Ultra-thick bed sintering method for reducing sinter return ratio and employing presintering

A sintering method and pre-sintering technology are applied in the sintering field of ultra-thick material layer using pre-sintering, which can solve the problems such as the decrease of the productivity and quality of the sintering machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

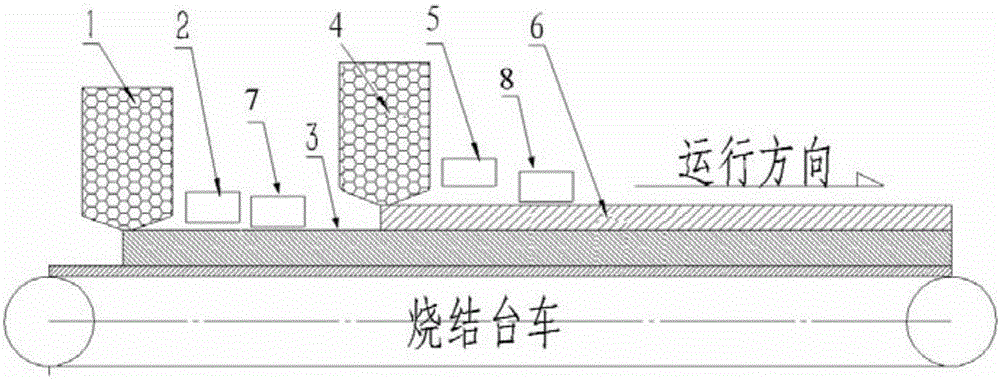

[0015] Concrete technological process of the present invention is as figure 1 , on the basis of the original sintering belt roasting machine distributor 1 and igniter 1, a set of mixture distributor 2 and igniter 2 is added. The whole sintering production adopts a set of ventilation system, and the first distribution is carried out first. The thickness is 700mm, the mixture contains coke powder with a weight percentage of 2.7%, and the water content is 7.2%. The ignition temperature is controlled at 1150°C. After ignition, two heat preservation covers are arranged, and the volume percentage of oxygen is introduced into the heat preservation cover. 18%, hot air with a temperature of 120°C;

[0016] The sintered mixture used for the second distributing enters into a separate coal blender, and fuel and water are added to the coal blender before entering the second distributing system. At this time, the moisture weight percentage of the sintered mixture is 7.6%. The weight percen...

Embodiment 2

[0022] Concrete technological process of the present invention is as figure 1 , on the basis of the original sintering belt roasting machine distributor 1 and igniter 1, a set of mixture distributor 2 and igniter 2 is added. The whole sintering production adopts a set of ventilation system, and the first distribution is carried out first. The thickness is 800mm, the mixture contains coke powder with a weight percentage of 2.4%, and the water content is 7.1%. The ignition temperature is controlled at 1200°C. After ignition, 3 heat preservation covers are arranged, and the volume percentage of oxygen is introduced into the heat preservation cover. 19%, hot air with a temperature of 150°C;

[0023] The sintered mixture used for the second distributing enters into a separate coal mixer, and fuel and water are added to the coal mixer before entering the second distributing system. At this time, the moisture weight percentage of the sintered mixture is 7.8%. The weight percent of t...

Embodiment 3

[0029] Concrete technological process of the present invention is as figure 1 , on the basis of the original sintering belt roasting machine distributor 1 and igniter 1, a set of mixture distributor 2 and igniter 2 is added. The whole sintering production adopts a set of ventilation system, and the first distribution is carried out first. The thickness is 850mm, the mixture contains coke powder with a weight percentage of 2.4%, and the water content is 7.3%. The ignition temperature is controlled at 1250°C. After ignition, 4 heat preservation covers are arranged, and the volume percentage of oxygen is introduced into the heat preservation cover. 20%, hot air at 200°C;

[0030] The sintered mixture used for the second distributing enters into a separate coal mixer, and fuel and water are added to the coal mixer before entering the second distributing system. At this time, the moisture weight percentage of the sintered mixture is 7.9%, and the The percentage by weight of the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com