, applied in chemical instruments and methods, ammonium salt fertilizers, nitrogen fertilizers, etc., can solve the problems of high energy consumption, large mechanical energy, difficulty in mechanized fertilization and preparation of blended fertilizers, etc. The effect of short reaction time and full utilization of reaction heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

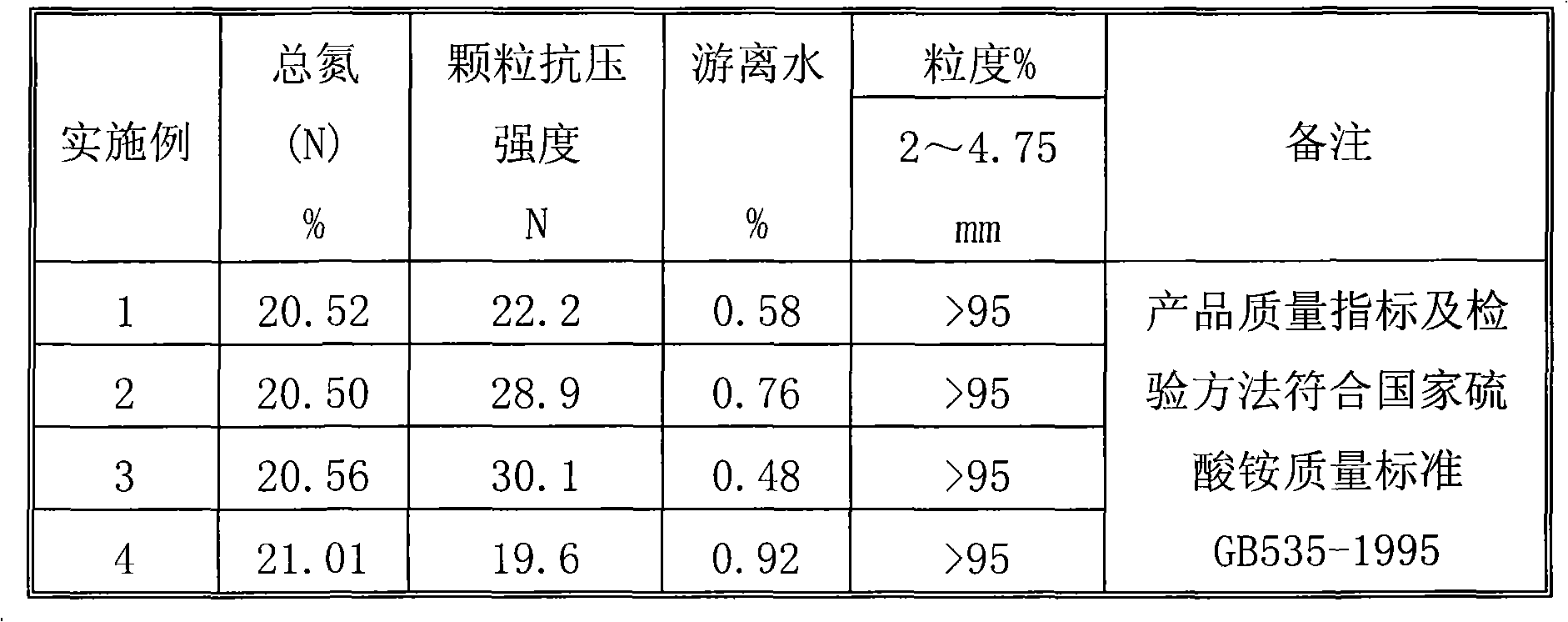

Embodiment 1

[0047] The total formula is sulfuric acid 1.41m 3 / h, liquid ammonia 0.848t / h, phosphoric acid 0.1m 3 / h, powdered ammonium sulfate 4t / h, magnesium powder 0.09t / h, granulation binder 0.065t / h, return material 30t / h.

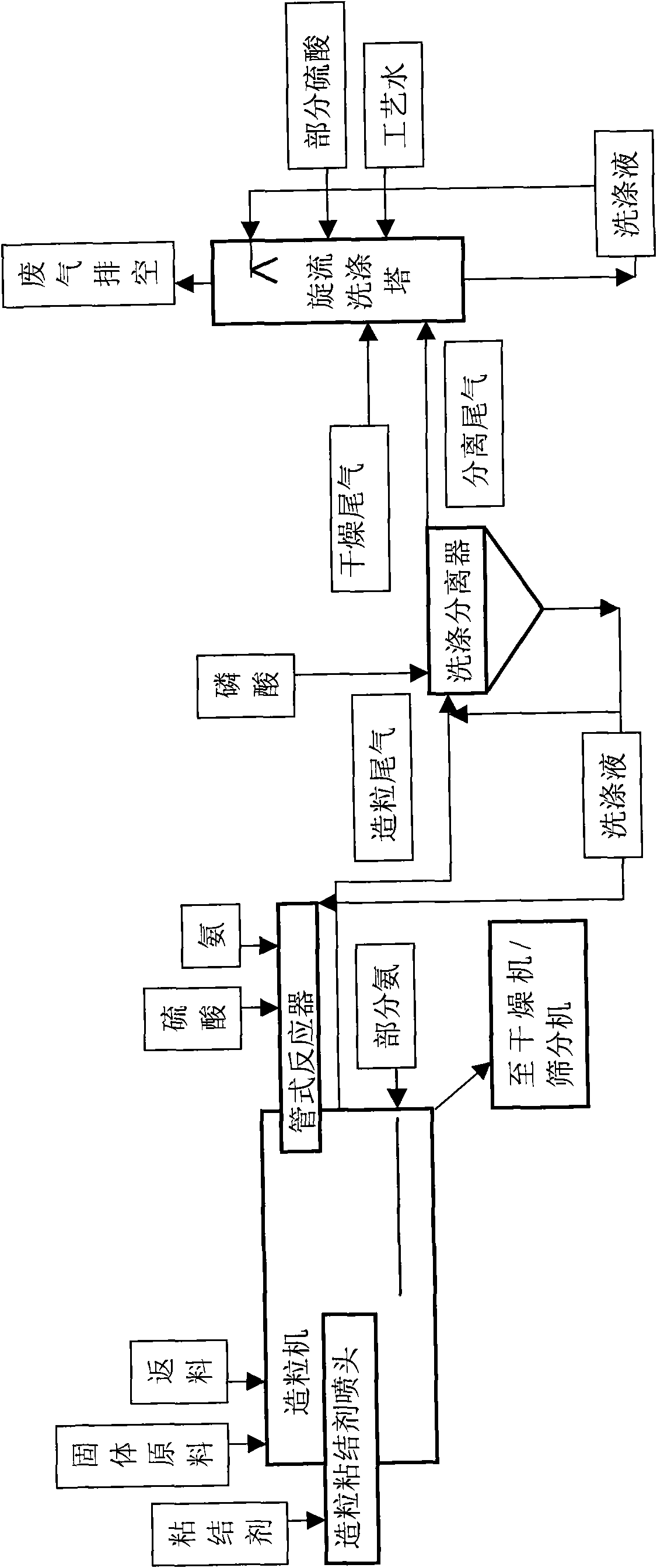

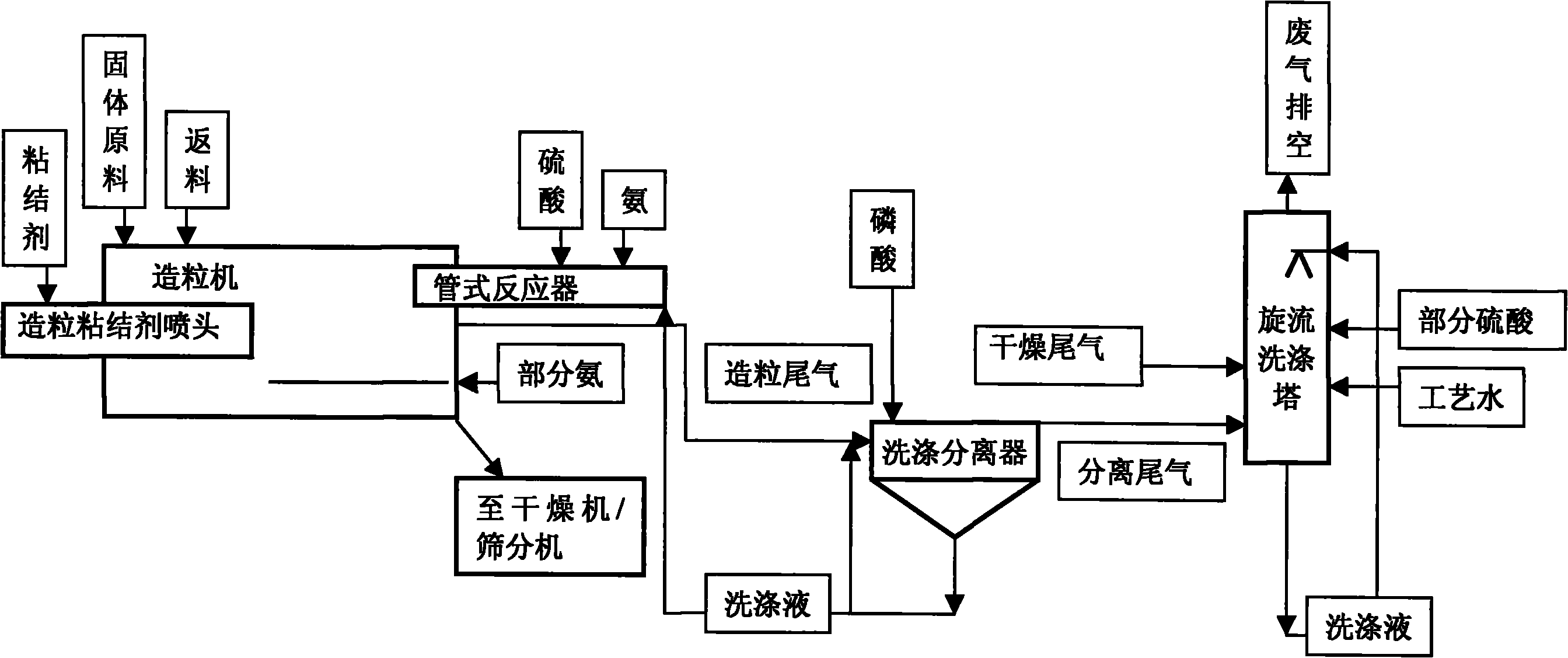

[0048] Such as figure 1 Shown is a schematic process flow diagram of the present invention. The concentration is 46% (P 2 o 5 Content) of phosphoric acid is pressurized to 1MPa by a phosphoric acid pump, measured and controlled by a flow meter and a regulating valve at a rate of 0.1m 3 / h into the cyclone scrubber. Sulfuric acid with a concentration of 95% is pressurized to 1MPa by a sulfuric acid pump, and is metered and controlled by a flow meter and a regulating valve respectively at a rate of 1.25m 3 / h and 0.16m 3 / h into the tubular reactor and the cyclone scrubber respectively. Liquid ammonia (concentration 99.5%) enters the tubular reactor and the ammonia injection shaft at 0.773t / h and 0.075t / h after being metered and controlled by the flow meter...

Embodiment 2

[0054] The total formula is sulfuric acid 1.24m 3 / h, liquid ammonia 0.744t / h, phosphoric acid 0.15m 3 / h, powdery ammonium sulfate 4.5t / h, powdery Peng Run soil 0.2t / h, mixture type (40 parts by weight of modified starch, 20 parts by weight of sodium lignosulfonate, 30 parts by weight of urea-formaldehyde resin, 10 parts by weight of cellulose ) granulation binder 0.04t / h, return material 20t / h. Other is identical with embodiment 1, and same kind raw material specification is with embodiment 1, and difference is not to add magnesium powder in the granulator, adds filler bentonite. Sulfuric acid concentration 95%, tubular reactor sulfuric acid 1.08m 3 / h, liquid ammonia (concentration 99.5%) enters the tubular reactor and the ammonia injection shaft at 0.707t / h and 0.037t / h after being metered and controlled by the flow meter and the regulating valve respectively, and the sulfuric acid of the cyclone washing tower is 0.16m 3 / h, gas-liquid separator 51% phosphoric acid (P ...

Embodiment 3

[0056] The total formula is sulfuric acid 2.35m 3 / h, liquid ammonia 1.41t / h, powdery ammonium sulfate 5t / h, powdery kaolin 0.11t / h, mixture type (10 parts by weight of modified starch, 5 parts by weight of sodium lignosulfonate, 80 parts by weight of urea-formaldehyde resin , 5 parts by weight of cellulose) granulation binder 0.06t / h, return material 25t / h.

[0057] Others are the same as in Example 1, and the specifications of the same kind of raw materials are the same as in Example 1, except that magnesium powder is not added in the granulator, and filler kaolin is added. Sulfuric acid concentration 93%, tubular reactor sulfuric acid 2.15m 3 / h, gas ammonia 1.0t / h. Ammonia injection shaft of granulator 0.41t / h, cyclone scrubber sulfuric acid 0.2m 3 / h, powdered ammonium sulfate 5t / h, kaolin 0.25t / h, granulation binder 0.06t / h, return material 25t / h, granulation temperature 90~100℃, drying hot air temperature 110~150℃, The drying tail gas temperature is 75-90°C, the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com