Simulated thermal-insulating reaction experimental method in laboratory

A laboratory simulation, adiabatic reaction technology, applied in the field of experimental equipment, simulated chemical synthesis adiabatic reaction, can solve the problems of difficult to obtain test data, difficult to apply industrial equipment, etc., to achieve the effect of shortening the process, reducing the possibility, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

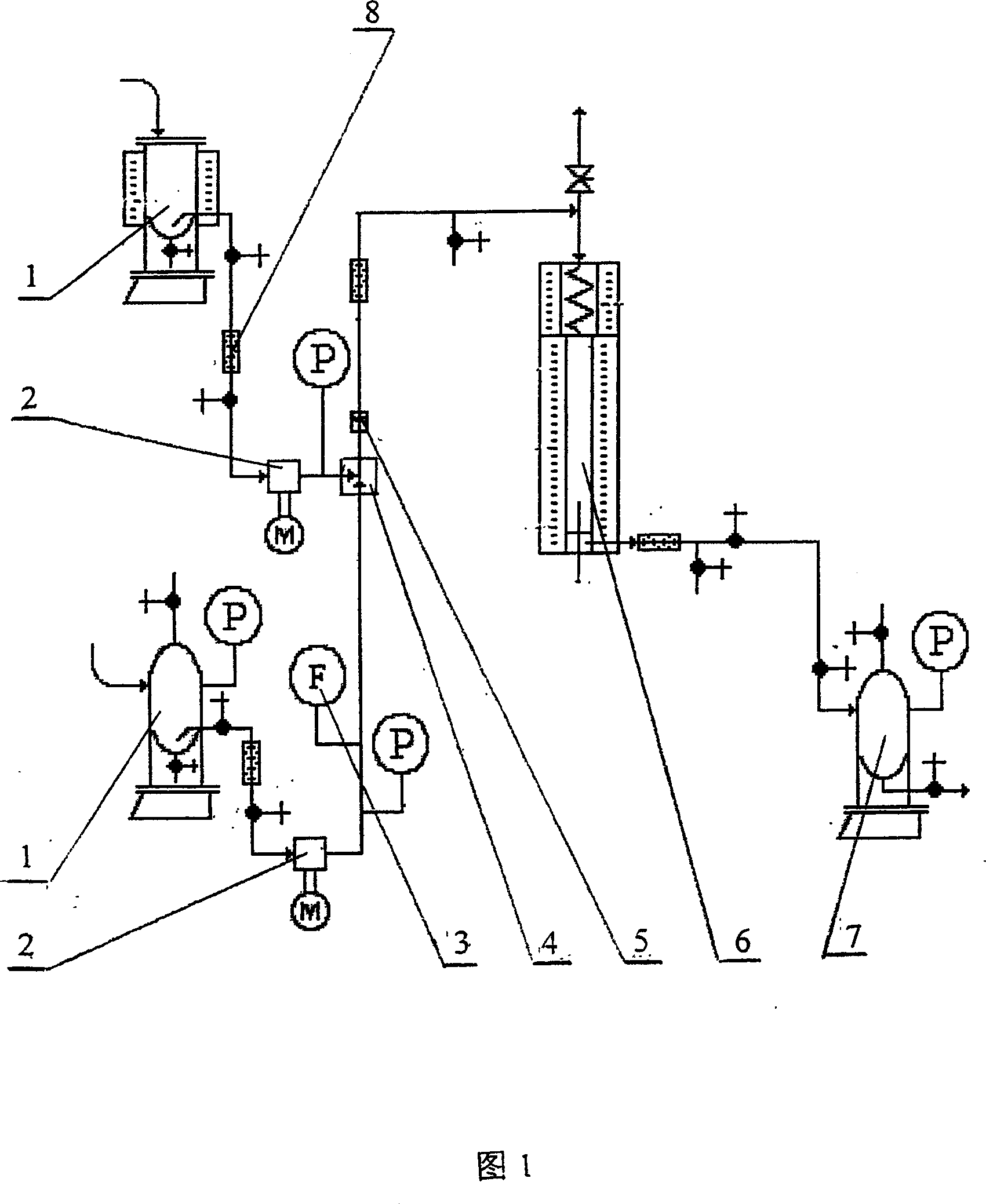

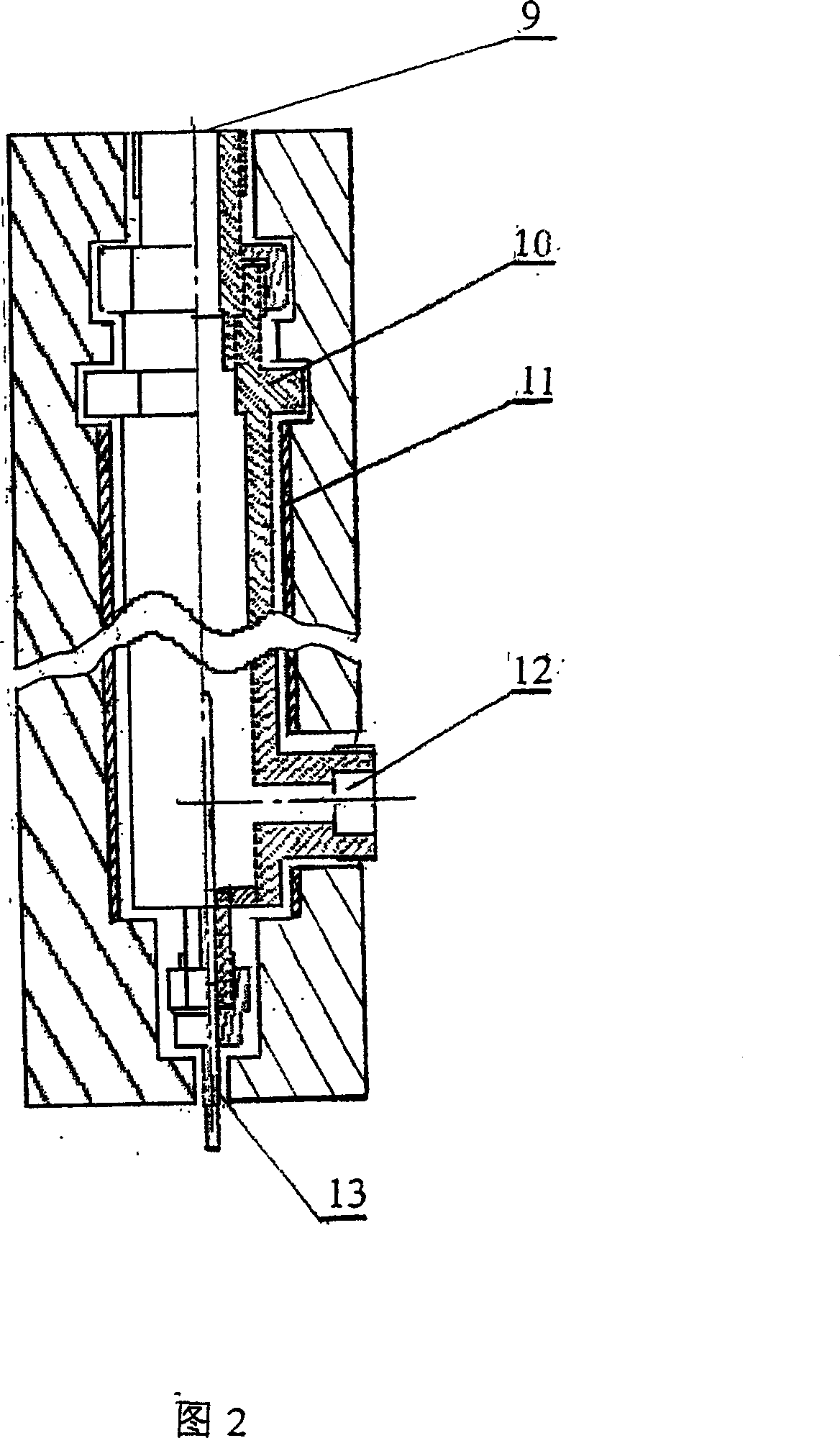

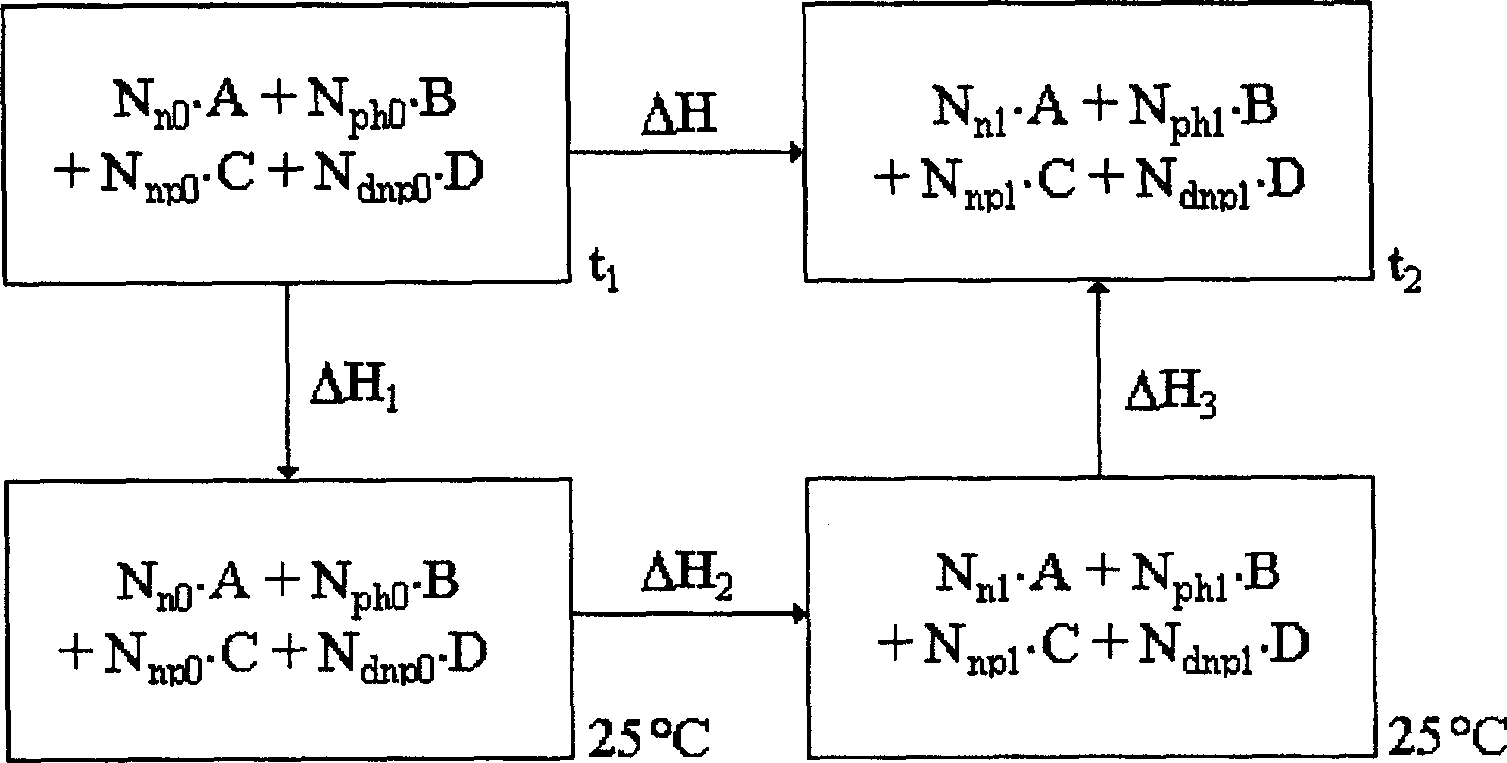

Method used

Image

Examples

Embodiment

[0070] Example: take the laboratory experiment of the alkylation reaction of nonene and phenol with this simulated adiabatic device as an example to further illustrate. See the reaction scheme for the reaction of nonene with phenol to form nonylphenol.

[0071] First, carry out laboratory research, determine the reaction law, and establish a mathematical model according to the reaction law. This step is the basis of all the work, and the data about the law of reaction obtained in this step will become the basis for establishing mathematical models in the future. According to the experimental plan and laboratory preliminary research results, the relationship between reaction temperature, material ratio and conversion rate was determined, the catalyst was determined to be cationic resin catalyst Amberlyst15, the single tube consumption was 15g, and the operating variables were reactor inlet and outlet temperature, Distribution ratio, to determine the effect of the manipulated v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com